Method of preparing pure titanium EBSD sample under room temperature

A pure titanium, room temperature technology, which is applied in the fields of instruments, analytical materials, and material analysis using wave/particle radiation, etc., can solve the problems of complex methods, high preparation costs, and high operating conditions, and achieve simple operation, low polishing voltage, Environmental conditions require less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

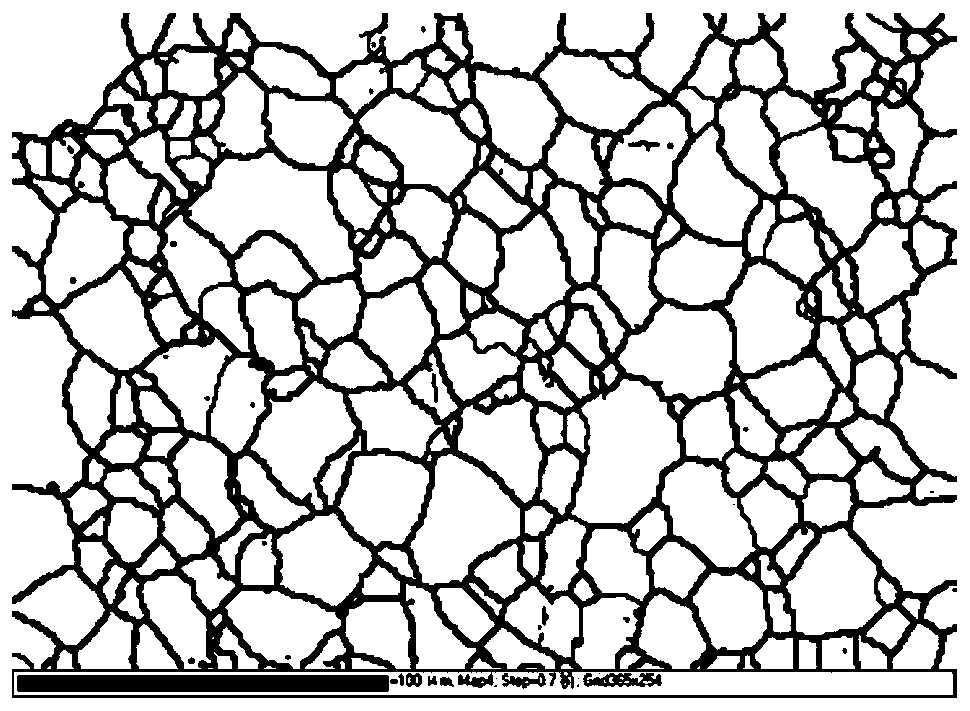

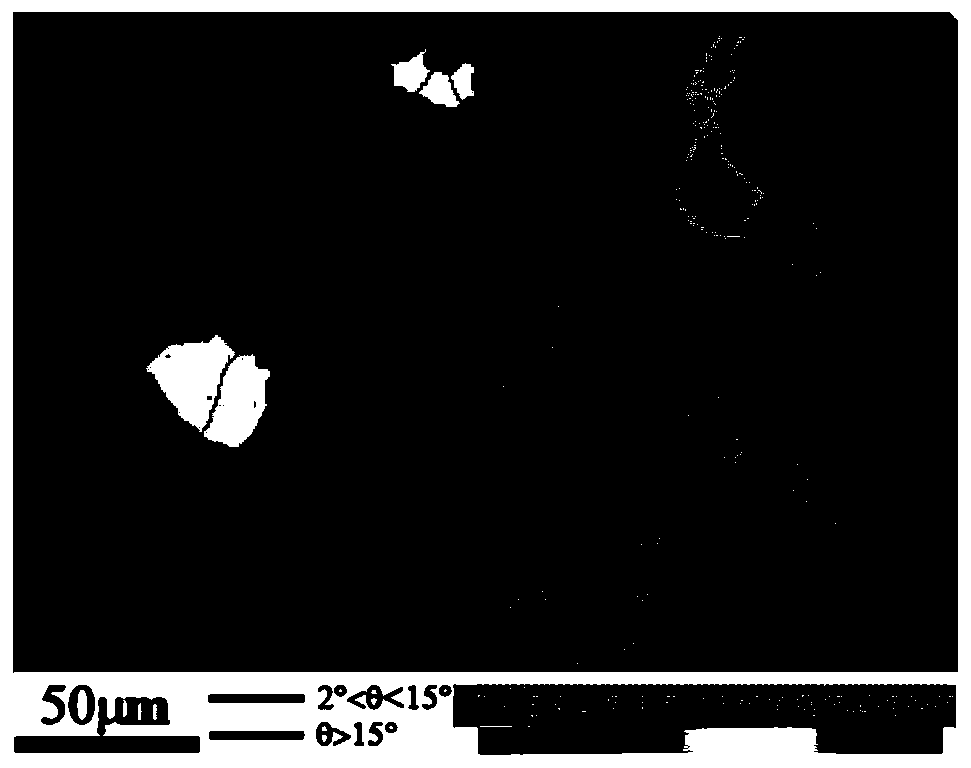

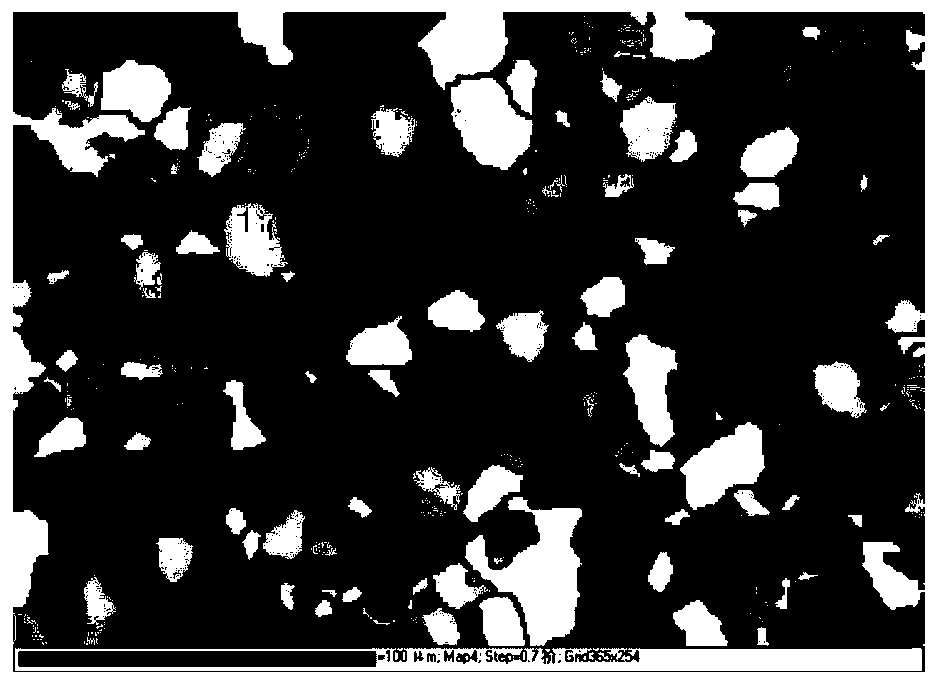

Image

Examples

Embodiment 1

[0026] A method for preparing pure titanium EBSD sample at room temperature, comprising the following steps:

[0027] a. Grinding the surface to be tested of the pure titanium sample: use 150#, 320#, 600# and 1000# SiC sandpaper to perform cross grinding on the surface to be tested of the pure titanium sample, and rinse with water continuously during the grinding process surface, in order to remove the abrasive sticking to the surface of the sample, each time when changing a piece of sandpaper, the sample should be rotated 90° before grinding, and all the grinding marks left by the previous piece of sandpaper should be removed, during the grinding process During the process, the sample should be uniformly stressed and the surface should be flat; after polishing, the surface of the sample should be rinsed with absolute ethanol, and the surface of the sample should be air-dried under the action of natural wind.

[0028] b. Perform electropolishing treatment on the surface to be ...

Embodiment 2

[0033] A method for preparing pure titanium EBSD sample at room temperature, comprising the following steps:

[0034] a. Grinding the surface to be tested of the pure titanium sample: use 150#, 320#, 600# and 1000# SiC sandpaper to perform cross grinding on the surface to be tested of the pure titanium sample, and rinse with water continuously during the grinding process surface, in order to remove the abrasive sticking to the surface of the sample, each time when changing a piece of sandpaper, the sample should be rotated 90° before grinding, and all the grinding marks left by the previous piece of sandpaper should be removed, during the grinding process During the process, it is necessary to keep the sample under uniform force and the surface is smooth; after grinding, rinse the surface of the sample with absolute ethanol, and let the surface of the sample be air-dried under the action of natural wind;

[0035] b. Perform electropolishing treatment on the surface to be teste...

Embodiment 3

[0039] A method for preparing pure titanium EBSD sample at room temperature, comprising the following steps:

[0040] a. Grinding the surface to be tested of the pure titanium sample: use 150#, 320#, 600# and 1000# SiC sandpaper to perform cross grinding on the surface to be tested of the pure titanium sample, and rinse with water continuously during the grinding process surface, in order to remove the abrasive sticking to the surface of the sample, each time when changing a piece of sandpaper, the sample should be rotated 90° before grinding, and all the grinding marks left by the previous piece of sandpaper should be removed, during the grinding process During the process, it is necessary to keep the sample under uniform force and the surface is smooth; after grinding, rinse the surface of the sample with absolute ethanol, and let the surface of the sample be air-dried under the action of natural wind;

[0041] b. Perform electropolishing treatment on the surface to be teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com