Pre-oxidized fiber/carbon fiber structure preform and preparation method thereof

A technology of carbon fiber and pre-oxygenated yarn, which is applied in the direction of textiles and papermaking, layered products, non-woven fabrics, etc. It can solve the problems of poor performance uniformity and long fiber retention rate of chopped carbon fiber mesh tires, dust pollution in the processing environment, and difficulty in carding technology Advanced problems, to reduce the possibility of brittle fracture damage, reduce dust pollution, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

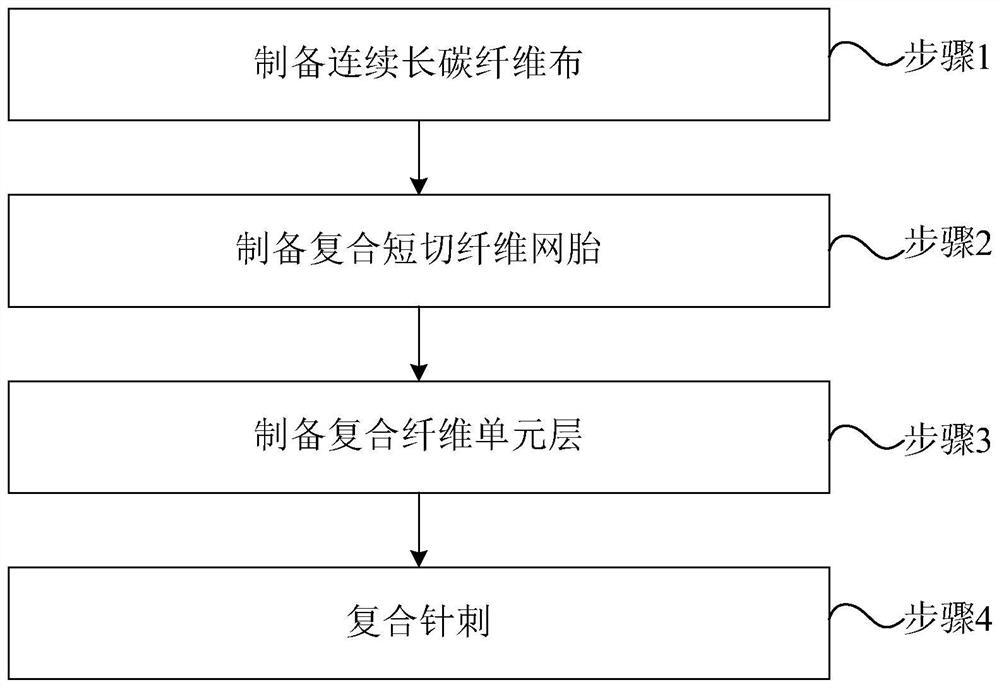

[0065] The second part: the embodiment of the present invention also provides a preparation method of a pre-oxygenated filament / carbon fiber structure preform, and the preparation method is used for preparing the pre-oxygenated filament / carbon fiber structure preform provided in the above-mentioned first part. figure 1 The flow chart of the preparation method of the pre-oxygen filament / carbon fiber structure preform provided by the embodiment of the present invention, such as figure 1 As shown, the preparation method of the pre-oxygen filament / carbon fiber structure preform provided in the embodiment of the present invention may include the following steps:

[0066] Step 1, prepare continuous long carbon fiber cloth.

[0067] Continuous long carbon fiber cloth includes structure types such as long carbon fiber non-weft cloth, long carbon fiber plain cloth and long carbon fiber satin cloth. In this step 1, the continuous long carbon fibers in the prepared continuous long carbo...

Embodiment 1

[0093] This embodiment specifically provides a preparation process of a pre-oxygenated filament / carbon fiber flat plate preform containing a structure of ordinary long carbon fiber non-woven fabric-interlayer composite chopped fiber mesh tire layer (hereinafter referred to as: composite fiber unit layer A) structure.

[0094] In this embodiment, the pre-oxygen filament / carbon fiber structure preform contains ordinary long carbon fiber non-woven fabric and interlayer composite chopped fiber mesh, wherein the ordinary long carbon fiber non-woven fabric adopts 3K long carbon fiber. The mesh made of chopped carbon fibers and the mesh made of chopped pre-oxidized silk fibers are superimposed and needle punched to form an interlayer composite chopped fiber mesh.

[0095] The specific process of this embodiment includes the following steps:

[0096] Step 1, prepare ordinary long carbon fiber weft-free cloth.

[0097] 3K ordinary continuous long carbon fibers are used to prepare ordi...

Embodiment 2

[0105] This embodiment specifically provides a preparation process of a pre-oxygenated filament / carbon fiber cylindrical preform having a structure of ordinary long carbon fiber plain weave-interlayer composite chopped fiber mesh unit layer (hereinafter referred to as: composite fiber unit layer B) structure.

[0106] In this embodiment, the pre-oxygen wire / carbon fiber cylinder preform contains ordinary long carbon fiber plain weave and interlayer composite chopped fiber mesh, wherein the ordinary long carbon fiber plain weave adopts 6K long carbon fiber. The mesh made of chopped carbon fibers and the mesh made of chopped pre-oxidized silk fibers are superimposed and needle punched to form an interlayer composite chopped fiber mesh.

[0107] The specific process of this embodiment includes the following steps:

[0108] Step 1, prepare ordinary long carbon fiber plain weave.

[0109] 6K ordinary continuous long carbon fiber is used to prepare ordinary long carbon fiber plain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com