A processing tool for the scroll disk of a scroll compressor

A technology of scroll compressors and scroll disks, applied in the field of scroll compressors, can solve the problems of repeated positioning errors of scroll disks, difficulties in meeting production needs, and high requirements of operators, and achieve high processing consistency and high positioning accuracy , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

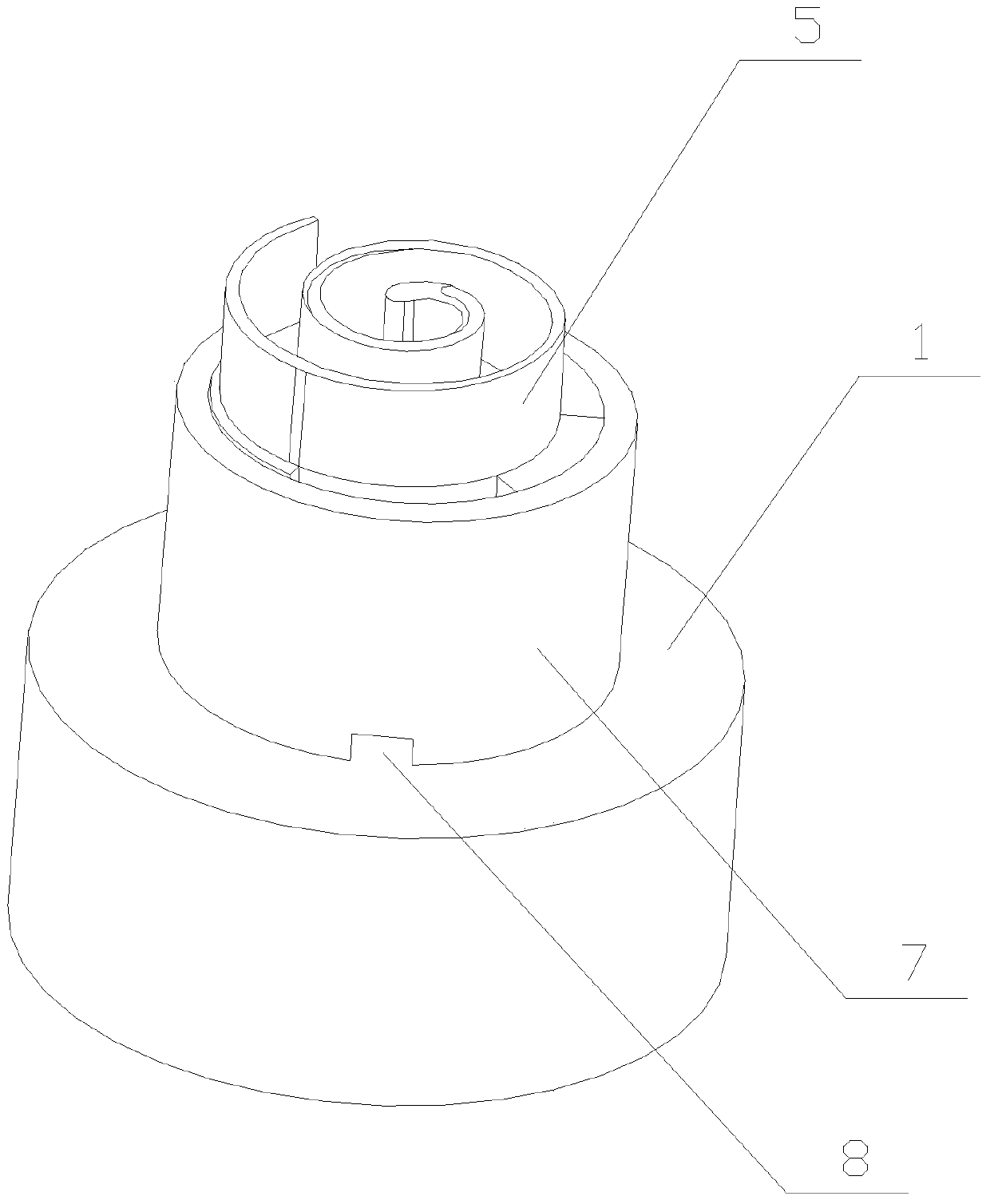

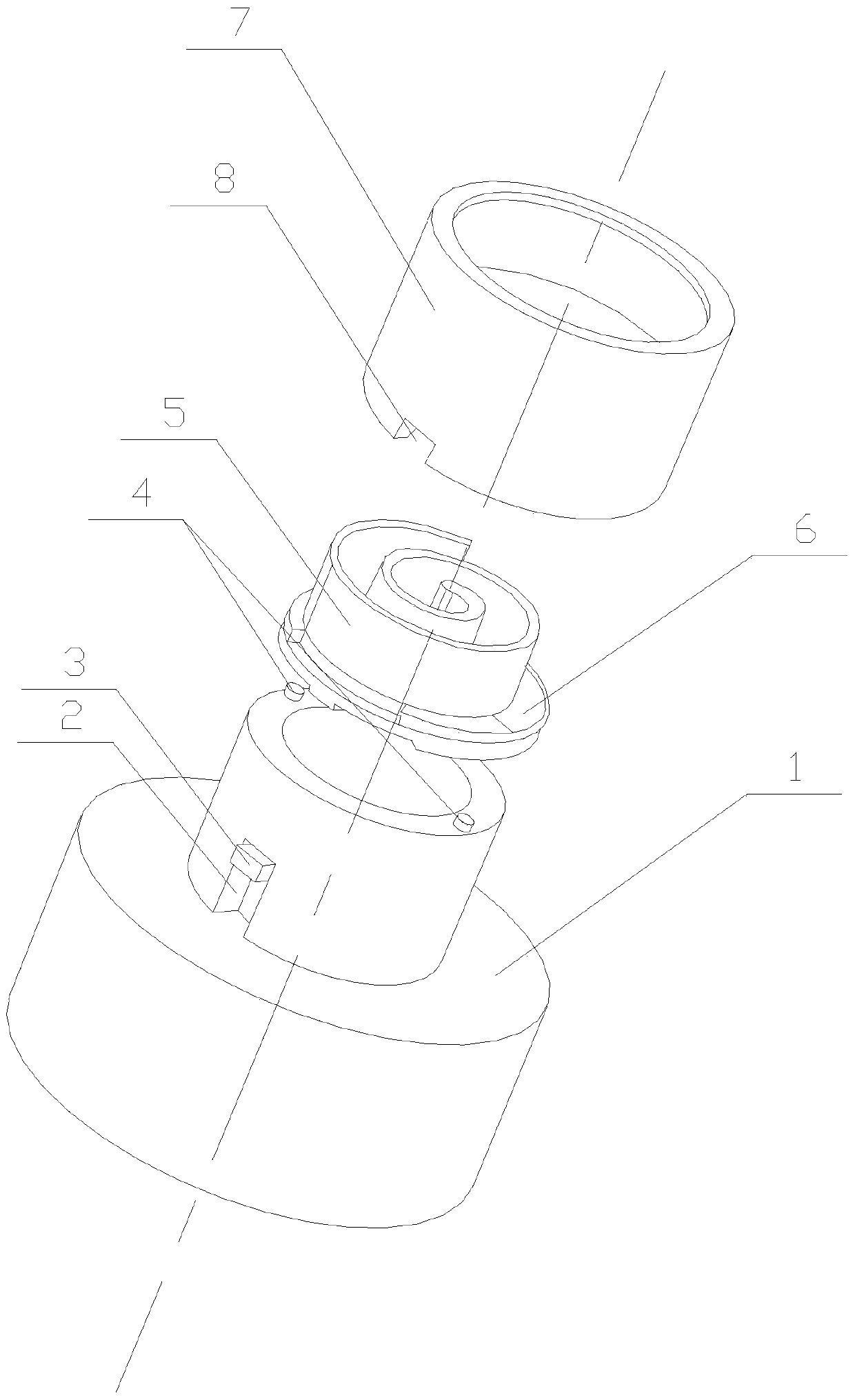

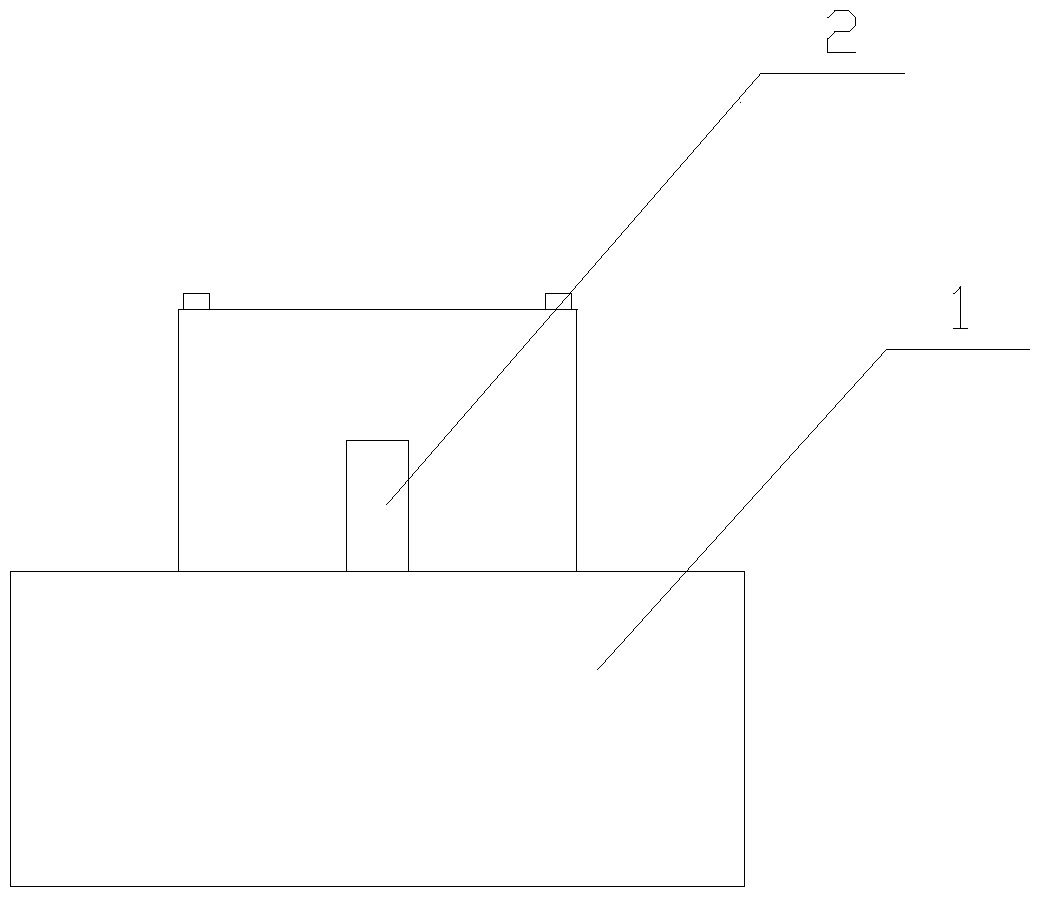

[0018] Such as Figure 1-Figure 8 As shown, this specific embodiment adopts the following technical scheme: it includes a clamp base 1, a slot 2, a pressure plate 3, a pin 4, a scroll 5, a scroll step 6, a sleeve 7, a sleeve keyway 8, and the clamp The base 1 is provided with a card slot 2, and the card slot 2 is provided with a pressure plate 3, the pressure plate 3 is connected with the cylinder main shaft, the cylinder main shaft is set in the fixture base 1, and two pins 4 are arranged symmetrically on both sides of the upper end surface of the fixture base 1 , the lower end surface of the scroll step 6 is provided with a pin hole corresponding to the position of the pin 4, and the scroll step 6 and the upper end surface of the fixture base 1 are engaged with each other, and the upper end of the scroll step 6 is provided with a scroll 5. The lower end of the sleeve 7 is provided with a sleeve keyway 8, and the sleeve 7 is sleeved on the fixture base 1 through the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com