Corrosion inhibitor container ii

A technology of anti-corrosion agent and container, applied in the direction of machine/engine, transmission parts, transportation and packaging, etc., can solve the problems of not providing screw plugs, delay in putting into operation of the transmission mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

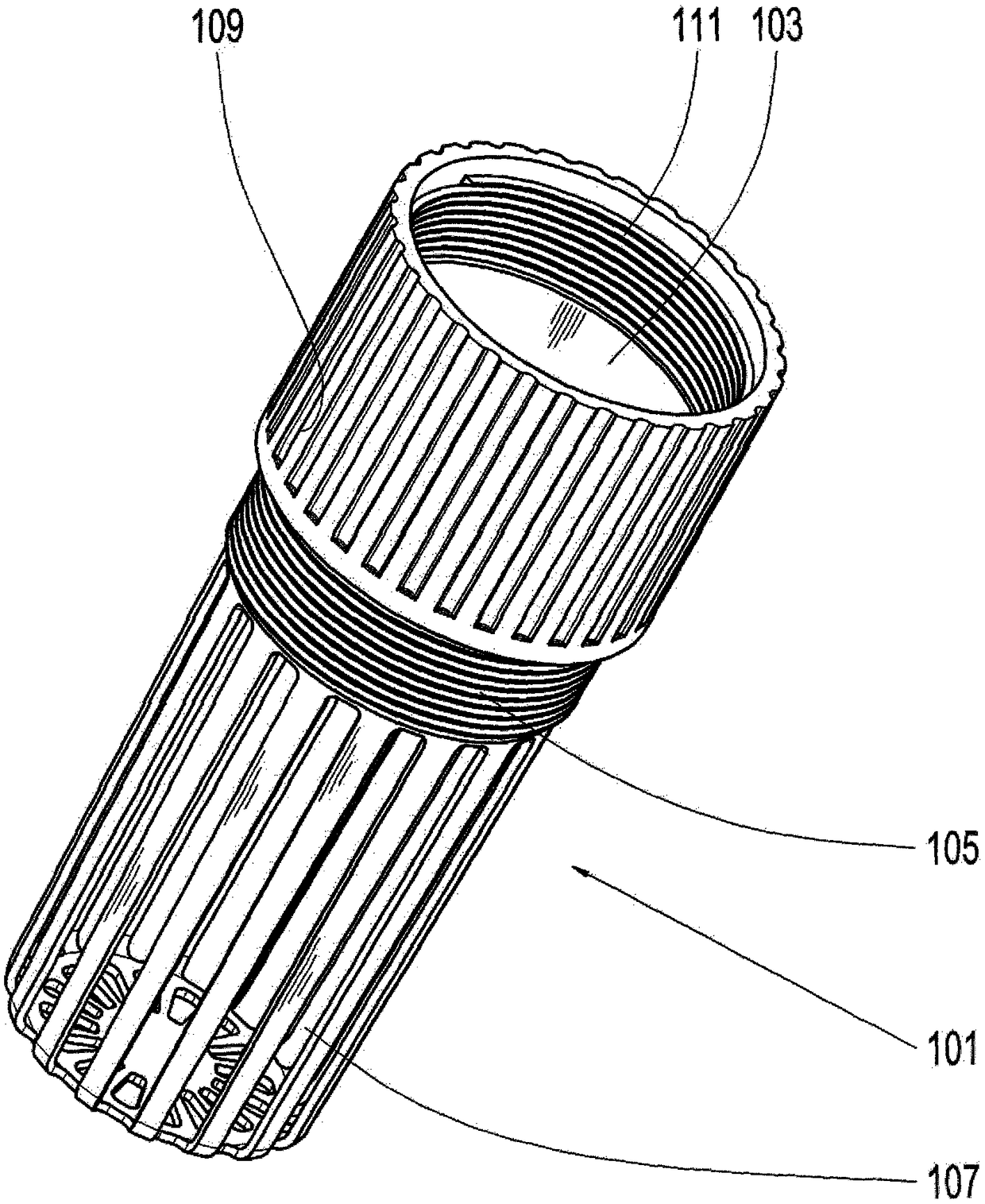

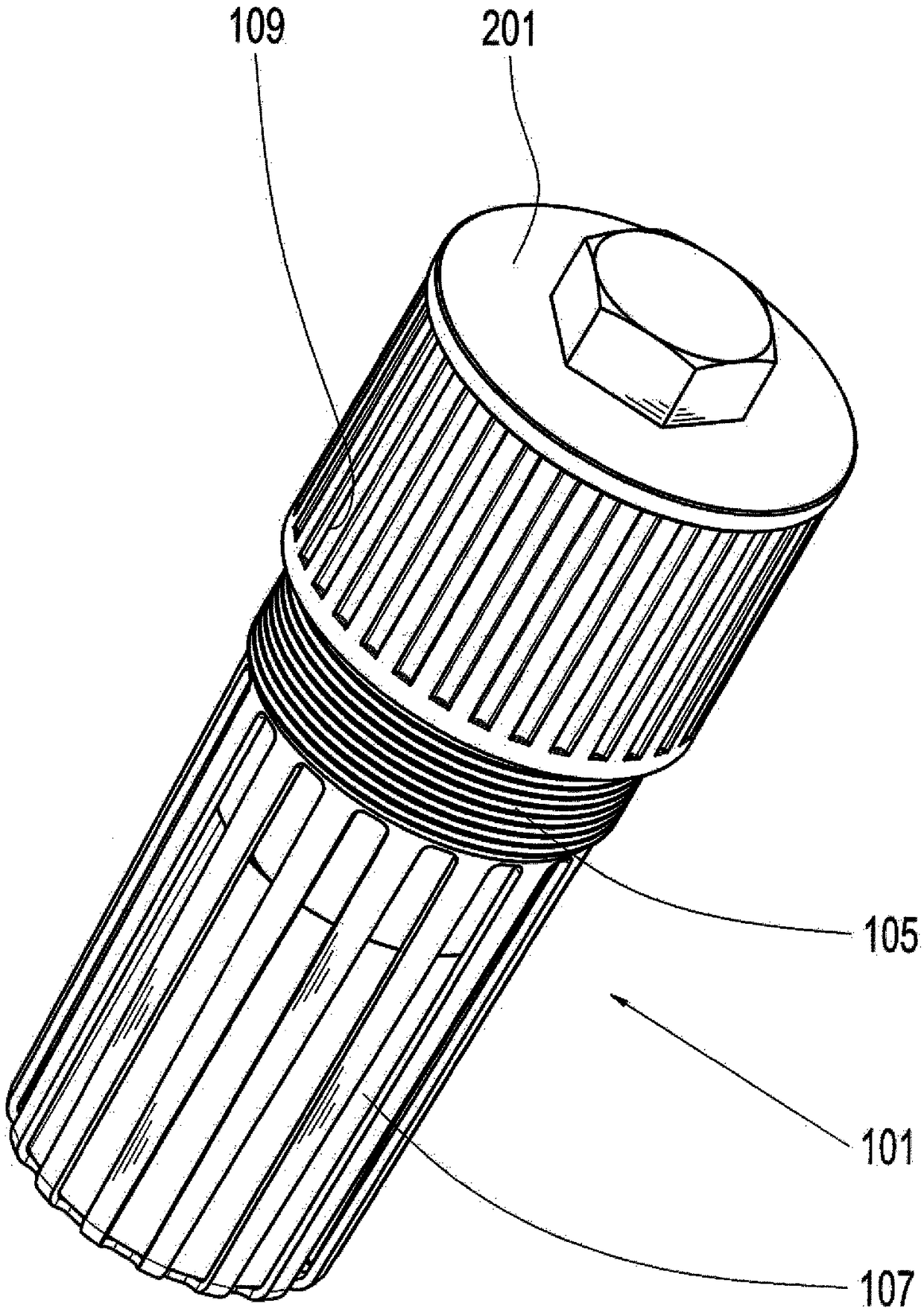

[0031] according to figure 1 The anticorrosion agent container 101 has openings 103 through which anticorrosion agent can be introduced into the container 101 .

[0032] The corrosion inhibitor container 101 can be screwed into a corresponding internal thread of the transmission housing by means of the external thread 105 . The lower region of the anti-corrosion agent container 101 is then located inside the transmission housing. In this area, the anticorrosion agent container 101 has an opening 107 through which anticorrosion agent can be discharged into the interior of the transmission.

[0033] In its upper region, the anticorrosion agent container 101 is equipped with grooves 109 . This groove 109 facilitates screwing the anti-corrosion agent container 101 into the transmission housing.

[0034] The corrosion inhibitor container 101 also has an internal thread 111 in its upper region. When the anti-corrosion agent container is screwed into the gear housing, the interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com