Numerically controlled lathe-based contour laser online measurement device and method for rotary type structure characteristic parts

A technology of structural features and numerically controlled lathes, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as the limitation of degrees of freedom, and achieve the effect of increasing adaptability and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with specific examples.

[0044] A laser on-machine measurement device and method for rotary structural feature parts based on a numerically controlled lathe. The present invention is based on a numerically controlled lathe, combined with the characteristics of fast measurement speed of laser sensors, and then designs supporting fixtures to realize on-machine measurement of rotary structural feature parts; in addition, the compilation algorithm processes the measurement data, and then the model is reconstructed to complete the process. Comprehensive evaluation and analysis of method measurement efficiency and measurement accuracy.

[0045] It is characterized in that, the realization process of described method is:

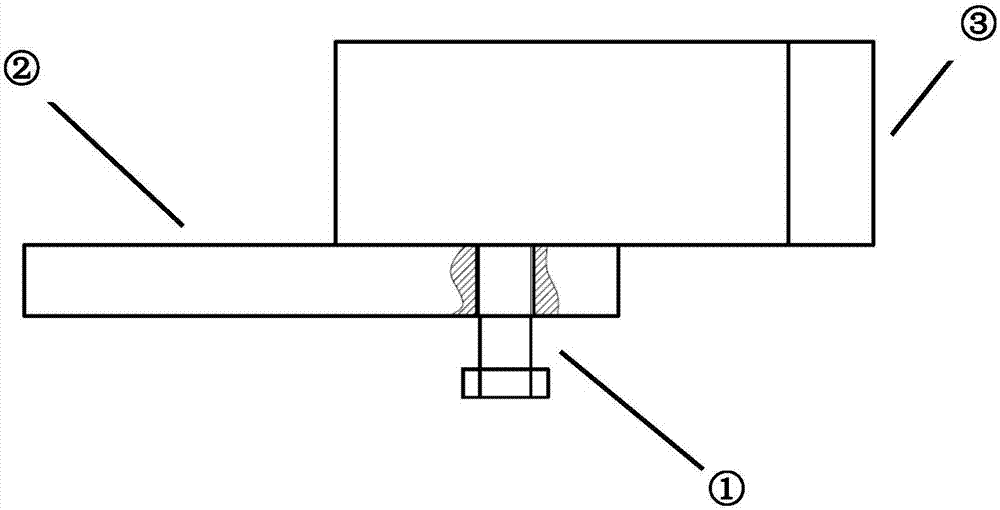

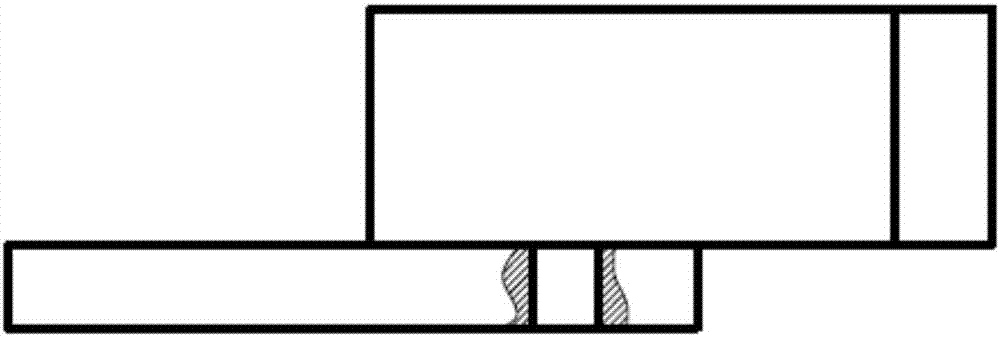

[0046] Step 1. Referring to the structural characteristics of the KEYENCE LK-G80 point scanning laser displacement sensor, design an adjustable and detachable fixture. After the sensor an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com