Structure of front end of gallium arsenide base monolithic photoelectron integrated receiver and manufacturing method thereof

A receiver front-end, gallium arsenide-based technology, which is applied in the field of front-end structure and production of gallium arsenide-based monolithic optoelectronic integrated receivers, can solve the problems of restricting the bandwidth advantage of distributed amplifiers, so as to improve the success rate of one-time casting, parasitic The effect of small capacitance and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

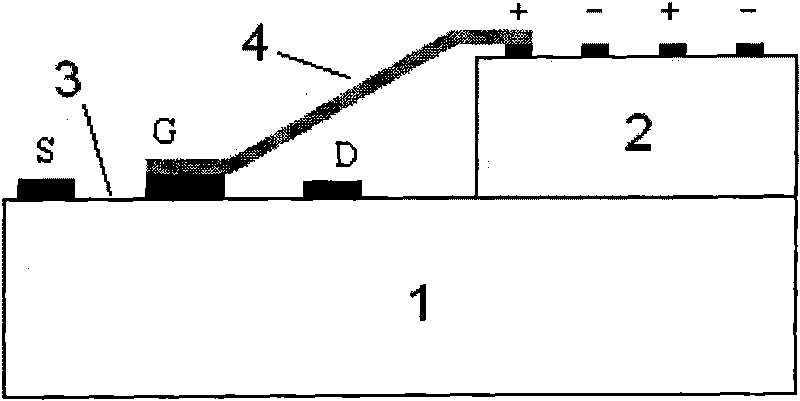

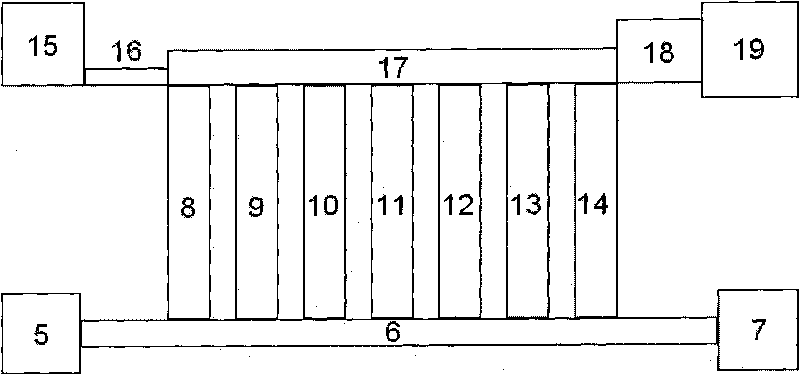

[0021]Embodiment 1: Design the GaAs-based monolithic optoelectronic integrated receiver front end, its structure includes a distributed preamplifier and a photodetector, wherein the length and width of the source electrode 33 of the distributed preamplifier PHEMT device are 10 μm and 50 μm respectively, and the gate The length and width of the electrode 34 are 0.5 μm and 100 μm respectively, and the length and width of the drain 35 are 10 μm and 50 μm respectively; the amplifier adopts 7 common source-common gate structures as the gain unit, the terminal load of the gate transmission line is 7, and the reverse terminal load of the drain transmission line The impedance of 15 is 50Ω, the grid transmission line input microstrip 6 has a width of 10 μm and a length of 1780 μm, the resistance values of resistors 24 and 27 are 15Ω and 148Ω respectively, the capacitance 22 is 2.1pF, and the width and length of microstrip line 20 are 10 μm and 200 μm, respectively. The width and lengt...

Embodiment 2

[0025] Embodiment 2: Design the GaAs-based monolithic optoelectronic integrated receiver front-end, its structure includes a distributed preamplifier and a photodetector, wherein the length and width of the source electrode 33 of the distributed preamplifier PHEMT device are 10 μm and 50 μm, and the gate The pole length and width are 340.5 μm and 100 μm respectively, and the length and width of the drain 35 are 10 μm and 50 μm respectively; the amplifier adopts 7 common source-common gate structures as the gain unit, and the characteristic impedance of the transmission line and the impedance of the terminal load 7 and 15 are both 50Ω , the gate transmission line input microstrip 6 has a width of 10 μm and a length of 1780 μm, the resistance values of the resistors 24 and 27 are 22Ω and 148Ω respectively, the capacitance 22 is 2.1pF, the width and length of the microstrip line 20 are 10 μm and 200 μm respectively, and the width of the microstrip line 23 The width and length of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com