Thermal error measurement device and measurement method of gear grinding machine in working state

A measurement method and working state technology, which is applied in the direction of measurement/indicating equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to measure the thermal error of the gear grinding machine and the low machining accuracy of the gear grinding machine, so that the measurement method is easy to master , easy to popularize, simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

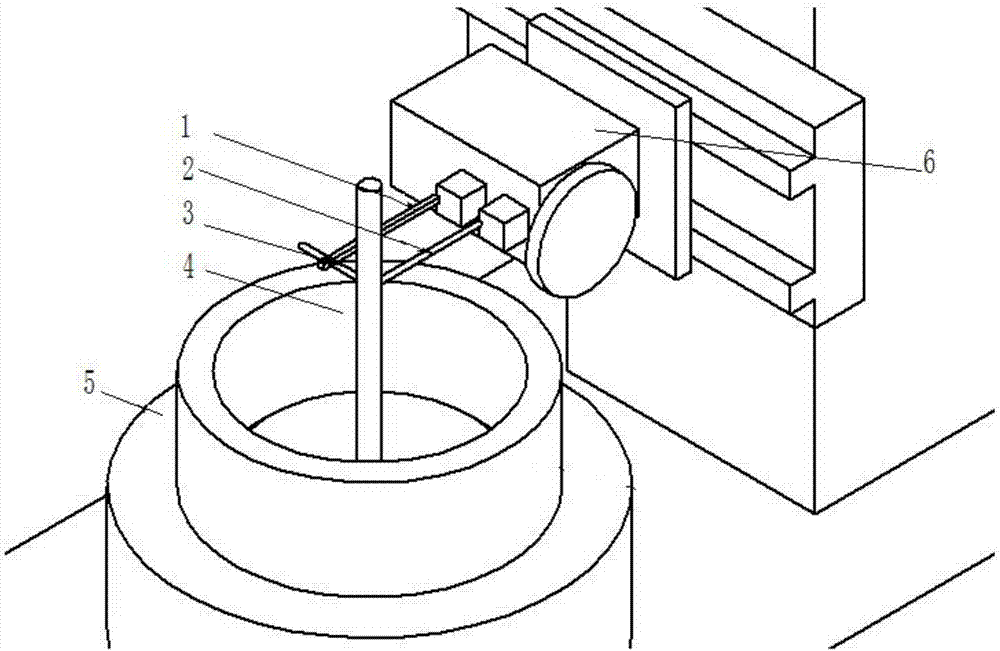

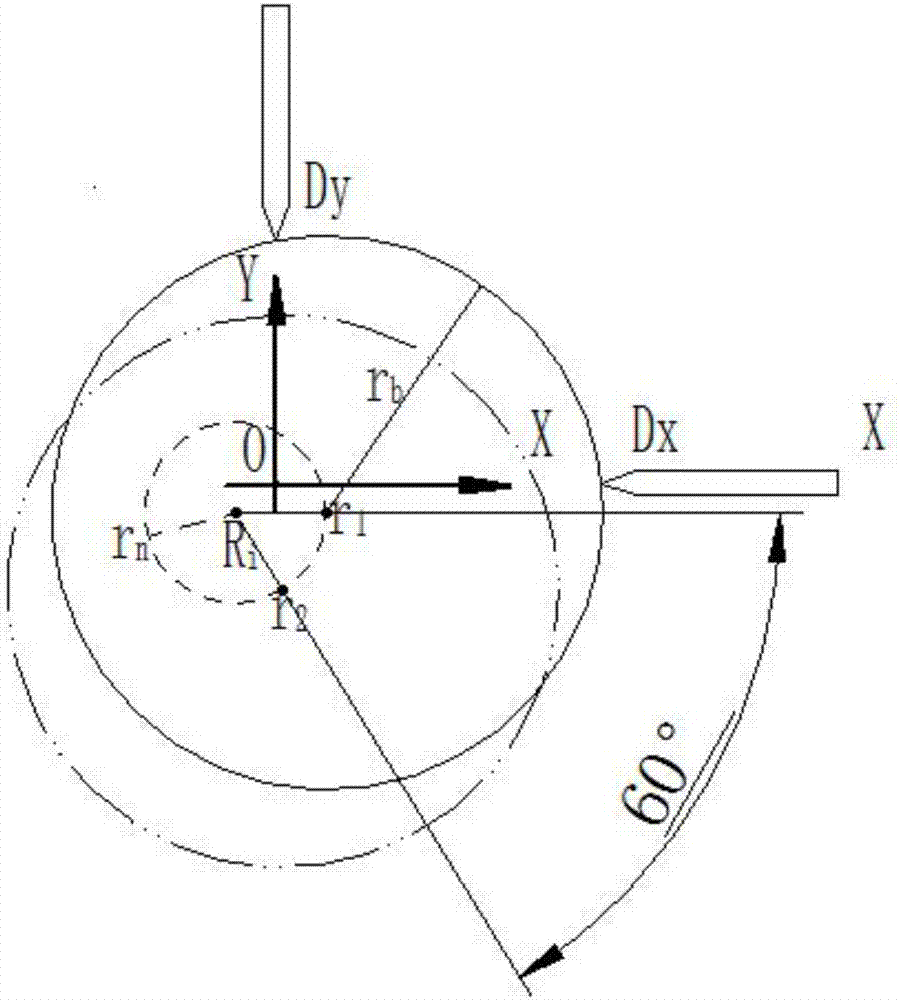

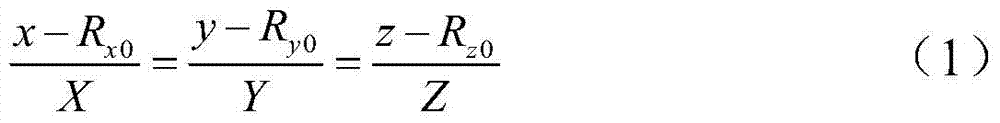

[0055] The structure of the thermal error measuring device in the working state of a gear grinding machine of the present invention is as follows: figure 1 As shown, it includes the temperature measurement part and the displacement measurement part; the temperature measurement part includes the spindle motor, the front and rear end covers of the spindle, the feed drive motor, the turntable surface, the coolant diversion groove, the column, the bed, and the turntable arranged on the gear grinding machine The temperature sensor on the base and the main shaft base; the displacement measurement part includes the X-direction displacement sensor 2 and the Y-direction displacement sensor 3 fixed on the gear grinding machine main shaft base 6 through the bracket 1, the X-direction displacement sensor 2 and the Y-direction displacement sensor The sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com