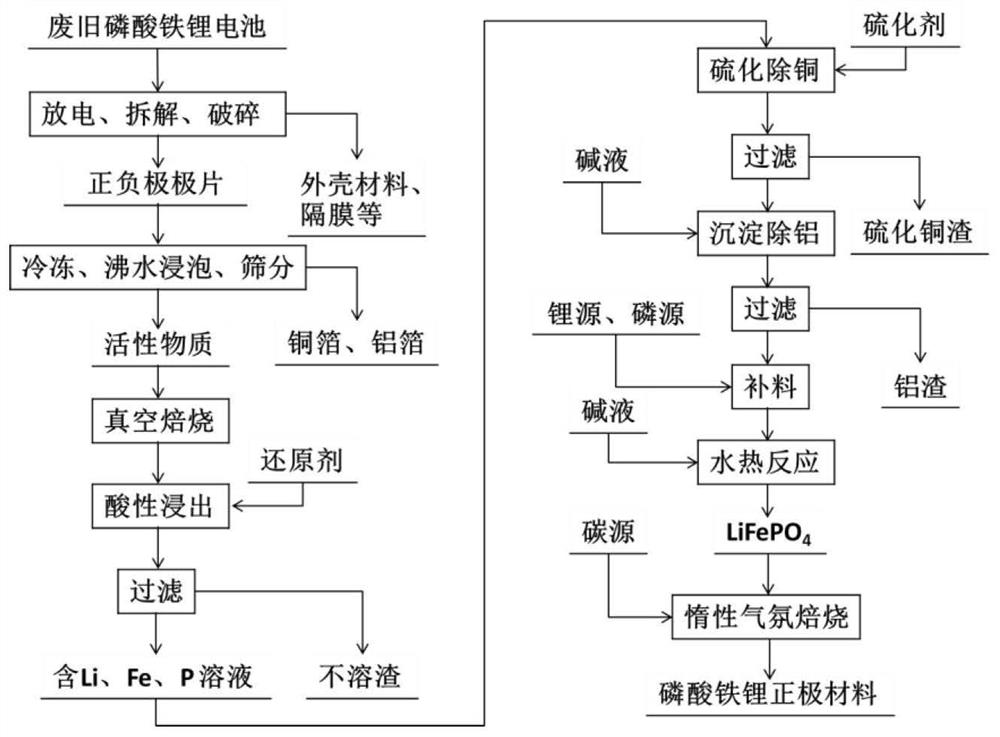

Method for preparing lithium iron phosphate cathode material by recycling waste lithium iron phosphate battery

A technology of lithium iron phosphate battery and lithium iron phosphate, which is applied in battery recycling, secondary battery, recycling technology, etc., can solve the problems of cumbersome and complicated process, high process cost, poor phase uniformity, etc., and achieve simplified process flow, Good separation effect and good material consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Soak the used lithium iron phosphate battery in 15g / L NaCl solution and discharge for 10h. Manually disassemble and separate the positive and negative pole pieces and diaphragm. After the pole piece is crushed, it is frozen at -10°C for 60 minutes, soaked in boiling water for 30 minutes, and vibrating and sieved to separate the active material, copper foil, and aluminum foil, and the active material is vacuum roasted at 600°C for 4 hours. The roasted active material is leached with 4mol / L sulfuric acid, the ratio of the molar amount of iron powder added to the molar amount of iron in the raw material is 1:40, the leaching time is 0.5h, the liquid-solid ratio is 3:1, and the leaching temperature is 30°C. After the leaching is completed, the leachate is obtained by solid-liquid separation. Add NaOH to the leaching solution to adjust the pH to 1.0, add NaOH 2 S precipitates impurity copper, filters the copper slag after fully reacting, then adds an appropriate amount of ...

Embodiment 2

[0030] Soak the used lithium iron phosphate battery in 15g / L NaCl solution and discharge for 10h. Manually disassemble and separate the positive and negative pole pieces and separators. After the pole pieces are broken, they are frozen at -20°C for 30 minutes, soaked in boiling water for 20 minutes, and vibrated and sieved to separate the active material, copper foil, and aluminum foil. Vacuum roasting for 1h. The roasted active material is leached with 4mol / L hydrochloric acid, the ratio of the molar amount of ascorbic acid added to the molar amount of iron in the raw material is 1:20, the leaching time is 2h, the liquid-solid ratio is 6:1, the leaching temperature is 20°C, and the leaching is over Afterwards, the leachate was obtained by solid-liquid separation. Add ammonia water to the leaching solution to adjust the pH to 0.5, add (NH 4 ) 2 S precipitates impurity copper, filters the copper slag after fully reacting, then adds an appropriate amount of ammonia solution d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com