Method for improving recovery rate of valuable metals

A technology of valuable metals and recovery rate, which is applied in the direction of improvement of process efficiency, solid separation, flotation, etc., and can solve the problems of difficult separation of fine particles, reduction of production energy consumption, reduction of lead recovery rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

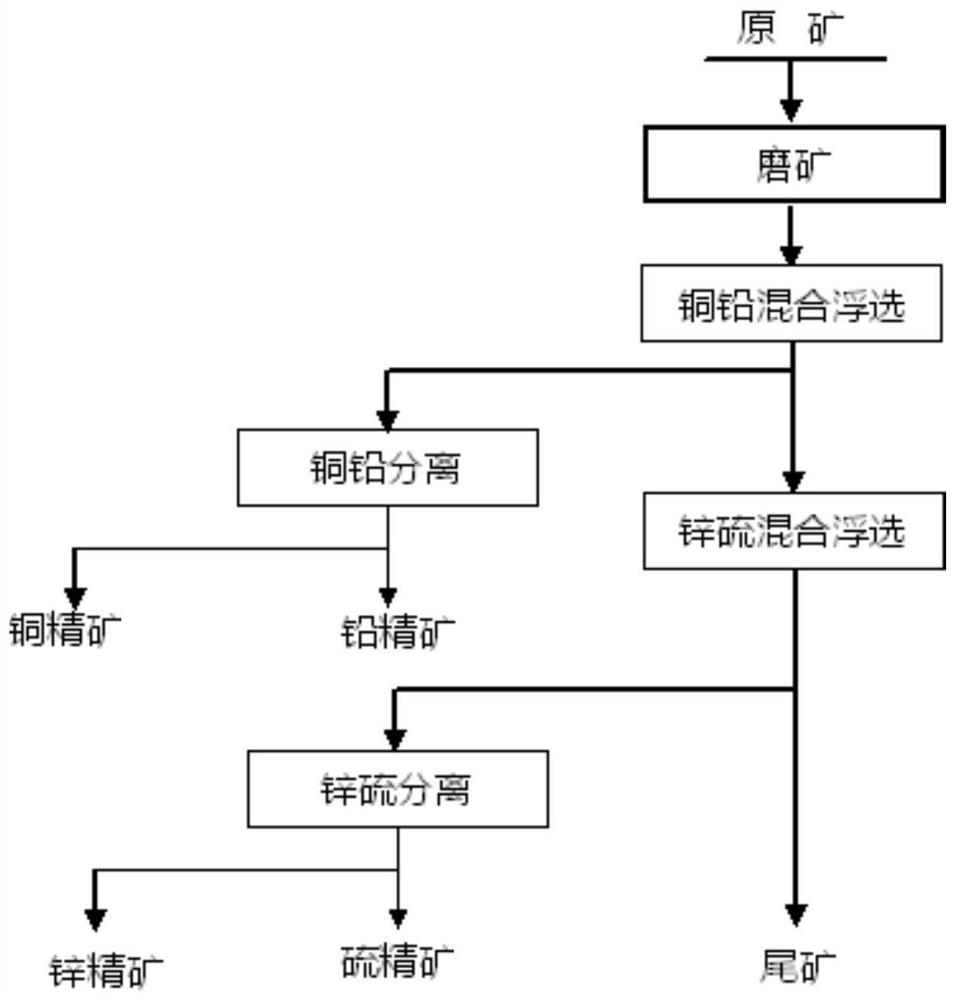

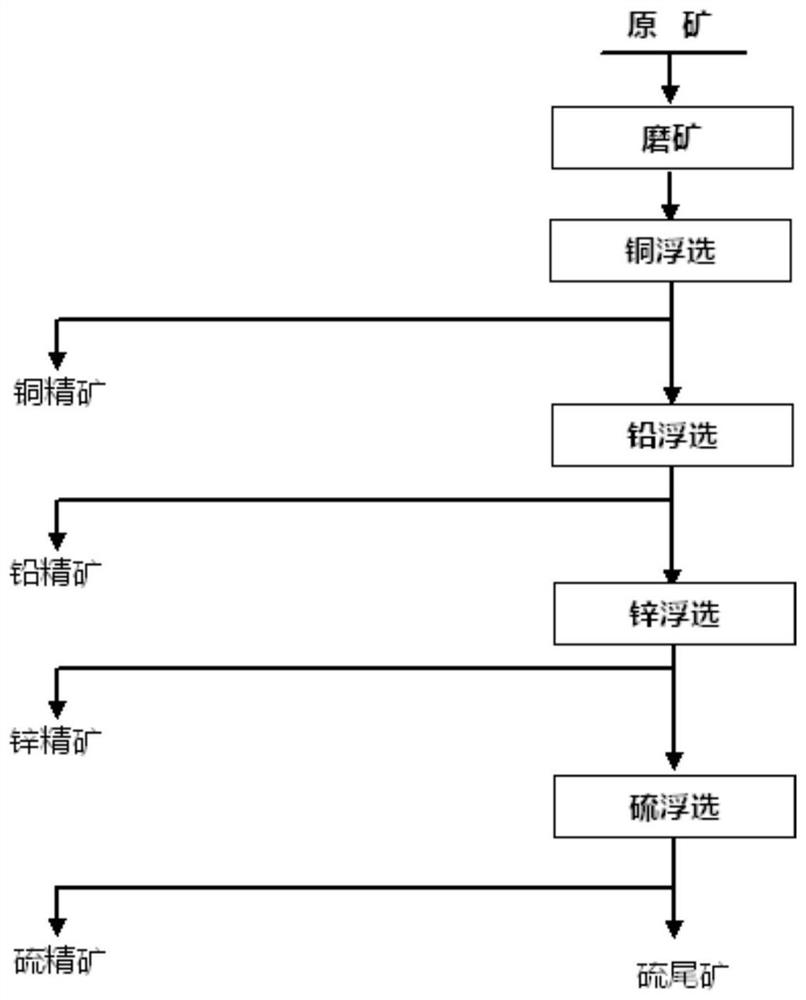

[0062] (1) if Image 6 As shown, the method for improving the recovery rate of valuable metals proposed by the present invention may include: when the copper-zinc sulfide ore containing fine-grained copper minerals or the copper-lead-zinc sulfide ore containing fine-grained copper minerals are used as raw ore for ore dressing , copper mineral recovery is carried out in the following two steps:

[0063] ① Step 1: Use copper-zinc sulfide ore or copper-lead-zinc sulfide ore as the raw ore for moderate grinding (the moderate grinding refers to controlling the grinding fineness of the raw ore so that the monomer dissociation degree of the recyclable minerals in the raw ore reaches best degree of dissociation) to obtain the raw ore pulp; then use a highly selective collector (the collector with strong selectivity can adopt the BK301 collector in the prior art, or other collectors in the prior art can be used Selective collector) carry out copper flotation or copper-lead flotation t...

Embodiment 1

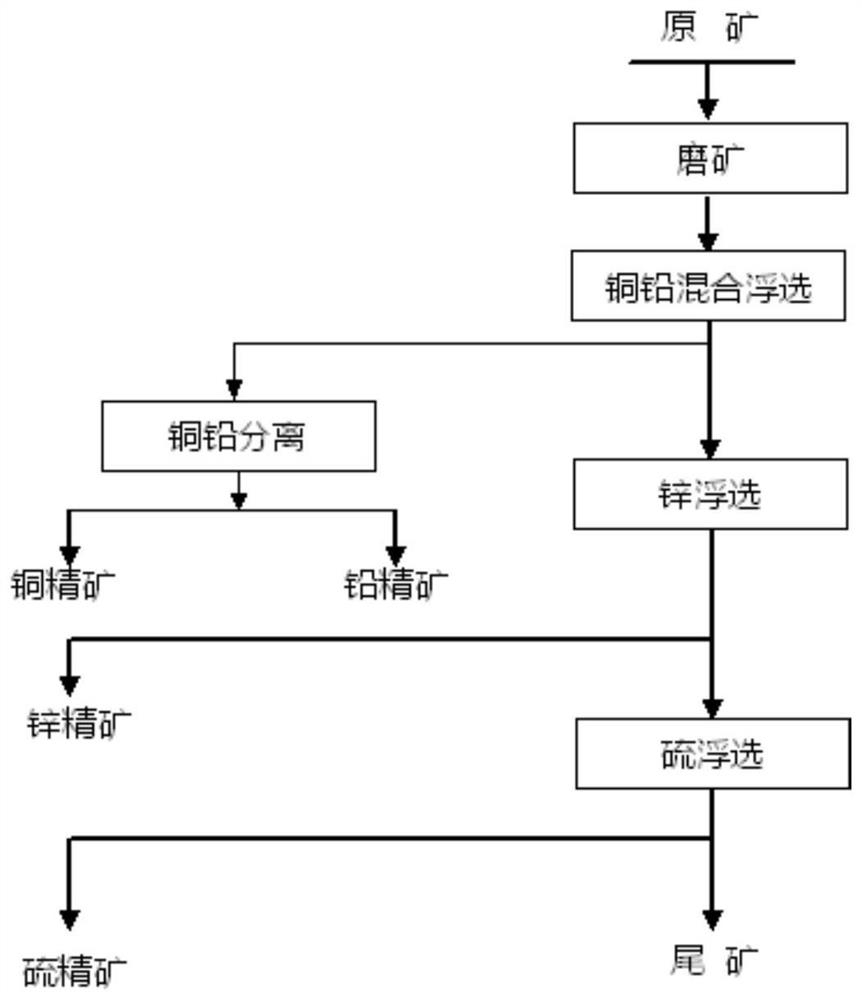

[0073] like Figure 8 As shown, a method to improve the recovery rate of valuable metals is used to treat a copper-lead-zinc sulfide ore containing fine-grained copper minerals. The treatment process is moderate grinding-copper-lead mixed flotation and copper-lead separation -zinc flotation-copper-sulfur mixed flotation-grinding-copper-sulfur separation flotation, it is for such as figure 1 The improvement of the existing process shown can specifically include: when the copper-lead-zinc sulfide ore containing fine-grained copper minerals is used as the raw ore for ore dressing, the copper minerals are recovered in the following two steps:

[0074] The first step: use the copper-lead-zinc sulfide ore containing fine copper minerals as the raw ore for grinding, and control the grinding fineness of the raw ore to -0.074mm, accounting for 80%, so that the monomers of the recyclable minerals in the raw ore are dissociated The degree of dissociation reaches the best degree, so as t...

Embodiment 2

[0078] like Figure 9 As shown, a method to improve the recovery rate of valuable metals is used to treat a copper-lead-zinc sulfide ore containing fine-grained copper minerals. The treatment process is moderate grinding-copper-lead mixed flotation and copper-lead separation - Zinc flotation - copper sulfur mixed flotation - roasting - leaching, it is for such as figure 1 The improvement of the existing process shown can specifically include: when the copper-lead-zinc sulfide ore containing fine-grained copper minerals is used as the raw ore for ore dressing, the copper minerals are recovered in the following two steps:

[0079] The first step: the same as the first step in Example 1.

[0080] Second step: adopt xanthate collector to carry out copper-sulfur mixed flotation to the zinc tailings (i.e. tailings containing fine-grained copper minerals) to obtain copper-sulfur concentrate and tailings; The concentrate is roasted to obtain calcined sand and flue gas (the flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com