Compression device, and thermodynamic system comprising such compression device

A compression device, compressor technology, applied in the direction of compressors, components of pumping devices for elastic fluids, pump devices, etc., can solve problems such as insufficient lubrication, damage to compressor integrity, etc., to avoid pressure Balancing the degradation of characteristics, avoiding cumulative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

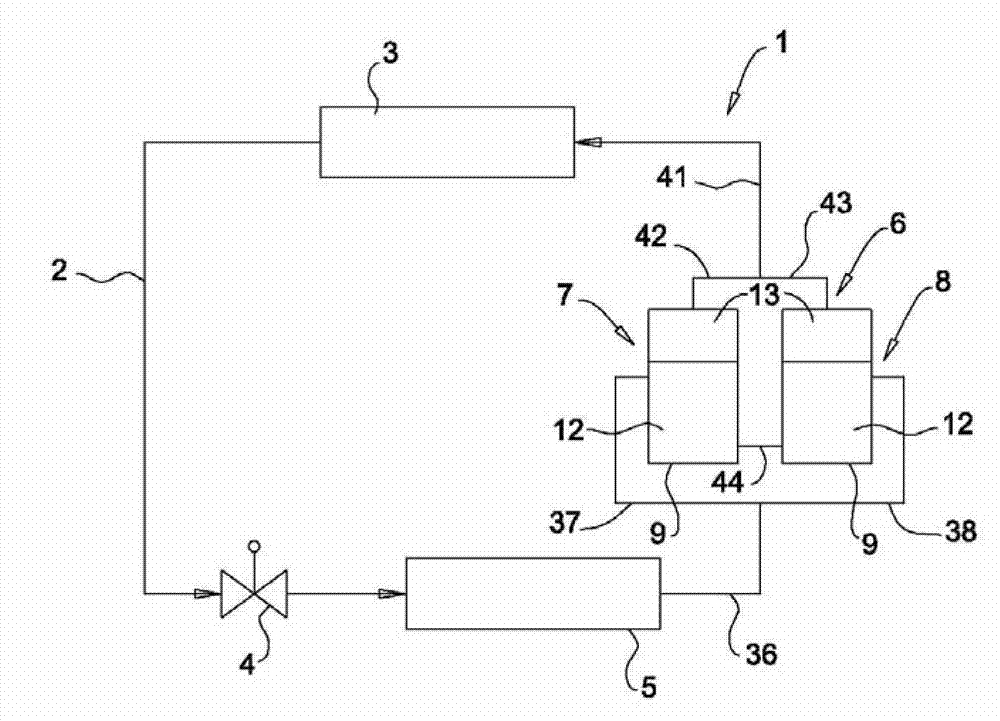

[0075] figure 1 The main components of the thermodynamic system 1 are shown schematically. The thermodynamic system 1 may be a refrigeration system, such as a reversible refrigeration system.

[0076] The thermodynamic system 1 comprises a circulation circuit 2 for a refrigerant comprising in turn a condenser 3 , an expander 4 , an evaporator 5 and a compression device 6 connected in series.

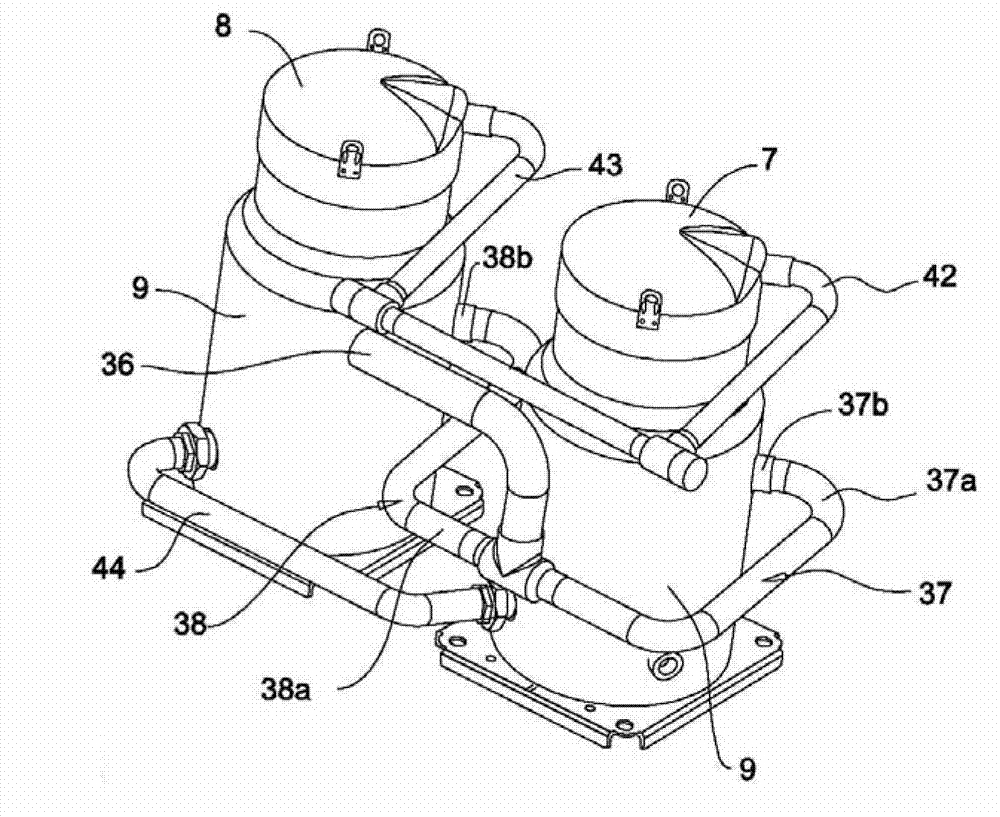

[0077] The compression device 6 comprises a first compressor 7 and a second compressor 8 installed in parallel, each compressor may have a variable capacity (more specifically variable speed) or a fixed capacity (more specifically constant speed). Advantageously, each compressor 7, 8 is a scroll compressor.

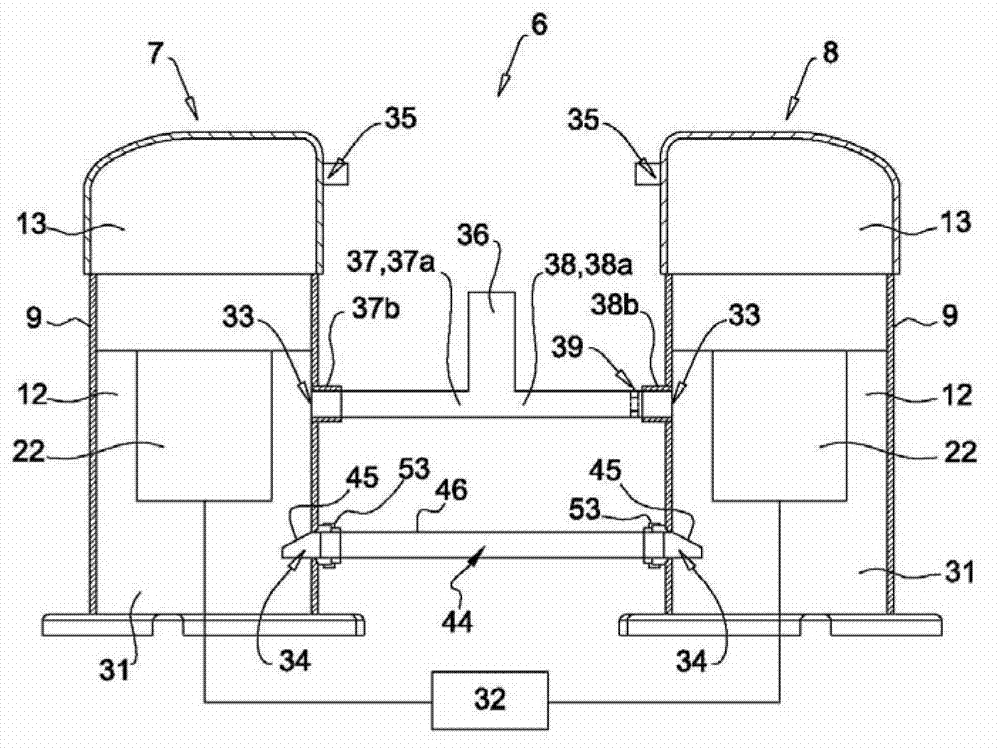

[0078] Such as Figure 4 As mentioned, each compressor 7, 8 includes a sealed casing 9 in which an organic body 11 is installed, and the body 11 defines a low-pressure area 12 below the body 11 and a high-pressure area 13 above the body 11.

[0079] Each compressor 7 , 8 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com