Electrochemical machining vibro-feed movement implementation device

A technology of feed motion and machining vibration, applied in electric machining equipment, electrochemical machining equipment, accessories, etc., can solve the problems of large differences in machining parameters and limited practicability, and achieve improved positioning accuracy and repeatable positioning accuracy. The effect of improving accuracy and stability, simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principle of the present invention, structure and working engineering are further described the present invention below in conjunction with accompanying drawing.

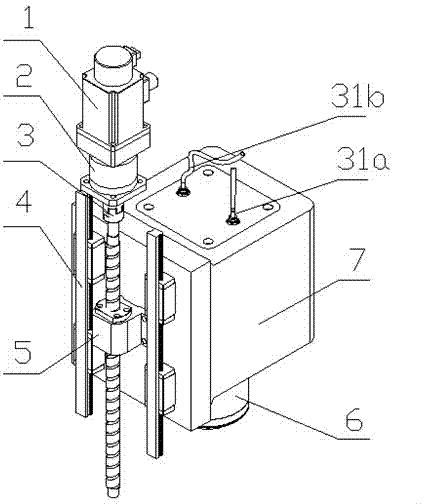

[0029] refer to figure 1 , the electrolytic machining vibration feed movement realization device of the present invention mainly includes a servo feed movement device and a vibration device 6 . in,

[0030] The servo feed movement device includes a servo motor 1 and its reducer 2 installed on the base of the electrolysis device. The reducer 2 is connected to the screw pair 5 through the coupling 3, and the screw pair 5 is installed on the side of the sliding seat 7. The side is also provided with a guide rail pair 4 for guiding the movement vibration device 6 of the sliding seat 7 and is installed on the servo feeding movement device through the sliding seat 7 .

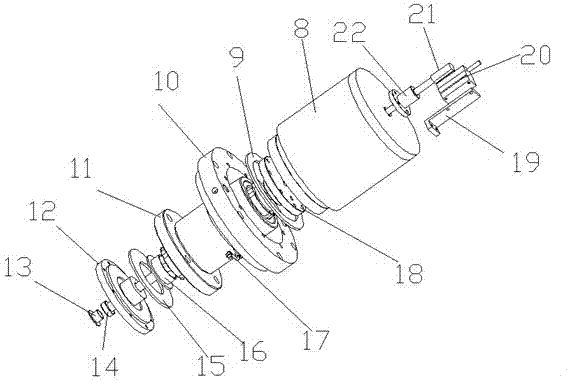

[0031] The vibration device mainly includes a voice coil motor 8, a connection block 18, a ball spline pair 11, a conductive block 12, a moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com