Machining method of shallow inclined hole of cylinder block

A processing method and cylinder technology, which is applied to the processing of shallow oblique holes in cylinders and the field of hole processing, can solve the problems of large fluctuations in position and dimension accuracy, inconvenient tool management, and low processing efficiency, and achieve stable processing quality and reduce Machining time, auxiliary tool change time, and machining efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

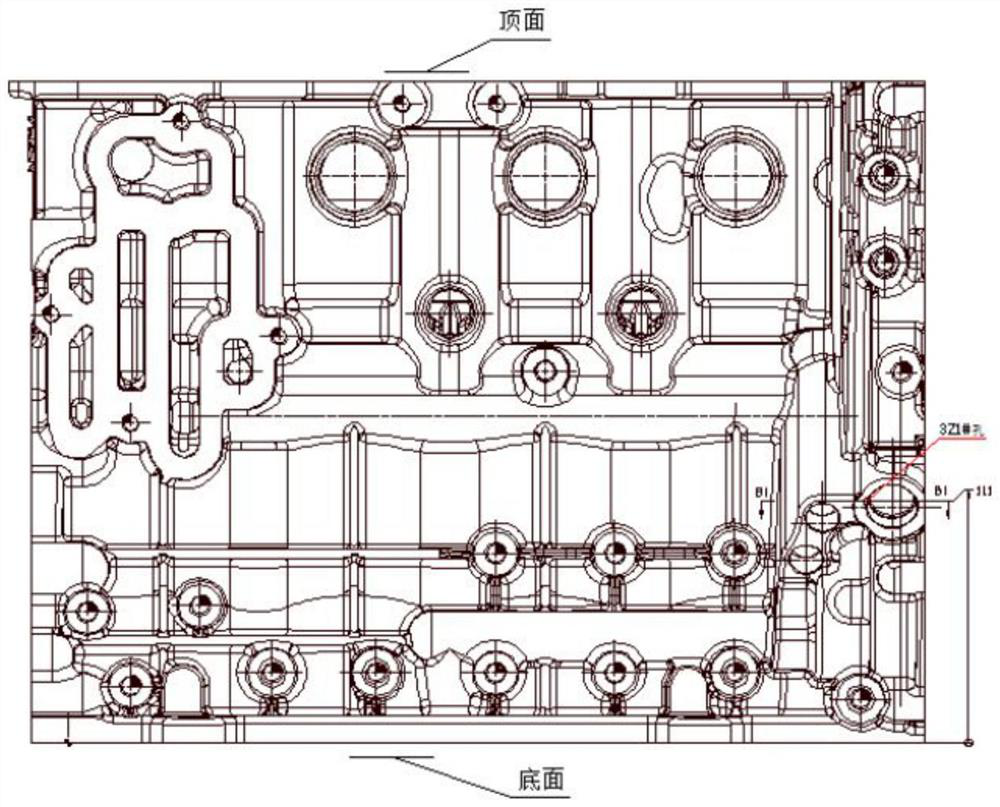

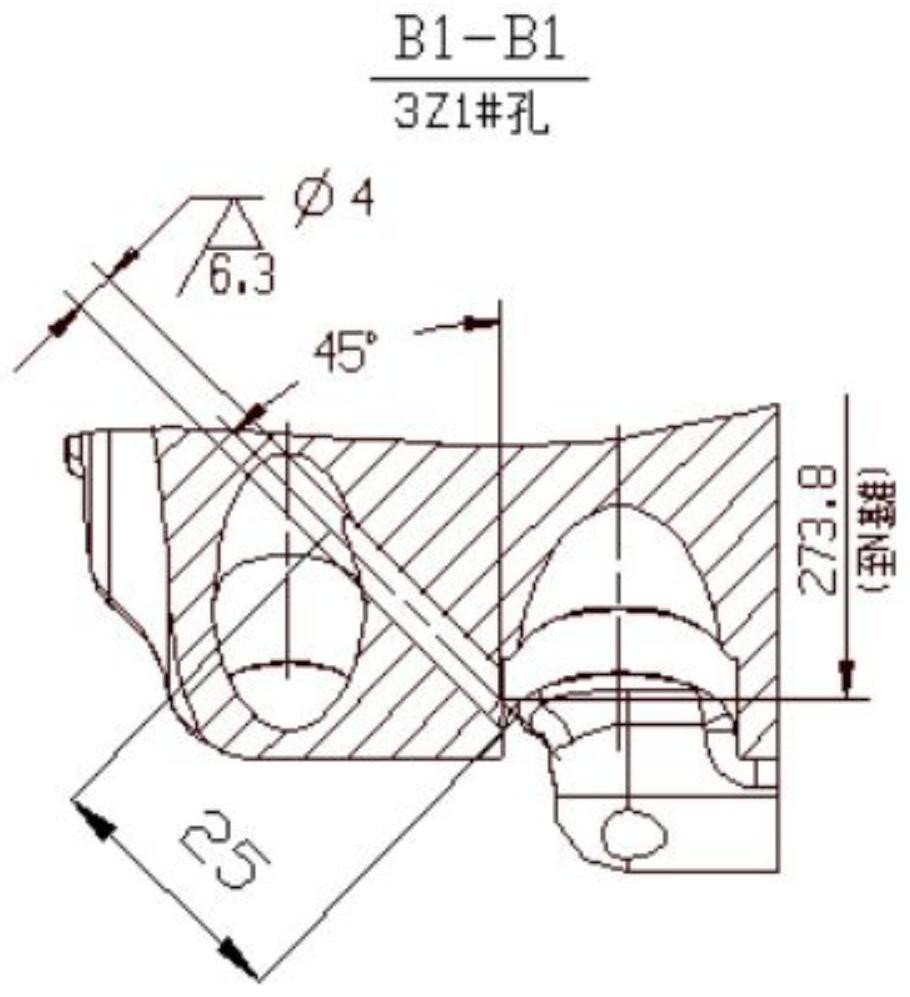

[0030] The processing method of the cylinder shallow oblique hole of the present embodiment, the processed cylinder material HT250, such as figure 1 shown.

[0031] The cylinder is placed on the fixture of the horizontal machining center with the upper and bottom facing down, and the positioning is performed by two pins on one side of the bottom of the cylinder, and the fixture pressure plate is pressed on the top of the cylinder for clamping, which is carried out by rotating the B axis of the machine tool to the angle of the hole to be processed. processing.

[0032] Positioning and clamping of the workpiece: the workpiece is positioned with the bottom face down, and two pins on one side of the bottom are used for positioning, and the clamping plate is pressed on the top surface of the cylinder body for clamping.

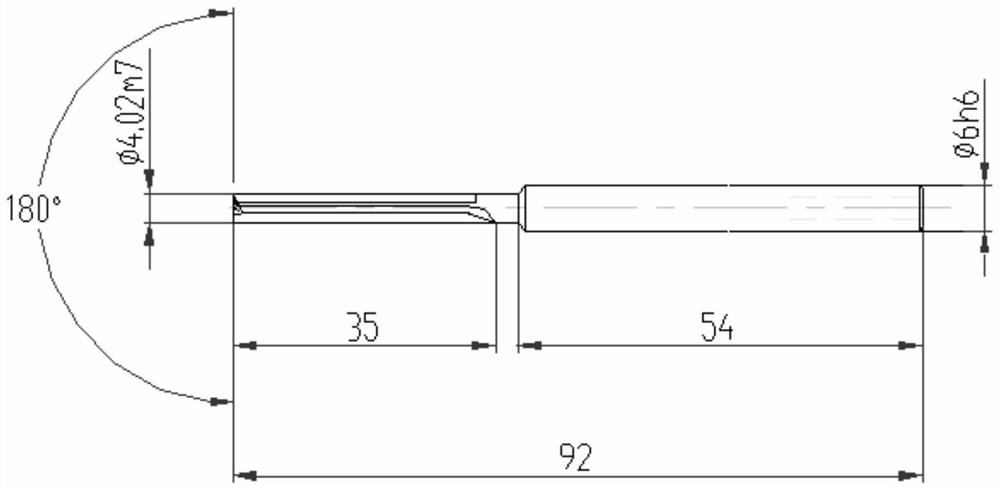

[0033] The cutting tool adopts a straight-fluted flat-bottomed drill with a large chip removal groove, and the drill bit has internal cooling holes, such as ima...

Embodiment 2

[0057] The processing method of the cylinder shallow oblique hole of the present embodiment, the processed cylinder material HT250, such as Figure 4 shown.

[0058] The cylinder is placed on the fixture of the horizontal machining center with the front end facing down, positioned with two pins on one side of the bottom of the cylinder, the clamp pressure plate is pressed against the bottom plate of the cylinder for clamping, and the machine tool B-axis rotates to the angle of the hole to be processed. processing.

[0059] Positioning and clamping of the workpiece: The front end of the workpiece faces downward, and the positioning is performed with two pins on one side of the bottom, and the clamping plate is pressed on the bottom plate of the cylinder body for clamping.

[0060] The cutting tool adopts a straight-fluted flat-bottomed drill with a large chip removal groove, and the drill bit has internal cooling holes, such as Image 6 As shown, the tool has 2 teeth, the spind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com