Special tool for processing end surface of bearing cover

A technology of end face and tooling, which is applied in the direction of supports, metal processing equipment, metal processing machinery parts, etc., can solve the problems that the support cover cannot meet the drawing requirements, is easily affected by the quality of the blank, and has low repeat positioning accuracy, so as to avoid repetition The effect of positioning error, saving tooling adjustment time, and saving loading and unloading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

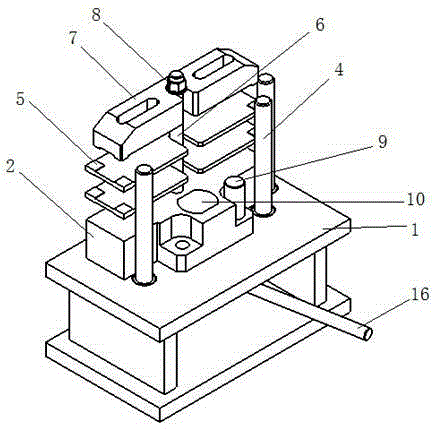

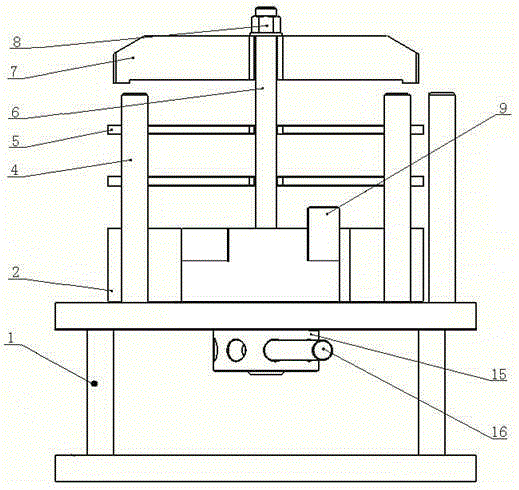

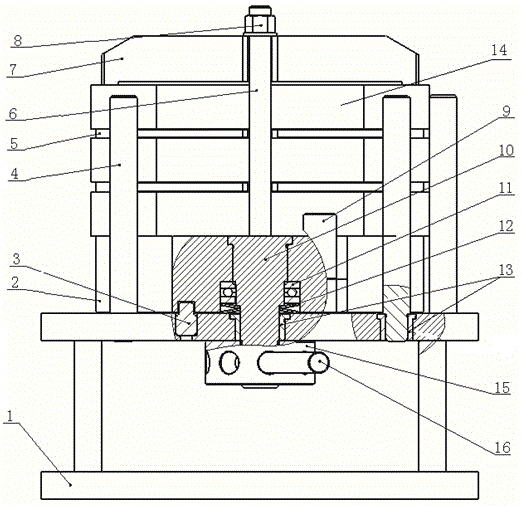

[0036] Such as figure 1 , 2 , 3, a special tool for processing the end face of the support cover, including a mold base 1, the upper end surface of the mold base 1 is connected to the rotary module 2 through a pin shaft 10, and the bottom of the pin shaft 10 located inside the rotary module 2 Plane bearings 11 and butterfly springs 12 are sheathed in turn on the outer periphery of the end; the bottom end of the pin shaft 10 passes through the mold base 1 and is connected with the lock nut 15; the rotating module 2 rotates on the mold base 1 around the pin shaft 10 , and positioning with the mold base 1 through the positioning pin 9; the upper end of the rotary module 2 is connected with a central stud 6, and the central stud 6 is movable with a backing plate 5 and a pressure plate 7, and the top of the central stud 6 A shoulder nut 8 is provided; a positioning column 4 for positioning the outer wall of the rotary module 2 is clamped on the mold base 1 located outside the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com