Electrical discharge machining method of die inserted block for forming microstructure

A technology of electric spark and electric spark wire, which is applied in the field of mold inserts for forming microstructures, can solve the problems of online production and repair of electrodes, practical application limitations, short life, etc., to avoid repeated positioning errors and narrow slit dimensional accuracy. High, relative position accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation process of the present invention will be described below in conjunction with the technical scheme and accompanying drawings.

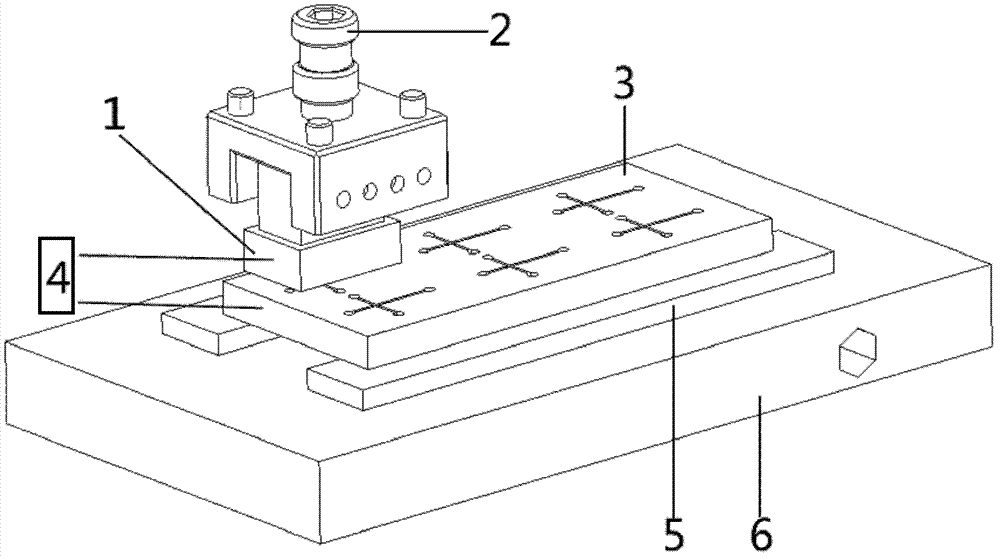

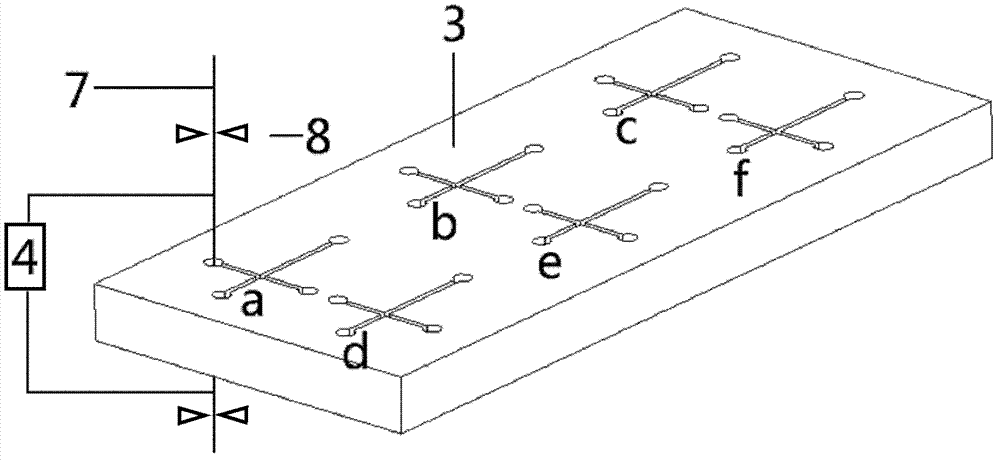

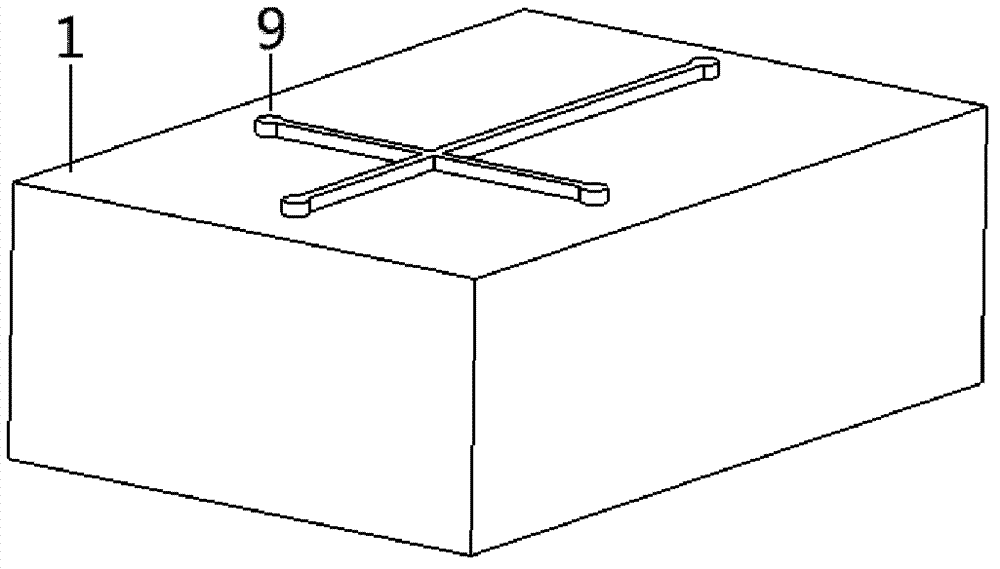

[0014] This implementation process takes the processing of polymer microfluidic chip mold microstructure inserts as an example, such as figure 1 As shown, the mold insert 1 is clamped by a special fixture 2, and there is a pulse power supply 4 indirectly between the mold insert 1 and the combined electrode 3 to form a discharge circuit; the combined electrode 3 and the steel pad 5 are connected by screws, and then adsorbed on the magnetic chuck 6. The electrode wire 7 passes through the wire guide nozzle 8 to process the slit, such as figure 2 shown. Finally, the characteristic structure obtained is the micro-protrusion structure 9 on the base surface, and the characteristic size of the micro-protrusion structure is 70 μm in height and 110 μm in width. Corresponding to the micro-protrusion structure of the workpie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com