High-mobility n-type nano diamond film of crystalline grain closely-packed structure and preparation method of high-mobility n-type nano diamond film

A nano-diamond, high-mobility technology, applied in the field of high-mobility n-type nano-diamond films and preparation, can solve problems such as hindering the electrical properties of the films, and achieve the effects of easy operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

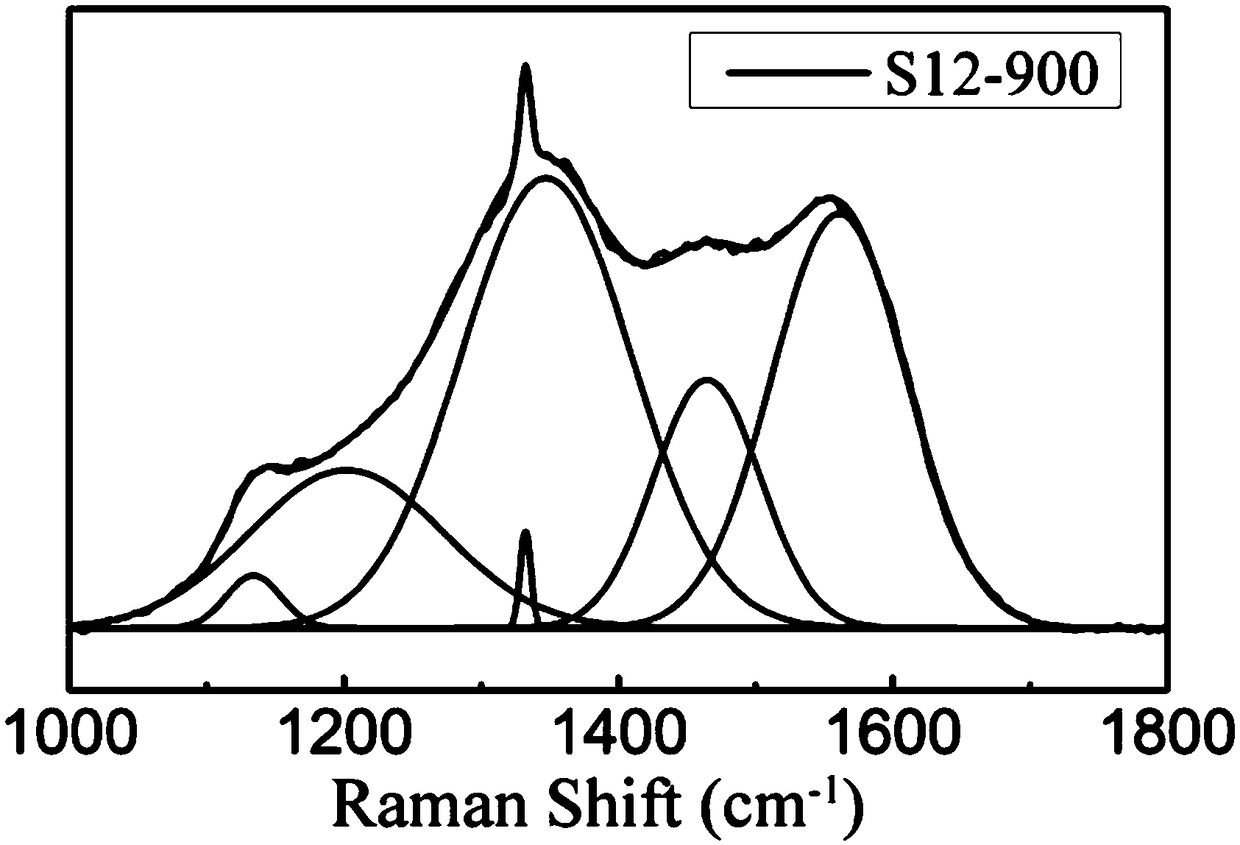

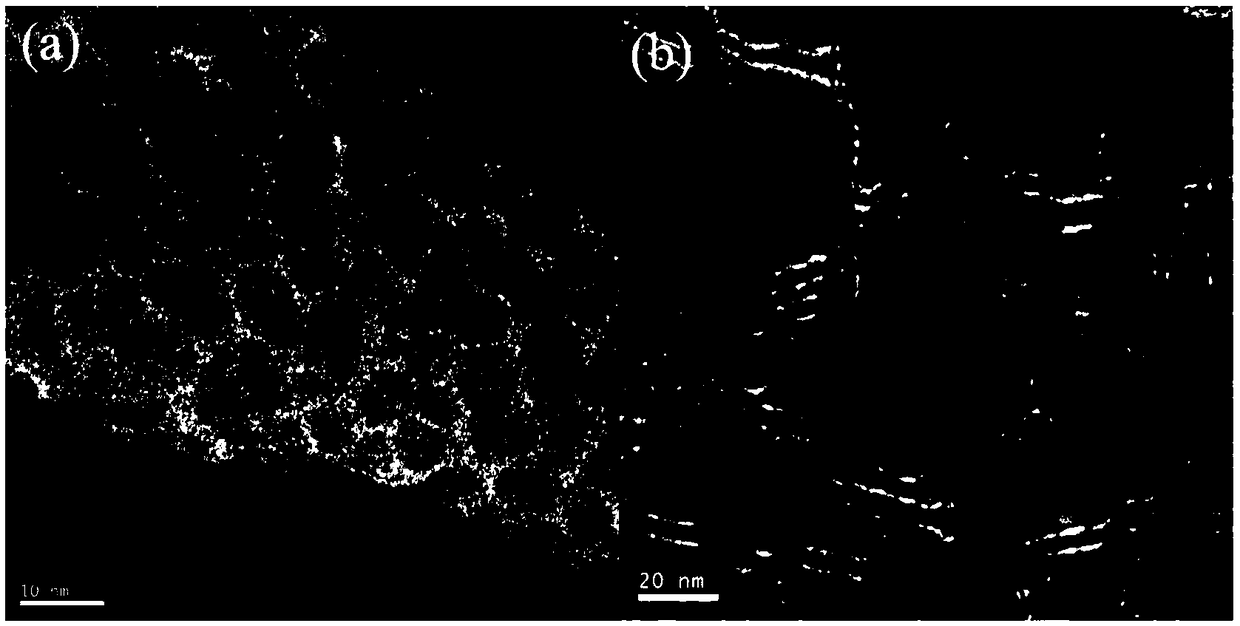

Embodiment 1

[0027]The monocrystalline silicon wafer was ultrasonically oscillated with a mixture of diamond micropowder (0.1 g) and acetone (50 ml), and the oscillating time was 30 min. The shaken silicon wafer was ultrasonically cleaned twice with acetone reagent, each time for 2 min, and the dried silicon wafer was used as the substrate for the growth of the nanocrystalline grain close-packed diamond film. Using hot wire chemical vapor deposition method (chemical vapor deposition equipment purchased from Shanghai Jiaoyou Diamond Coating Co., Ltd., equipment model: JUHFCVD001), using acetone at 0°C as the carbon source, and using hydrogen bubbling to bring acetone into the reaction chamber , the flow rate is 80sccm, the additional hydrogen flow rate is 200sccm, the temperature of the reaction chamber is controlled within the range of 500-600°C, the power of the hot wire is 2200W, the bias voltage is turned off during the growth process, the growth time of the nano-diamond film is 50 minut...

Embodiment 2

[0033] The monocrystalline silicon wafer was ultrasonically oscillated with a mixture of diamond micropowder (0.1 g) and acetone (50 ml), and the oscillating time was 30 min. The shaken silicon wafer was ultrasonically cleaned twice with a clean acetone reagent, each time for 2 min, and the dried silicon wafer was used as the substrate for the growth of the nanocrystal grain close-packed diamond film. Using hot wire chemical vapor deposition method (chemical vapor deposition equipment purchased from Shanghai Jiaoyou Diamond Coating Co., Ltd., equipment model: JUHFCVD001), using acetone at 0°C as the carbon source, and using hydrogen bubbling to bring acetone into the reaction chamber , the flow rate is 90 sccm, the additional flow rate of hydrogen gas is 200 sccm, the temperature of the reaction chamber is controlled in the range of 500-600 ° C, the power of the hot wire is 2400 W, the bias voltage is turned off during the growth process, and the growth time of the nano-diamond...

Embodiment 3

[0039] The monocrystalline silicon wafer was ultrasonically oscillated with a mixture of diamond micropowder (0.1 g) and acetone (50 ml), and the oscillating time was 30 min. The shaken silicon wafer was ultrasonically cleaned twice with acetone reagent, each time for 2 min, and the dried silicon wafer was used as the substrate for the growth of the nanocrystalline grain close-packed diamond film. Using hot wire chemical vapor deposition method (chemical vapor deposition equipment purchased from Shanghai Jiaoyou Diamond Coating Co., Ltd., equipment model: JUHFCVD001), using acetone at 0°C as the carbon source, and using hydrogen bubbling to bring acetone into the reaction chamber , the flow rate is 80sccm, the additional hydrogen flow rate is 200sccm, the temperature of the reaction chamber is controlled within the range of 500-600°C, the power of the hot wire is 2200W, the bias voltage is turned off during the growth process, the growth time of the nano-diamond film is 50 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com