Stirring device and stirring system thereof

A mixing device and mixing tank technology, which is applied in the direction of cement mixing device, clay preparation device, liquid ingredient supply device, etc., can solve the problems of centrifugal pump impeller clogging and poor water supply, etc., and achieve high working efficiency, exquisite structure and easy maintenance. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

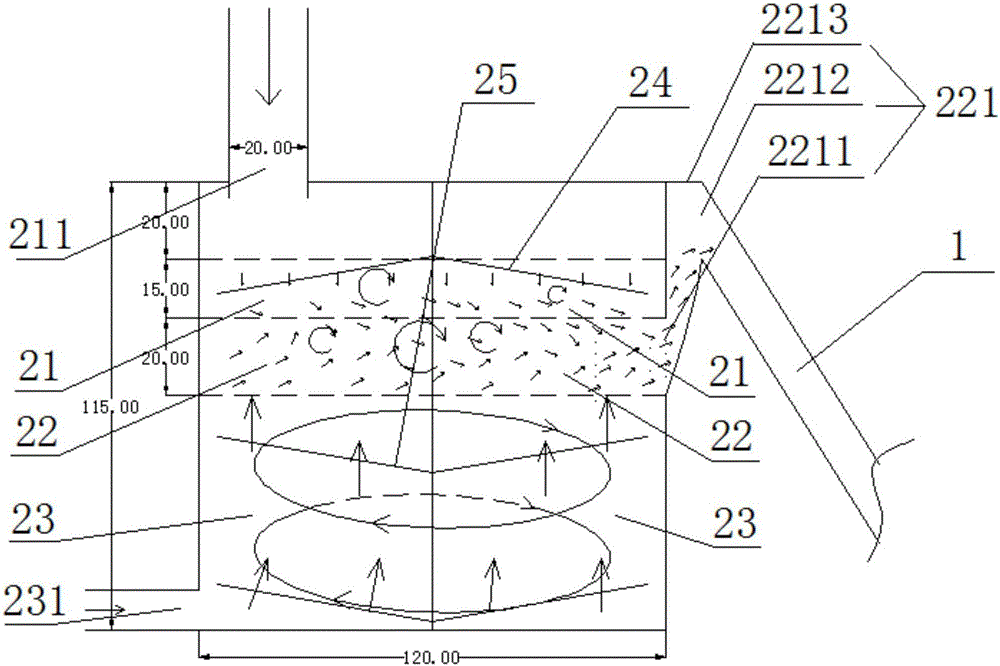

[0026] An automatic pulping system includes a primary stirring device and a secondary stirring device (not shown in the figure); the primary stirring device and the secondary stirring device are connected through a pipeline 1 .

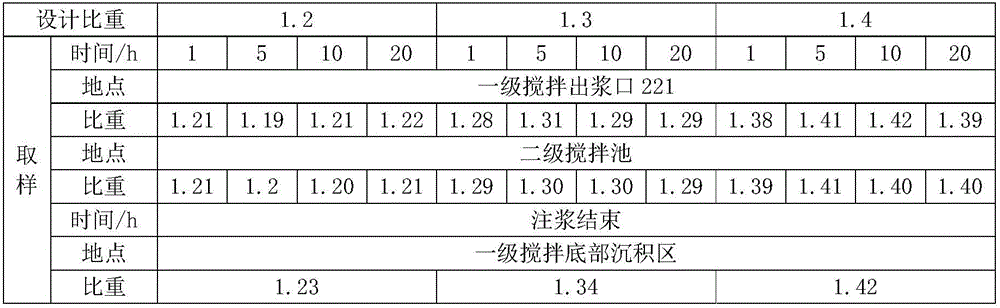

[0027] A first-stage mixing device, including a mixing bucket 2; the mixing bucket 2 is divided into a lower ash area 21, a convection mixing area 22, and an upper water area 23 from top to bottom in the height direction; the top of the lower ash area 21 has a lower ash port 211; The mixing zone 22 has a slurry outlet 221; the upper water zone 23 has a water inlet 231; in the mixing tank 2, there are multiple sets of stirring fins, and the rotating shafts of the multiple sets of stirring fins are coaxial. Amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com