Preparation method of Fe and N co-doped hierarchical porous carbon material with ultrahigh specific surface area

A technology with ultra-high specific surface area and hierarchical porosity, applied in the preparation/purification of carbon, etc., can solve the problems of complex process and low yield, achieve the effect of increasing specific surface area, reducing cost, and avoiding cumbersome procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

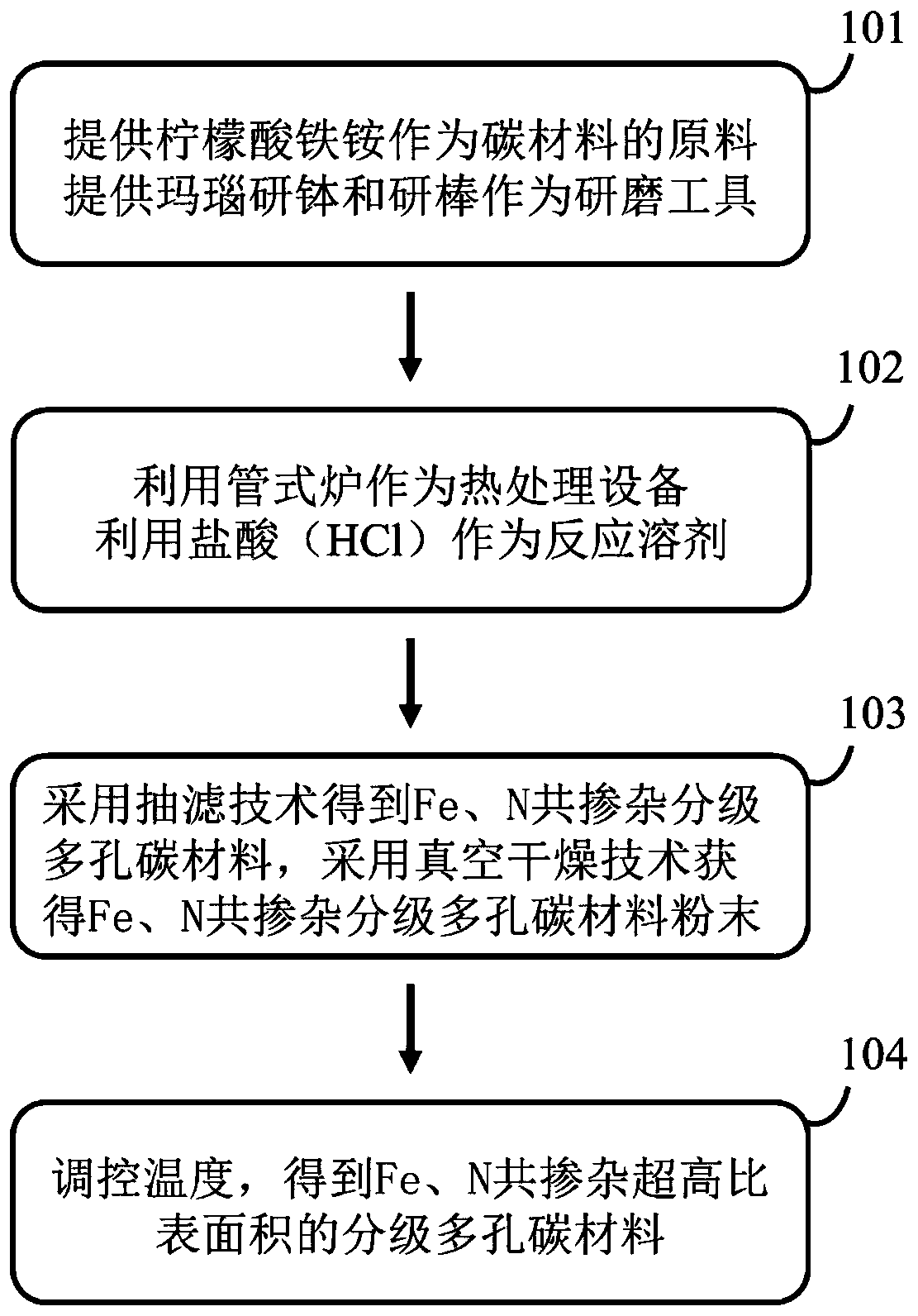

[0025] A preparation method of Fe, N element co-doped ultra-high specific surface area graded porous carbon material, such as figure 1 As shown, it specifically includes the following processes:

[0026] Step 101: using ferric ammonium citrate as the raw material of the carbon material, and using an agate mortar and pestle as grinding tools.

[0027] Specifically, the purity of ferric ammonium citrate is analytical grade (AR).

[0028] Specifically, the ferric ammonium citrate is fully ground and pulverized with an agate mortar and pestle, so that it is uniformly dispersed, and then heated evenly in the subsequent heat treatment process.

[0029] Step 102: using a tube furnace as an annealing device, and using hydrochloric acid (HCl) as a reaction solvent.

[0030] Specifically, the ferric ammonium citrate powder is annealed, and the tube furnace used for annealing should be a high-temperature furnace, and the atmosphere for annealing should be an inert gas with a purity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com