Multi-component cartridge

A multi-component, cartridge technology, applied in the direction of containers, containers, mixers, etc. with multiple items, can solve the problems that the distributing pipe cannot be ensured, and the dispensing pipe cannot be placed cleanly on the injection parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

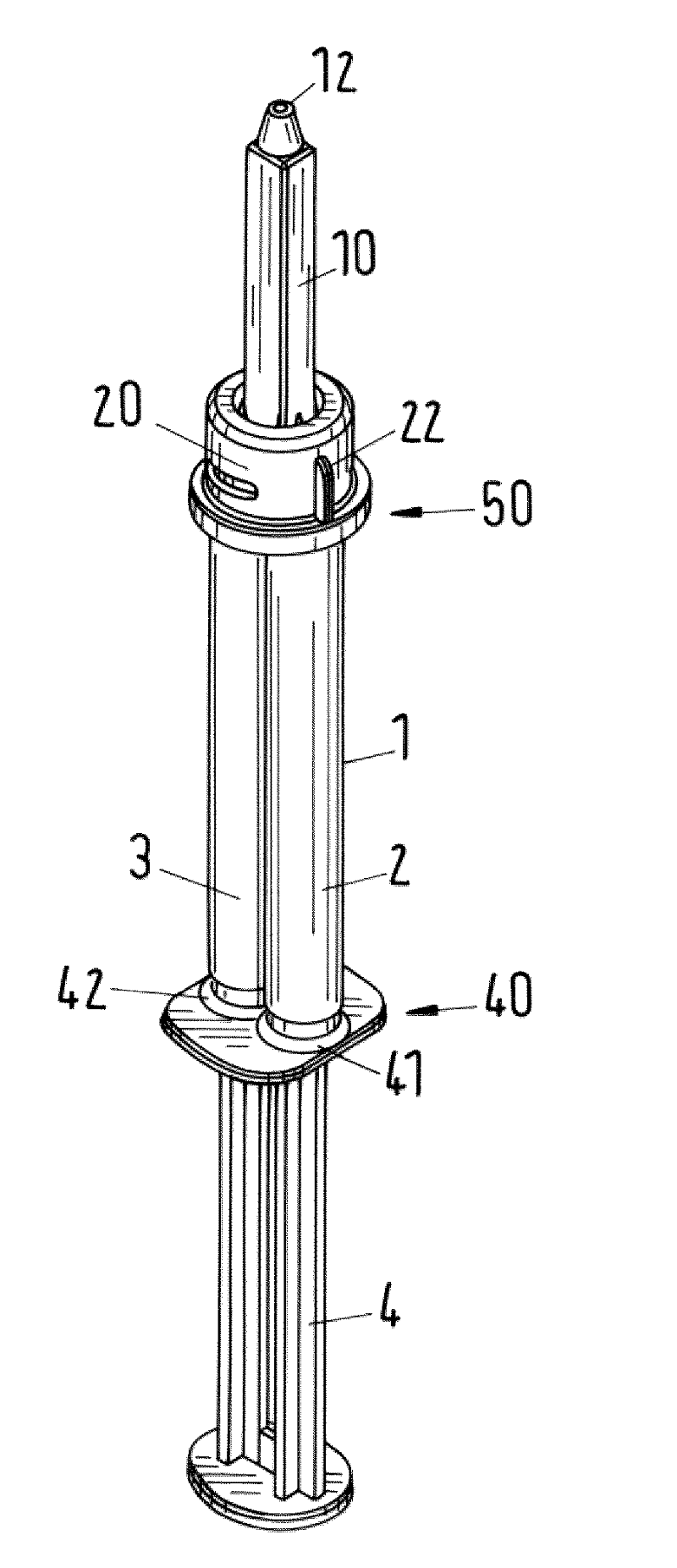

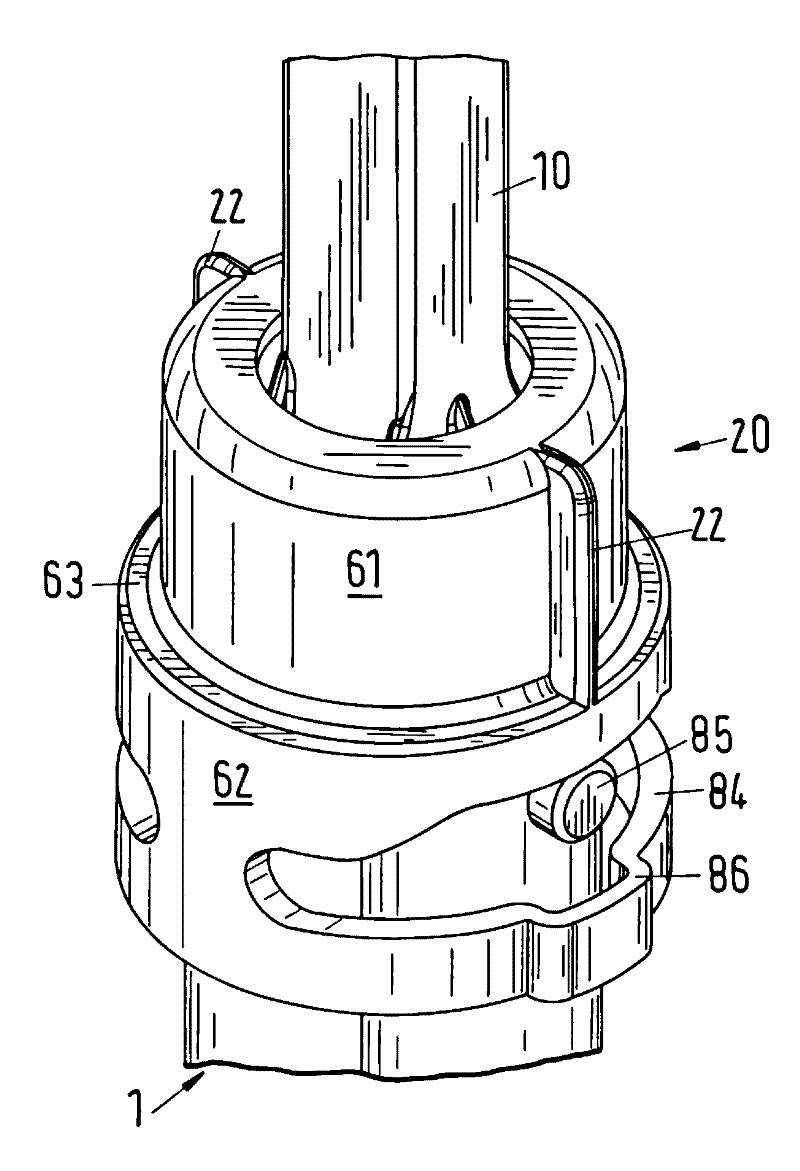

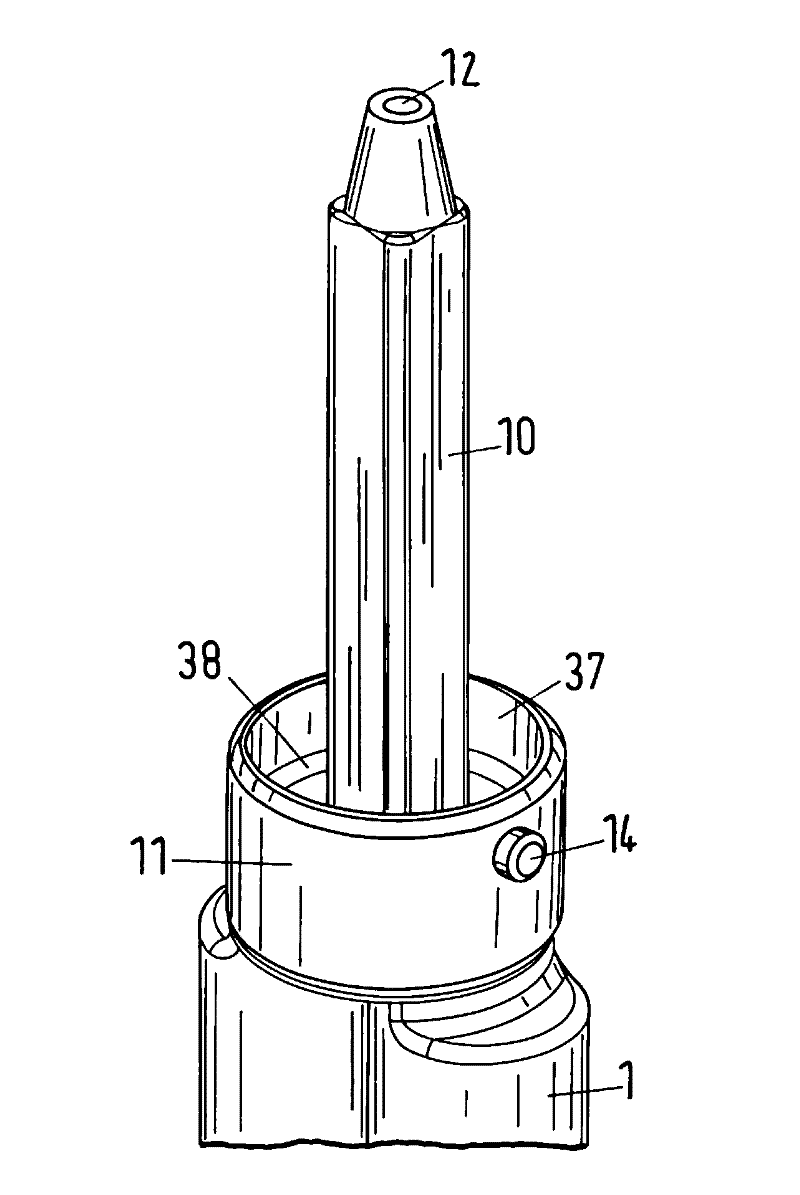

[0057] figure 1 A dispensing device according to the invention is shown for mixing and dispensing multi-component substances according to a preferred embodiment. Multi-component cartridge 1 in figure 1 is designed as a double syringe with a container having two substantially cylindrical chambers 2, 3 fixedly connected to receive the different components. The components in this example are the two components of a two-component glue, which are only allowed to mix with each other shortly before being distributed to the objects to be glued. However, there are also other components that can be stored in the chamber, for example in bulk for dental applications. Primarily, the present multi-component cartridges are suitable, especially in all applications where small amounts of components should be applied at once.

[0058] The multi-component cartridge has an inlet end 40 and an outlet end 50 . The inlet port 40 comprises inlet holes 41 , 42 through which the chambers 2 , 3 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com