A kind of lightweight high-strength silt ceramsite and preparation method thereof

A silt ceramsite, high-strength technology, applied in the field of materials, can solve the problems of low density and high strength, increased gas generation, high density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

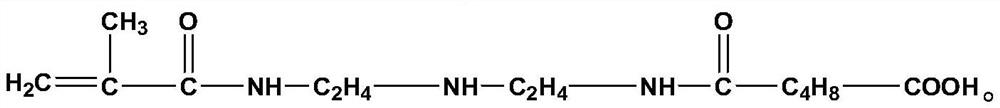

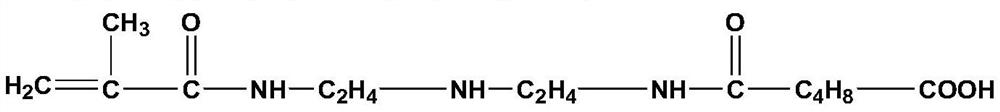

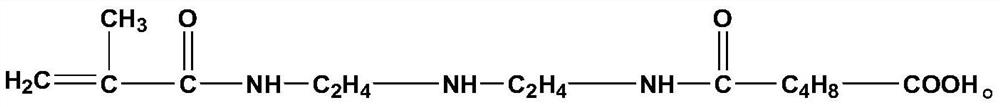

Method used

Image

Examples

Embodiment 1

[0054] The embodiment of the present invention provides a method for preparing lightweight high-strength silt ceramsite, comprising the following steps:

[0055] According to the mass ratio of each component: sludge: fly ash=50:32 select sludge and fly ash respectively, mix the two evenly, and obtain the raw material main material mixture;

[0056] Sludge is dried, dehydrated and crushed urban sewage plant sludge or sewage sludge, with a moisture content of 0.2% and a particle size of ≤0.8mm;

[0057] Fly ash is fine ash recovered from coal-fired power plants, and its particle size is ≤0.9mm;

[0058] According to the mass ratio of each component: water glass: ultrafine composite pore-forming agent: auxiliary dispersant = 3.8:9:0.9, respectively select water glass, ultrafine composite pore-forming agent and auxiliary dispersant, and mix the three evenly, Obtain the mixture of raw materials and auxiliary materials; place the mixture of raw materials and main materials in a rig...

Embodiment 2

[0078] The embodiment of the present invention provides a method for preparing lightweight high-strength silt ceramsite, comprising the following steps:

[0079] According to the mass ratio of each component: sludge: fly ash=42:53 select sludge and fly ash respectively, mix the two evenly, and obtain the raw material main material mixture;

[0080] Sludge is dried, dehydrated and crushed urban sewage plant sludge or sewage sludge, with a moisture content of 0.2% and a particle size of ≤0.8mm;

[0081] Fly ash is fine ash recovered from coal-fired power plants, and its particle size is ≤0.9mm;

[0082] According to the mass ratio of each component: water glass: ultrafine composite pore-forming agent: auxiliary dispersant = 5:7:0.5, respectively select water glass, ultrafine composite pore-forming agent and auxiliary dispersant, and mix the three evenly, Obtain the mixture of raw materials and auxiliary materials; place the mixture of raw materials and main materials in a rigid...

Embodiment 3

[0100] The embodiment of the present invention provides a method for preparing lightweight high-strength silt ceramsite, comprising the following steps:

[0101] According to the mass ratio of each component: sludge: fly ash=72:28 select sludge and fly ash respectively, mix the two evenly, and obtain the main raw material mixture;

[0102] Sludge is dried, dehydrated and crushed urban sewage plant sludge or sewage sludge, with a moisture content of 0.2% and a particle size of ≤0.8mm;

[0103] Fly ash is fine ash recovered from coal-fired power plants, and its particle size is ≤0.9mm;

[0104] According to the mass ratio of each component: water glass: superfine composite pore-forming agent: auxiliary dispersant = 1:15:2, respectively select water glass, ultrafine composite pore-forming agent and auxiliary dispersant, and mix the three evenly, Obtain the mixture of raw materials and auxiliary materials; place the mixture of raw materials and main materials in a rigid container...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com