A kind of equipment and method for preparing isocyanate by pressurized pyrolysis

An isocyanate and equipment technology, applied in the field of isocyanate preparation, can solve the problems of difficulty in product concentration and separation, complex process routes, environmental pollution, etc., and achieve the effects of reducing the possibility of side reactions, cheap and easy-to-obtain solvents, and shortening reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

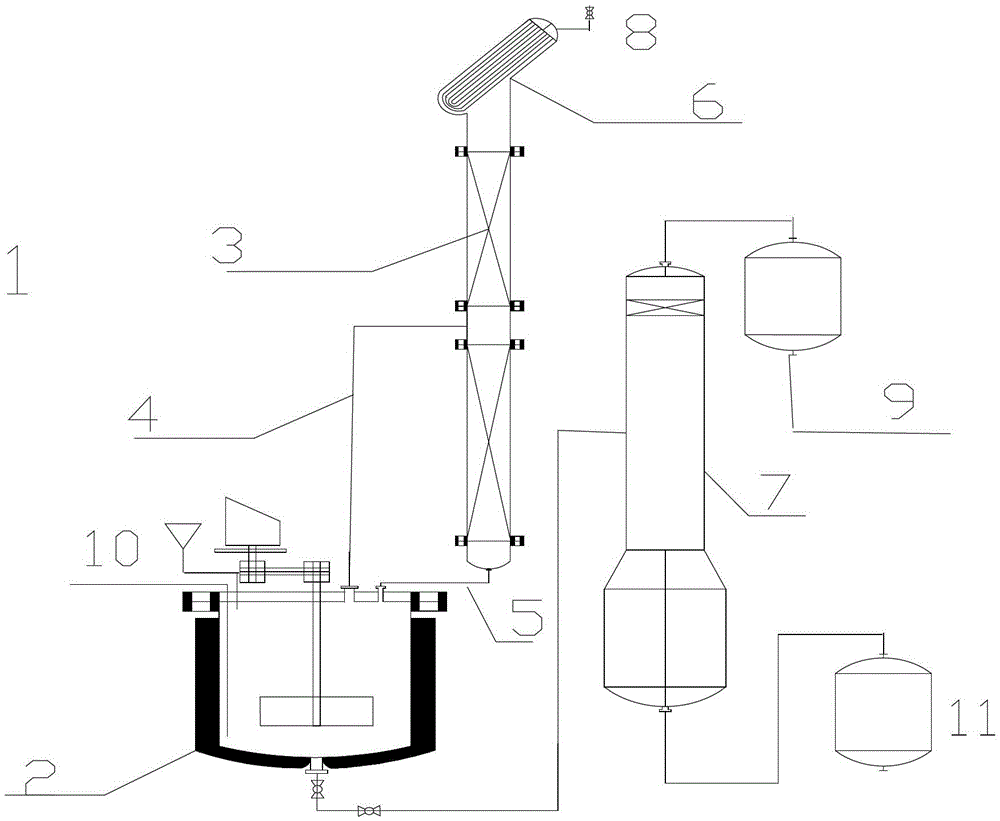

[0029] Weigh 160g of phenylcarbamate and 3L of chlorobenzene into the pyrolysis reactor, seal the reactor, replace the air with nitrogen for 3 times, heat up to 240°C and 1.5MPa, fill the rectification tower with structured packing, and The temperature is 160-220°C. During the reaction, argon gas is continuously fed into the reaction kettle 2 through the inert gas purge port 10, and the low-carbon alcohol gas generated by the reaction enters the precision reactor through the gas rising pipeline 4 along with the argon gas and the vaporized chlorobenzene solvent. In the distillation column 3, the solvent and low-carbon alcohol are separated in the rectification column 3, chlorobenzene is refluxed from the liquid return port 5 of the tower body to the reaction kettle 2, and the argon and low-carbon alcohol are discharged through the condenser 6 and the gas discharge port 8 . The reaction is kept for 1 hour. After the reaction, the product is separated by the falling film evaporat...

Embodiment 2

[0032] Weigh 3000g of phenylcarbamate and add 0.5L of nitrobenzene into the pyrolysis reactor, seal the reactor, replace the air with nitrogen for 3 times, then heat up to 190°C and 0.4MPa, and the rectification tower is packed neatly Packing, the temperature of the tower is 110-170°C, during the reaction process, argon gas is continuously fed into the reaction kettle 2 through the inert gas purge port 10, and the low-carbon alcohol gas generated by the reaction passes through the gas riser along with the argon gas and the vaporized nitrobenzene solvent Road 4 enters the rectifying column 3, and the solvent and lower-carbon alcohol are separated in the rectifying column 3, and nitrobenzene flows back into the reaction kettle 2 from the tower body liquid return port 5, and argon and lower-carbon alcohol pass through the condenser 6 and The gas discharge port 8 is discharged. The reaction is maintained for 8 hours. After the reaction is completed, the product is separated by the...

Embodiment 3

[0035] Weigh 500g of diphenylmethane dicarbamate and 3L of o-dichlorobenzene into the pyrolysis reactor, seal the reactor, replace the air with nitrogen for 3 times, heat up to 250°C and 1.7MPa, Filled with structured packing, the temperature of the tower is 170-230°C, during the reaction process, nitrogen gas is continuously passed into the reactor 2 through the inert gas purge port 10, and the low-carbon alcohol gas generated by the reaction rises with the nitrogen gas and the vaporized o-dichlorobenzene solvent through the gas The pipeline 4 enters the rectification column 3, and the solvent and low-carbon alcohol are separated in the rectification column 3, and o-dichlorobenzene flows back into the reactor 2 from the liquid return port 5 of the tower body, and nitrogen and low-carbon alcohol pass through the condenser 6 And the gas outlet 8 is discharged. The reaction is maintained for 3 hours. After the reaction is completed, the product is separated by the falling film e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com