Patents

Literature

44results about How to "Ensure existence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

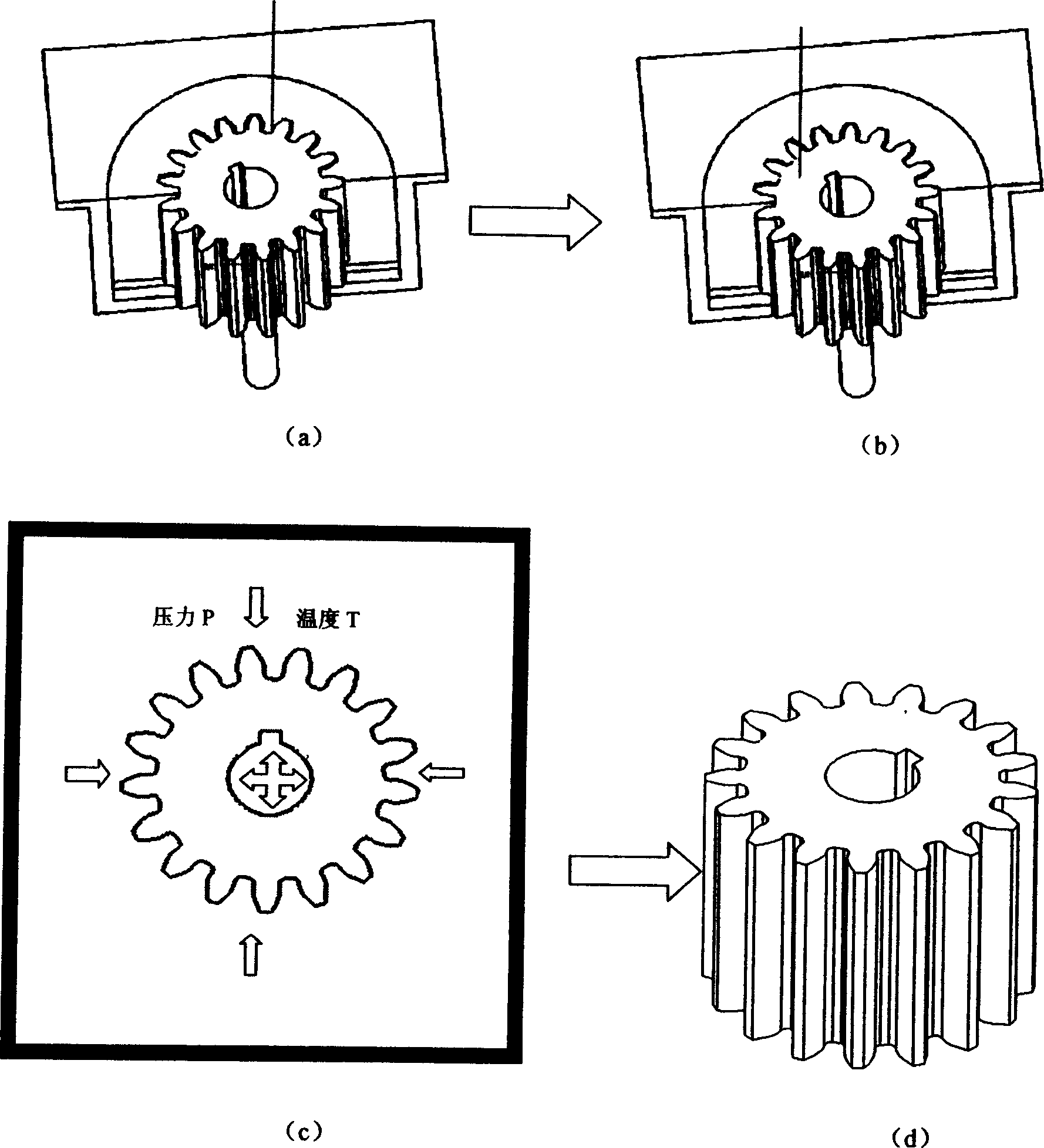

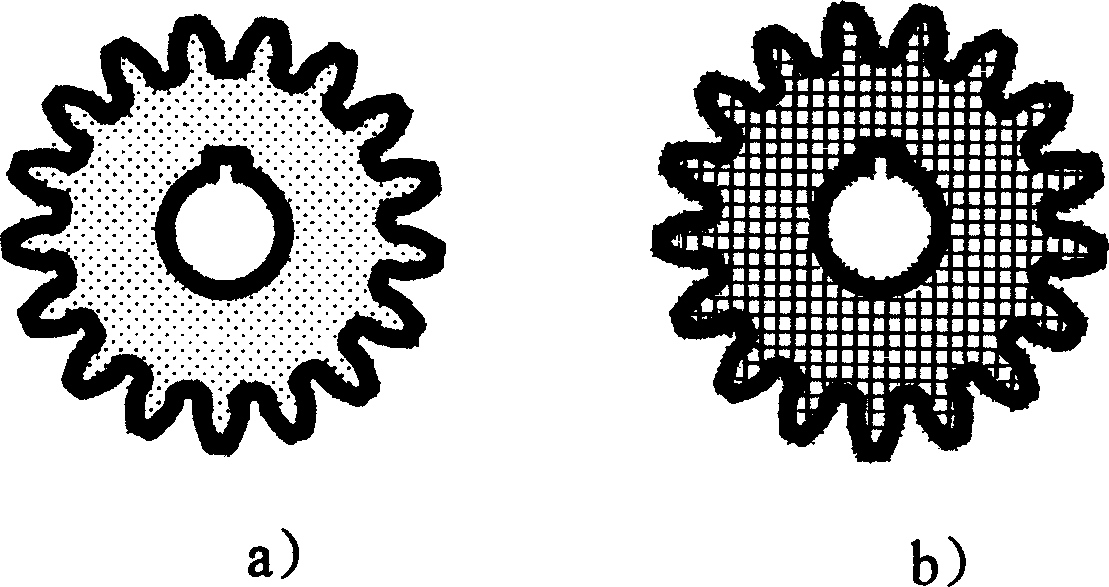

Method for near-purification formation of parts

InactiveCN1861296AEnsure existenceAvoid pollutionIncreasing energy efficiencySelective laser meltingSelective laser sintering

A technology for manufacturing a part by proximal forming method includes such steps as inputting the 3D model of a part to a fast SLM or SLS machine, vacuumizing the shaping chamber of SLM or SLS machine, using laser to scan the metal powder outside the boundary for smelting it, scan the metal powder inside the boundary to form mesh structure, forming a compact shell sealed part, and HIP processing.

Owner:HUAZHONG UNIV OF SCI & TECH

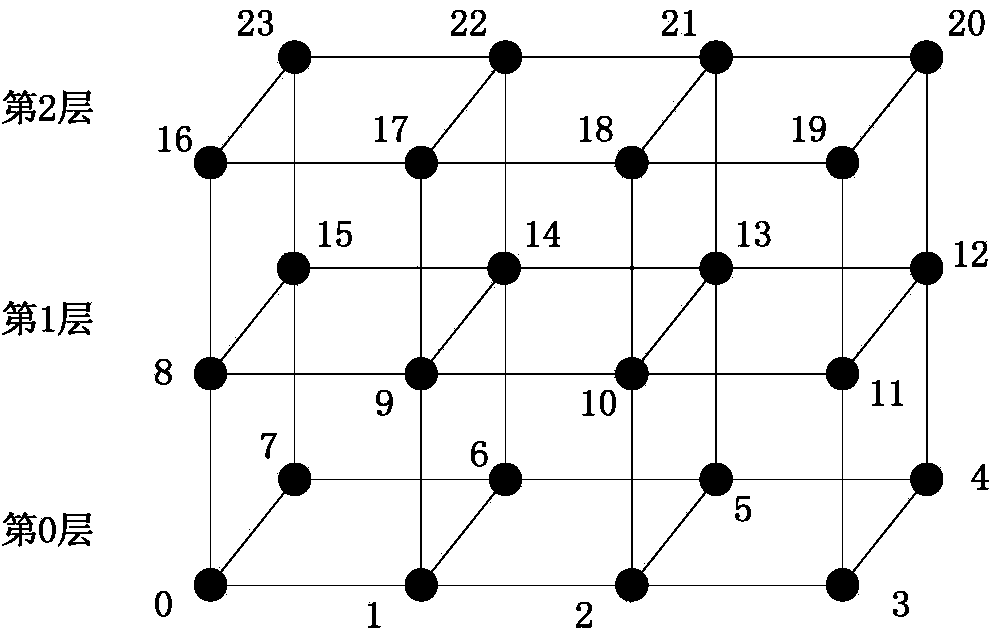

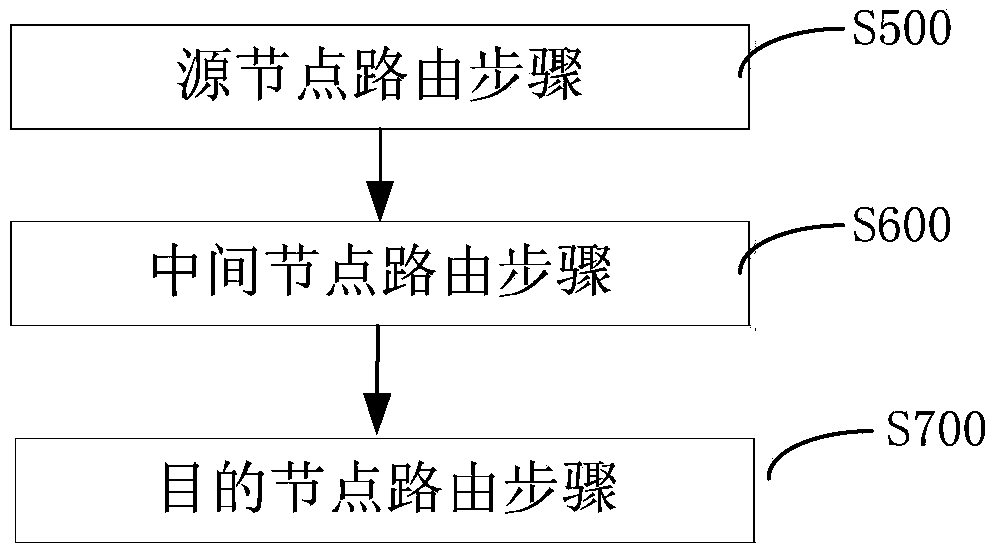

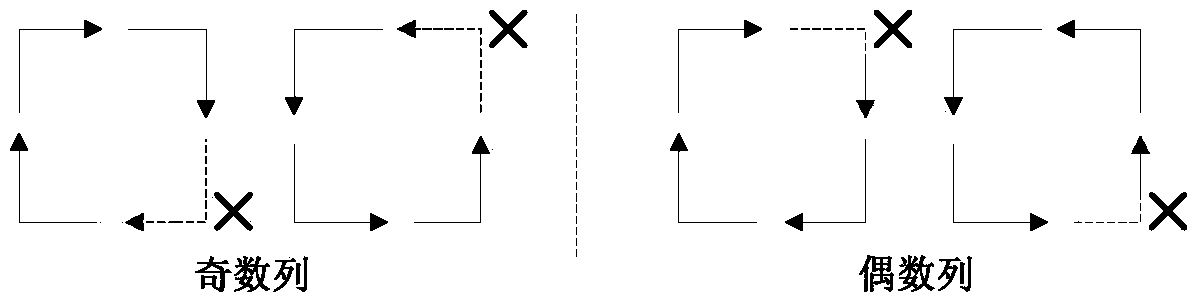

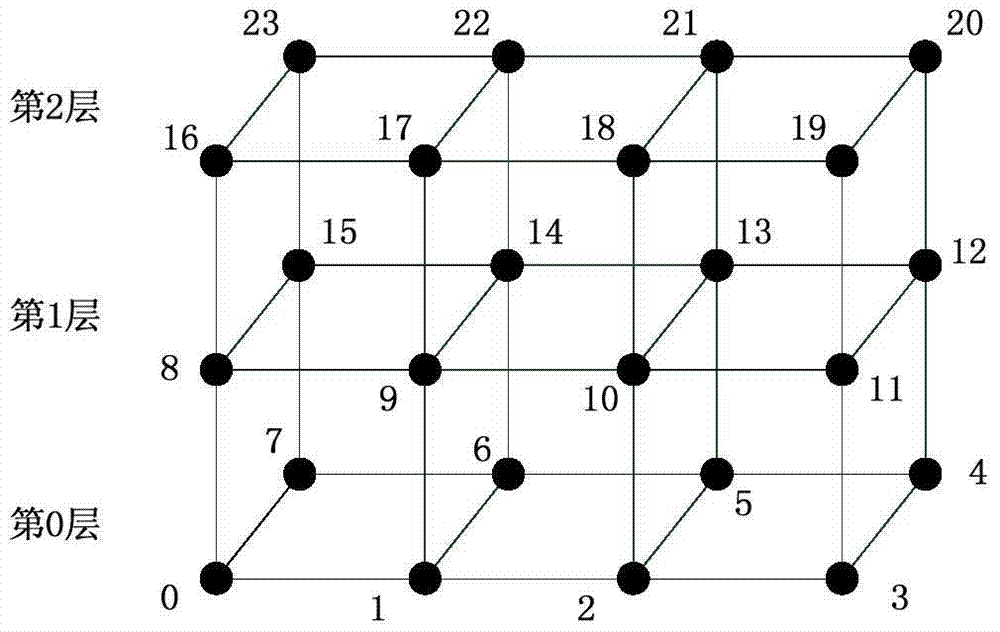

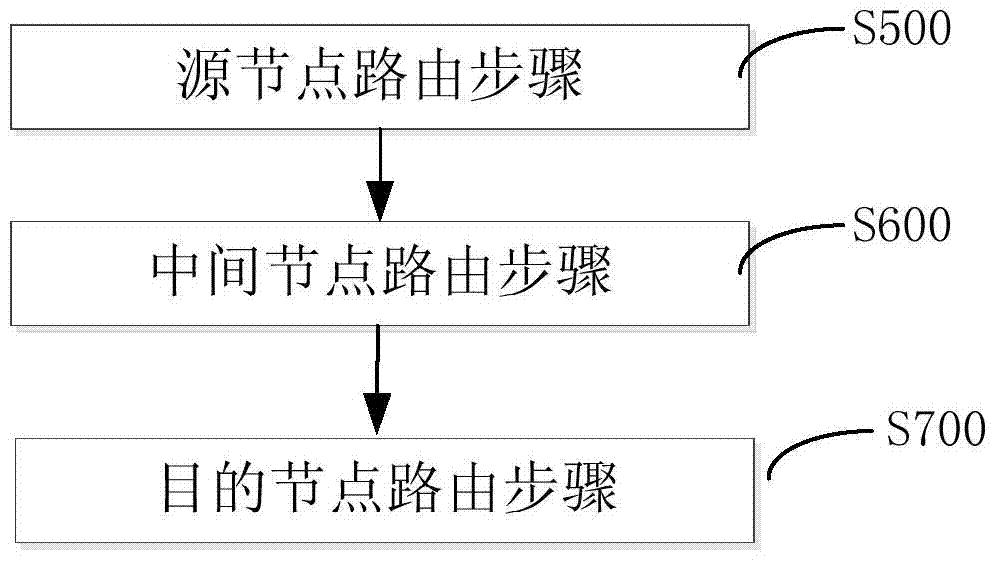

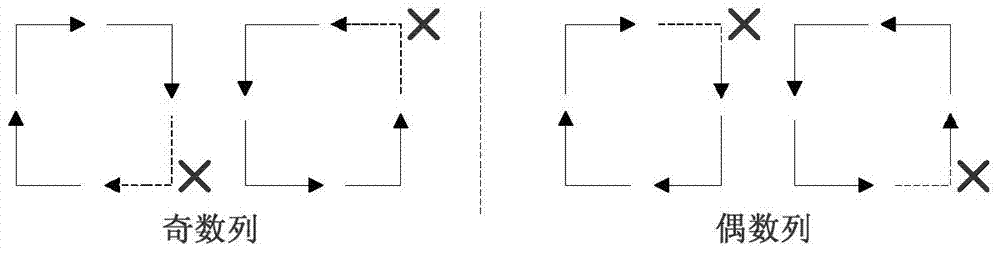

Three-dimensional integrated circuit on-chip network routing method and system thereof

The invention discloses a three-dimensional integrated circuit on-chip network routing method. According to the method, a three-dimensional steering model is adopted for routing guidance, a port selection mechanism is adopted for selection of a legal output port, and a data packet is routed in a unidirectional manner from a source node to a destination mode. The three-dimensional steering model is a parity-based steering model, an X-Y plane or an X-Z plane or a Y-Z plane of a three-dimensional scene is used as the datum plane, a routing path between the source node and the destination mode is mapped to the datum plane, and steering limiting is performed on the datum plane by adoption of an inter-layer illegal steering principle of a device layer and a corresponding supplementary principle. The invention further discloses a three-dimensional integrated circuit on-chip network routing system.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

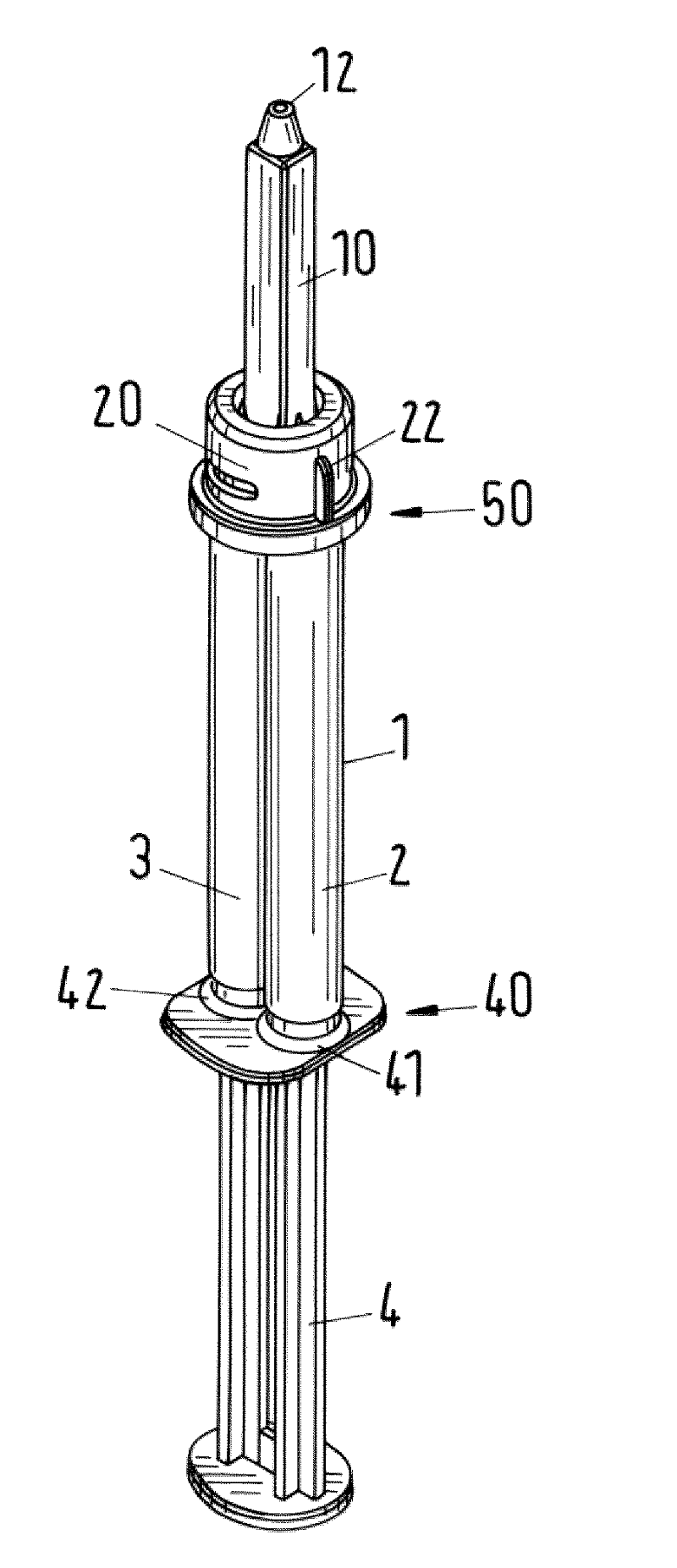

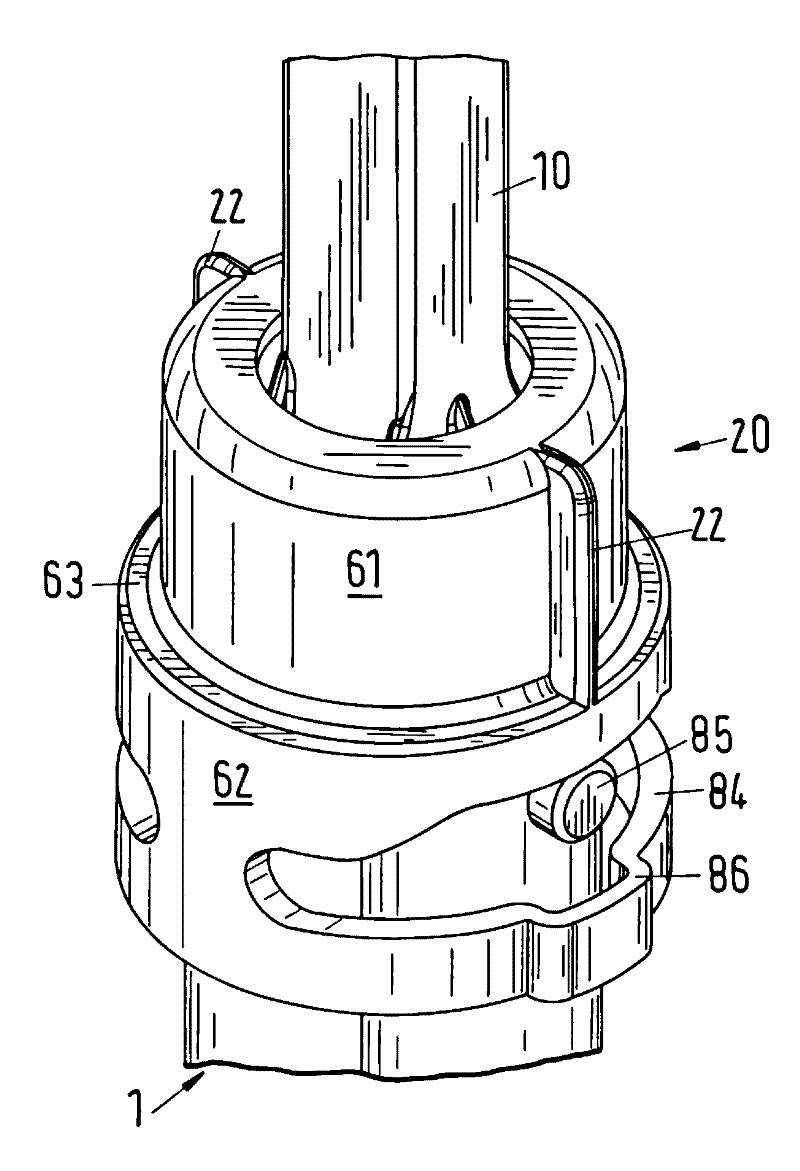

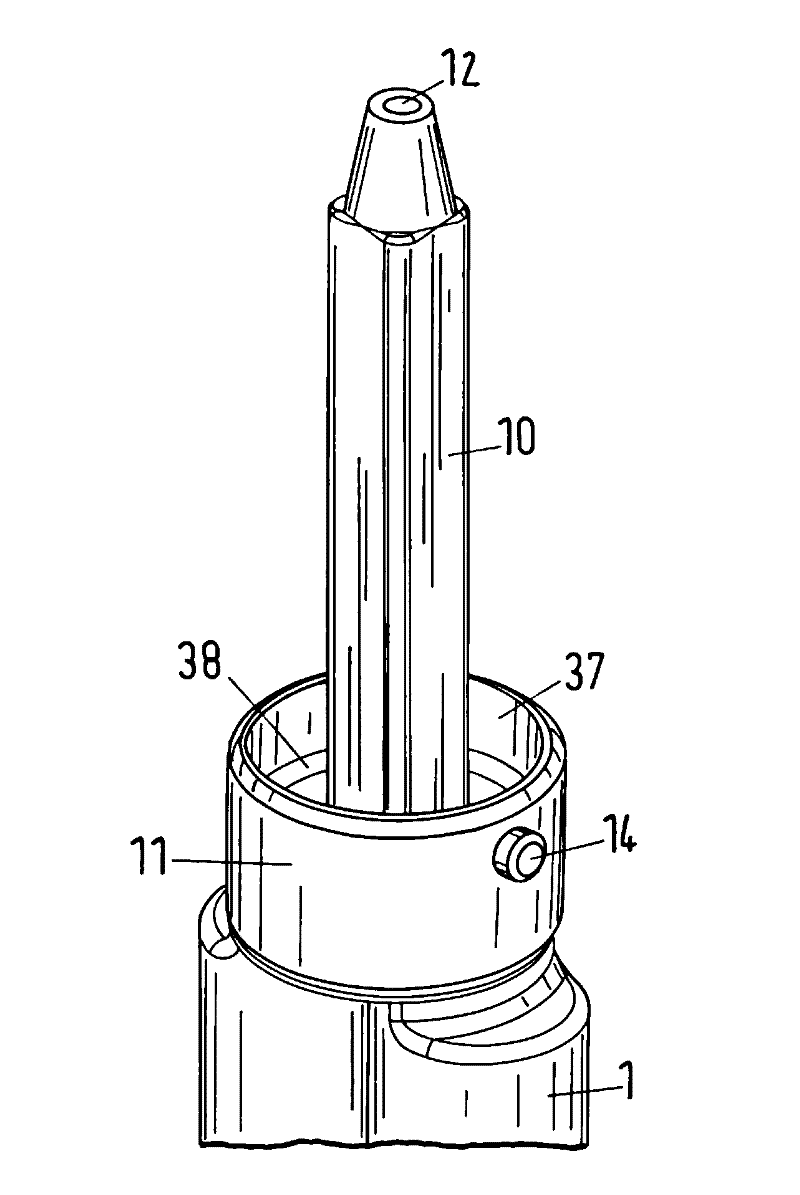

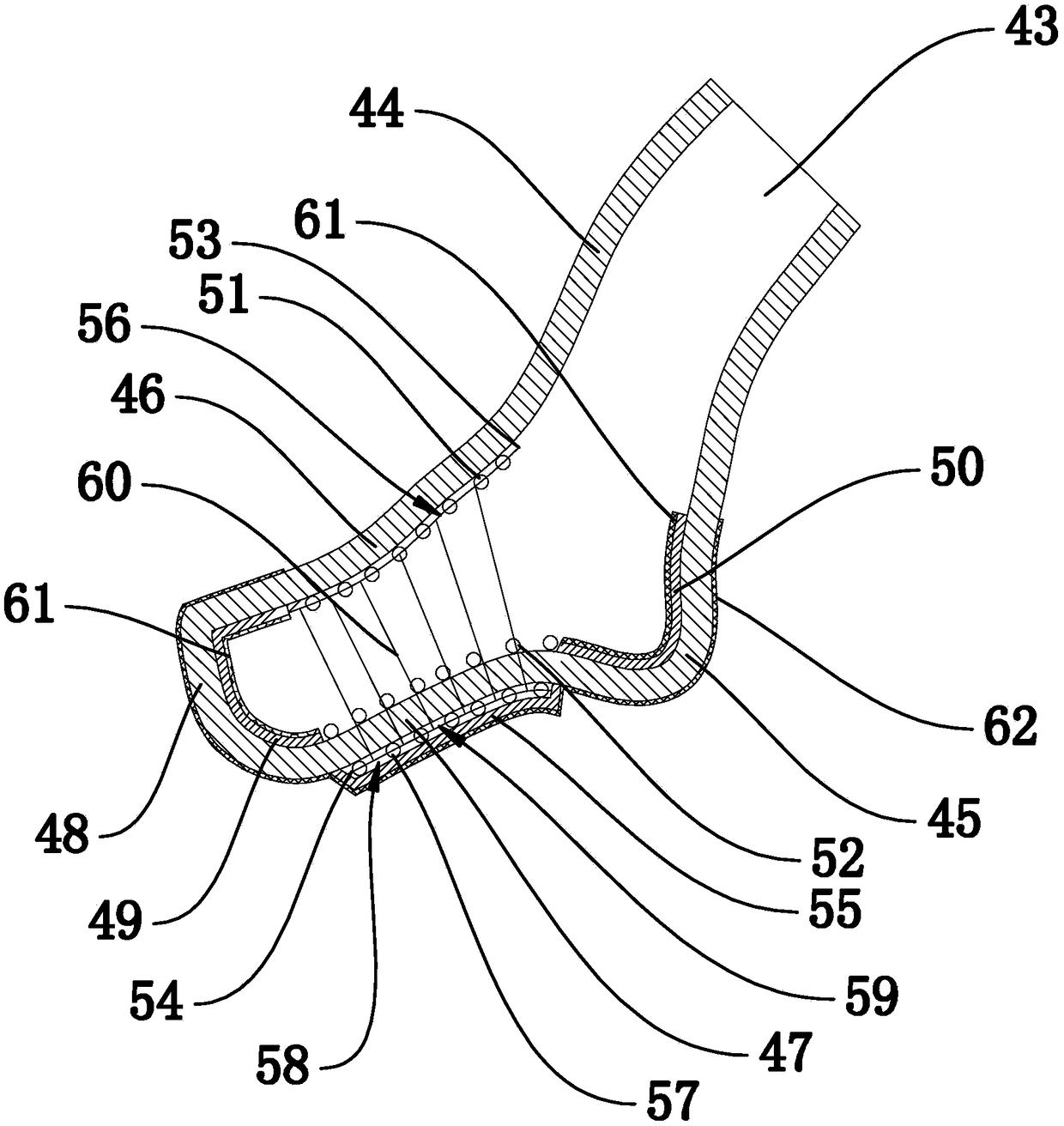

Multi-component cartridge

InactiveCN102673897AEnsure axial movementGuaranteed to move normallyLiquid surface applicatorsFlow mixersSyringeEngineering

The invention relates to a multi-component cartridge. Concretely, a dispensing apparatus for mixing and dispensing multi-component masses including a multi-component cartridge or syringe having a plurality of chambers, a mixer element having a longitudinal axis and a mixer housing placed over the mixer element. The mixer element and the multi-component cartridge are formed by unit elements, wherein each chamber is provided with a dispensing opening, which can be closed by a closing element fixed at the mixer housing. The outer surface of the mixer element and the inner wall of the mixer housing have a cooperating guide element which only allows a displacement of the mixer housing at the mixer element along the longitudinal axis of the mixer element. The mixer housing is axially displaceably connected to the multi-component cartridge through a connecting element, wherein, the multi-component cartridge can be transferred from a closed position locking the dispensing opening to a dispensing position releasing the dispensing opening.

Owner:SULZER MIXPAC AG

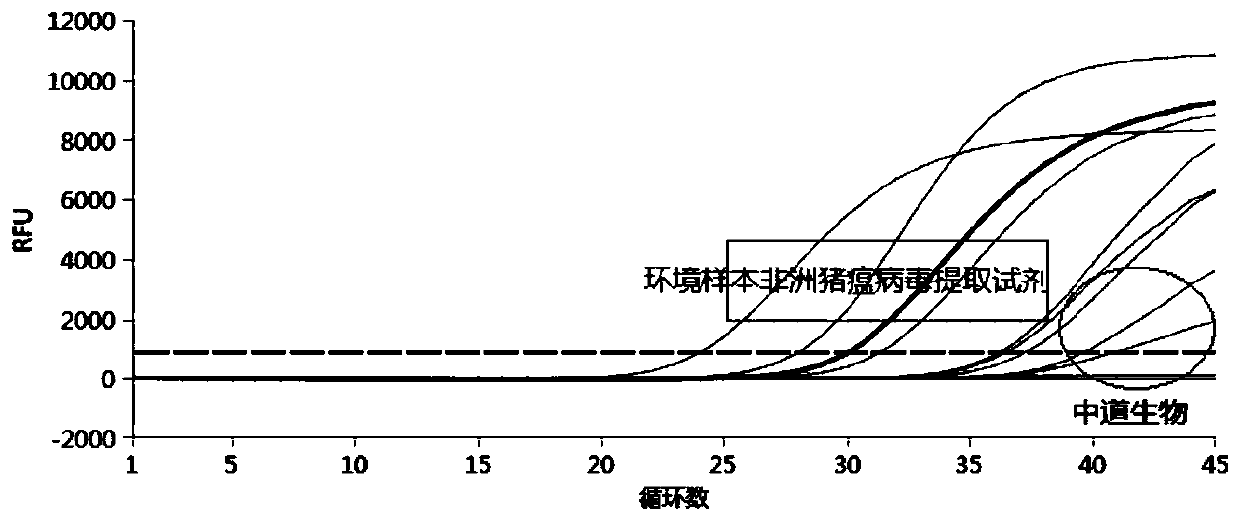

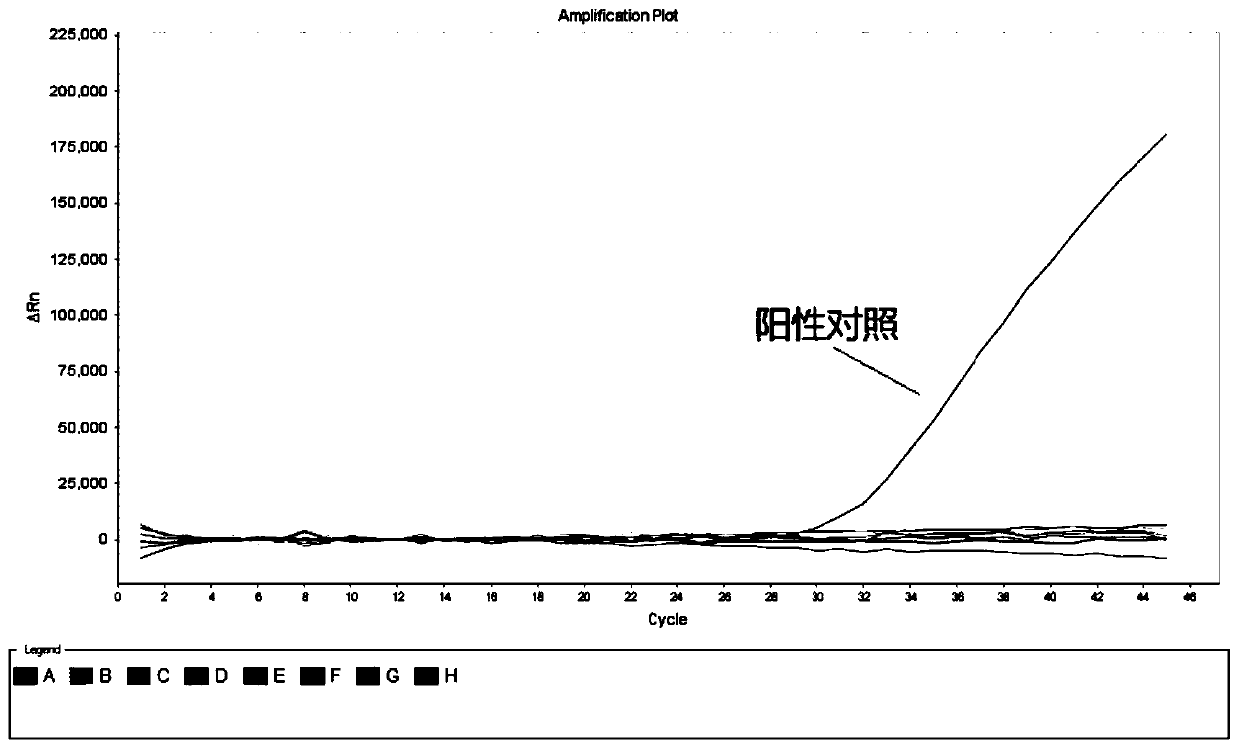

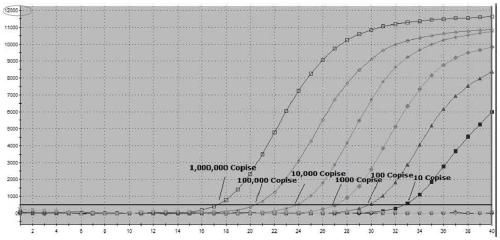

African swine fever virus detection reagent kit for environment samples and detection method

ActiveCN111218527AWidely suitable for real-time monitoringBreaking through the limitations of detectionMicrobiological testing/measurementAgainst vector-borne diseasesAfrican swine feverViral test

The invention relates to an African swine fever virus detection reagent kit for environment samples and a detection method, and belongs to the technical field of biology. The African swine fever virusdetection reagent kit for environment samples provided by the invention comprises specific primers AP72-F ( SEQ ID NO:1 ) and AP72-R ( SEQ ID NO:2 ), and a TaqMan probe AP72-P ( SEQ ID NO:3 ), wherein 5' end marked report fluorescent dye of the probe is FAM, and a 3' end marked fluorescent quenching group is BHQ-1. The African swine fever virus detection reagent kit for environment samples and the detection method provided by the invention can be widely used for detecting various environment samples in breeding environment, the limitation for detecting a single environment sample is broken, the sensitivity of the detection method reaches 10copise / [mu]l, the detection of African swine fever viruses of the environment samples does not have a cross reaction with various viruses, and the African swine fever virus detection reagent kit for environment samples and the detection method can be widely suitable for real-time monitoring of rehabilitation and breeding of pigs suffering from African swine fever.

Owner:广州赛百纯生物科技有限公司

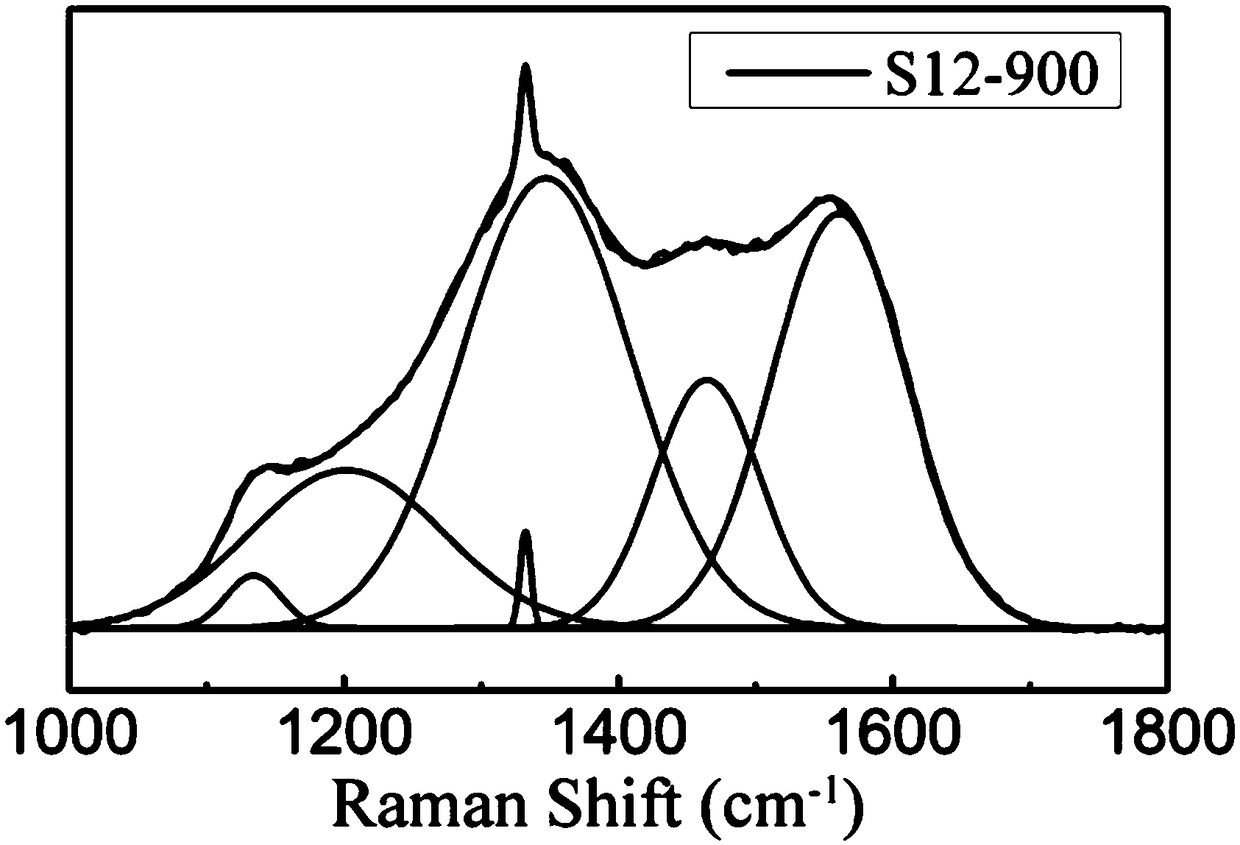

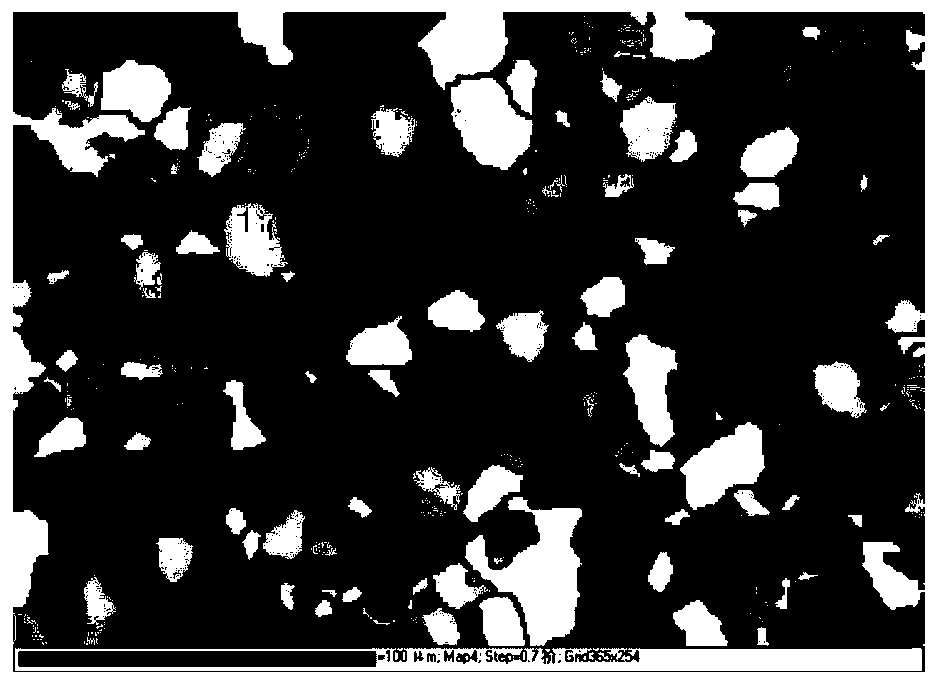

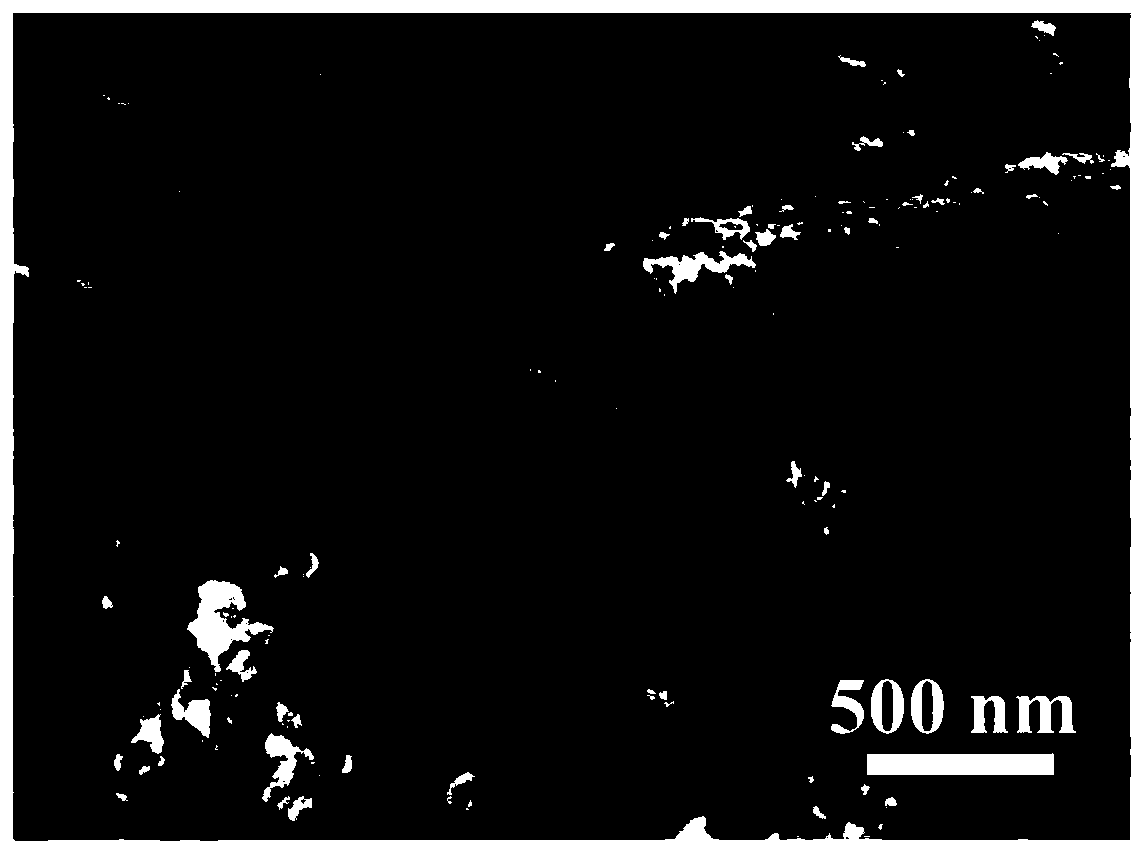

High-mobility n-type nano diamond film of crystalline grain closely-packed structure and preparation method of high-mobility n-type nano diamond film

ActiveCN108660432AEvenly distributedRepair damage damageVacuum evaporation coatingSputtering coatingMicro structureGas phase

The invention discloses a high-mobility n-type nano diamond film of a novel micro-structure and a preparation method of the high-mobility n-type nano diamond film. A hot filament chemical vapor deposition (HFCVD) method is adopted, and the nano diamond film is prepared on a monocrystalline silicon substrate. Acetone serves as a carbon source, the carbon source is brought into a reaction chamber cavity body in a hydrogen bubbling manner, the growth time is about 40-60 minutes, the nano diamond film with the thickness being about 1-3 microns is prepared, the crystalline grain size is 10-30 nm, and the content of the amorphous carbon grain boundary in the film is quite small. The crystalline grain closely-packed nano diamond film is subjected to injection of sulfur ions and oxygen ions, an injected sample is then subjected to low-vacuum annealing, and the n-type nano diamond film with the mobility universally reaching 400 cm<2> / V.s or above can be obtained. The high-mobility n-type nano diamond film has quite great significance and value for achieving the goal of applying the diamond film to the fields such as semiconductor devices, photoelectron and field emission displays.

Owner:ZHEJIANG UNIV OF TECH

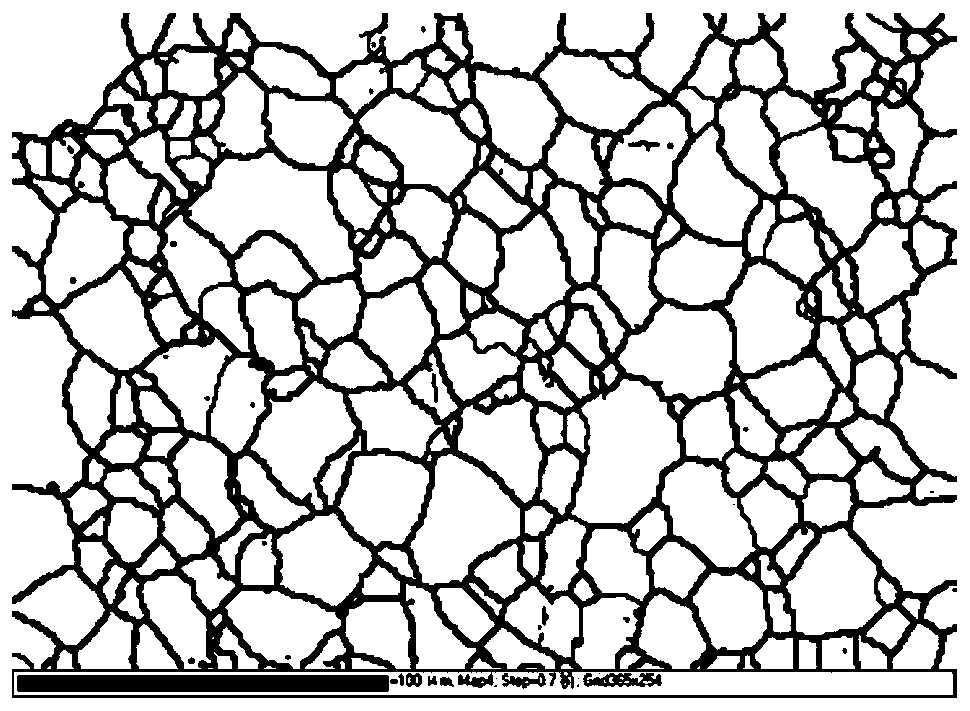

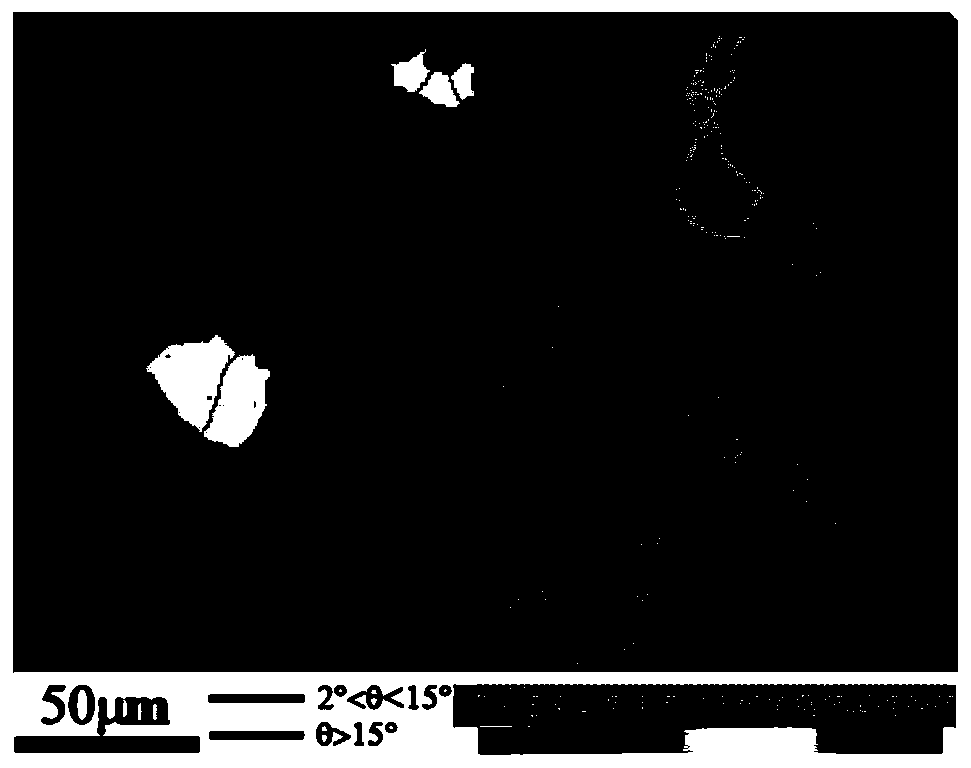

Method of preparing pure titanium EBSD sample under room temperature

ActiveCN110726743AImprove controllabilityEnsure existenceMaterial analysis using wave/particle radiationPhysical chemistryMetallic materials

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Light high-strength sludge ceramsite and preparation method thereof

The invention relates to a light high-strength sludge ceramsite and a preparation method thereof. The preparation method comprises the following steps: S100, mixing sludge, fly ash, water glass, an ultrafine composite pore-forming agent and an auxiliary dispersant, and carrying out ultrasonic aging to obtain a raw material; S200, granulating and molding the raw material, and controlling the watercontent of molded raw material particles to be less than 0.5%; and S300, roasting and hardening the raw material particles obtained in the step S200 to obtain the light high-strength sludge ceramsite.A superfine composite pore-forming agent with superfine particles is selected as a gas-forming component, and the superfine composite pore-forming agent is uniformly dispersed into the material by adopting the auxiliary dispersant and an ultrasonic dispersing mode. By controlling a roasting system, different gas-forming components in the superfine composite pore-forming agent generate gas holes which are different in size and are uniformly and densely distributed to form a pore structure form of 'filling' macropore gaps with micropores, so that the lightweight high-strength sludge ceramsite is low in apparent density and high in strength, and the problem that the density and the strength are difficult to balance in a ceramsite preparation process is solved.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

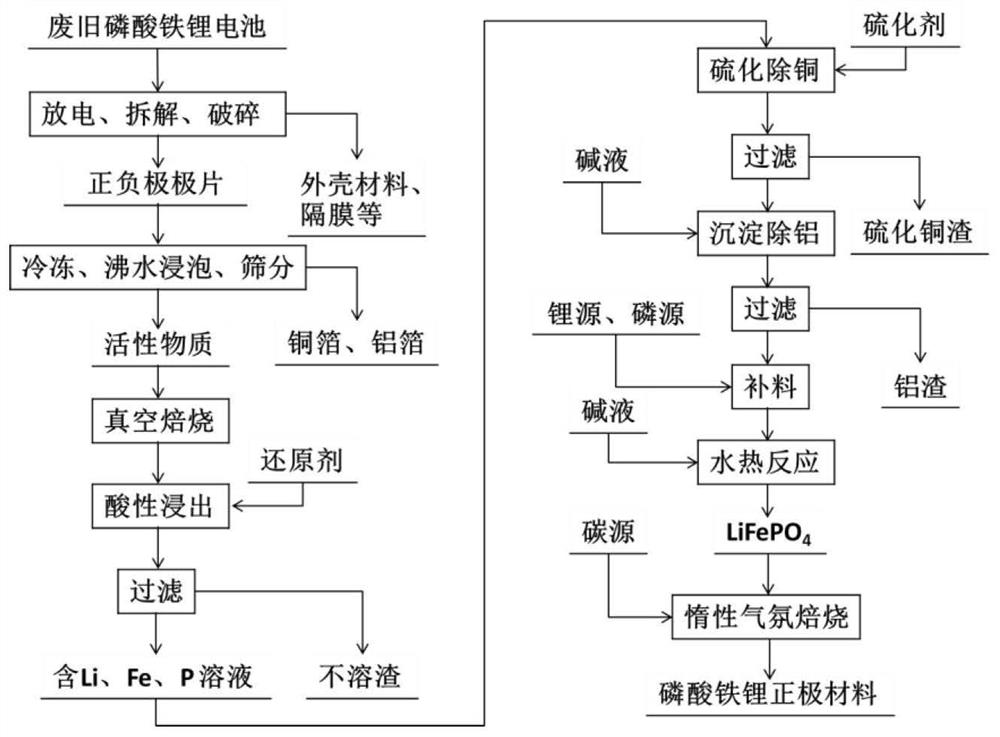

Method for preparing lithium iron phosphate cathode material by recycling waste lithium iron phosphate battery

ActiveCN110112481BReduce mutual inclusionEasy to separateWaste accumulators reclaimingBattery recyclingLithium iron phosphatePhysical chemistry

Owner:GUANGDONG GUANGHUA SCI TECH

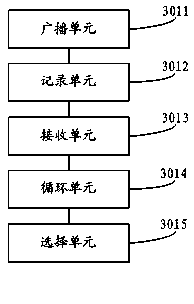

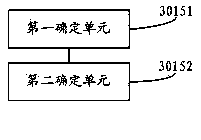

Networking method and equipment in Internet of things

The invention discloses a networking method and equipment in the Internet of things and belongs to the technical field of the Internet of things. The method comprises steps that: a networking request is sent, and a networking grade is received in the first preset time segment; if the networking grade is not received, the networking request is sent another time till the sending times is equal to the first preset times; if the sending times is equal to the first preset times, base station node equipment is re-determined, and a networking request is sent till the networking grade is received within the first preset time segment. According to the method, through networking request sending, the networking grade is received in the first preset time segment, if the networking grade is not received, the networking request is set another time till the sending times is equal to the first preset times, the base station node equipment is re-determined, the networking request is sent till the networking grade is received within the first preset time segment, and networking is carried out according to the networking grade, a sensor node equipment is determined to exist in a sub network, and thereby the utilization rate of the sensor node equipment in the sensing network is improved.

Owner:掌通万维(北京)科技有限公司 +1

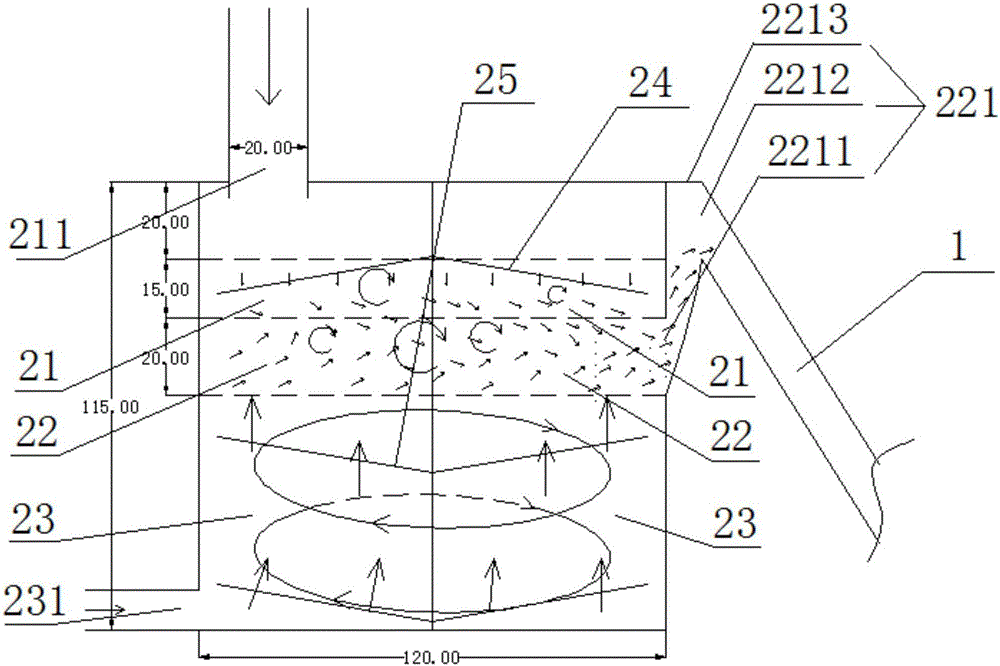

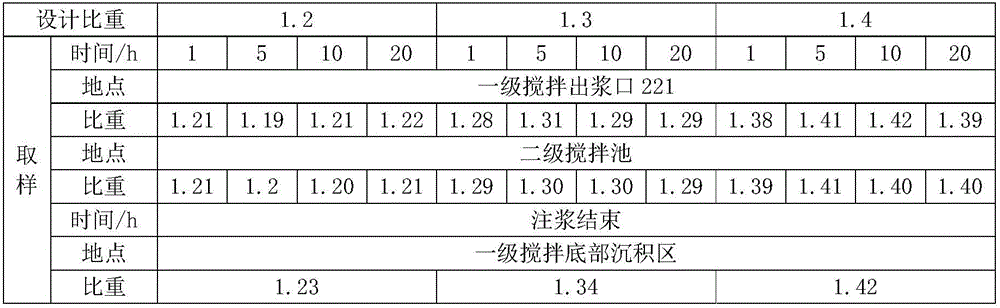

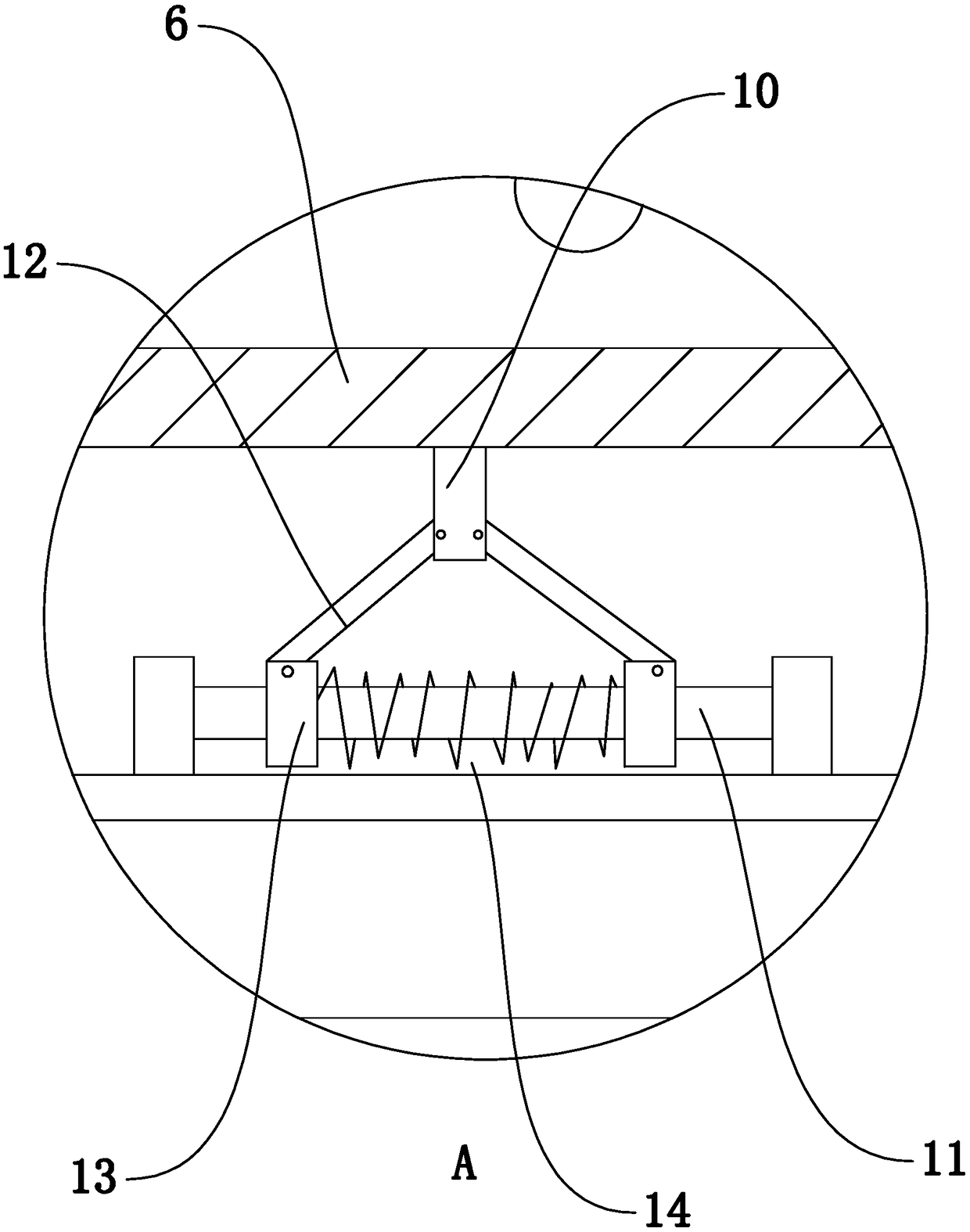

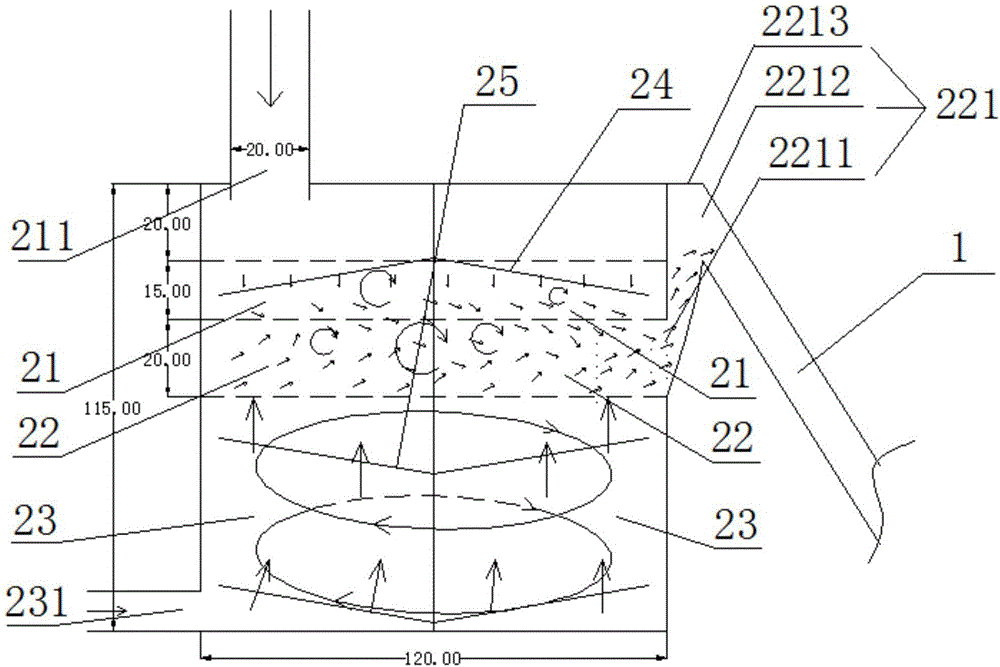

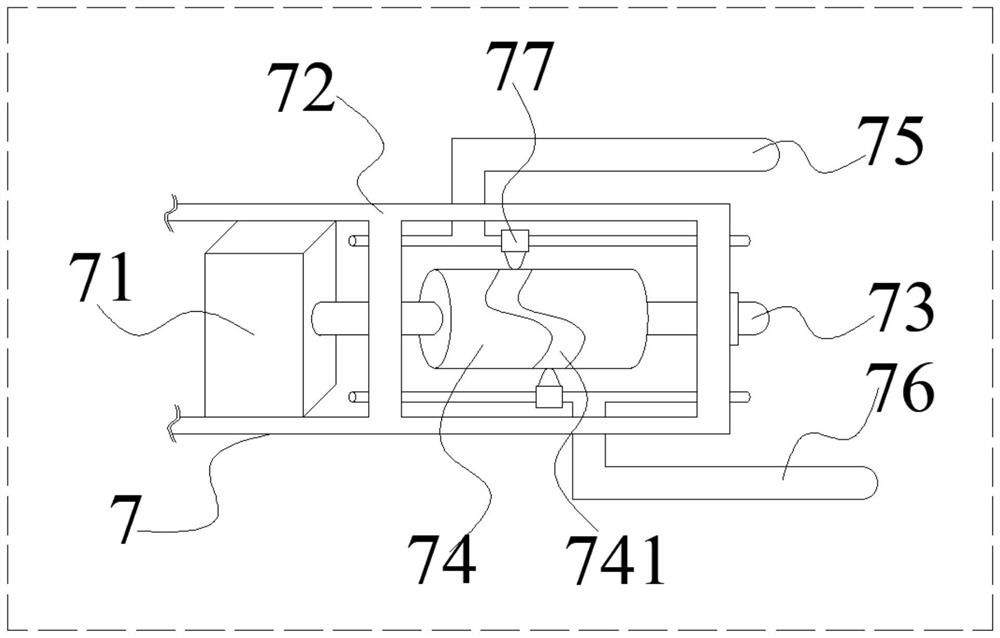

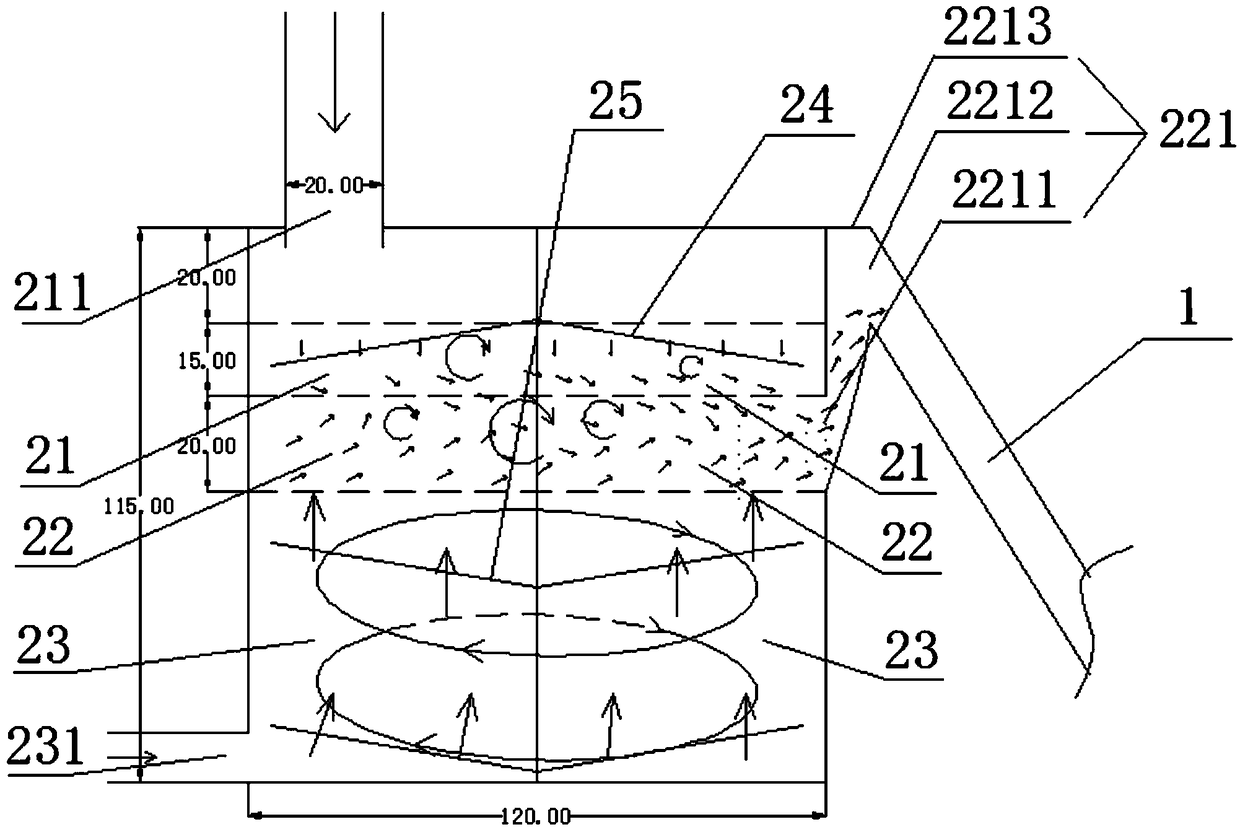

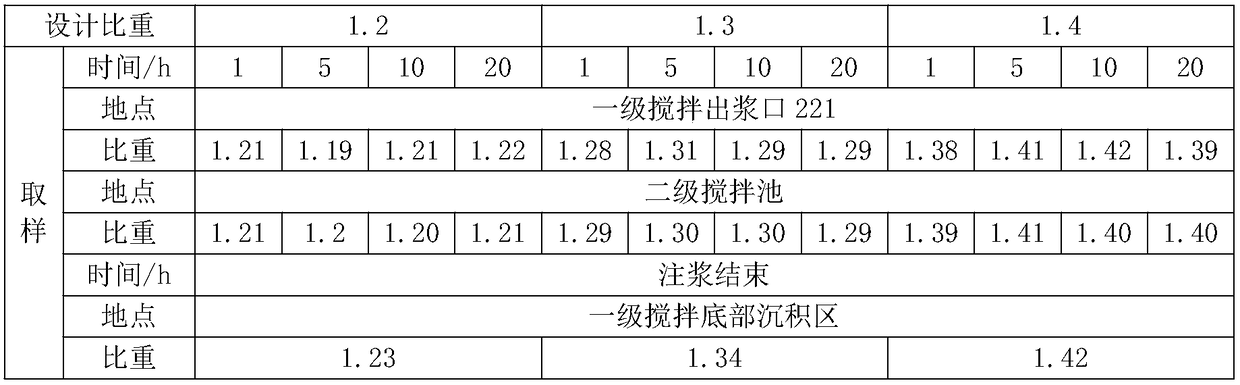

Stirring device and stirring system thereof

ActiveCN105904589AExquisite structureImprove work efficiencyCement mixing apparatusLiquid ingredients supply apparatusSlurryEngineering

The invention provides a stirring device. The stirring device comprises a stirring barrel, wherein the stirring barrel is divided into an ash discharging region, a convection mixing region and a water feeding region from top to bottom in the height direction; an ash discharging opening is formed in the top of the ash discharging region; the convection mixing region is provided with a slurry outlet; the water feeding region is provided with a water inlet; the water inlet is positioned in a side wall of the lower end of the stirring barrel; a plurality of groups of stirring fins are further arranged in the stirring barrel; rotating shafts of the different groups of the stirring fins are coaxial; the uppermost group of stirring fins are forward spinning stirring fins while the rest groups of stirring fins are reverse spinning stirring fins; the forward spinning stirring fins are positioned in the ash discharging region; and the reverse spinning stirring fins are positioned in the water feeding region. Compared with the prior art, the stirring device has the advantages that the forward spinning stirring fins and the reverse spinning stirring fins are designed in the stirring barrel, the convection mixing region is formed between the forward spinning stirring fins and the reverse spinning stirring fins, in a rotating process, the forward spinning stirring fins accelerate sinking of cement ash, the reverse spinning stirring fins increase water feeding speed, therefore, deposited large particles are reduced, and the strong convection mixing region is formed nearby the slurry outlet.

Owner:HUAINAN MINING IND GRP

High-performance wear resistant modified antibacterial sock

The invention provides a high-performance wear resistant modified antibacterial sock. The sock is used for solving the problem that bacterium is germinated because the existing sock is poor in hygroscopic and sweat releasing properties. The sock comprises a sock body, wherein the sock body comprises a welt, a boot, a heel, a surface, a sole and a toe, and further comprises toe lining, a heel lining, breathable balls and antibacterial balls; the toe lining is fixed in the inner layer of the toe; the heel lining is fixed in the inner layer of the heel; the breathable balls are fixed in the innerlayer of the surface; the antibacterial balls are fixed in the inner layer of the sole; both the toe lining and the heel lining are provided with breathable holes; the sock body takes cotton fiber and modified polyester fiber as main materials.

Owner:海宁威尔斯针织股份有限公司

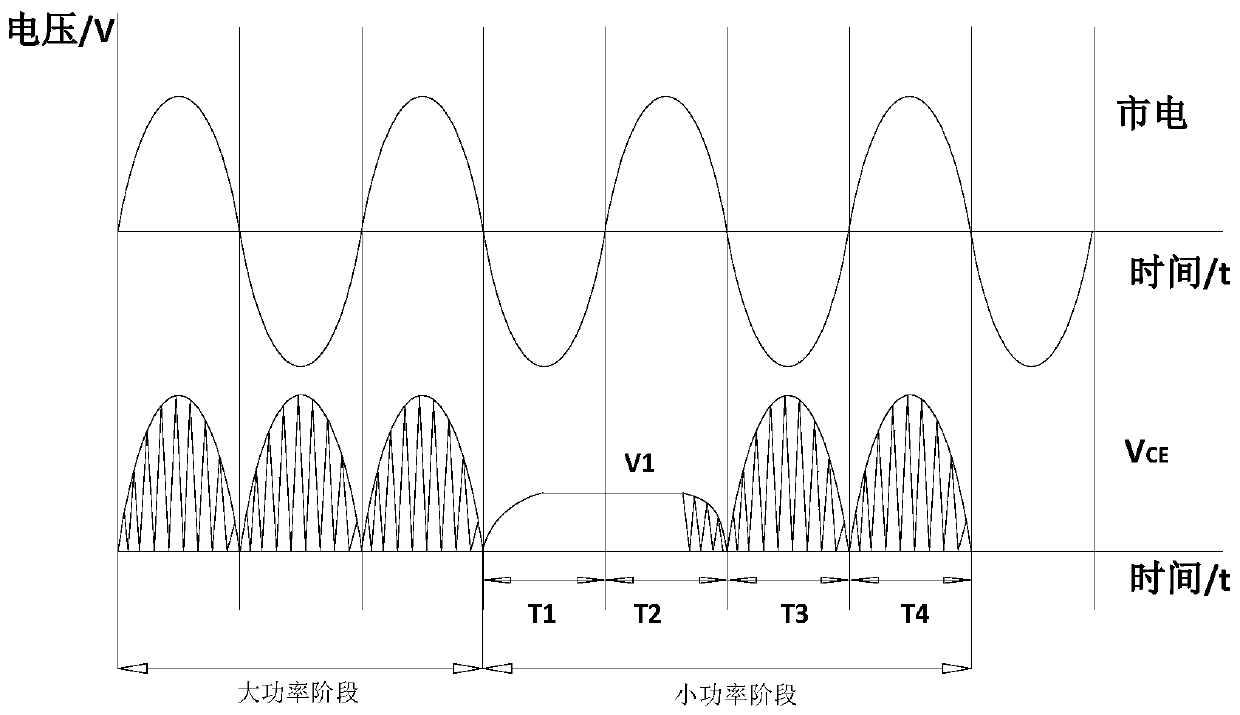

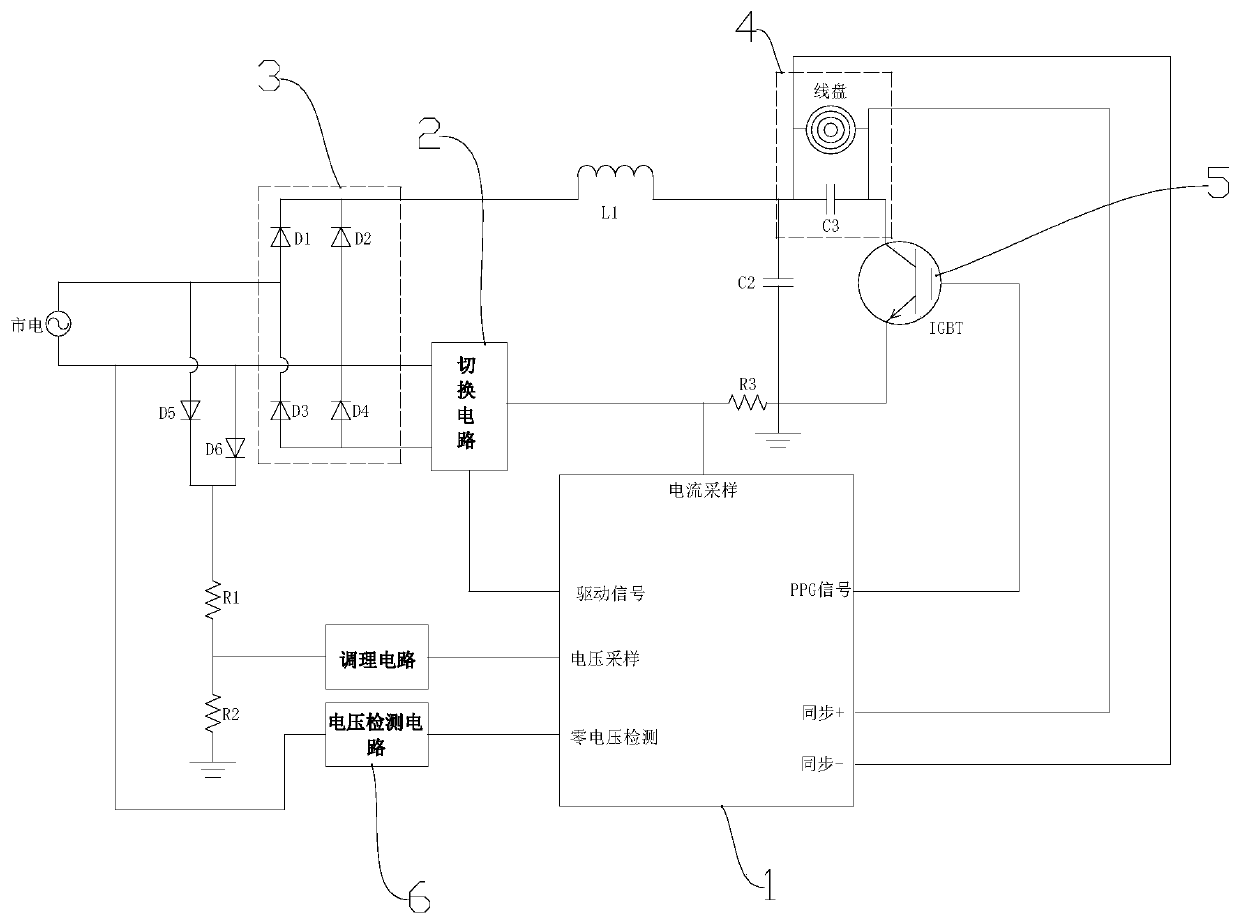

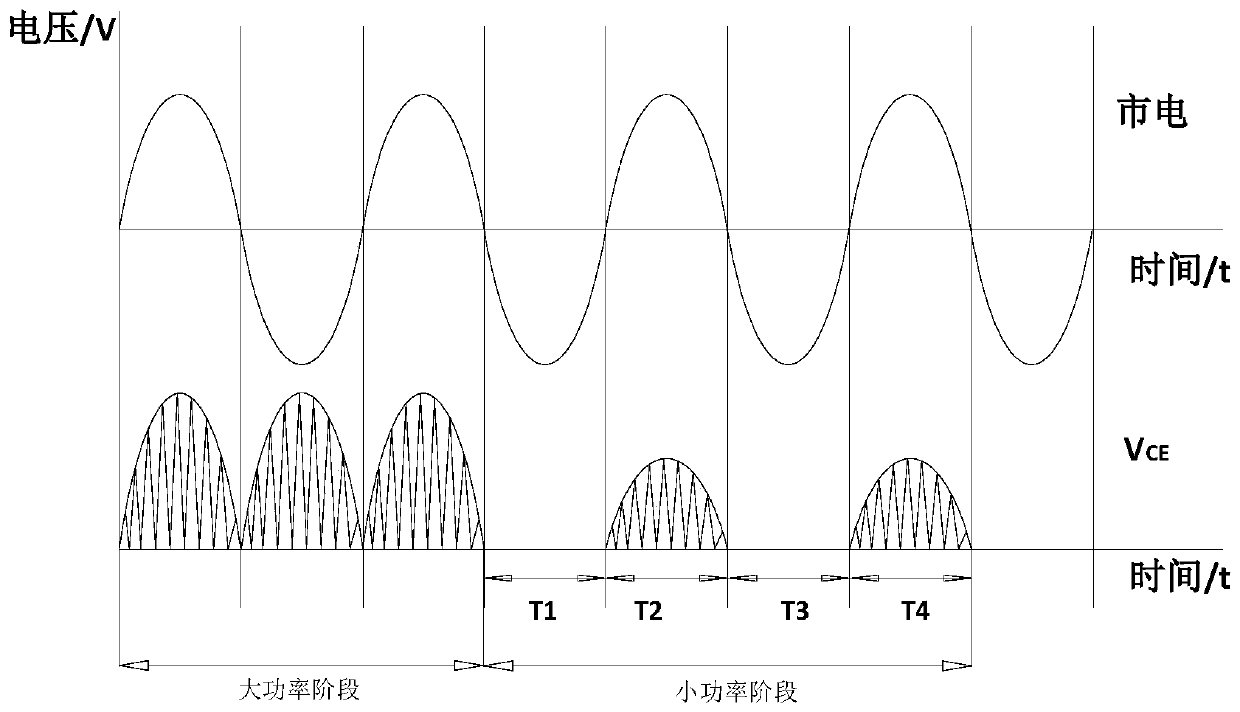

Power control method of electromagnetic heating device

InactiveCN109905932ATurn-on current reductionImprove service life technical effectInduction heating controlFull waveLow voltage

The invention provides a power control method of an electromagnetic heating device. The method comprises the following steps: judging whether target heating power is greater than a preset value; adjusting a switching circuit to control a rectifying circuit to output full-wave rectified waveform when the target heating power is greater than the preset value, and enabling the controller to send outa control signal to drive the connection of the power tube, thereby enabling a resonance circuit to work; when the target heating power is less than the preset value, adjusting the switching circuit to control the rectifying circuit to output half-wave rectified waveform, and then enabling the controller to send out the control signal to drive the connection of the power tube at the subsequent t1moment, thereby enabling the resonance circuit to work, wherein the t1 moment is the moment without waveform output of the half-wave rectified waveform, or the moment after the half-wave rectified waveform at least experiences a half-wave cycle without waveform. The IGBT is turned on at zero voltage or low voltage when the small power heating is guaranteed, the noise is reduced, and the service life of the IGBT is improved.

Owner:JOYOUNG CO LTD

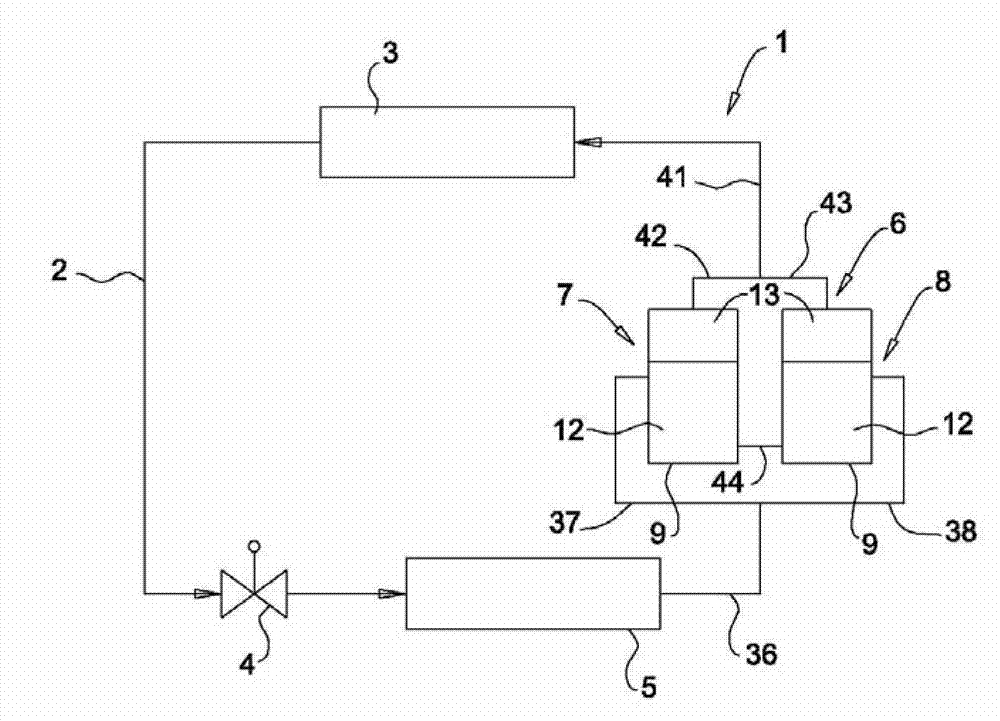

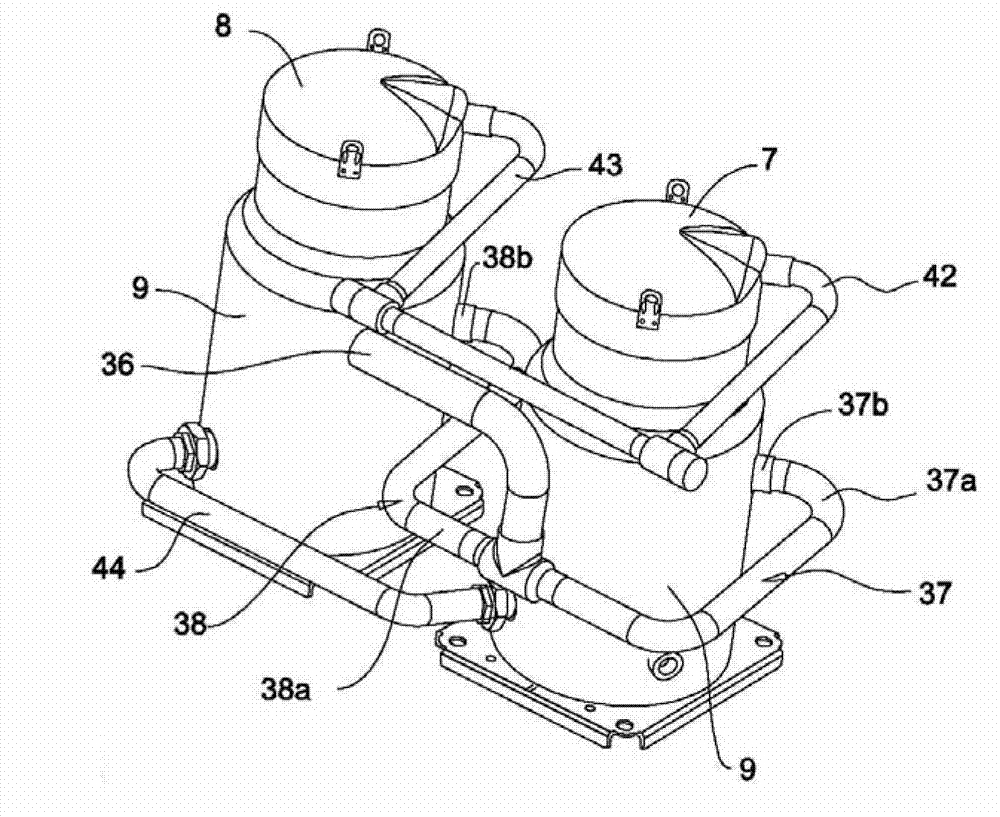

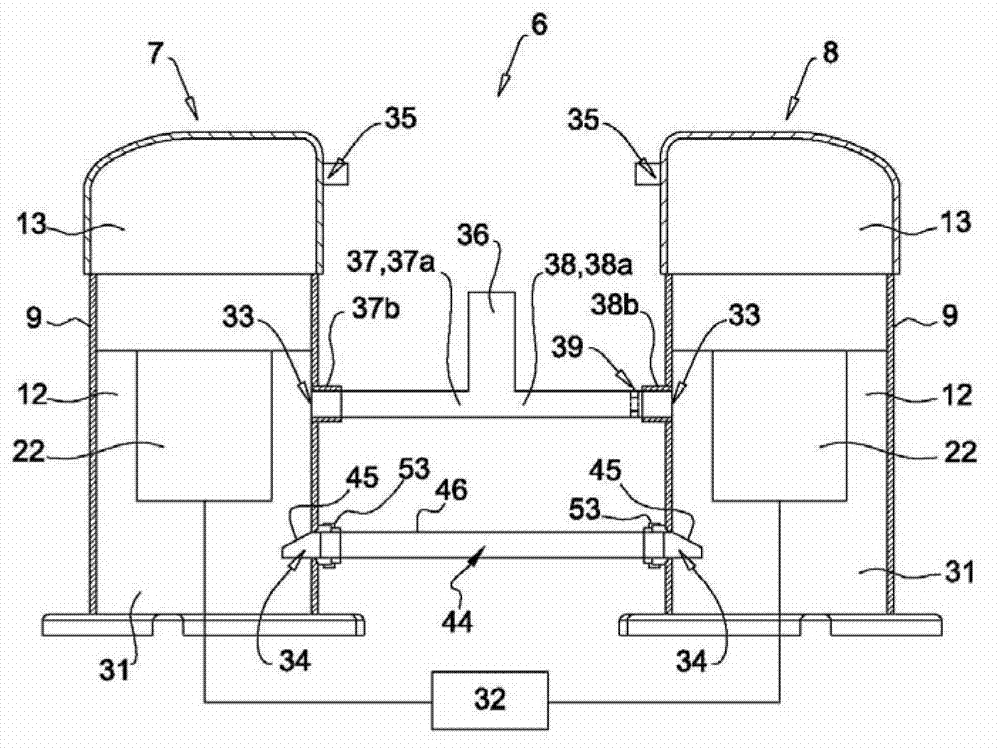

Compression device, and thermodynamic system comprising such compression device

ActiveCN103486768AEnsure existenceDegradation of pressure balance characteristicsRotary/oscillating piston combinations for elastic fluidsCompressorLevel lineFuel tank

The compression device according to the invention includes first and second compressors mounted in parallel and an oil level equalization line arranged to fluidly connect the oil sumps of the first and second compressors. The oil level equalization line includes at least one oil level regulating portion positioned near one of the first and second compressors and including a dam wall extending transversely to the longitudinal direction of said oil level regulating portion and a flow opening arranged such that, when the oil level in the oil sump of the compressor situated near the oil level regulating portion extends above the upper level of the dam wall, oil flows through the flow opening toward the other compressor.

Owner:DANFOSS COMML COMPRESSORS

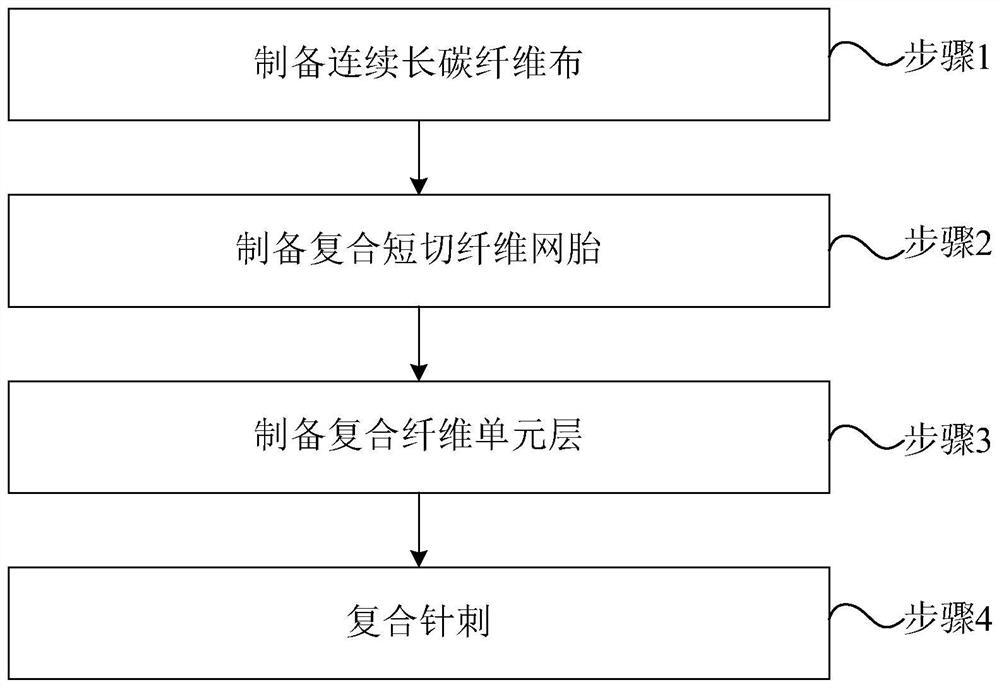

Pre-oxidized fiber/carbon fiber structure preform and preparation method thereof

PendingCN114801353AReduces the likelihood of brittle fracture damageReduce technical difficultyLayered productsNon-woven fabricsCarbon fibersFiber structure

The invention discloses a pre-oxidized fiber / carbon fiber structure preform and a preparation method thereof. The preparation method comprises the following steps: preparing continuous long carbon fiber cloth and a composite chopped fiber web; needling a layer of continuous long carbon fiber cloth and a layer of composite chopped carbon fiber net tire to prepare multiple types of composite fiber unit layers; and needling the composite fiber unit layers layer by layer or in a group by multiple layers in a crossed lamination manner, and repeating until the thickness requirement of the pre-oxidized fiber / carbon fiber structure preform is met. According to the technical scheme, the problems that the carding technology difficulty is high due to the brittleness characteristic caused by the small elongation at break of an existing carbon fiber overall needled preform, the prepared short carbon fiber net tire is poor in performance uniformity and long fiber retention rate, large fine carbon fiber dust can be generated when the net tire is carded, and the service life of the net tire is prolonged are solved. The dust pollution of the processing environment is serious, and the health of workers is damaged.

Owner:XIAN AVIATION BRAKE TECH

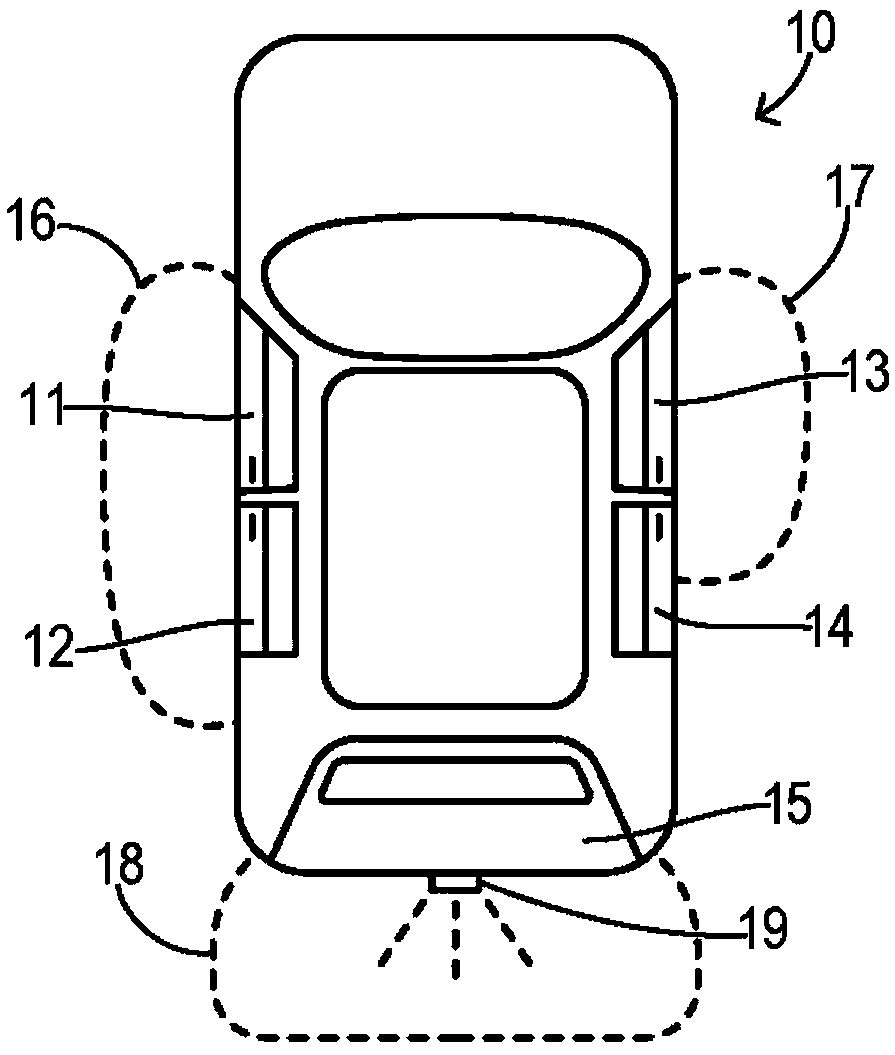

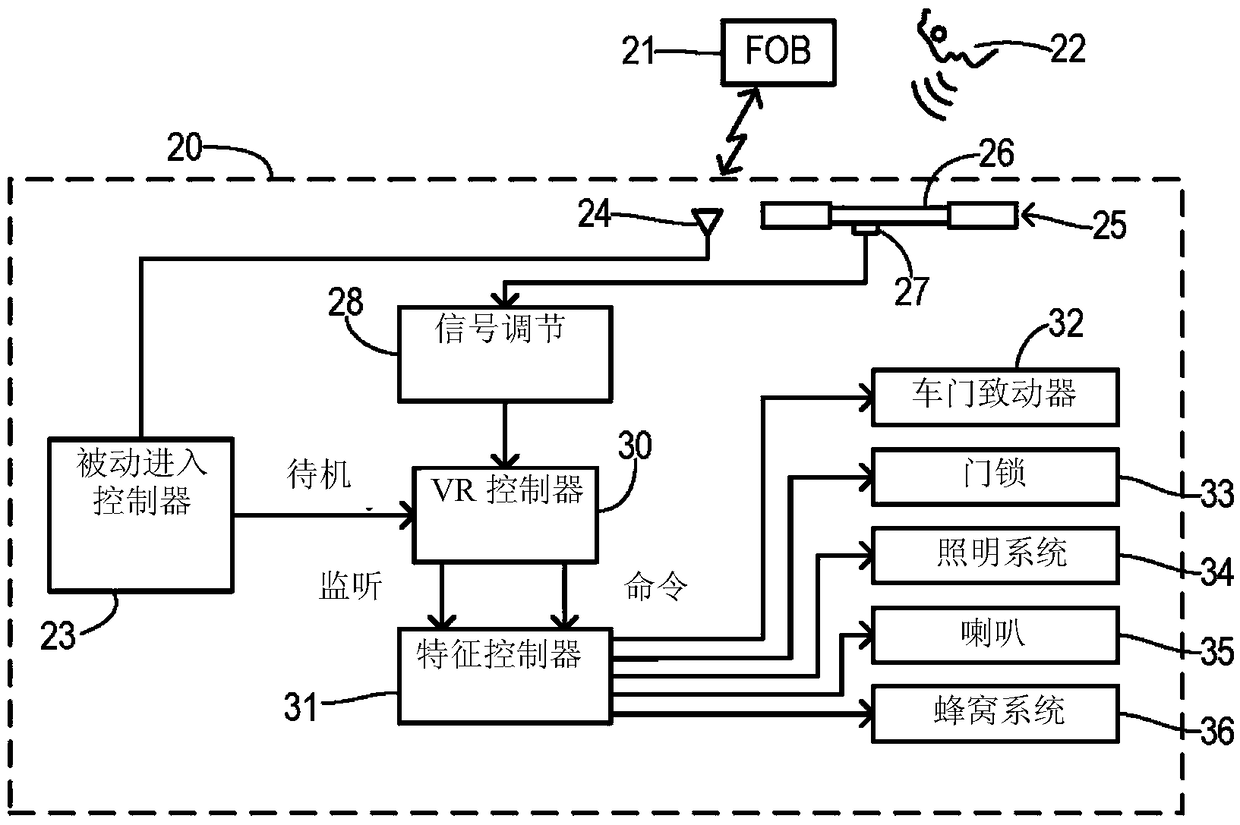

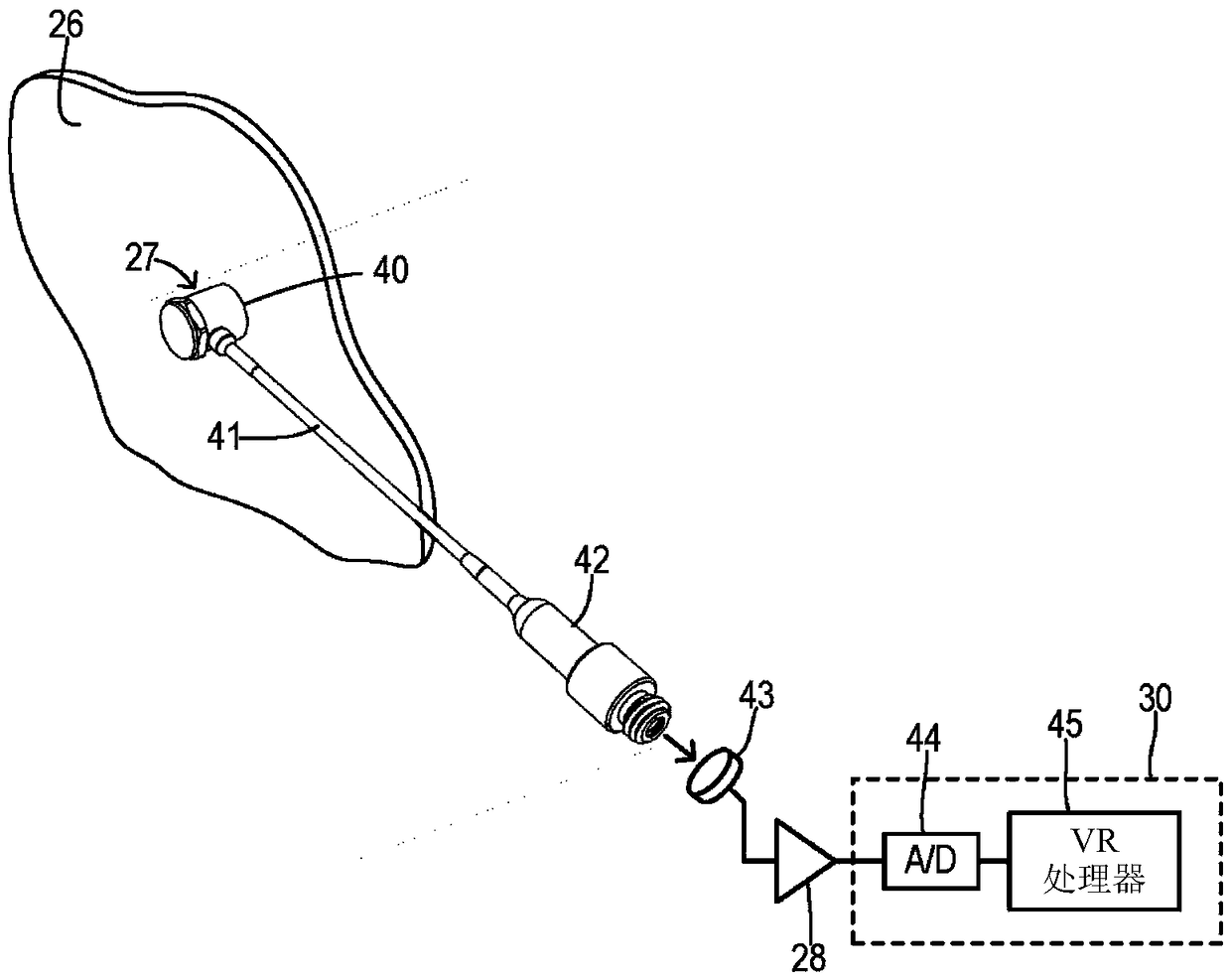

Automotive powered door activation using accelerometer

PendingCN109318855AEnsure existenceAvoid harsh environmentTransmission systemsAnti-theft devicesAccelerometerActuator

Voice control is extended outside of an automotive vehicle by an access system associated with a door and window. An accelerometer is mounted on the window to generate a vibration signal. A passive entry system generates an unlock standby signal when an authorized user carrying a wireless fob is detected proximate the door. A voice recognizer in the vehicle is activated by the standby signal to scan the vibration signal for a spoken command for opening the door. A door actuator is activated by the voice recognizer when the command is detected.

Owner:FORD GLOBAL TECH LLC

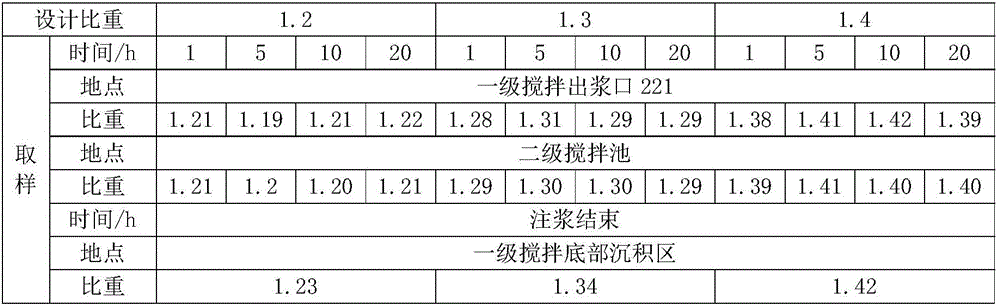

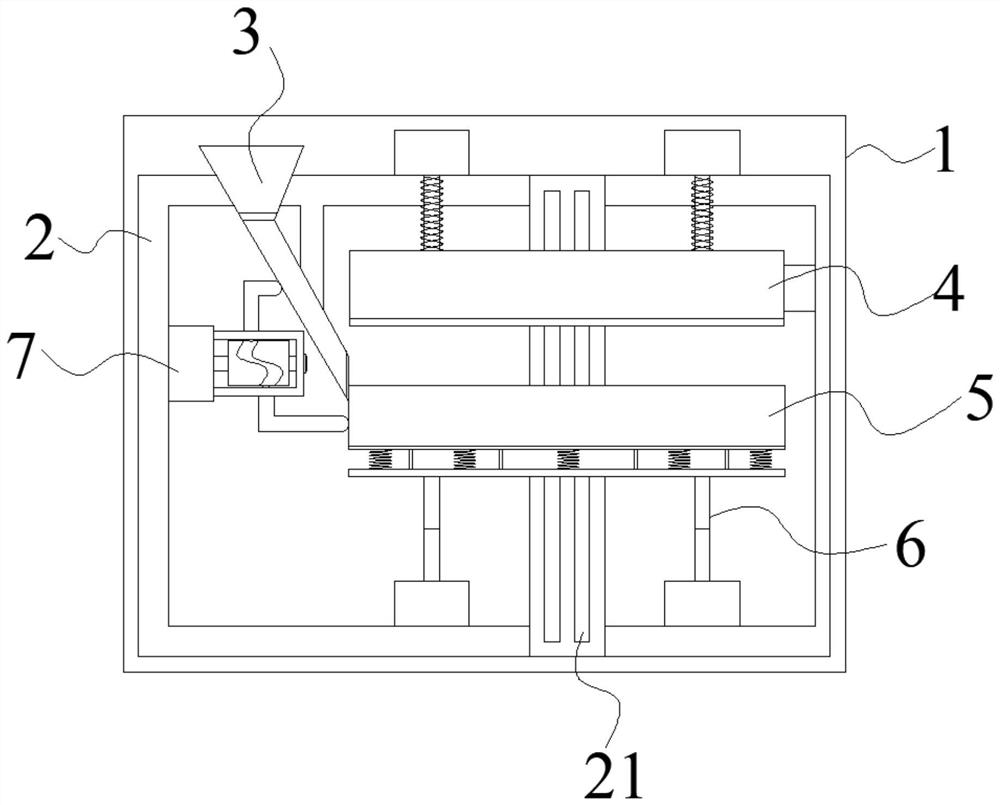

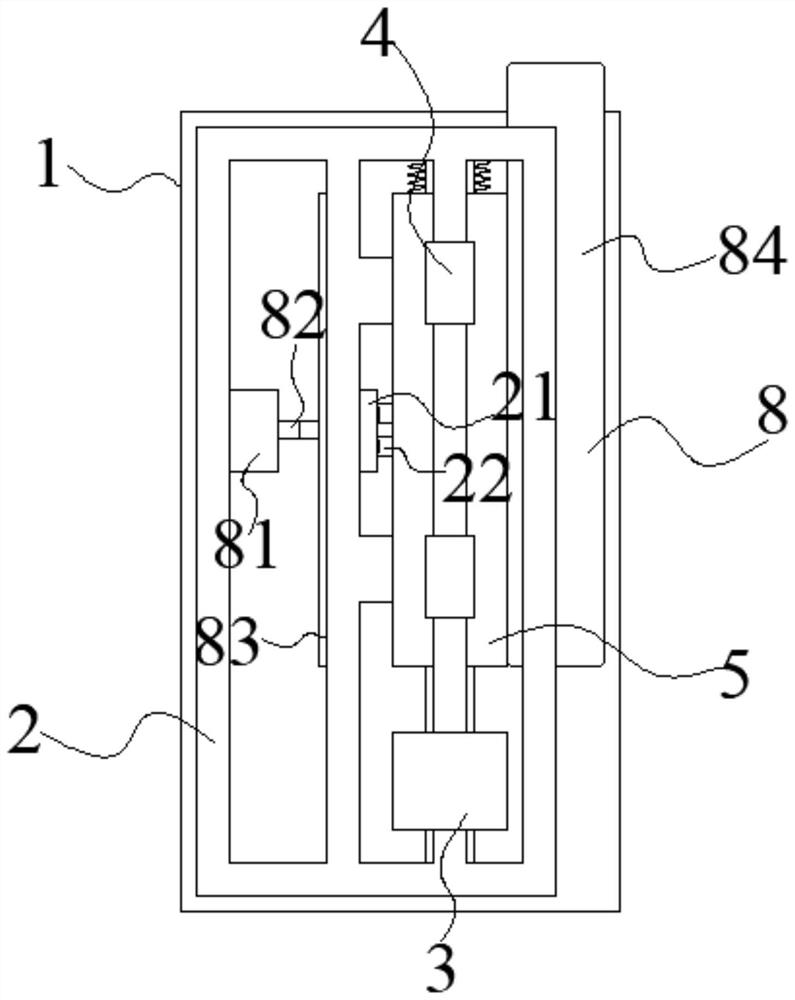

Stirring system

ActiveCN106079070AExquisite structureImprove work efficiencyCement mixing apparatusSlurryEngineering

The invention provides a stirring system which comprises a primary stirring device, wherein the primary stirring device comprises a stirring barrel; the stirring barrel is divided into a cement feeding region, a convective mixing region and a water supply region from top to bottom in sequence in a height direction; a cement feeding opening is formed in the top of the cement feeding region; a slurry outlet is formed in the convective mixing region; a water inlet is formed in the water supply region; the water inlet is located on the side wall of the lower end of the stirring barrel; a plurality of groups of stirring fins are arranged in the stirring barrel; rotating shafts of the groups of stirring fins are coaxial; the uppermost group of stirring fins are right-handed spiral fins; the other groups of stirring fins are left-handed spiral fins; the right-handed spiral fins are located in the cement feeding region; and the left-handed spiral fins are located in the water supply region. Compared with the prior art, through the design of the right-handed spiral fins and the left-handed spiral fins in the stirring barrel, the convective mixing region is formed between the right-handed spiral fins and the left-handed spiral fins, and during a rotating process, the right-handed spiral fins accelerate sinking of cement, and the left-handed spiral fins accelerate rising of water, so that deposition of large particles is reduced and a strong convective mixing region is formed near the slurry outlet.

Owner:HUAINAN MINING IND GRP

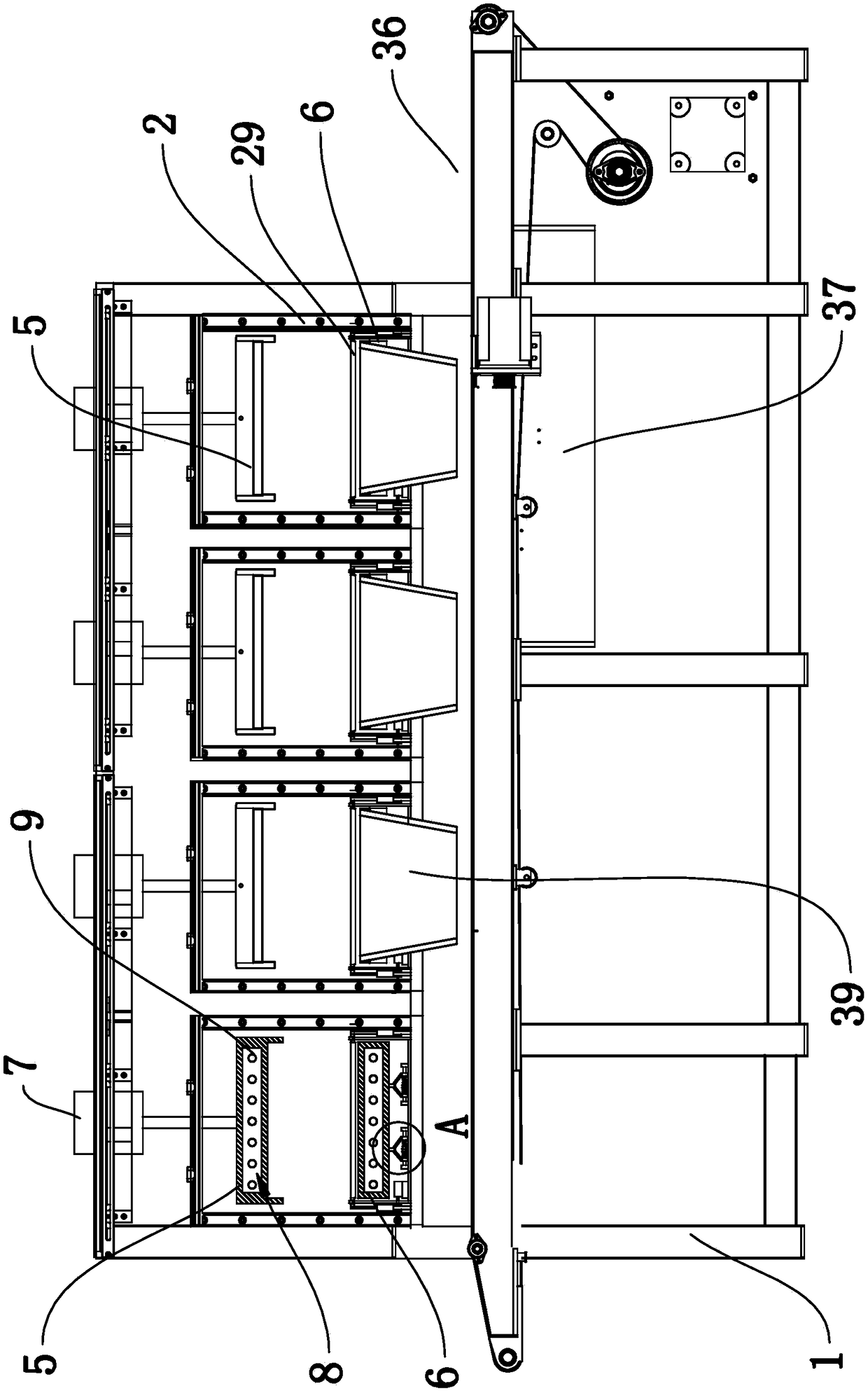

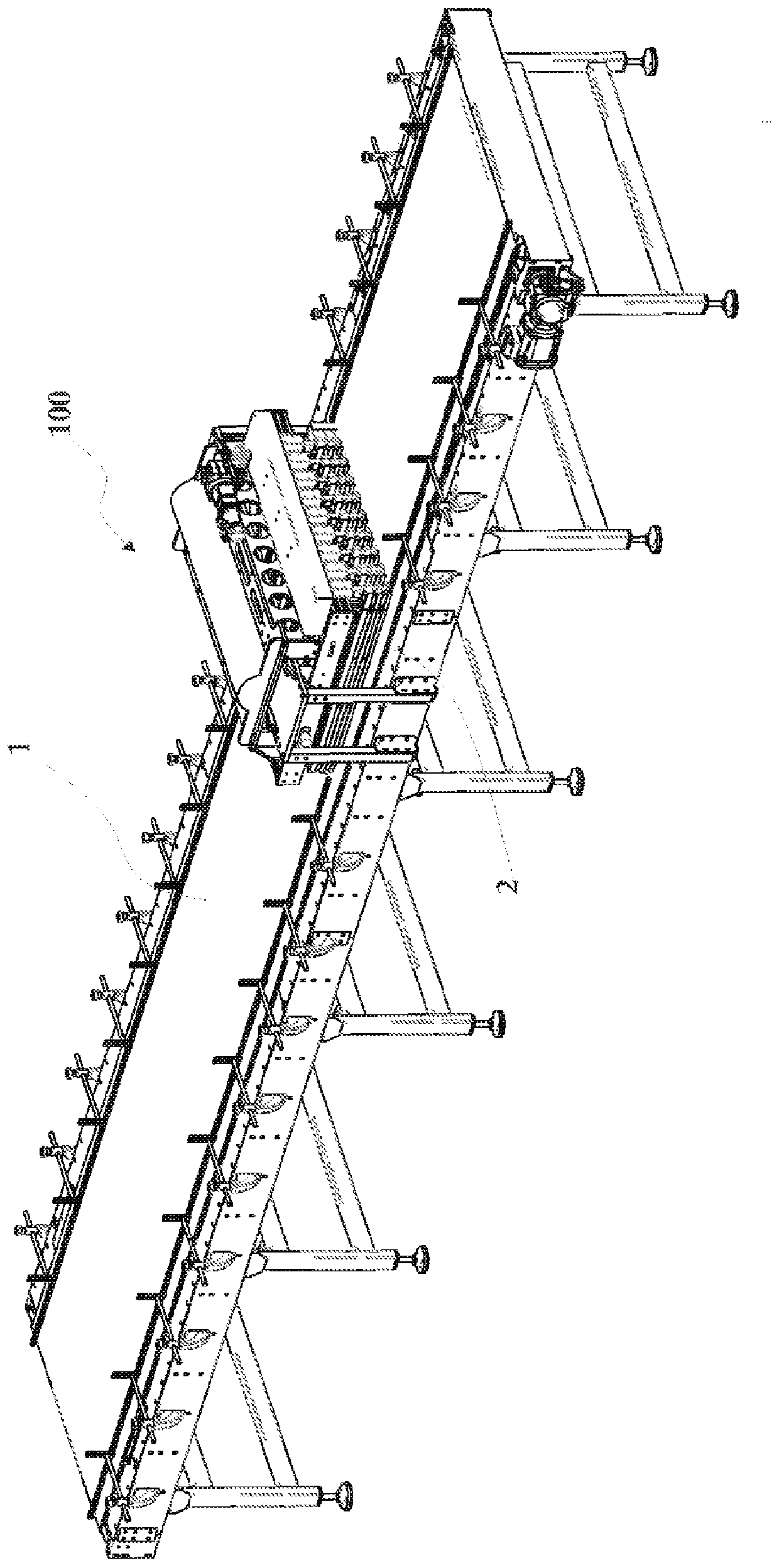

Quick forming and slitting integrated equipment for sintered brick production

ActiveCN112339071AReduce frictional energy lossUniform compactnessMouldsFeeding arrangmentsBrickStructural engineering

The invention discloses quick forming and slitting integrated equipment for sintered brick production. The equipment comprises an equipment body, a rack, a feeding mechanism, an extrusion forming mechanism, a die cavity, a slitting mechanism, a shaking mechanism and supplying mechanisms, wherein the rack is located in the equipment body, the feeding mechanism is fixedly welded to the rack and is located on one side of the extrusion forming mechanism, the extrusion forming mechanism is arranged at the upper end of the rack, the die cavity is hollow and is fixed to the rack, the die cavity is formed right below the extrusion forming mechanism in a horizontal direction, the slitting mechanism is arranged right below the die cavity in parallel, the bottom end of the slitting mechanism is fixedly connected to the rack, one end of the shaking mechanism is fixed to the rack and the other end of the shaking mechanism is in contact with the feeding mechanism and the side wall of the die cavity,separately, the supplying mechanisms are distributed on two sides of the die cavity, the feeding mechanism comprises a feeding hopper, a feeding pipe and a spiral pipe, the feeding pipe is arranged obliquely, the upper end of the feeding pipe is connected to the bottom end of the feeding hopper, an opening in the other end of the feeding pipe is formed vertically, and the spiral pipe is arrangedin the feeding pipe in a penetrating manner.

Owner:宜兴市鼎诚建筑陶瓷有限公司

A three-dimensional integrated circuit on-chip network routing method and system thereof

The invention discloses a routing method for a three-dimensional integrated circuit on-chip network. The method adopts a three-dimensional steering model for routing guidance, and adopts a port selection mechanism for legal output port selection, and unidirectionally routes data packets from a source node to a destination node. The three-dimensional steering model is based on the odd-even steering model, using the X-Y plane or X-Z plane or Y-Z plane in the three-dimensional scene as the reference plane, and mapping the routing path between the source node and the destination node to the reference plane, And by adopting the principle of illegal steering between layers of the device layer on the reference plane, and the corresponding supplementary principles to restrict the steering. The invention also discloses a routing system of the three-dimensional integrated circuit on-chip network.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

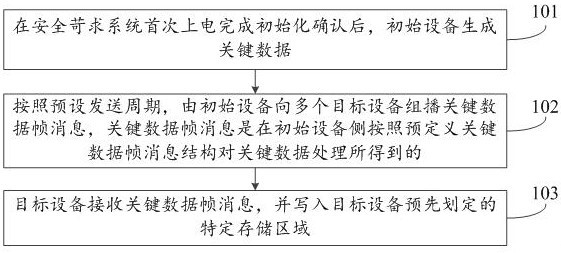

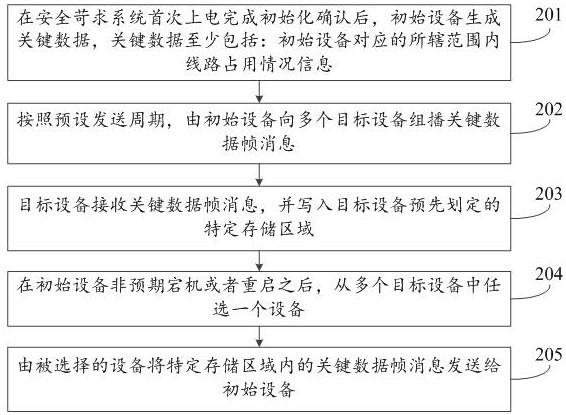

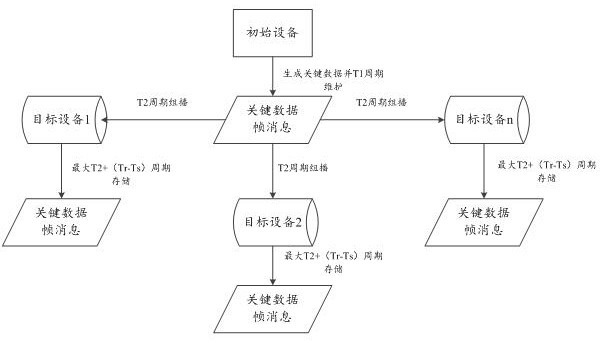

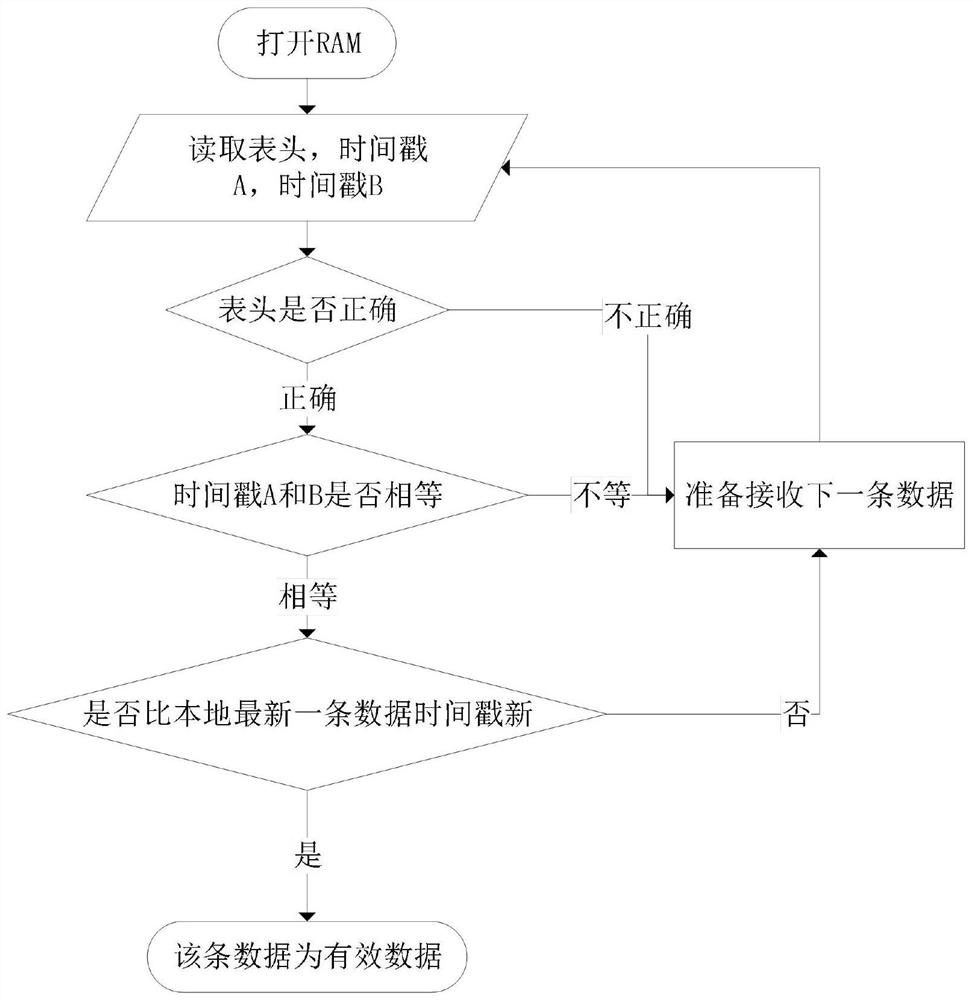

Confidence storage method and system for key data of safety-critical equipment

ActiveCN112073541AEnsure existenceEasy to multicastSpecial service provision for substationRailway traffic control systemsDowntimeMessage structure

The invention discloses a confidence storage method and system for key data of safety-critical equipment, relates to the technical field of safety-critical systems, and aims to ensure the existence ofthe key data and ensure the security confidence without manual intervention after initial equipment encounters unexpected downtime or restart. The main technical scheme is as follows: after the safety critical system is powered on for the first time and initialization confirmation is completed, the initial equipment generates key data, and the key data at least comprises line occupation conditioninformation in a jurisdiction range corresponding to the initial equipment; according to a preset sending period, the initial equipment multicasts key data frame messages to the multiple target devices, and the key data frame messages are obtained by processing key data on the initial equipment according to a predefined key data frame message structure; and the target device receives the key dataframe message and writes the key data frame message into a specific storage area pre-defined by the target device. The method and the system are applied to confidence storage of key data of safety-critical equipment.

Owner:卡斯柯信号(北京)有限公司

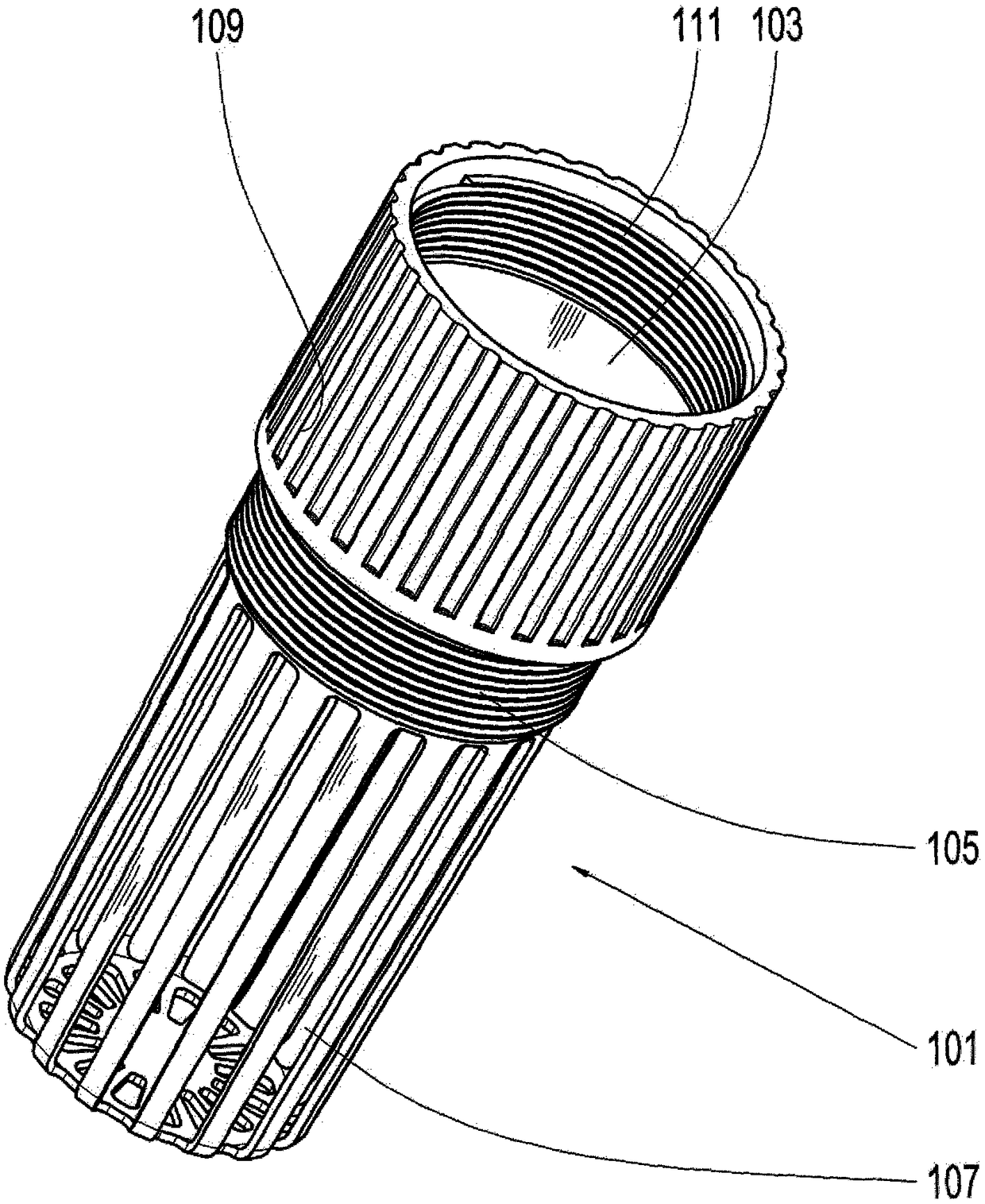

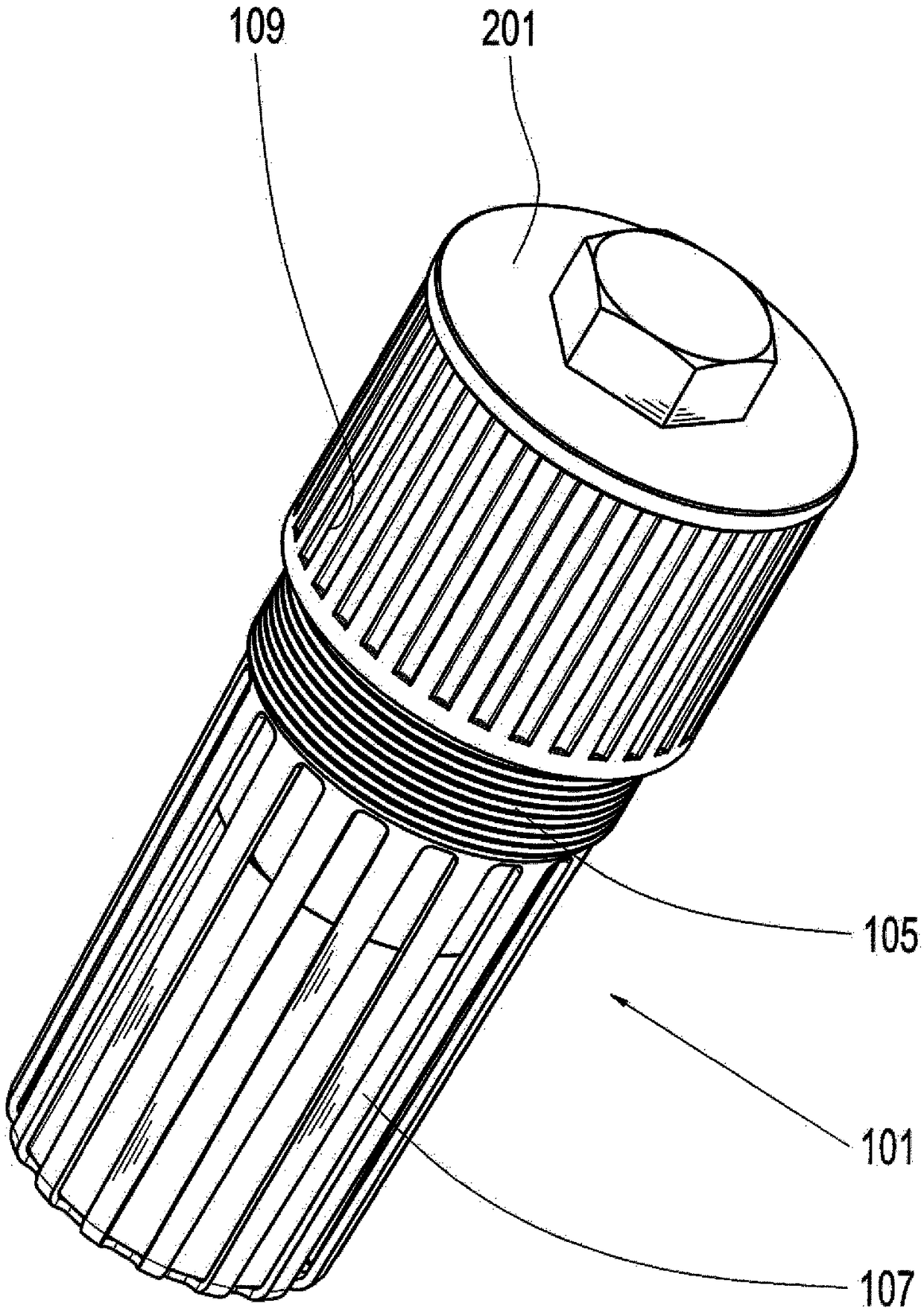

Corrosion inhibitor container ii

The invention relates to a corrosion inhibitor container (101) having at least one chamber for accommodating a corrosion inhibitor, having at least one gas-permeable wall and having at least one external thread (105); wherein the corrosion inhibitor container (101) is able to be screwed into a core hole in a gearbox housing by way of the external thread (105); wherein the wall separates the chamber from an interior of the gearbox housing when the corrosion inhibitor container (101) has been screwed into the core hole. The corrosion inhibitor container (101) has at least one internal thread (111); wherein a screw plug (201) is able to be screwed into the internal thread (111); and wherein the screw plug (201) is able to be screwed into the core hole when the corrosion inhibitor container (101) is not screwed into the core hole.

Owner:ZF FRIEDRICHSHAFEN AG +1

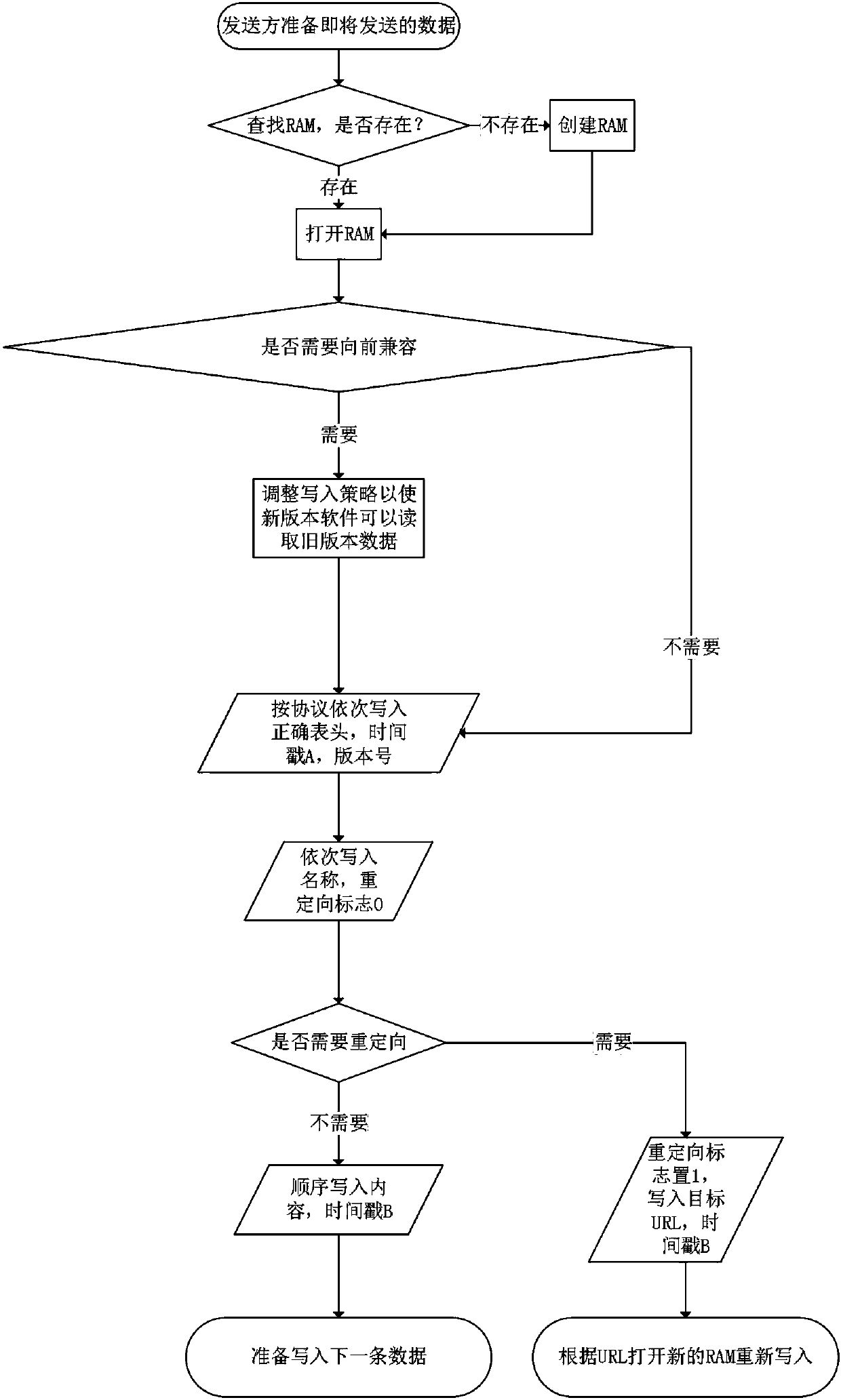

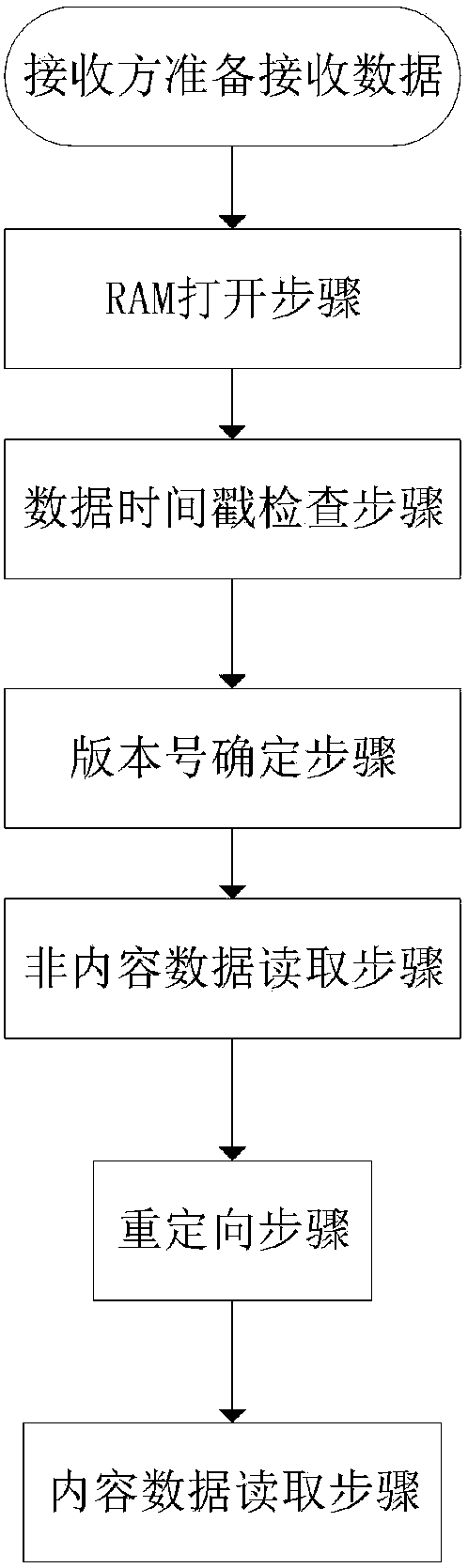

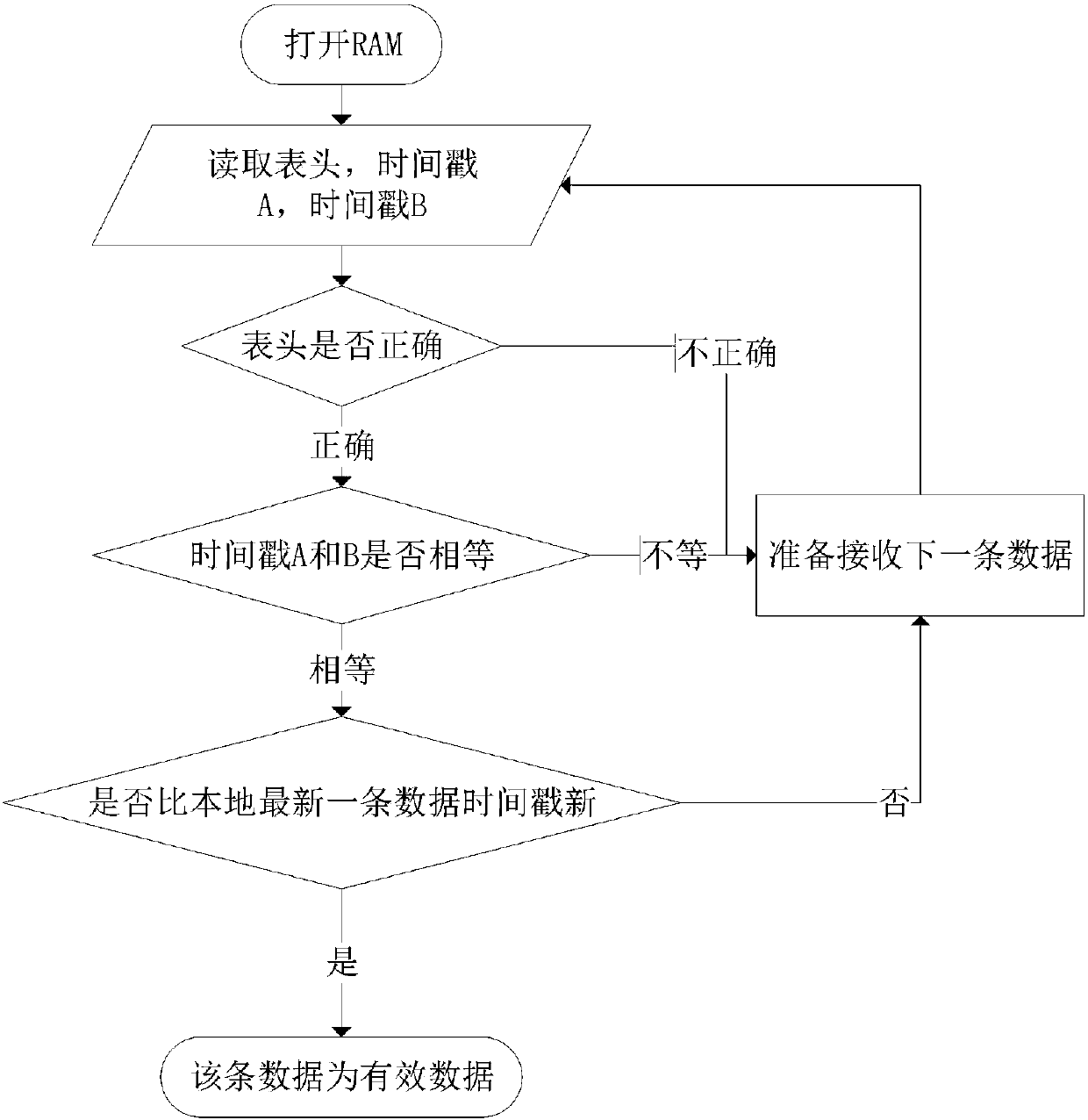

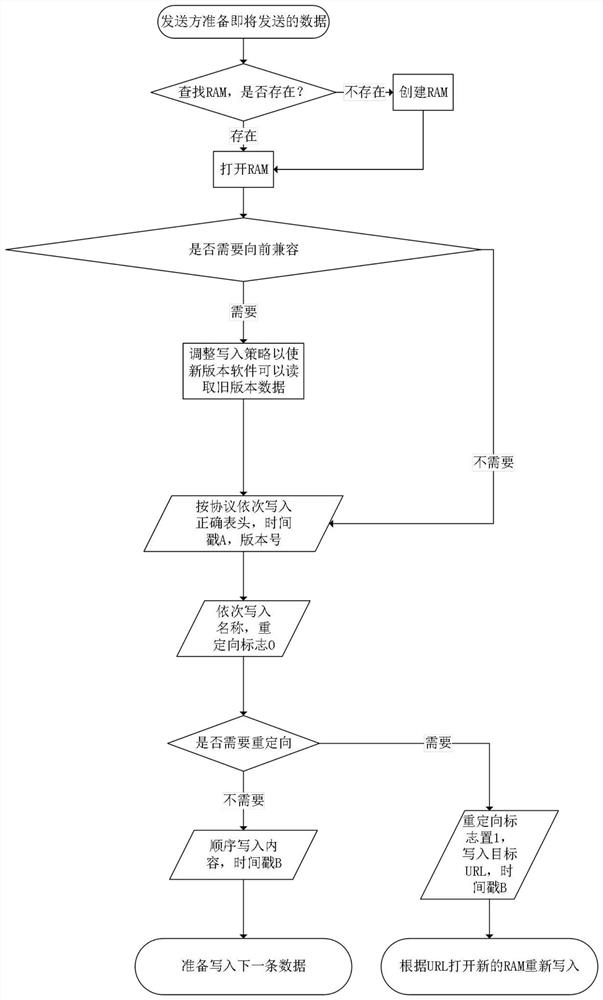

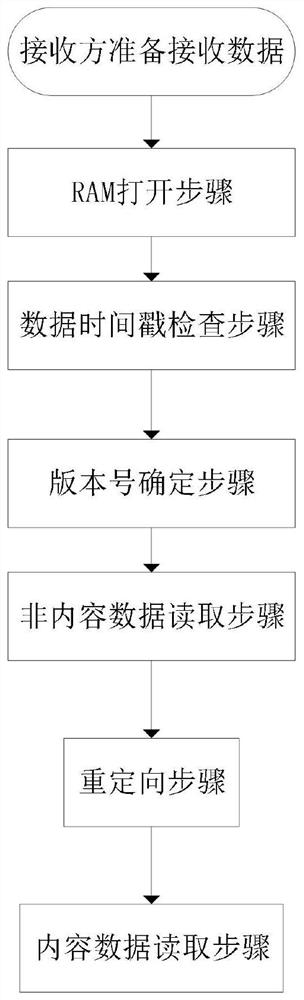

Data distribution method

ActiveCN107562550AGuaranteed validityEasy to updateInterprogram communicationInformation processingOperational system

The invention relates to a data distribution method, belongs to the technical field of information processing, and is applied to various computer platforms. The data distribution method can complete one-to-many distribution of data and includes the steps that a sender writes the data into an RAM in sequence according to a protocol format; a receiver reads the data from the RAM according to certainrules, if read data is valid, receiving of the piece of data is finished, and a next piece of data is ready to receive. The data distribution method has no connection with operation systems and is only connected with read-write methods so that the data distribution method can be applied to the various computer platforms; in the whole read-write process, the data is written in by the sender, the situation is supported that a plurality of receivers synchronously receive the data, it is unnecessary to lock resources in the read-write process, and the data distribution method has the advantages of being effective and having real-time performance.

Owner:成都瀚蓝科技有限公司

A kind of lightweight high-strength silt ceramsite and preparation method thereof

ActiveCN111285630BLow densityGood dispersionSolid waste managementPhysical chemistryUltrasonic dispersion

The invention relates to lightweight high-strength silt ceramsite and a preparation method thereof. S100, mixing sludge, fly ash, water glass, ultrafine composite pore-forming agent and auxiliary dispersant, and performing ultrasonic aging to obtain raw meal; S200 1. Pelletizing the raw meal, and controlling the water content of the formed raw meal particles to be less than 0.5%; S300, roasting and hardening the raw meal particles obtained in S200 to obtain light-weight high-strength silt ceramsite. The superfine composite pore-forming agent with ultra-fine particles is selected as the gas-generating component, and the ultra-fine composite pore-forming agent is uniformly dispersed into the interior of the material by means of auxiliary dispersant and ultrasonic dispersion, and the ultra-fine composite pore-forming agent is made by controlling the roasting system. Different gas-generating components in the porogen produce uniformly dense pores of different sizes, forming a pore structure in which the fine pores "fill" the large pore gaps. The lightweight and high-strength silt ceramsite has low apparent density and high strength, which solves the problem of ceramics It is difficult to balance the density and strength in the process of pellet preparation.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

A data distribution method

ActiveCN107562550BGuaranteed validityEasy to updateInterprogram communicationInformation processingOperational system

The invention relates to a data distribution method, belongs to the technical field of information processing, and is applied to various computer platforms. The data distribution method can complete one-to-many distribution of data and includes the steps that a sender writes the data into an RAM in sequence according to a protocol format; a receiver reads the data from the RAM according to certainrules, if read data is valid, receiving of the piece of data is finished, and a next piece of data is ready to receive. The data distribution method has no connection with operation systems and is only connected with read-write methods so that the data distribution method can be applied to the various computer platforms; in the whole read-write process, the data is written in by the sender, the situation is supported that a plurality of receivers synchronously receive the data, it is unnecessary to lock resources in the read-write process, and the data distribution method has the advantages of being effective and having real-time performance.

Owner:成都瀚蓝科技有限公司

a mixing system

The invention provides a stirring system which comprises a primary stirring device, wherein the primary stirring device comprises a stirring barrel; the stirring barrel is divided into a cement feeding region, a convective mixing region and a water supply region from top to bottom in sequence in a height direction; a cement feeding opening is formed in the top of the cement feeding region; a slurry outlet is formed in the convective mixing region; a water inlet is formed in the water supply region; the water inlet is located on the side wall of the lower end of the stirring barrel; a plurality of groups of stirring fins are arranged in the stirring barrel; rotating shafts of the groups of stirring fins are coaxial; the uppermost group of stirring fins are right-handed spiral fins; the other groups of stirring fins are left-handed spiral fins; the right-handed spiral fins are located in the cement feeding region; and the left-handed spiral fins are located in the water supply region. Compared with the prior art, through the design of the right-handed spiral fins and the left-handed spiral fins in the stirring barrel, the convective mixing region is formed between the right-handed spiral fins and the left-handed spiral fins, and during a rotating process, the right-handed spiral fins accelerate sinking of cement, and the left-handed spiral fins accelerate rising of water, so that deposition of large particles is reduced and a strong convective mixing region is formed near the slurry outlet.

Owner:HUAINAN MINING IND GRP

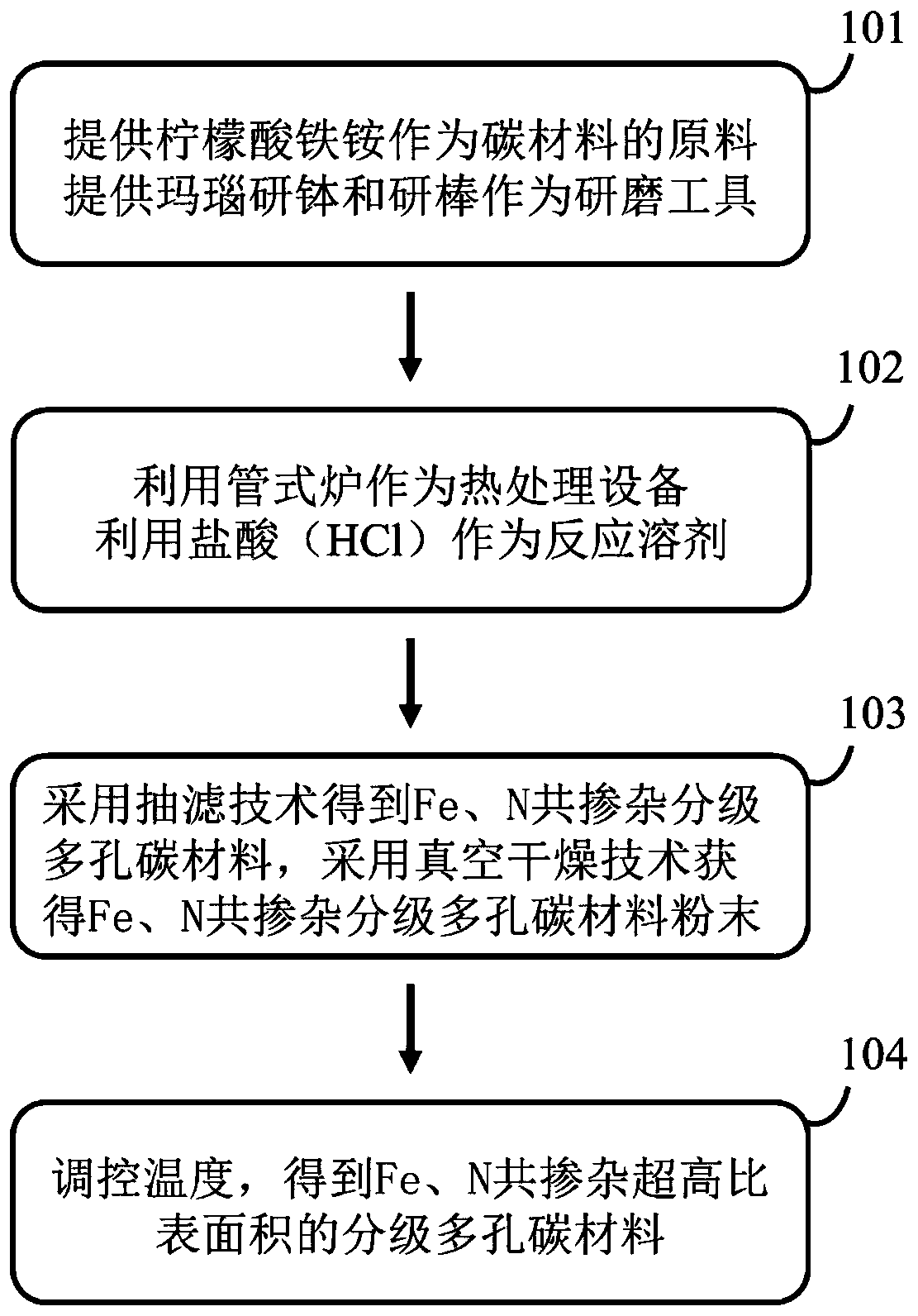

Preparation method of Fe and N co-doped hierarchical porous carbon material with ultrahigh specific surface area

PendingCN110577205AEnsure existenceGood dispersionCarbon preparation/purificationFiltrationHierarchical porous

The invention discloses a preparation method of a Fe and N element co-doped hierarchical porous carbon material with an ultrahigh specific surface area. The preparation method specifically comprises the following steps: grinding a raw material ammonium ferric citrate to form a powder, annealing the powder, and then sequentially carrying out acidification treatment, suction filtration and vacuum drying on the obtained annealed sample in order to obtain the Fe and N element co-doped hierarchical porous carbon material with the ultrahigh specific surface area. The problems of complex process andlow yield in existing preparation technologies of element co-doped carbon materials are solved, and the Fe and N element co-doped hierarchical porous carbon material with the ultrahigh specific surface area is provided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

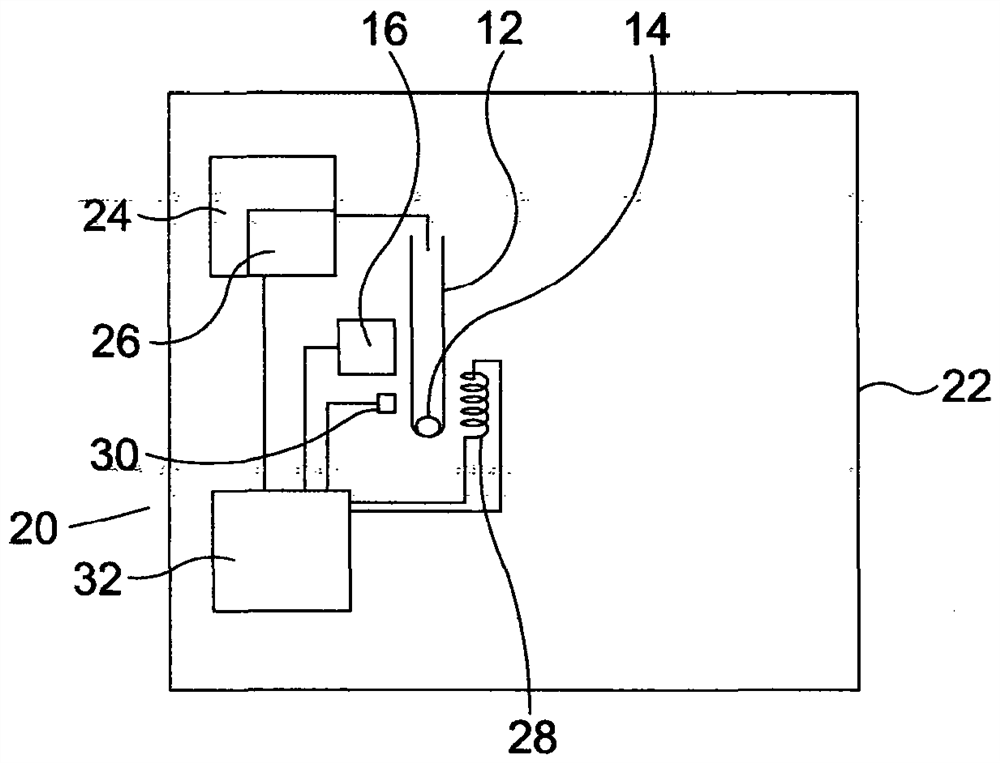

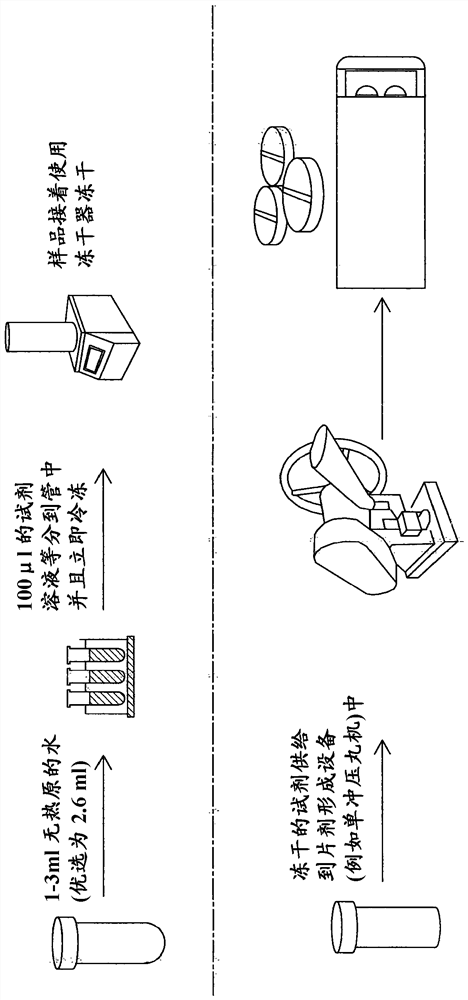

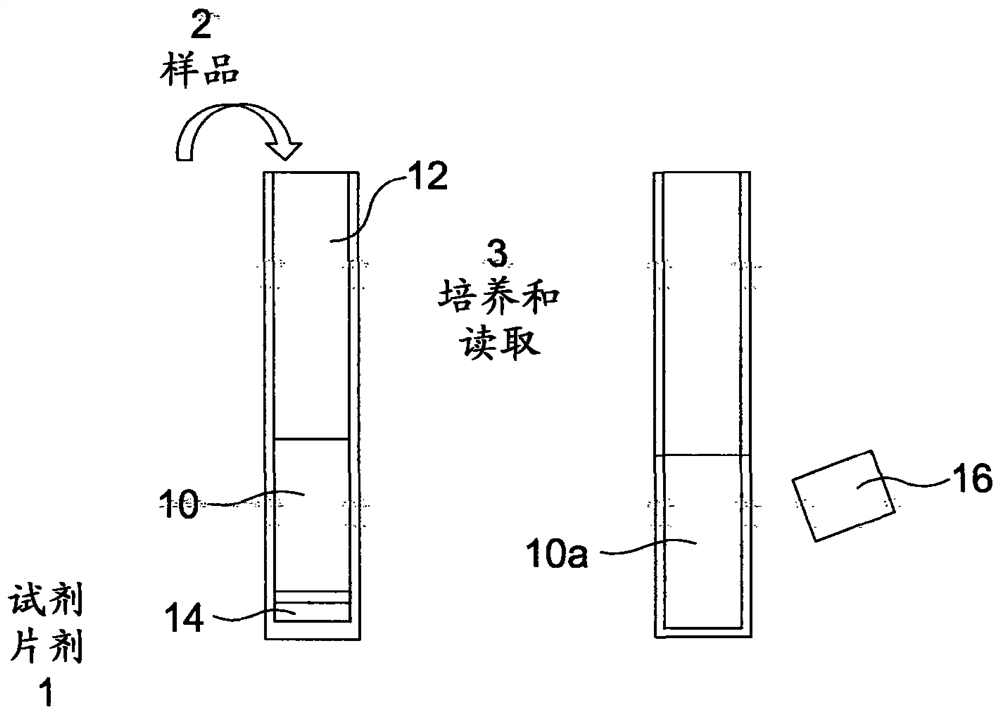

Water quality testing

InactiveCN111771118AEasy to useEnsure existenceAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorFaecal pollutionWater quality

A water quality testing method, operable to detect the presence or level of faecal contamination of water, is described comprising the steps of placing a water sample (10) within a reaction chamber (12) containing a reagent, the reagent being in, for example, tablet form, or placing the water sample (10) within a single use reaction chamber (12) pre-packaged with a single dose of the reagent, incubating the sample (10) at a predetermined temperature for a predetermined period of time to form a reaction solution (10a), and using the colour or darkness of the solution (10a) to provide an indication of the water quality.

Owner:莫兰多科技有限公司

A rapid prototyping and cutting integrated equipment for sintered brick production

ActiveCN112339071BReduce frictional energy lossUniform compactnessMouldsFeeding arrangmentsMechanical engineeringIndustrial engineering

The invention discloses a rapid prototyping and cutting integrated equipment for sintered brick production, which comprises a device body, a frame, a feeding mechanism, an extrusion molding mechanism, a mold groove, a cutting mechanism, a shaking mechanism and a feeding mechanism. Inside the equipment body, the feeding mechanism is fixedly welded on the frame. The feeding mechanism is located on the side of the extrusion forming mechanism. The extrusion forming mechanism is located on the upper end of the frame. The horizontal direction is set directly below the extrusion molding mechanism, the slitting mechanism is set parallel to the directly below the mold groove, the bottom end of the slitting mechanism is fixedly connected with the frame, one end of the shaking mechanism is fixed on the frame, and the other end is respectively The feeding mechanism is in contact with the side wall of the mold cavity, and the feeding mechanism is distributed on both sides of the mold cavity. The feeding mechanism includes a feeding hopper, a feeding pipe and a spiral pipe. The feeding pipe is arranged obliquely. The upper end of the feeding pipe is connected with the bottom end of the feeding hopper. It is installed inside the feed pipe.

Owner:宜兴市鼎诚建筑陶瓷有限公司

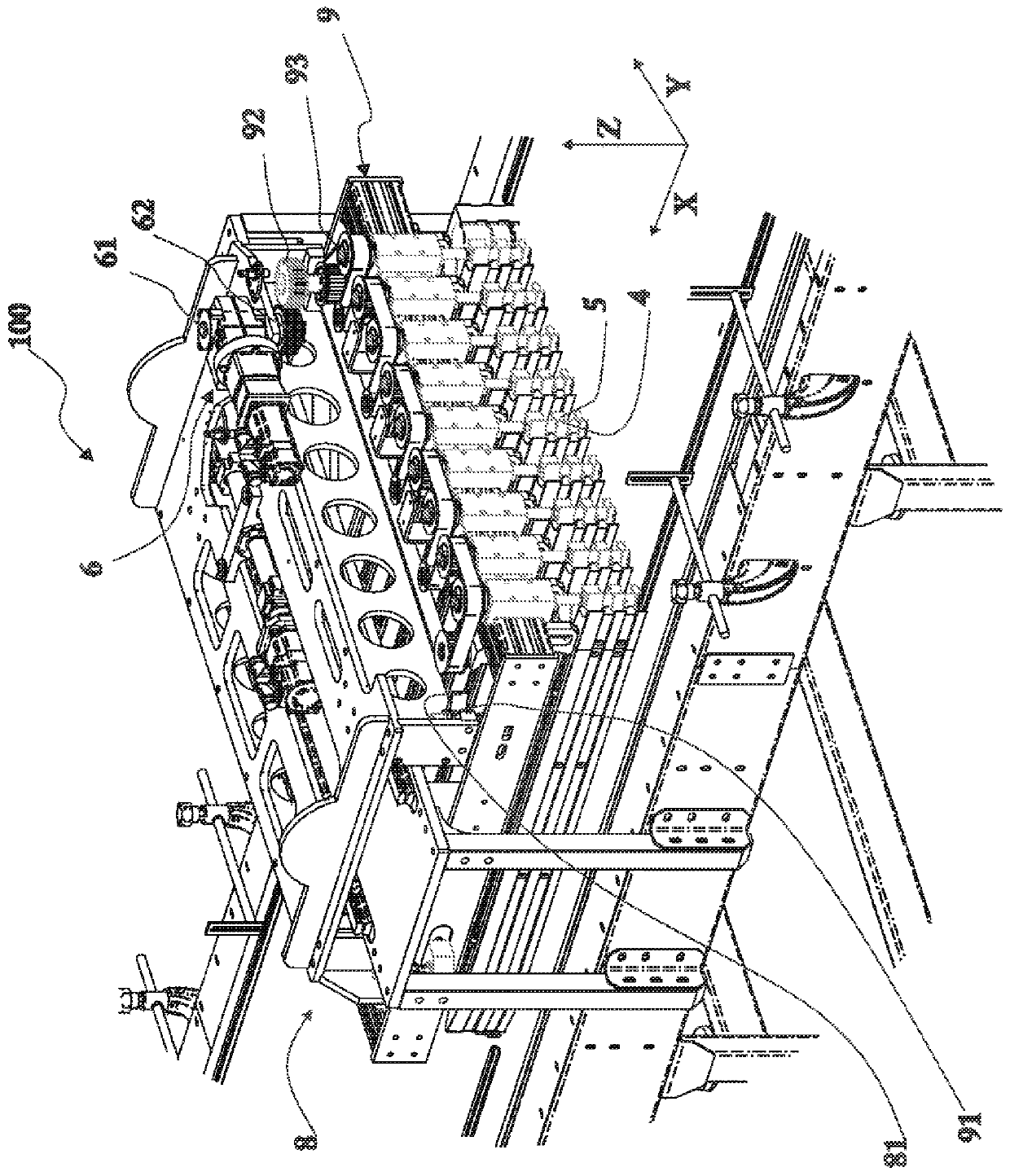

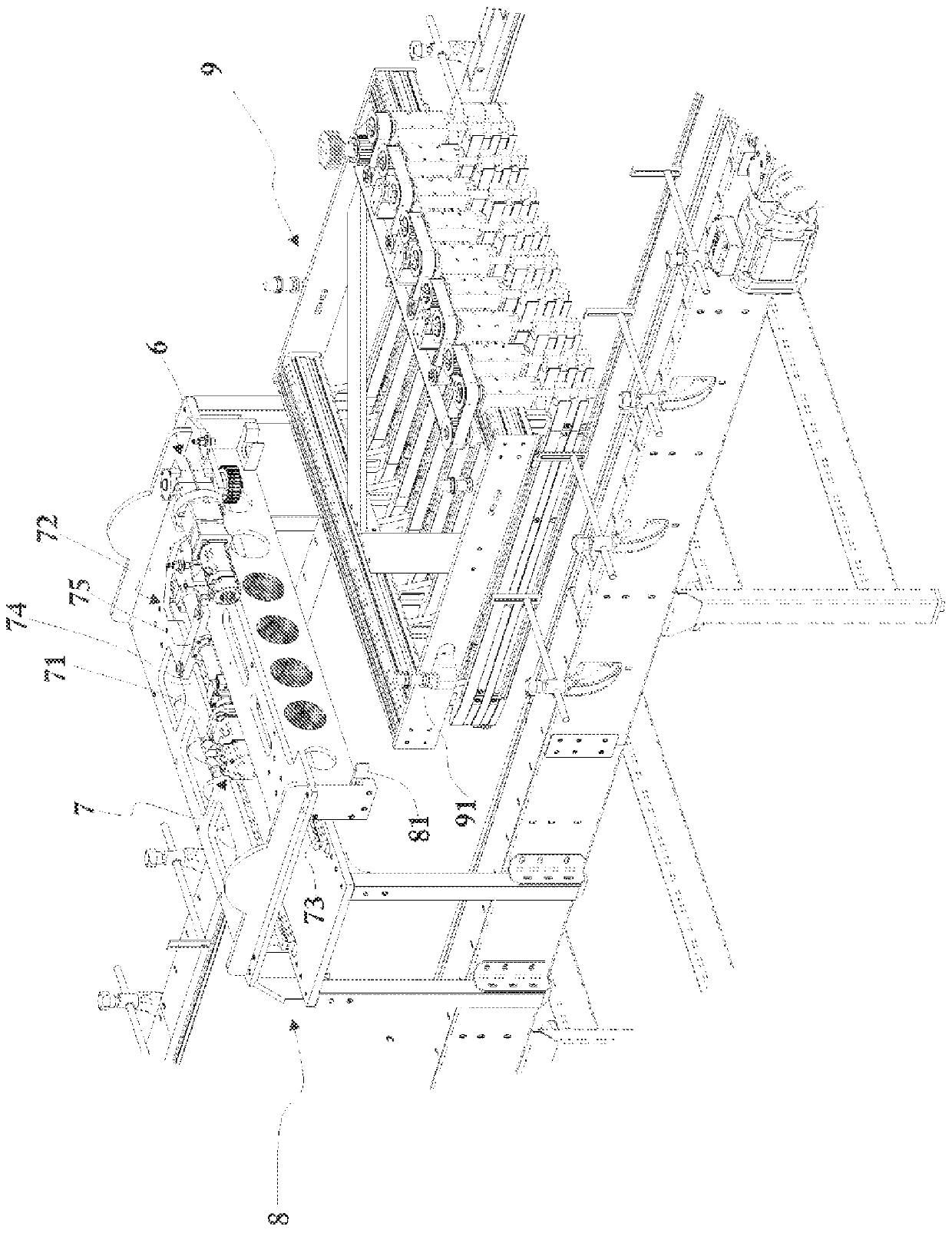

Forming device for forming layer of containers arranged as quincunx

ActiveCN111164031AEnsure existenceDestruction arrangementConveyorsPackaging bottlesQuincunxTransmission belt

A forming device 100 for forming a layer of containers 300 arranged as a quincunx, comprises a conveyor belt 1 configured to advance the containers 300 according to a feeding direction X of the conveyor belt 1, an equipment piece 9 bearing a plurality of partitions 2 positioned parallel to the direction X, wherein the partitions 2 divide the upper surface of the conveyor belt 1 into a plurality ofchannels 3, and each channel has a width to allow the passage of a single row of containers 300. The equipment piece 9 further comprises a series of feeding devices 4 configured for dosing and releasing, in a controlled manner, the containers 300 exiting from the channels 3, each container is placed at the outlet of each channel 3, and the equipment piece 9 is movable according to direction Y substantially perpendicular to the feeding direction X of the conveyor belt.

Owner:EMS集团股份公司

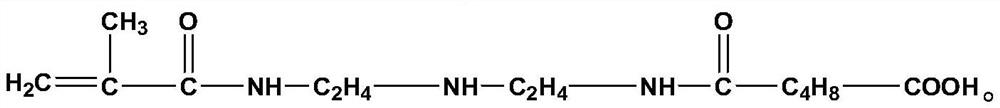

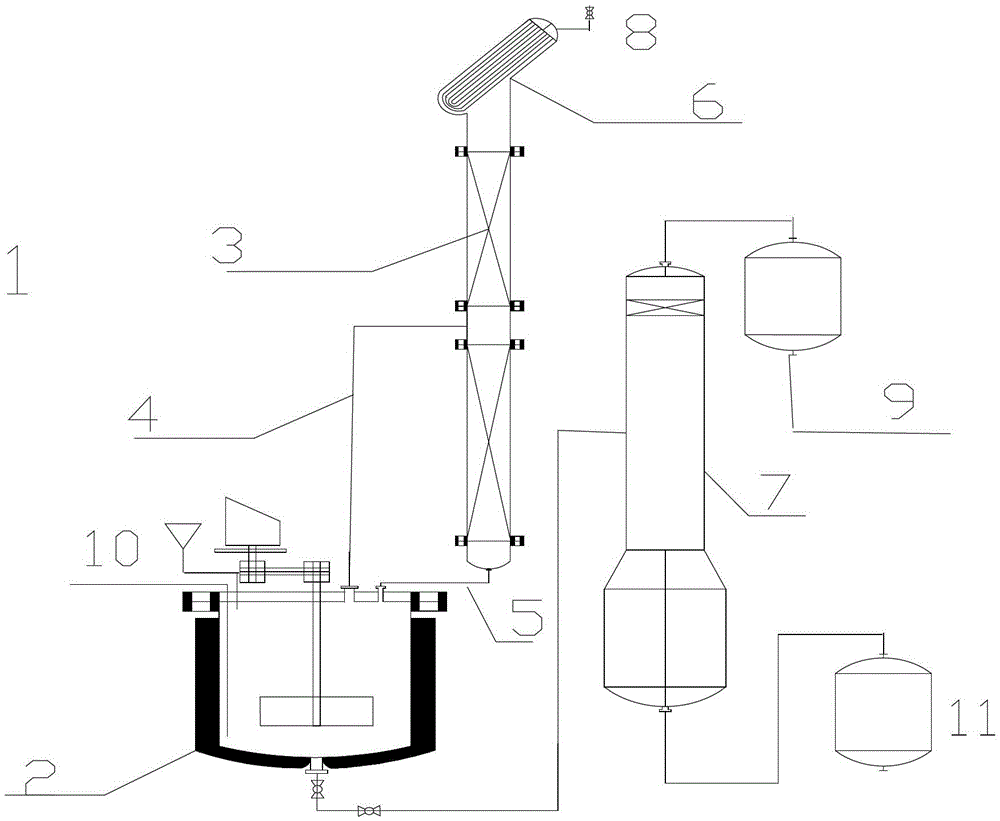

A kind of equipment and method for preparing isocyanate by pressurized pyrolysis

The invention relates to equipment and a method for preparing isocyanate through compression pyrolysis, and belongs to the technical field of preparation of isocyanate through pyrolysis. The reactor is an integrated reactor of a high pressure pyrolytic reaction kettle and a rectifying tower and comprises a pyrolytic reaction kettle and a rectifying tower; a gas rising pipeline and a liquid return pipeline are connected between the pyrolytic reaction kettle and the rectifying tower; a condenser is arranged on the upper part of the rectifying tower; liquid in the condenser can reflow by inner circulation or outer circulation; a gas outlet is arranged on the upper part for connecting a pressure adjusting system to keep the pressure of the system; and the pyrolytic reaction kettle is simultaneously connected with a liquid phase output discharge processing system. Under the compression pyrolysis condition, solvent can be effectively separated from lower alcohol generated from reaction in the reaction process through separation of the rectifying tower, so that the reaction rate is improved, and the yield of isocyanate is enhanced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

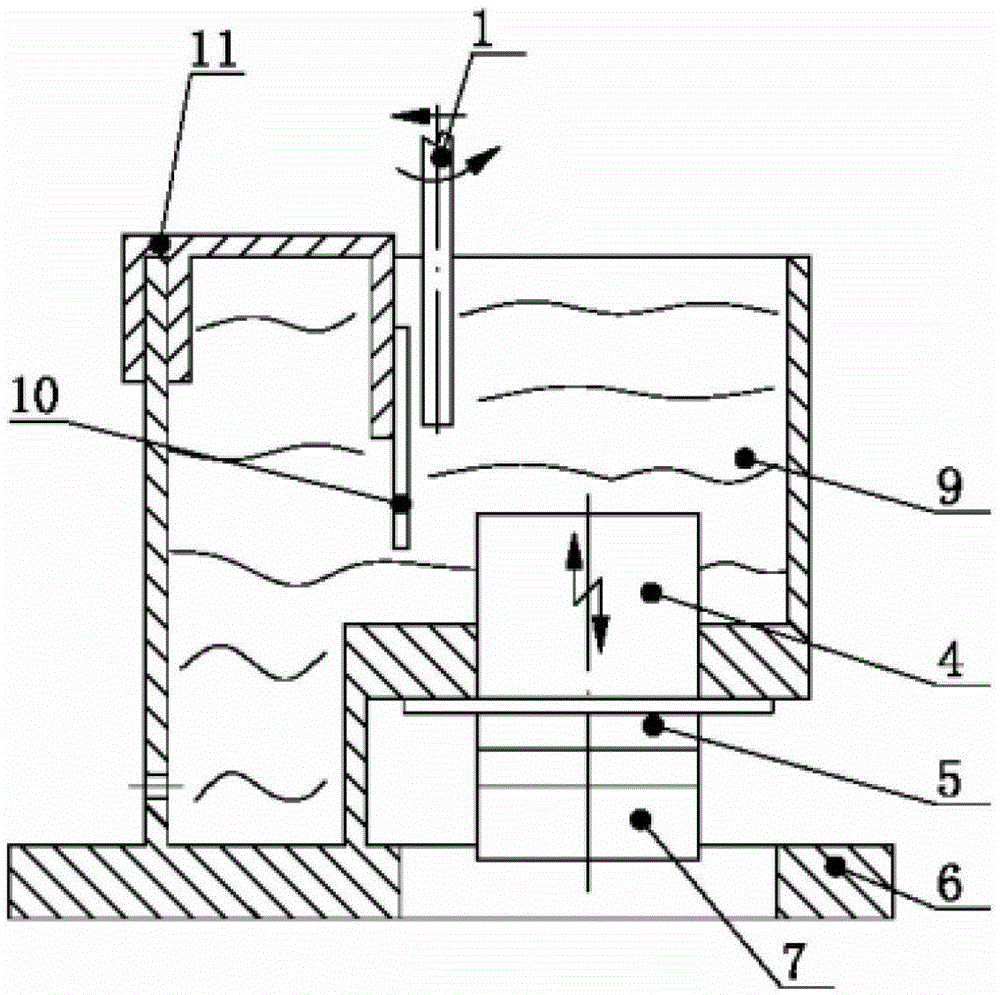

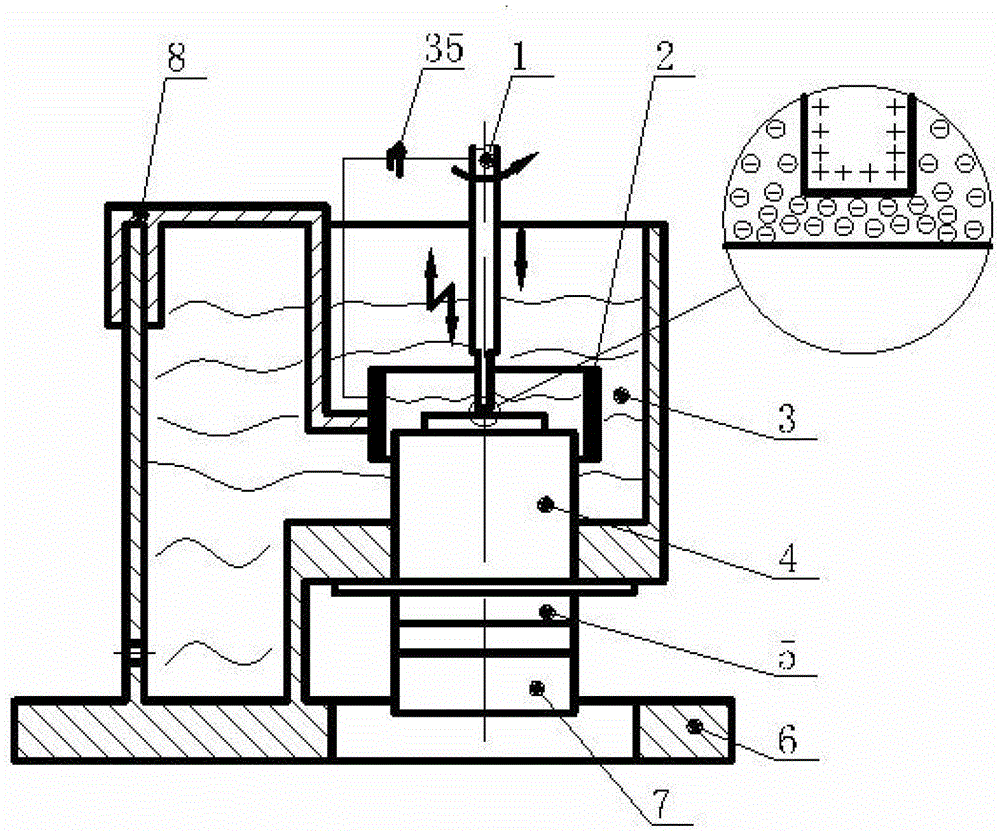

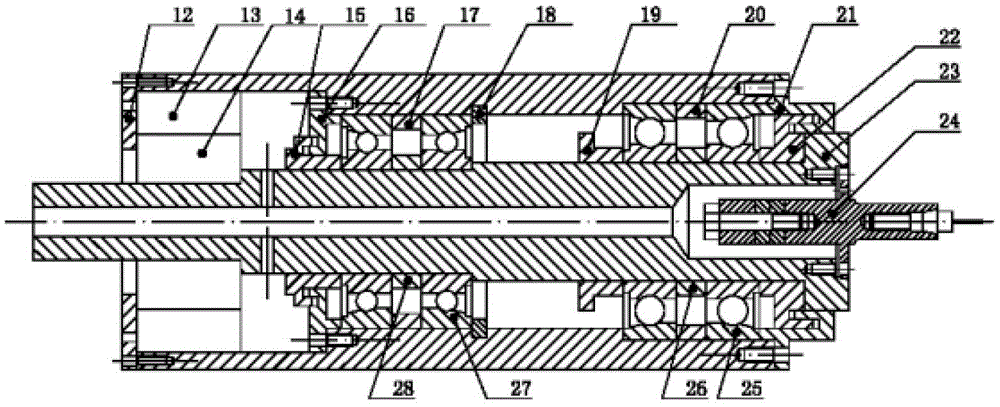

An electrophoresis-assisted micro-ultrasonic processing machine tool and processing method

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com