Forming device for forming layer of containers arranged as quincunx

A quincunx-shaped container technology, applied in the field of quincunx-shaped structure, can solve the problems of vacancies in containers, inability to ensure complete filling of layers, complexity of equipment parts, etc., and achieve the effect of high production speed/frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

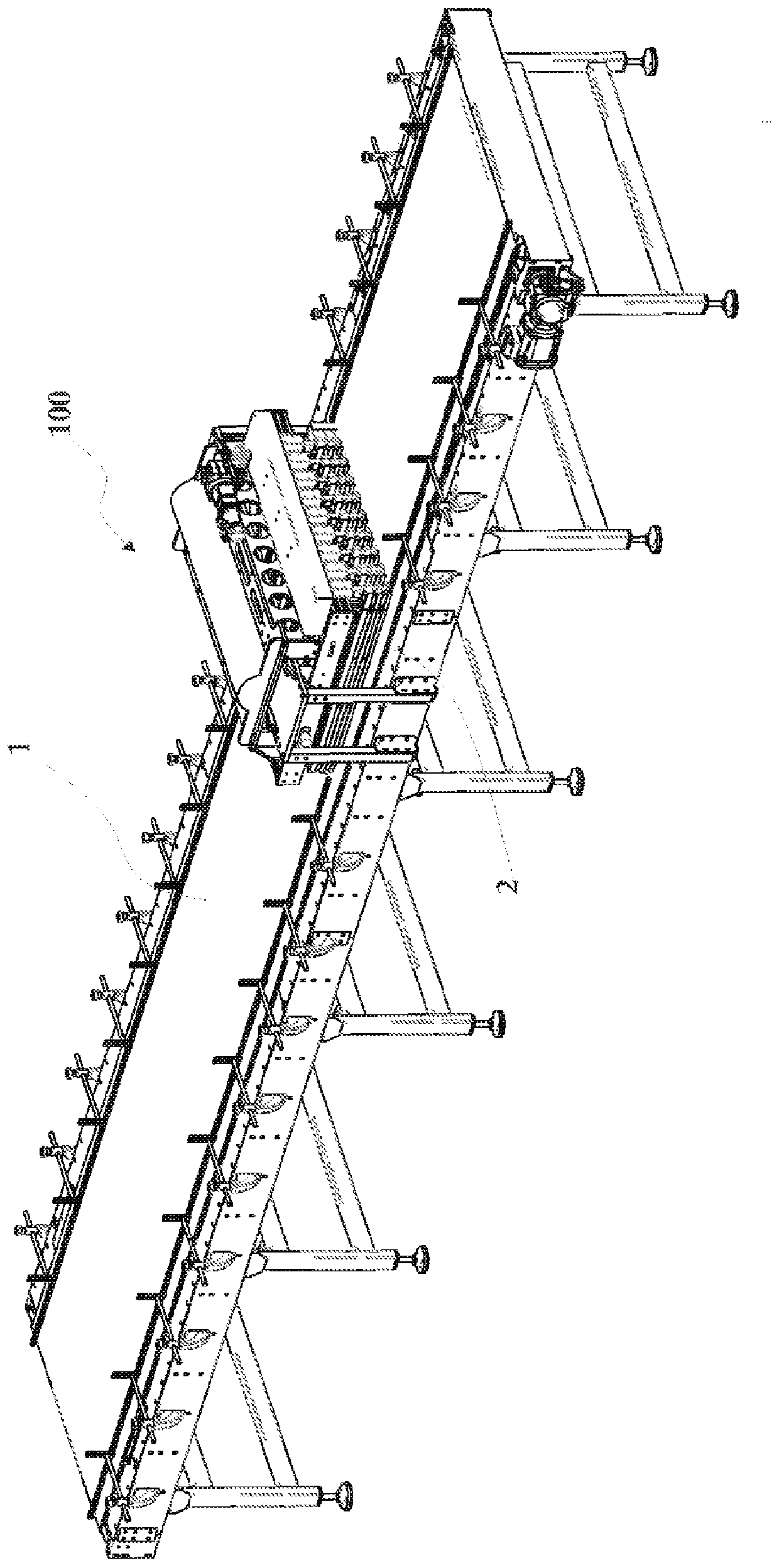

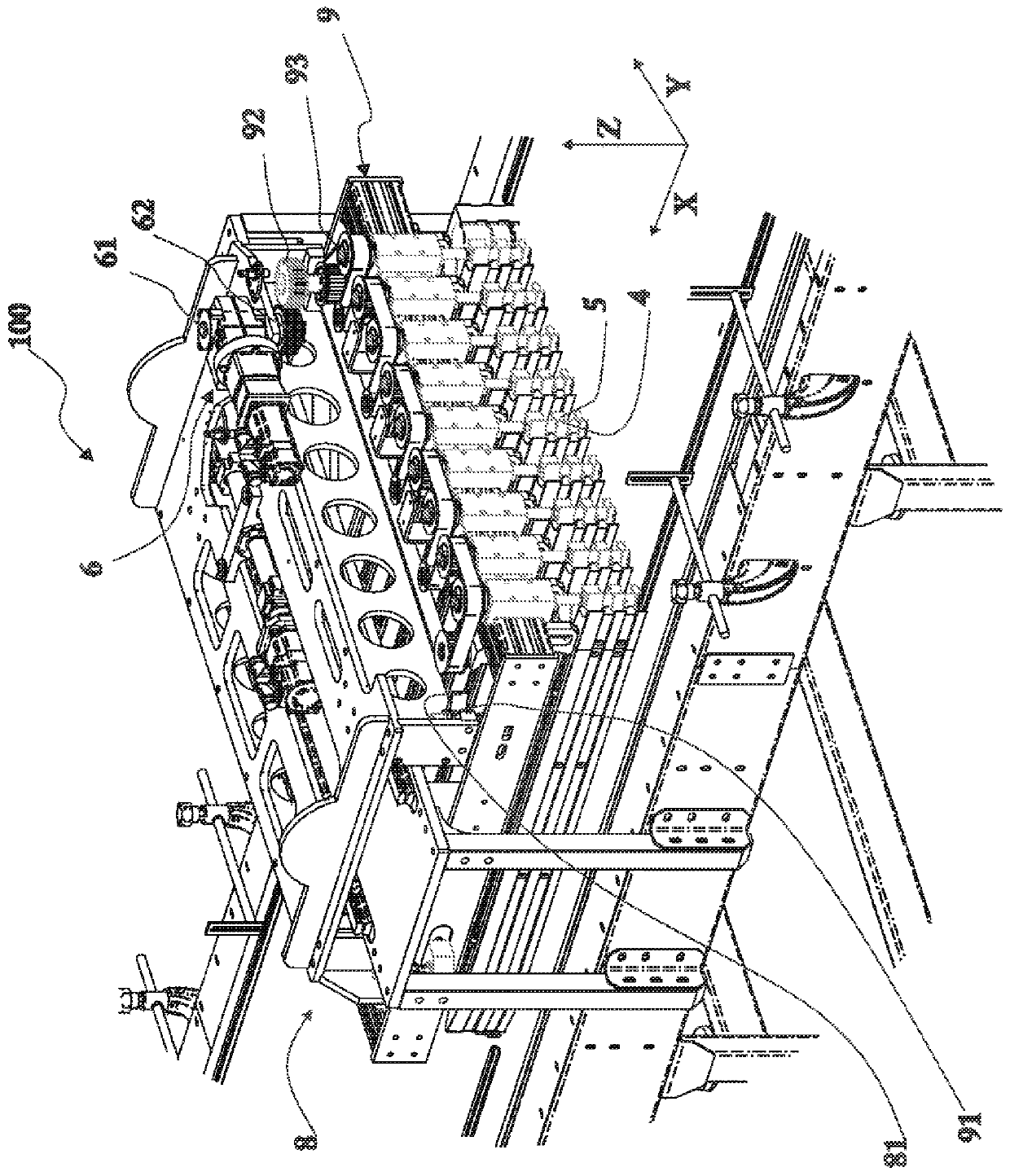

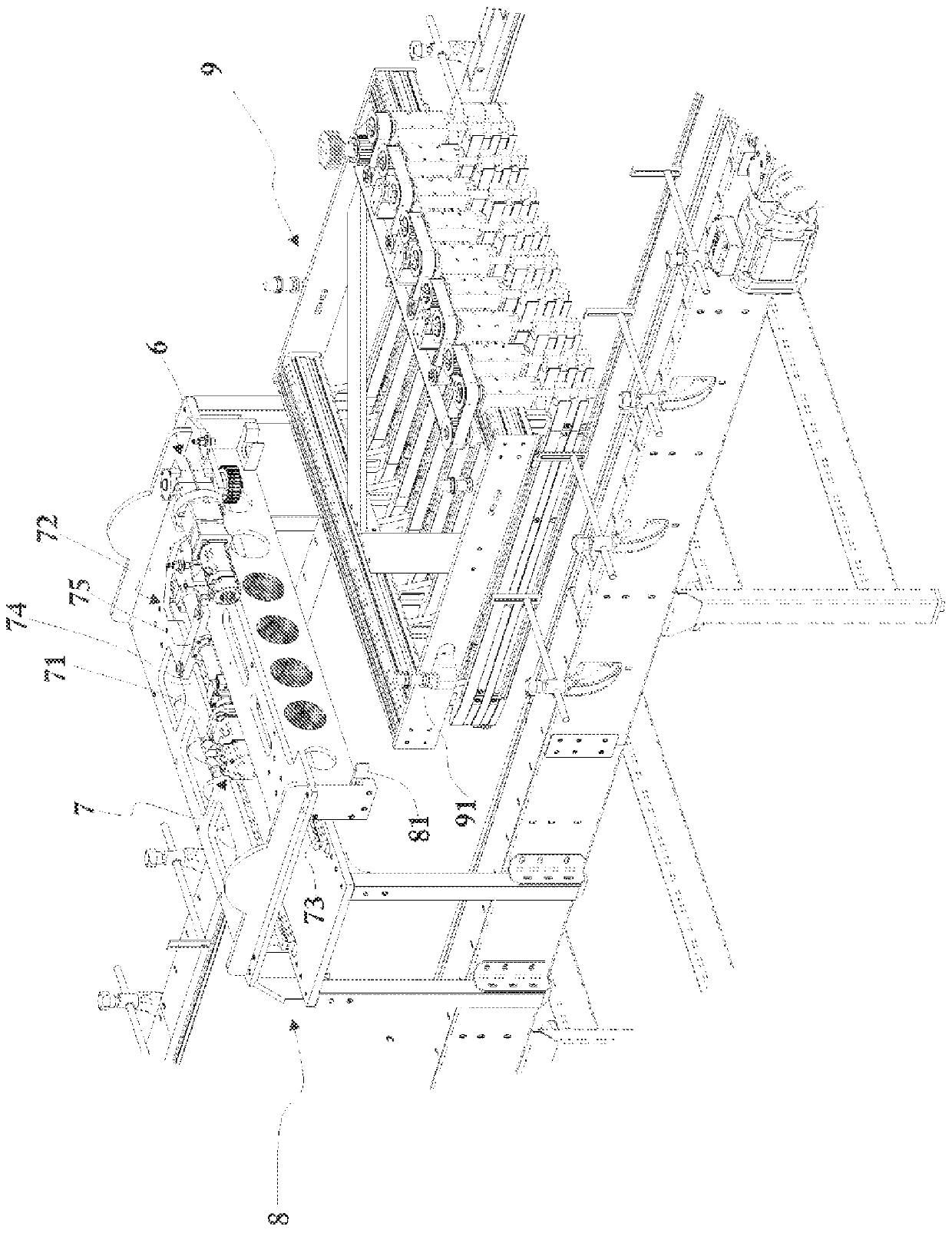

[0046] Specifically, refer to the attached figure 1 , shows an arrangement device 100 according to the present invention, which is used to arrange containers 300 into a quincunx-shaped layer 200 .

[0047] The containers 300 from the feed line are accumulated on the conveyor belt 1 on which they proceed according to the direction X.

[0048] The arranging device 100 includes a fixing structure 8 arranged above the conveyor belt 1 .

[0049] In a preferred embodiment, as figure 1 As shown, the fixed structure 8 is mechanically connected to the structure of the conveyor belt 1 .

[0050] In a second embodiment not shown in the figure, the fixing structure 8 can also be directly fixed on the ground instead of the conveyor belt 1 .

[0051] The conveyor belt 1 is preferably provided with transverse accommodation guides at the entrance and exit of the arrangement device 100 .

[0052] The arrangement device 100 also includes an equipment part 9 on which a plurality of partitions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com