A processing tool and processing method for a multi-cavity product

A multi-cavity, product technology, used in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of long positioning and alignment time, large repeated positioning error, adjacent tool interference, etc., and achieve a small positioning surface. , The effect of ensuring positioning accuracy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following describes the present invention in detail, and the features and advantages of the present invention will become more clear and definite along with these descriptions.

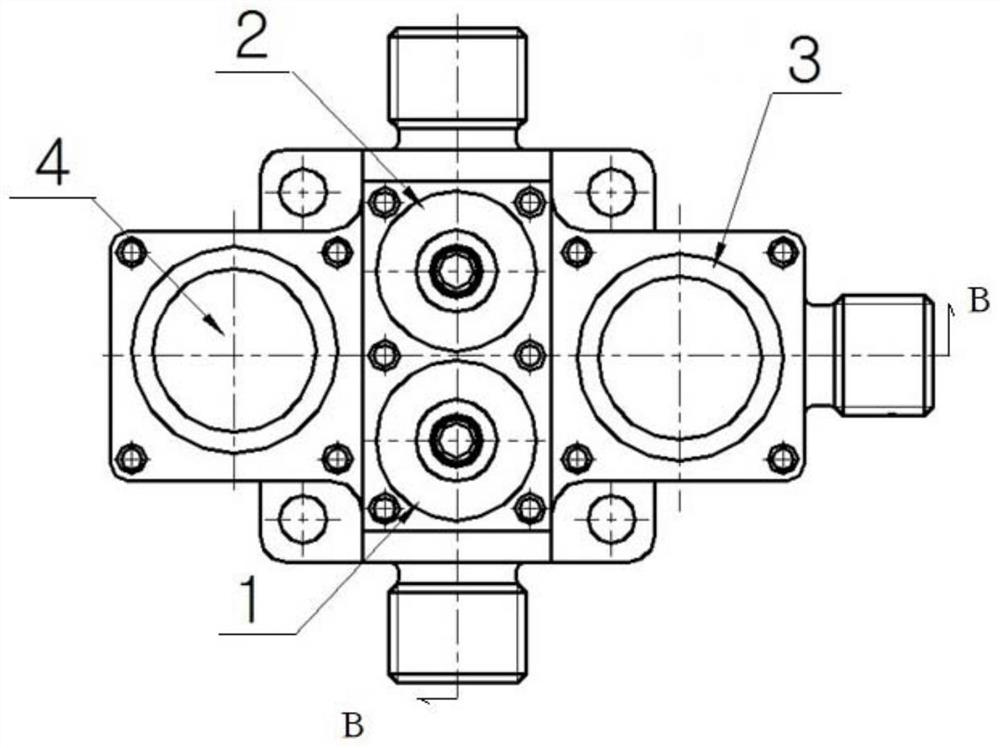

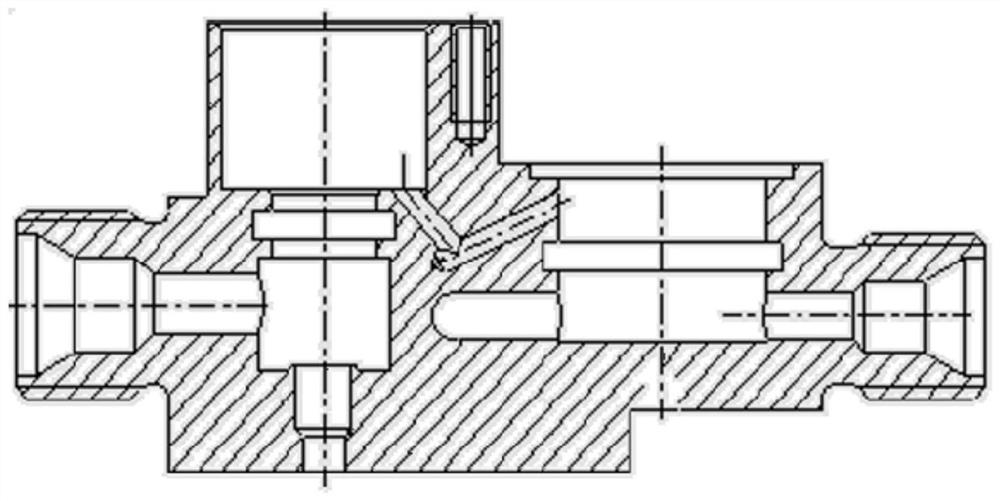

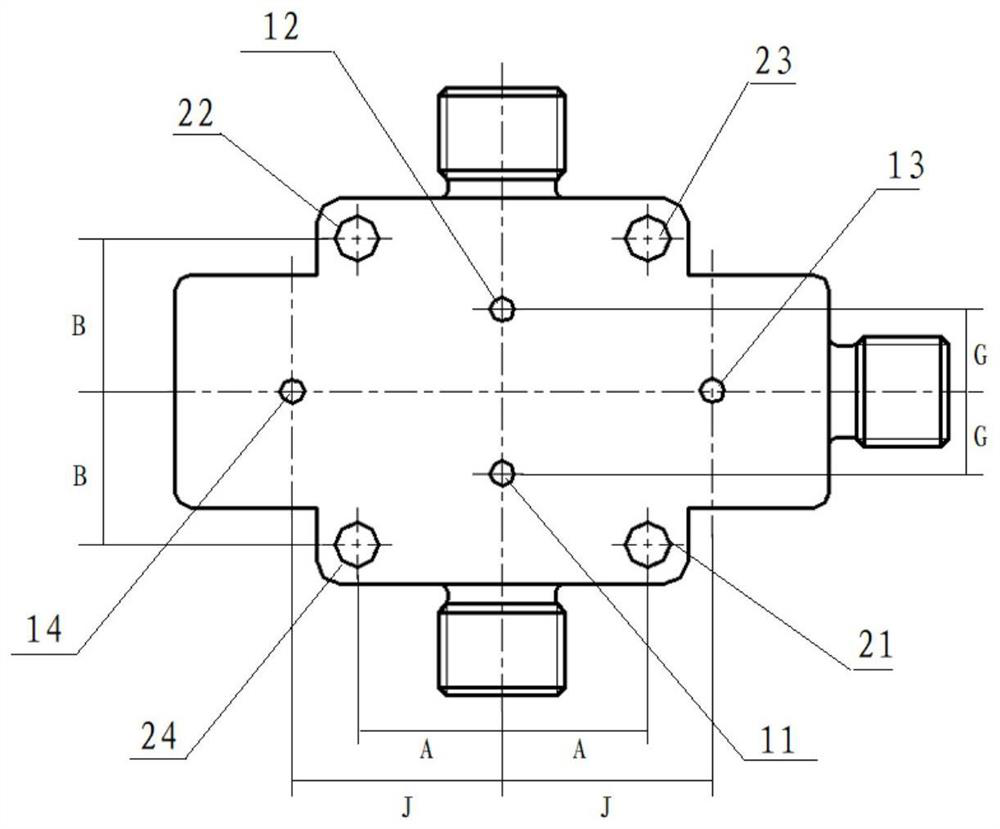

[0040] The inventor has analyzed the structural characteristics and traditional processing technology of the multi-cavity product-electric valve body, and found that: (i) four positioning holes (respectively defined as the first positioning hole 11 and the second positioning hole 11) on the bottom surface of the product The positioning hole 12, the third positioning hole 13, and the fourth positioning hole 14) respectively correspond to the center positions of the two main valve chambers and the two auxiliary valve chambers (the first positioning hole 11 corresponds to the first inner cavity 1, and the second positioning hole 12 Corresponding to the second inner cavity 2, the third positioning hole 13 corresponds to the third inner cavity 3, and the fourth positioning hole 14 corresponds to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com