Rotary ic card punching and milling equipment

A rotary and blanking technology, which is applied in metal processing equipment, other manufacturing equipment/tools, manufacturing tools, etc., can solve the accumulation of coaxiality errors in card milling slots, out-of-tolerance groove size surface finish, and out-of-tolerance coaxiality Scrap and other issues, to achieve the effect of improving product qualification rate, high dimensional accuracy and surface finish, and ensuring dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, but the scope of implementation of the present invention is not limited thereto.

[0039]The material tape used for making the card used in this embodiment is supplied in the form of a material roll, which includes an unwinding roll and a rewinding roll, so as to facilitate the continuous supply of raw materials.

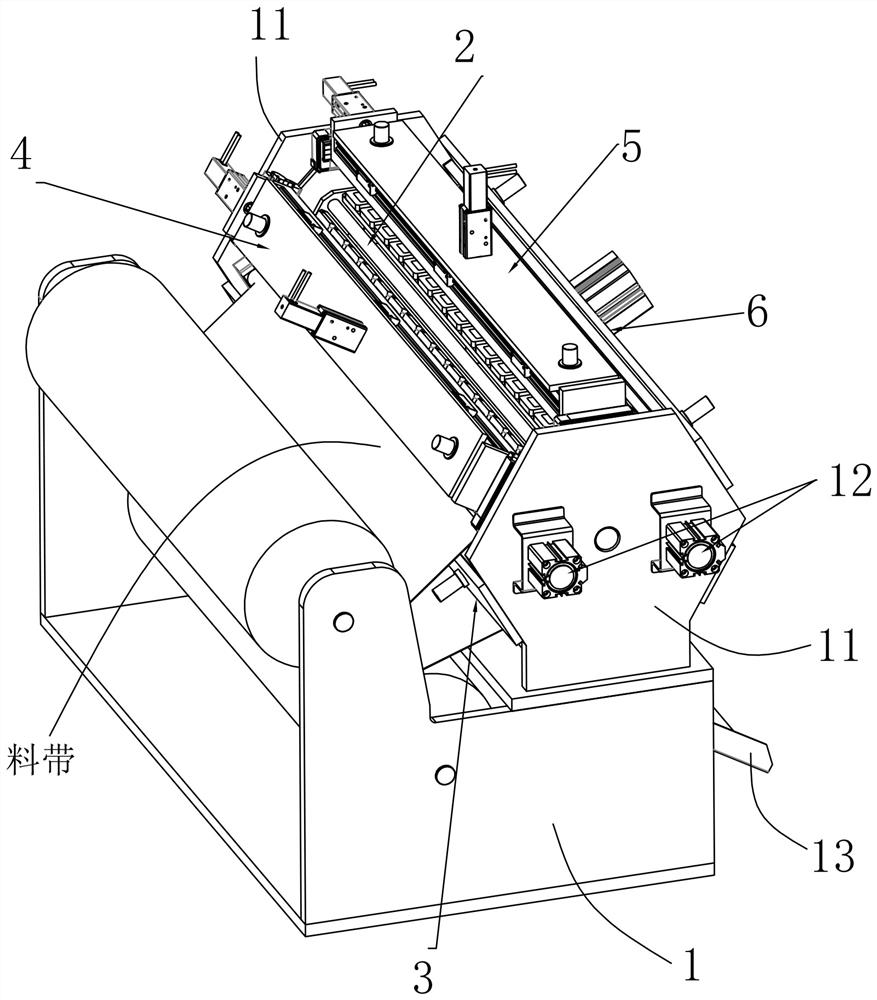

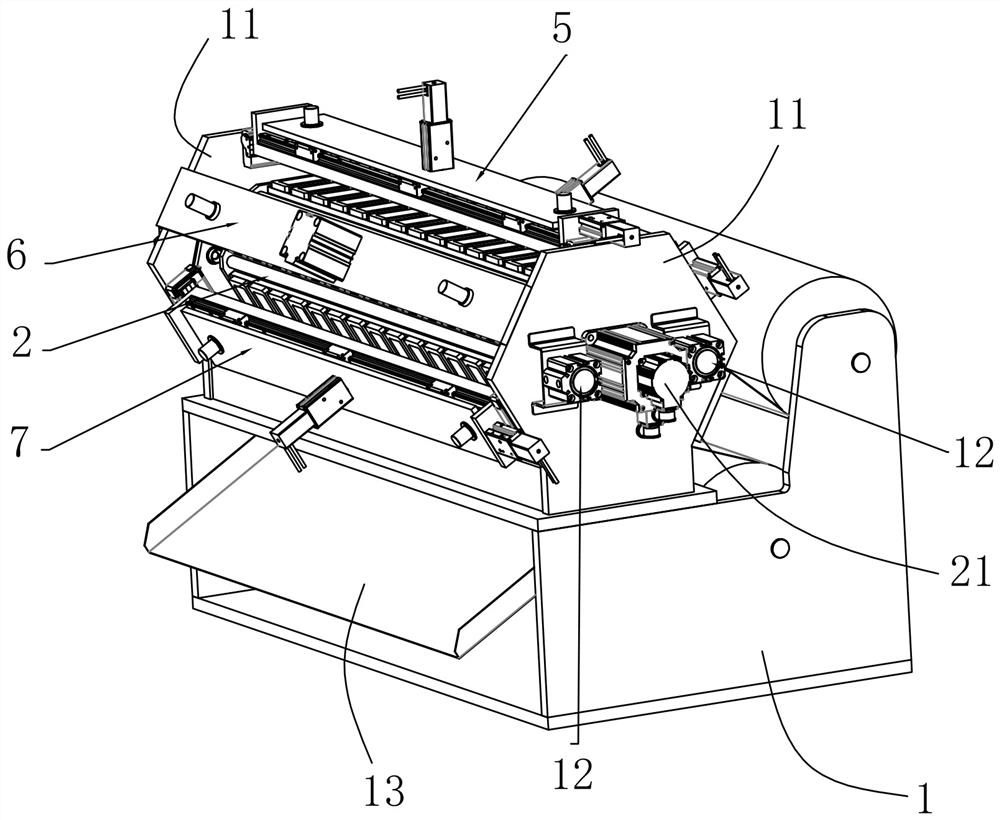

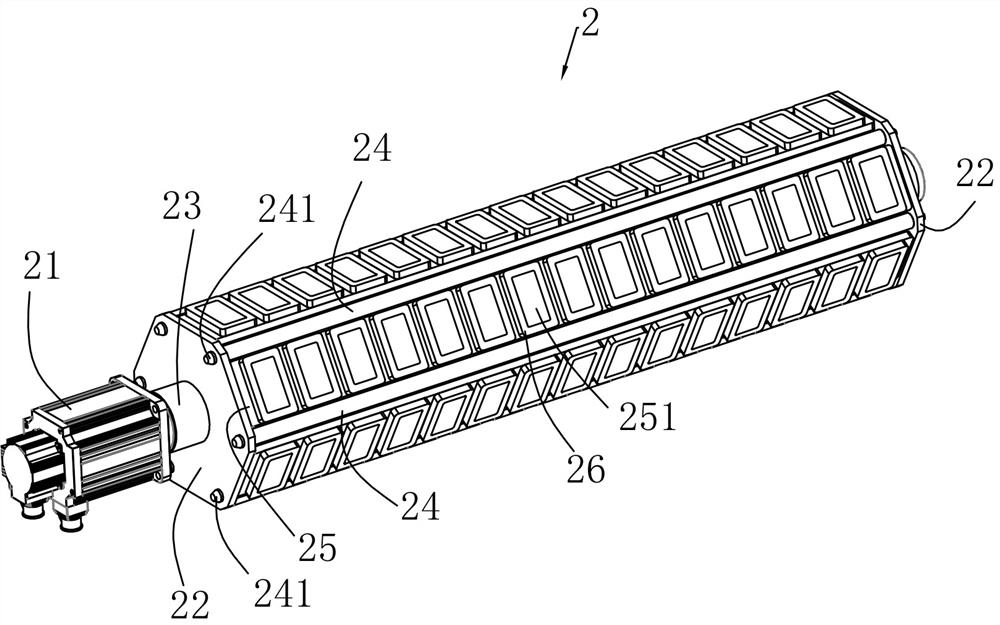

[0040] like Figure 1 to Figure 9 As shown, a rotary IC card punching and milling device described in this embodiment includes a frame 1, and the frame 1 has two side plates 11 in the shape of regular hexagons and arranged opposite to each other. The side plates 11 are all provided with a positioning mechanism 12; it also includes a station rotation mechanism 2 rotatably connected between the middle parts of the two side plates 11 and in the form of a regular hexagonal prism, and a position rotation mechanism 2 corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com