Patents

Literature

31 results about "Quadratic integral" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, a quadratic integral is an integral of the form ∫dx/(a+bx+cx²). It can be evaluated by completing the square in the denominator. ∫dx/(a+bx+cx²)=1/c∫dx/(x+b/2c)²+(a/c-b²/4c²).

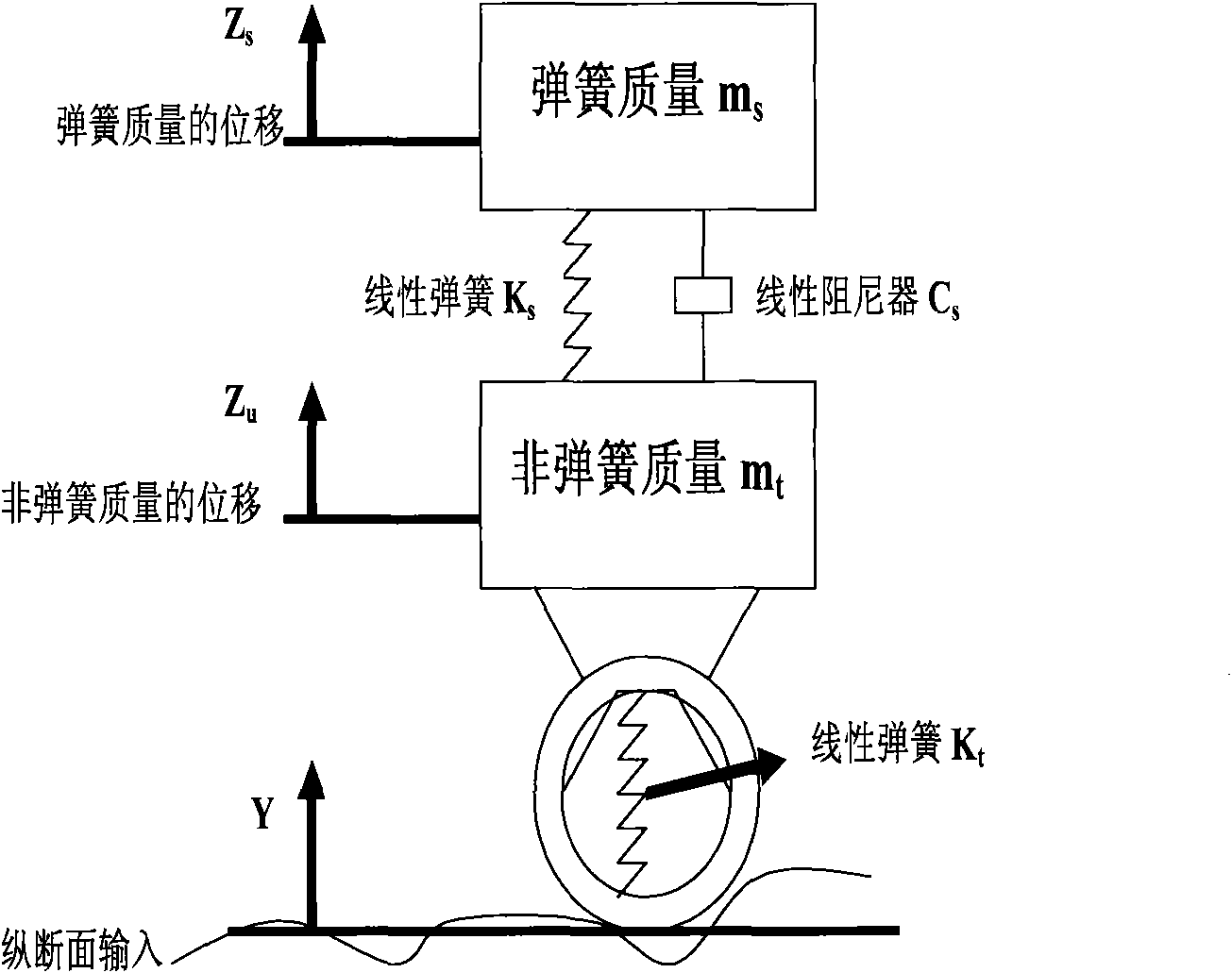

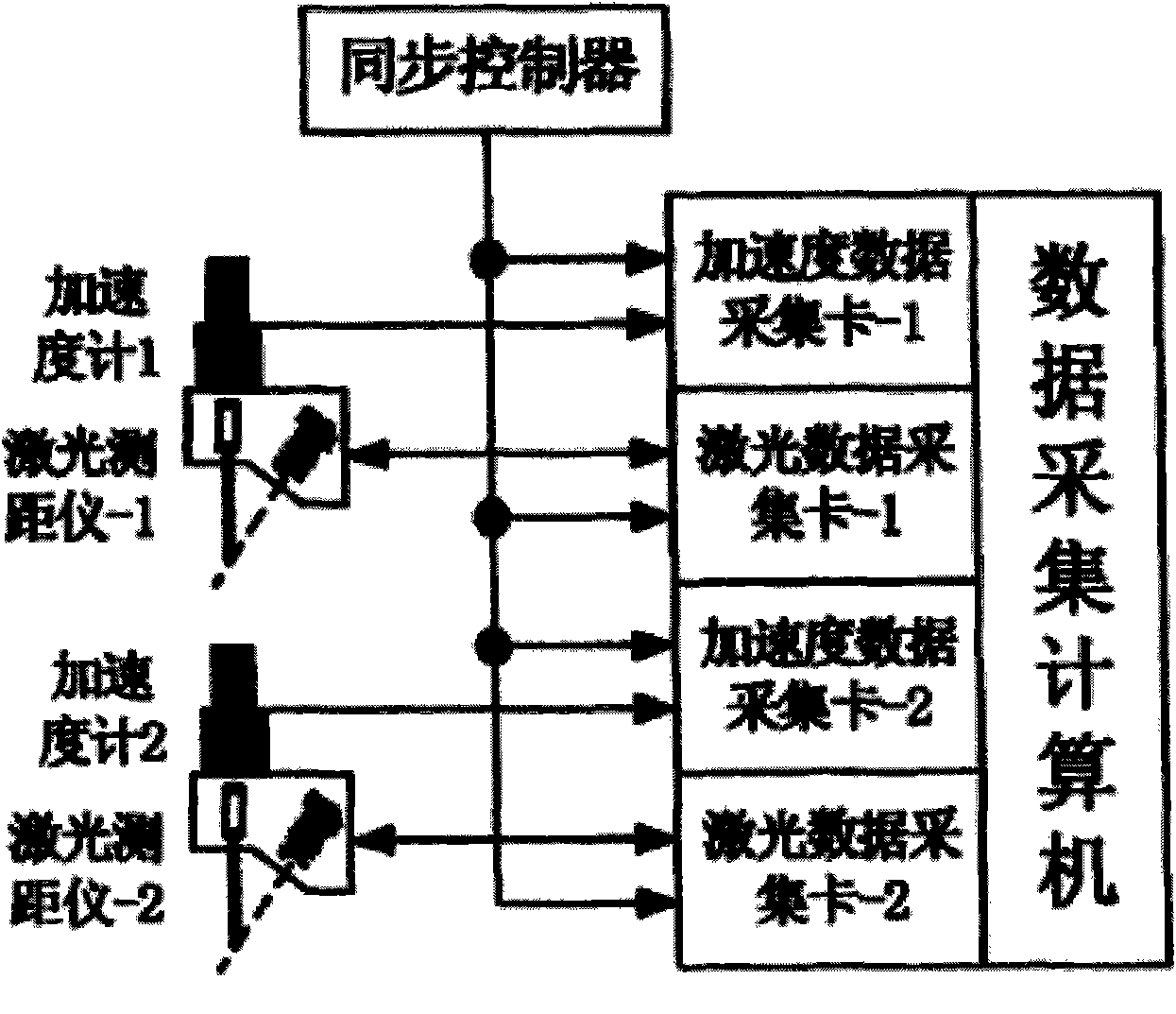

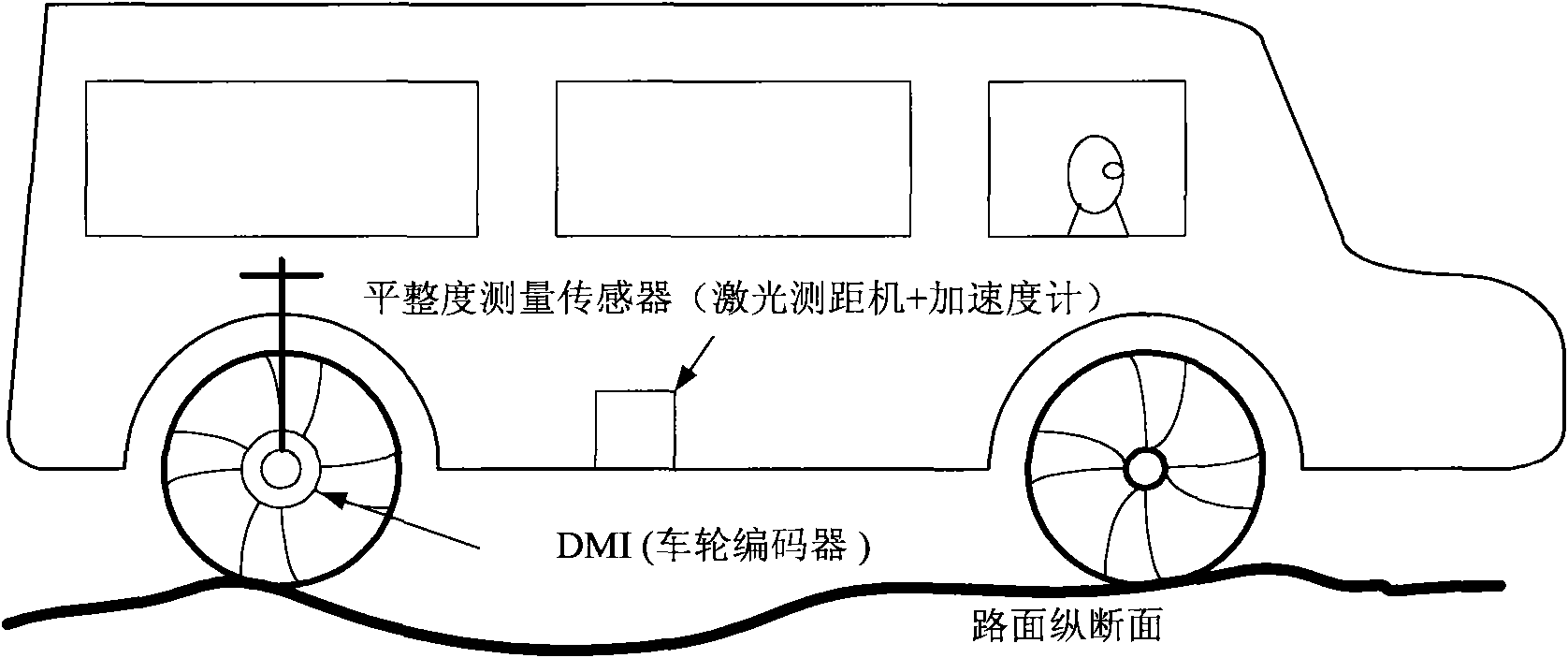

Laser evenness measuring system and method based on acceleration compensation

InactiveCN101914889ARealize flatness measurementRealize measurementRoads maintainenceRoad surfaceLeast squares

The invention provides a laser evenness measuring system and a method based on acceleration compensation. The method of the invention comprises the following steps: at regular time interval, measuring the vertical distance between a specific point on a road vertical section and a car body; at the moment of measuring the distance, synchronously measuring the acceleration of the car body in the vertical direction; according to the progression of the recorded vertical direction, fitting the distance progression of the road vertical section and the car body with the least square method; carrying out quadratic integral to the recorded acceleration value progression to obtain a car body bumping value; according to the bumping value, fitting the bumping progression of the car body in the vertical direction with the least square method; subtracting the car body and road surface distance progression from the vertical bumping progression of the car body to obtain a road surface undulate progression; re-sampling the road surface undulate progression at the interval of 25 cm; and calculating to obtain the road surface evenness value according to 1 / 4 vehicle model. The invention can realize the evenness measurement with wide variable speed, high precision and high reliability.

Owner:WUHAN WUDA ZOYON SCI & TECH

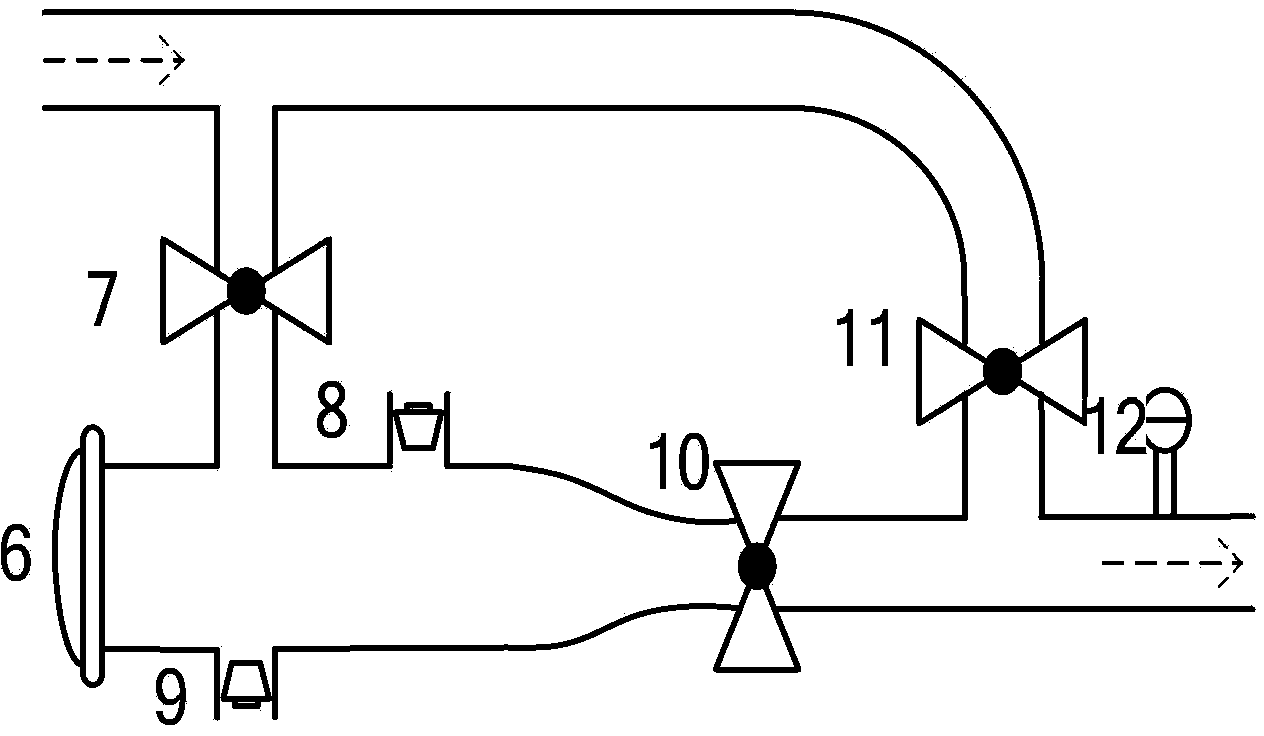

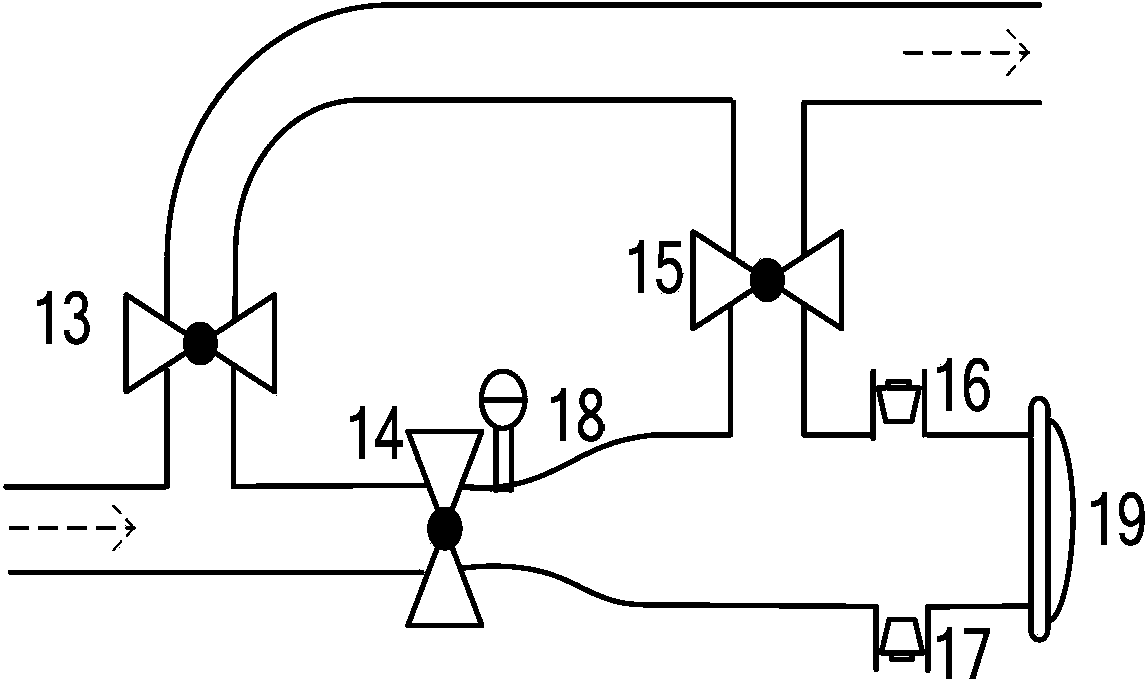

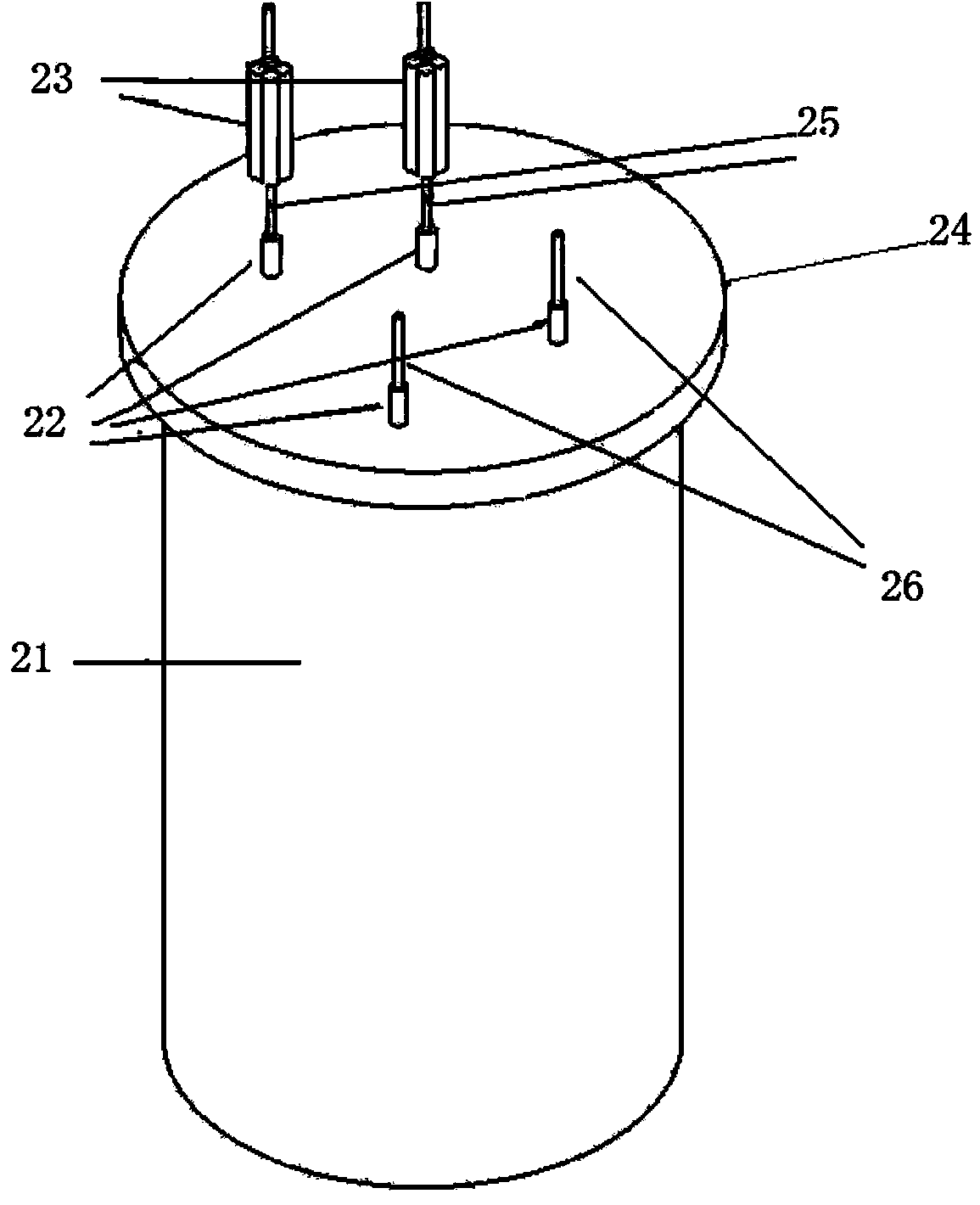

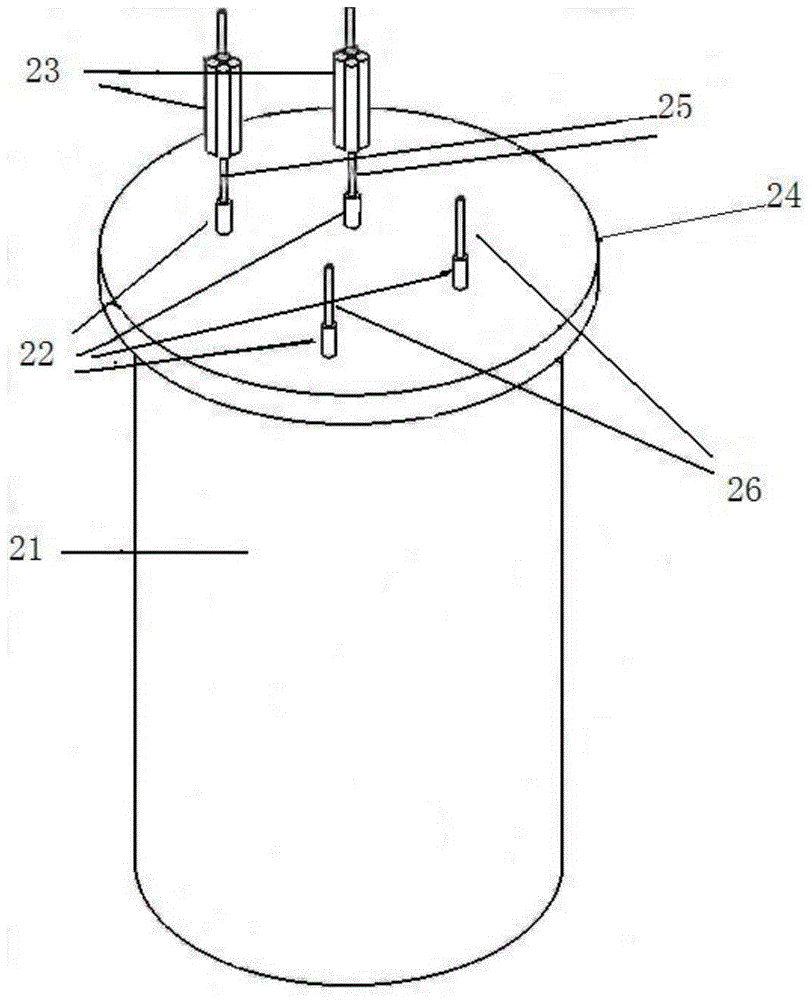

Small leakage detection system for liquid pipeline

The invention discloses a small leakage detection system for a liquid pipeline and relates to the technical fields of tests not included in other classes, acoustic wave measurement and pipeline systems. On the premise of not changing technological processes of current pipelines, a leakage detection ball is sent out by a pipe cleaner ball sending device and flows along with a medium in the pipeline; meanwhile, acoustic signals inside the pipeline and state information of the leakage detection ball are acquired, stored and tagged with time labels; after the leakage detection ball is collected back from a ball collecting bucket, the small leakage detection system is connected with an upper computer, so that the acoustic information stored in the pipeline and the state information of the leakage detection ball are obtained; the obtained acoustic information is directly displayed in an oscillograph on the upper computer; except a ball sending bucket and the ball collecting bucket, if an acoustic amplitude is higher than that of noise in the pipeline, the corresponding time is judged to be the leakage point and recorded; according to the recorded time of the leakage point, the state information of the leakage detection ball is subjected to quadratic integral so as to obtain displacement of the leakage detection ball relative to the ball sending bucket, namely the leakage position. The small leakage detection system for the liquid pipeline can detect small and even tiny leakages and is high in sensitivity.

Owner:PETROCHINA CO LTD

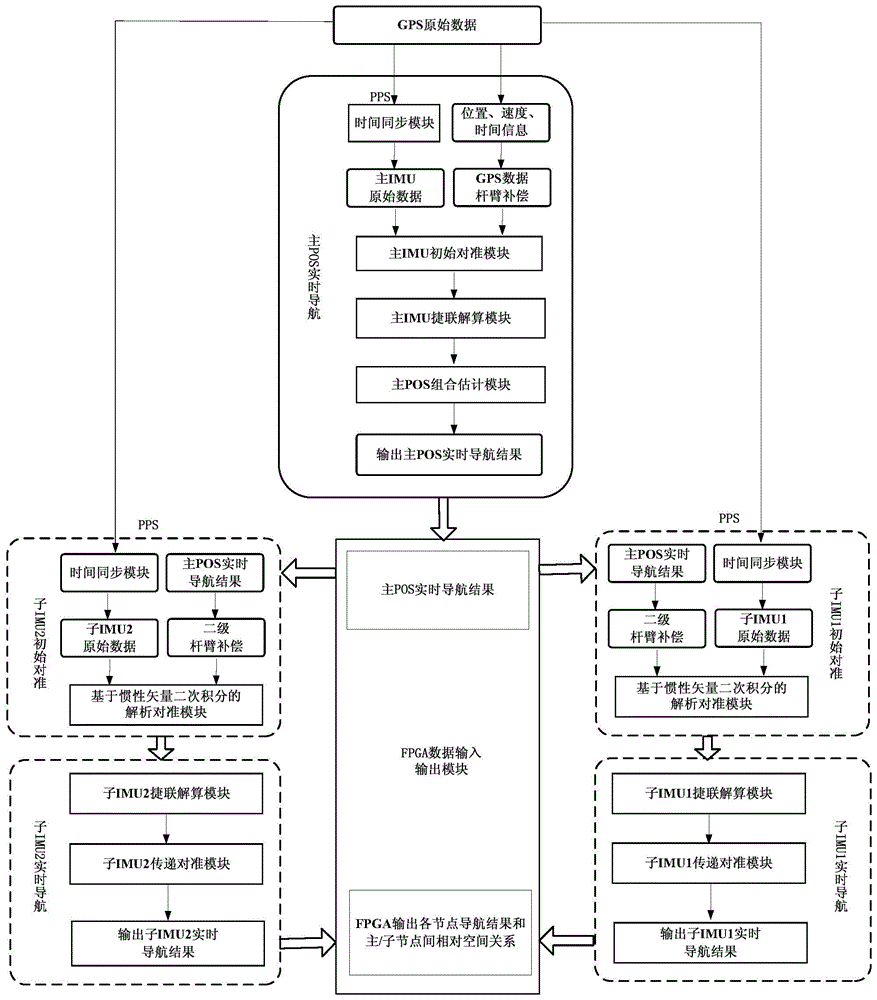

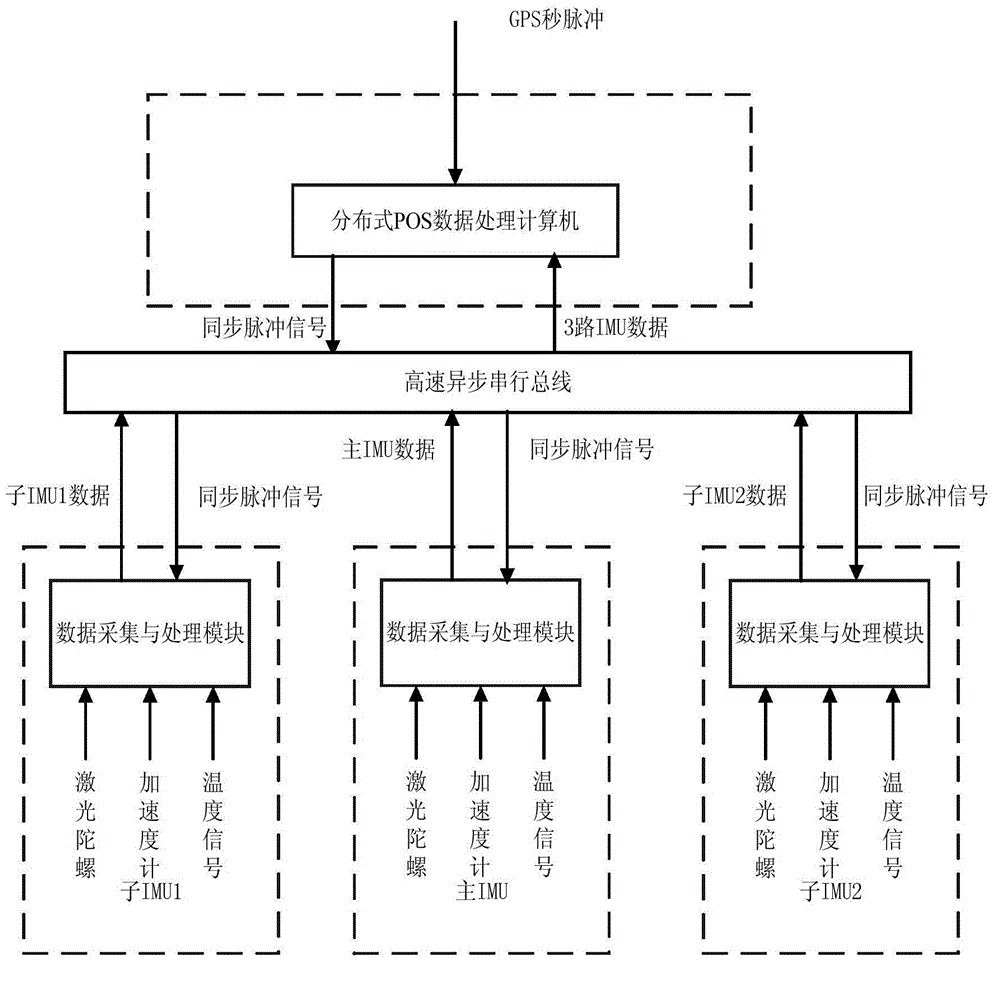

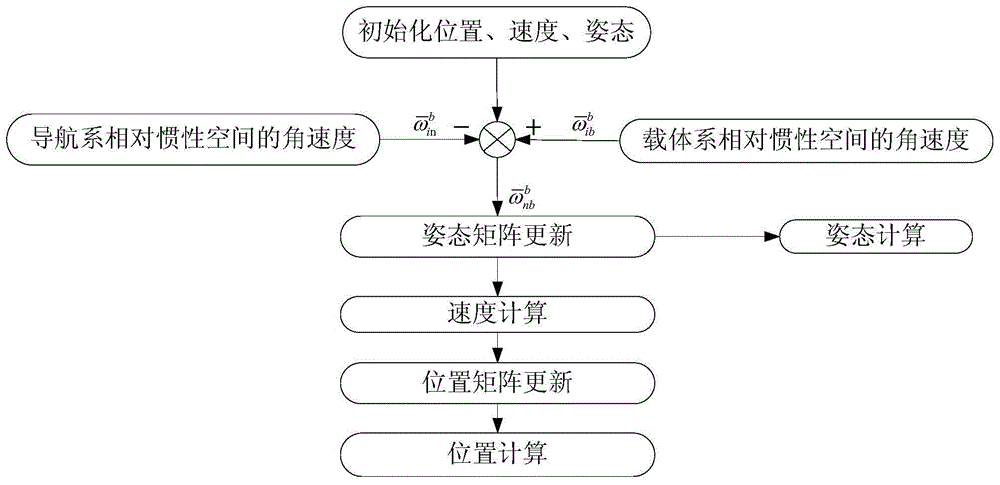

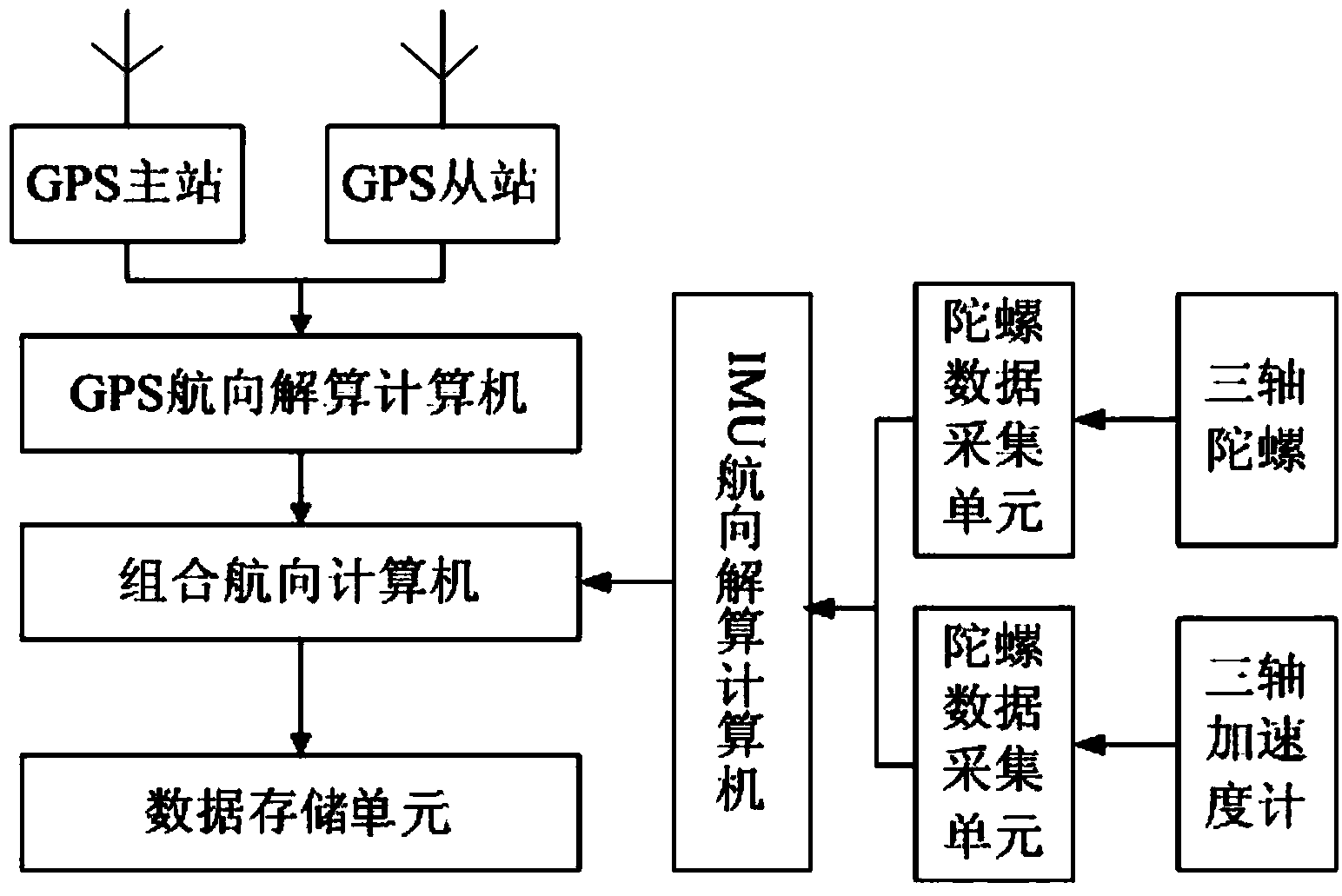

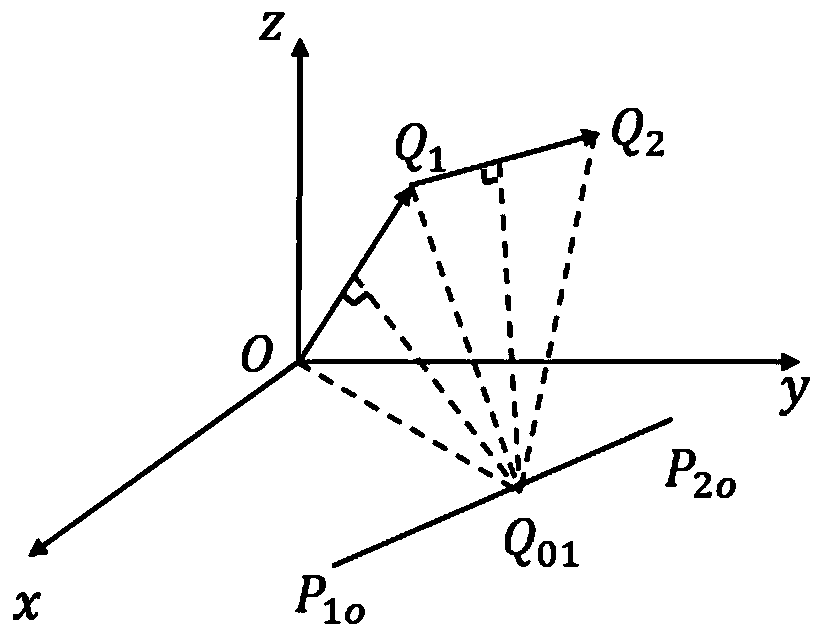

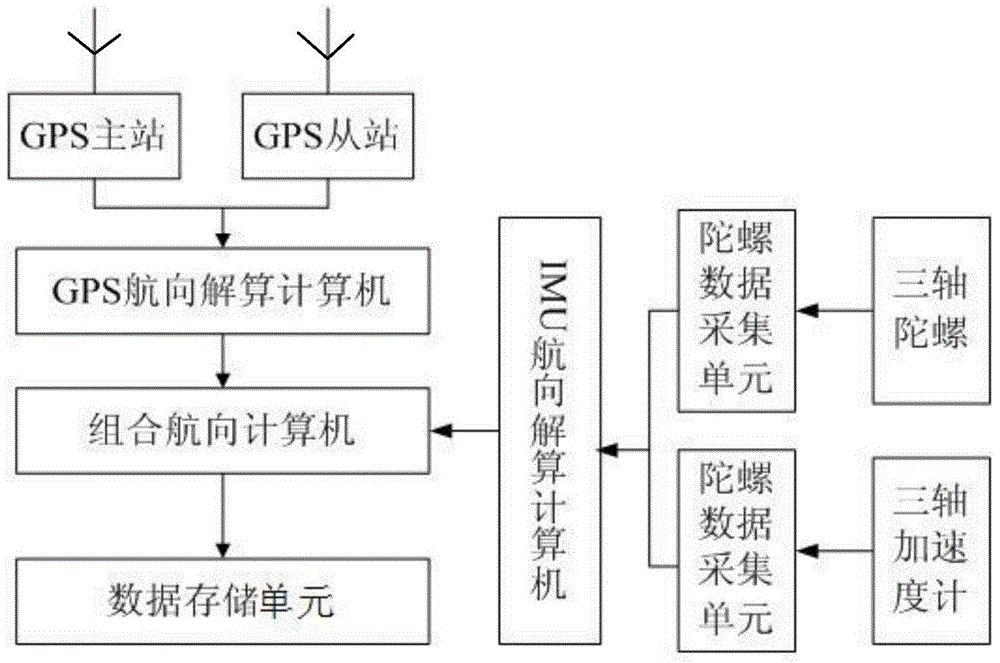

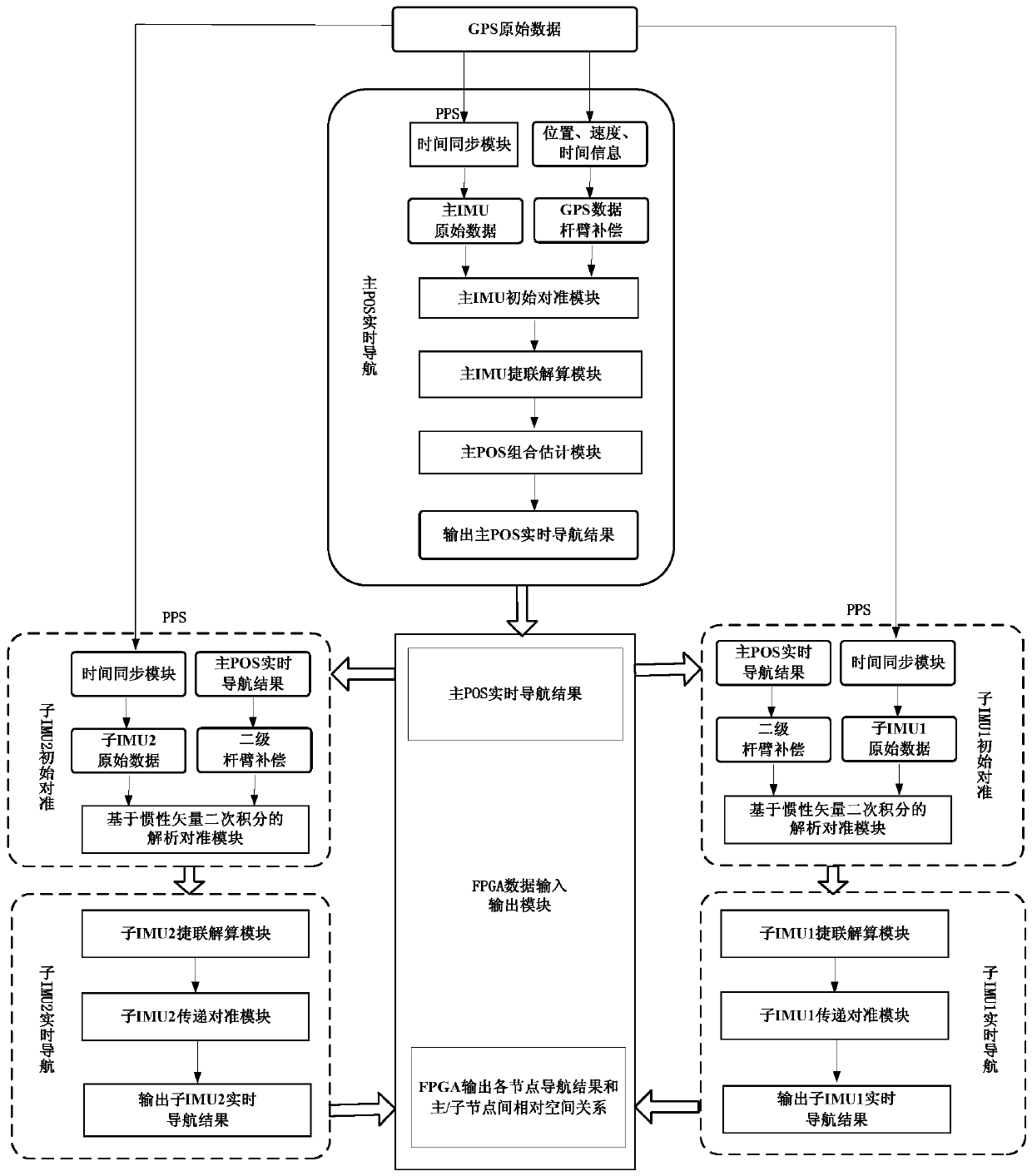

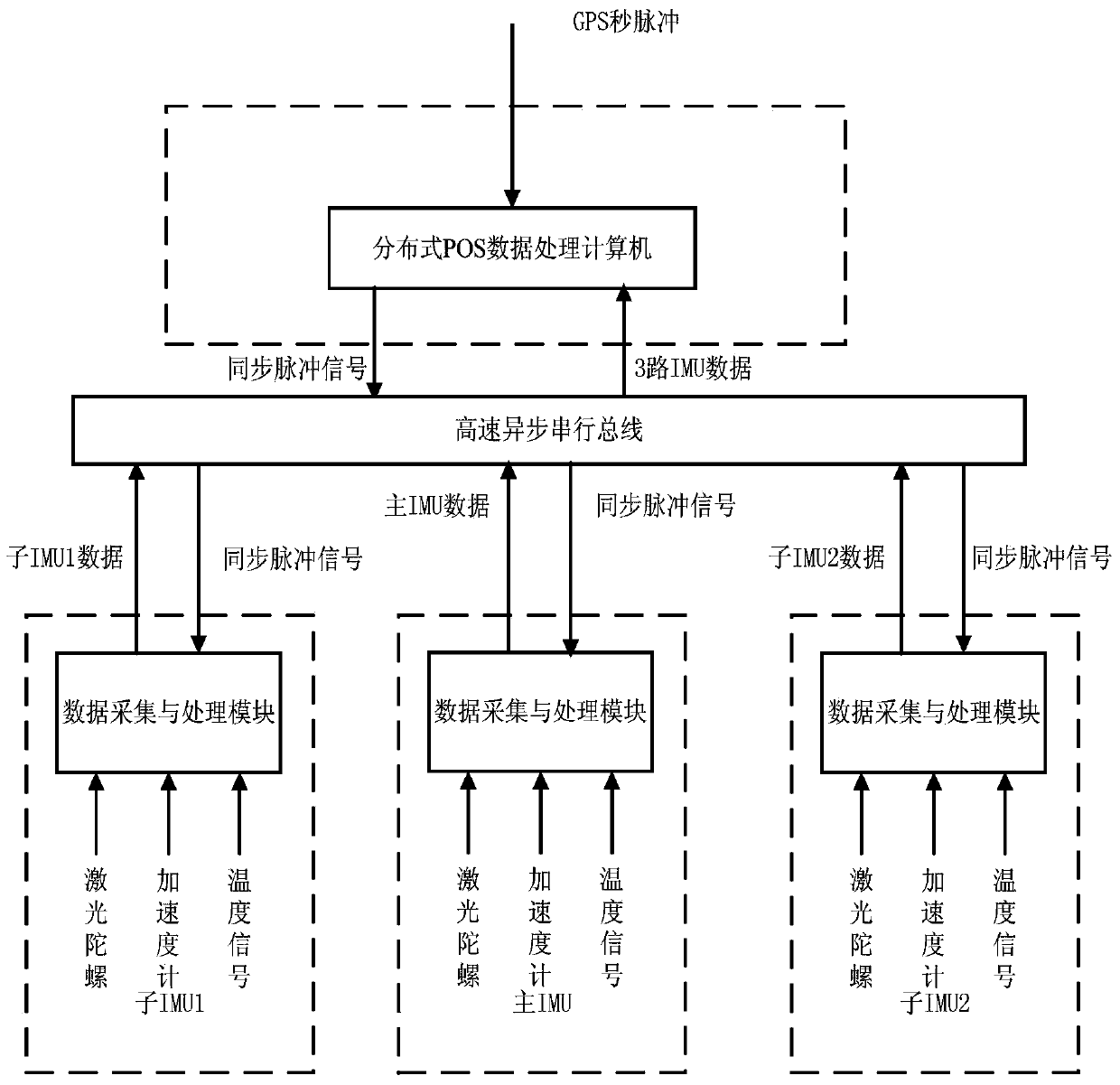

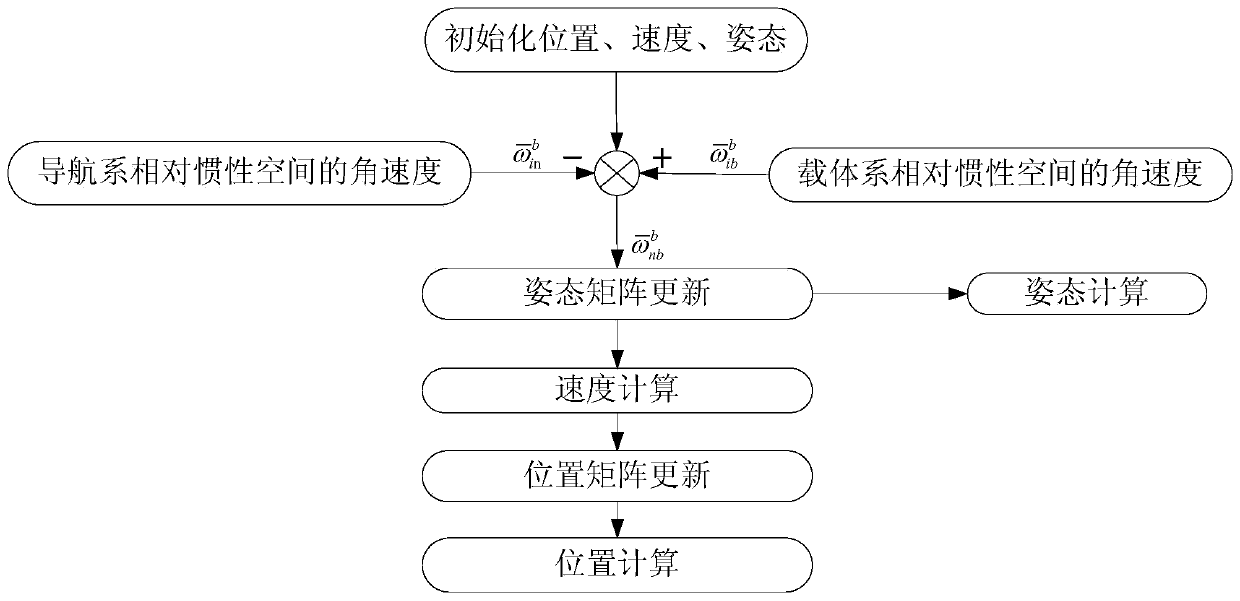

Real-time navigation method of data processing computer system for distributed POS

ActiveCN104698486AOvercoming the deficiency of low alignment accuracyReduce mistakesSatellite radio beaconingSpecial data processing applicationsReal time navigationReal-time data

The invention provides a real-time navigation method of a data processing computer system for a distributed POS. The method comprises the steps of acquiring three IMU original data at the same time by the PPS actual calibration and frequency division time synchronizing method; fusing the main IMU data with the GPS data to obtain the main POS real-time navigation result; initially aligning a shaking base through the secondary IMU by the inertia vector quadratic integral based analysis aligning method; performing the transmission aligning of the distributed POS by the multi-stage lever arm compensation based kalman filtering method so as to obtain the real-time navigation result of the secondary IMU and the relative spatial relationship between the main IMU and the secondary IMU. The method achieves the real-time data processing of the distributed POS with one main IMU and two secondary IMUs and is applicable to high-precision distributed inertia measurement, navigation and combined navigation systems.

Owner:BEIHANG UNIV

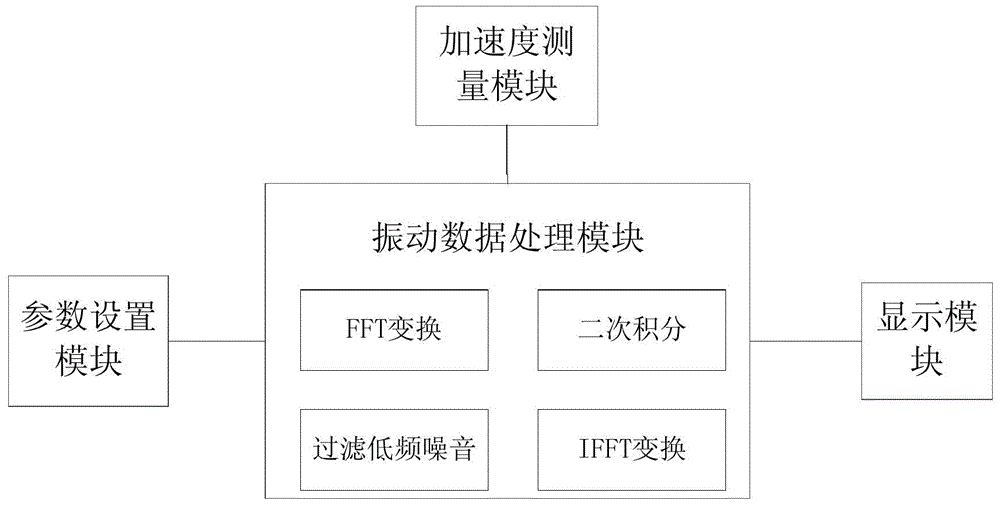

Device and method for measuring dynamic displacement of bridge based on mobile terminal

The invention discloses a device and a method for measuring the dynamic displacement of a bridge based on a mobile terminal. The mobile terminal is integrated with an acceleration sensor. The device comprises a parameter setting module, an acceleration measuring module, a vibration data processing module and a display module. The invention further discloses the measuring method comprising the following steps: the sampling length and the direction of measured acceleration are set; the mobile terminal is fixed to a bridge dynamic displacement monitoring point; an API provided by a mobile terminal operating system is called to access underlying hardware and read a bridge vibration signal acquired by the acceleration sensor; an acceleration time-history signal is obtained according to the bridge vibration signal, FFT transform is performed on the acceleration time-history signal, quadratic integral is carried out in a frequency domain to obtain a frequency domain signal of displacement, low-frequency noise is filtered by use of a low-frequency cutoff algorithm, and IFFT transform is performed on the processed frequency domain signal of displacement to obtain a time-history signal of displacement. The device and the method of the invention have the advantages of simple detection process, low cost, small size, convenient carrying, and no need for adding any hardware.

Owner:SOUTH CHINA UNIV OF TECH

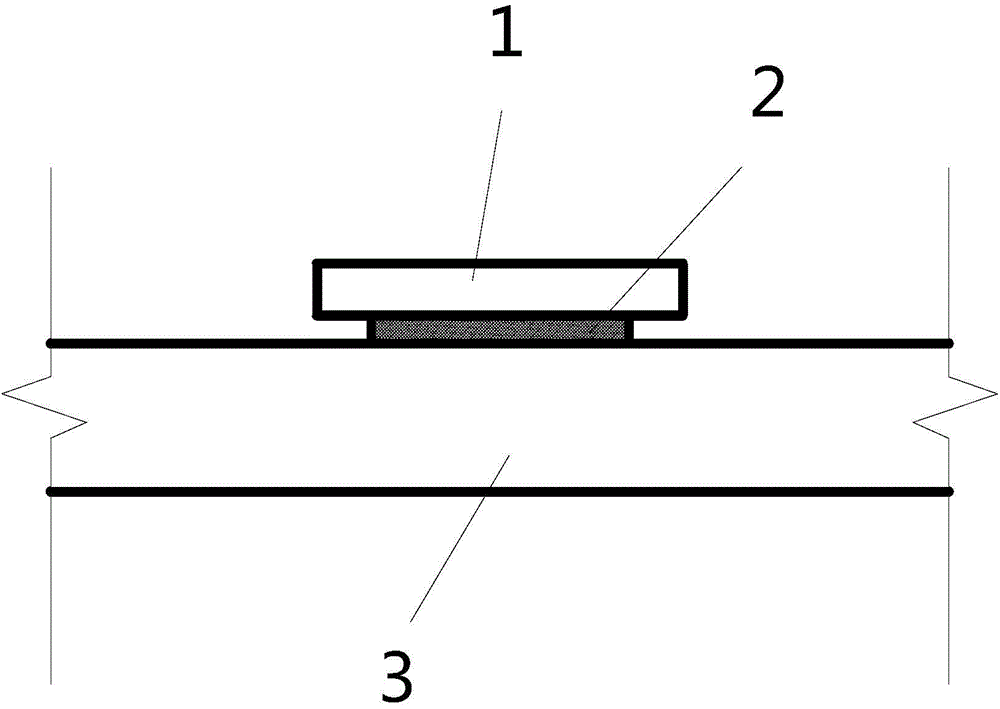

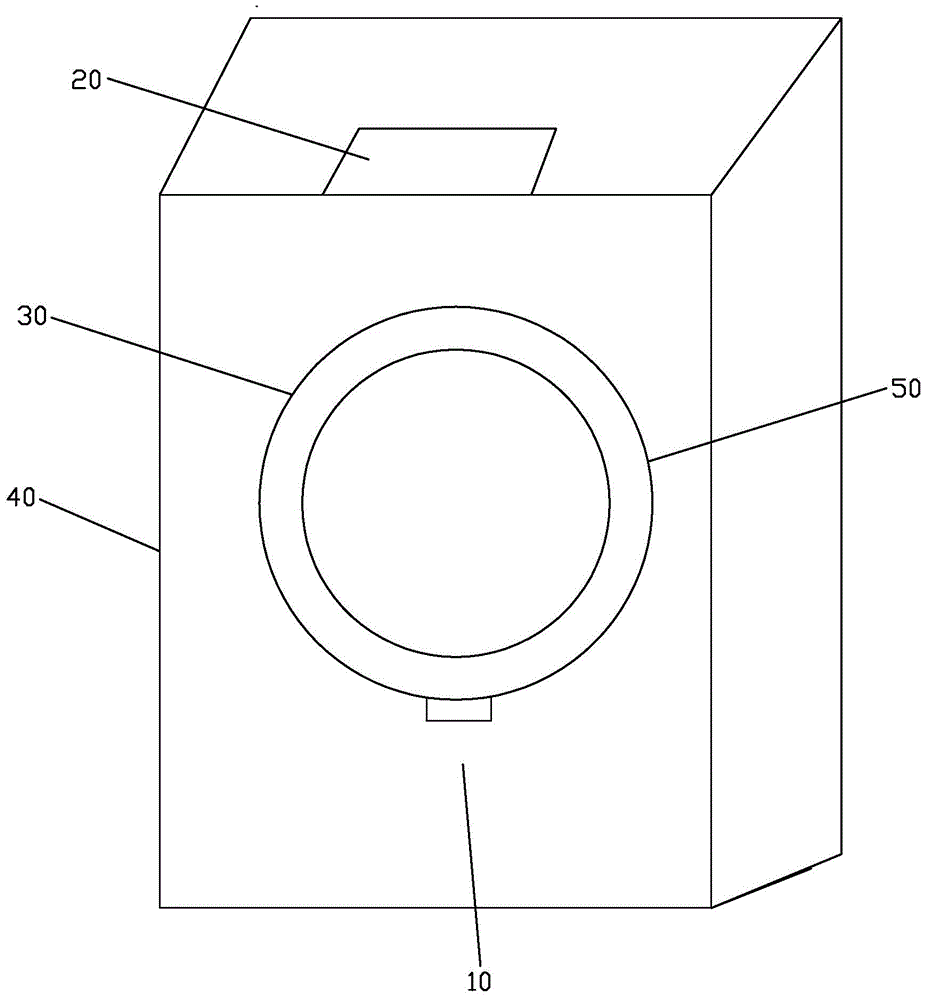

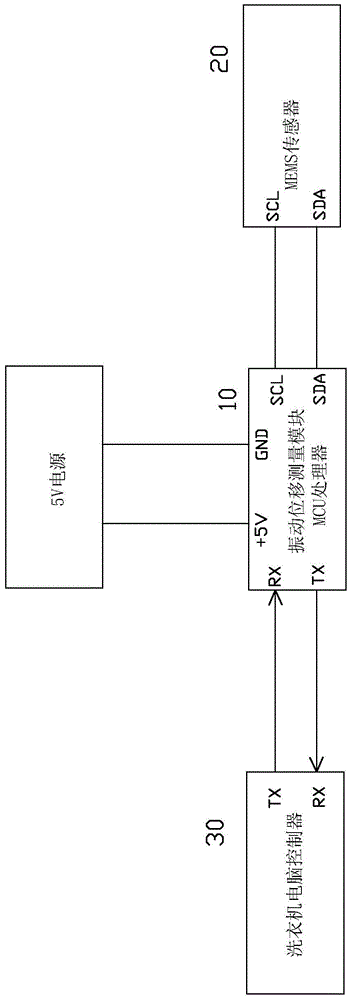

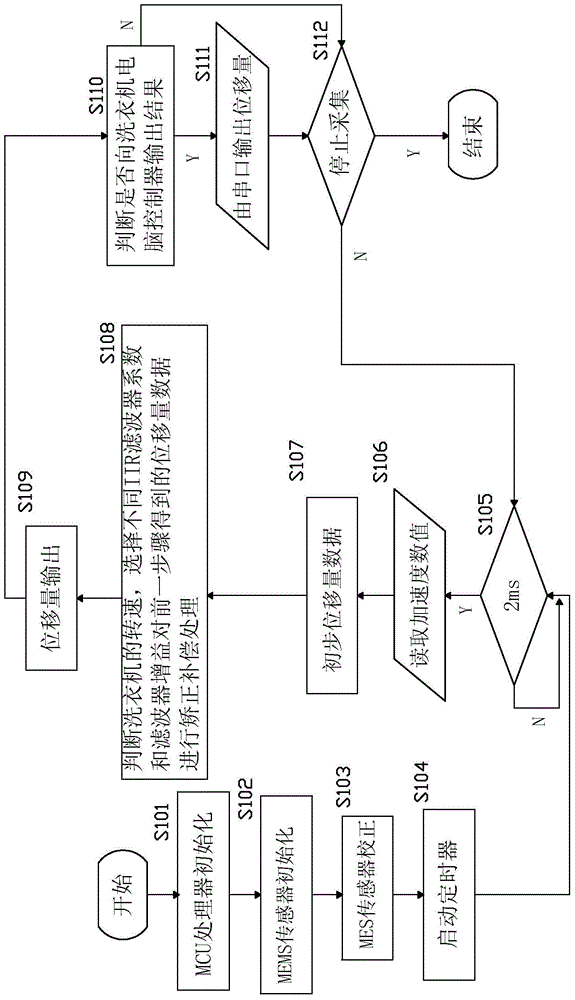

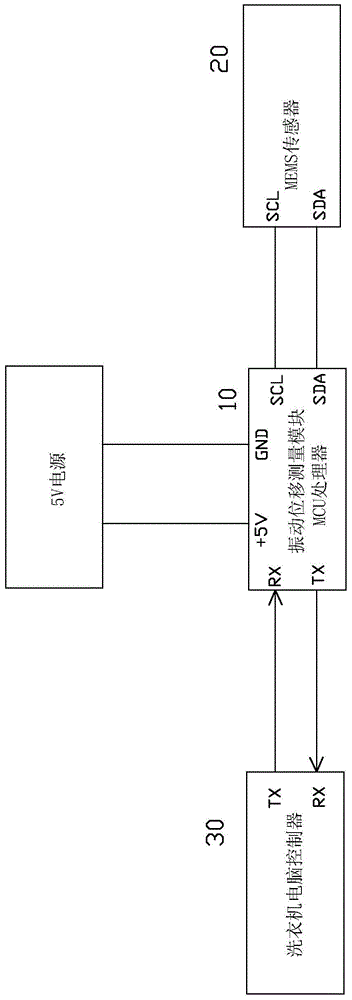

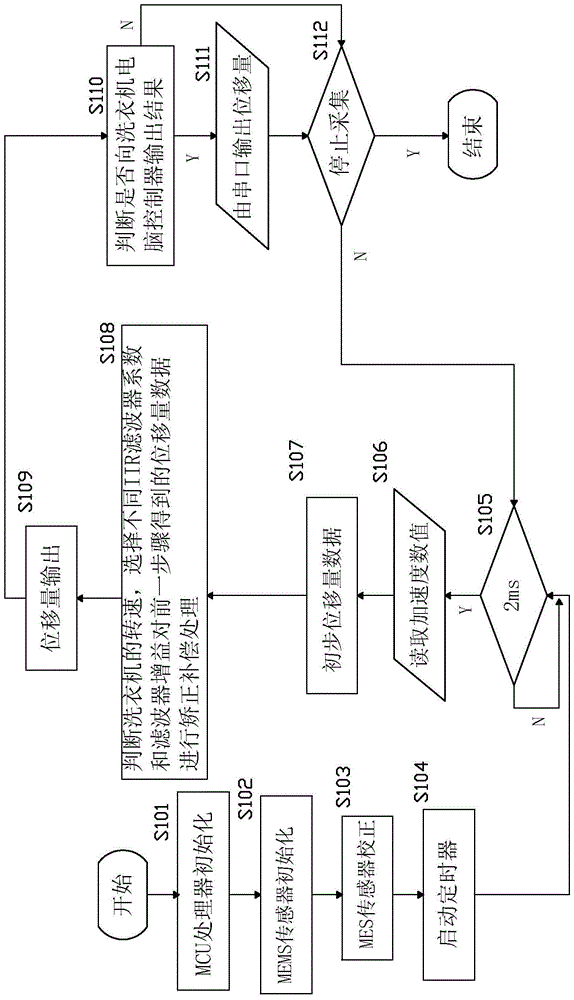

Method for detecting washing machine vibration displacement data based on MEMS sensor

ActiveCN104947371AEliminate vibration interference signalsImprove efficiencyControl devices for washing apparatusTextiles and paperIir filteringMachining vibrations

The invention relates to a method for detecting washing machine vibration displacement data based on an MEMS sensor. The method comprises the steps that triaxial acceleration data of a washing machine external barrel are collected by the MEMS sensor; the triaxial acceleration data are converted into corresponding displacement data through the quadratic integral; before conversion, an IIR filter is adopted for filtering away data with the signal frequency lower than the preset frequency; after conversion, the rotating speed of a washing machine is judged, and different IIR filter coefficients and filter gains are selected based on the rotating speed of the washing machine for carrying out correcting and compensation on the displacement data obtained in the previous step, so that various vibration interference signals existing in the washing machine running process are eliminated, and vibration displacement data output with the high precision is obtained. Vibration displacement data are filtered two times, so that the vibration displacement data with the high precision are obtained, the current vibration displacement data are output to a washing machine computer controller in real time, the rotating speed of a washing machine running motor is controlled, the washing program is optimized, the washing machine working noise is lowered, and the washing efficiency is improved.

Owner:厦门翰普电子有限公司

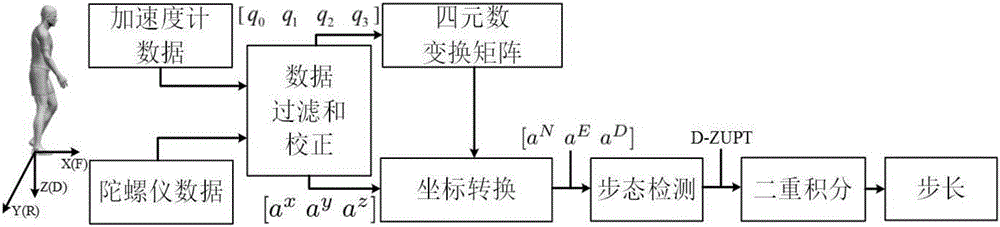

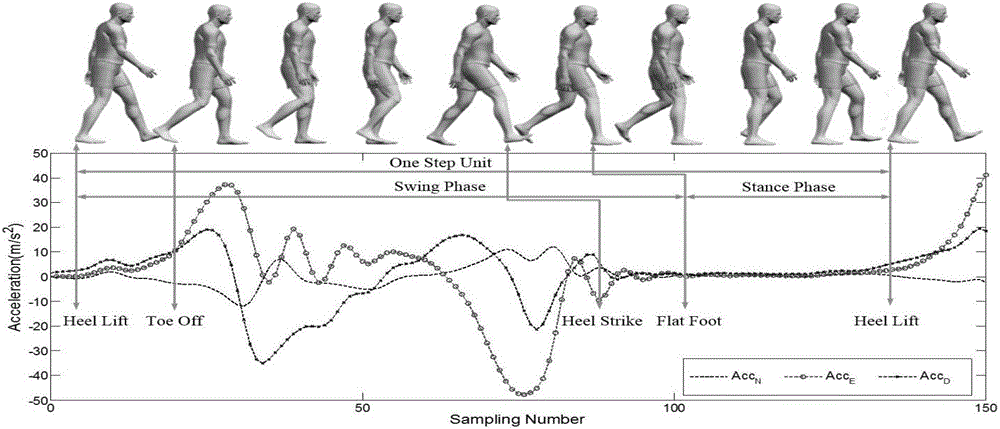

Method for estimating step size of personnel based on inertial sensing

InactiveCN106225801AAvoid error accumulationReduce error accumulationDistance measurementQuaternionComputer science

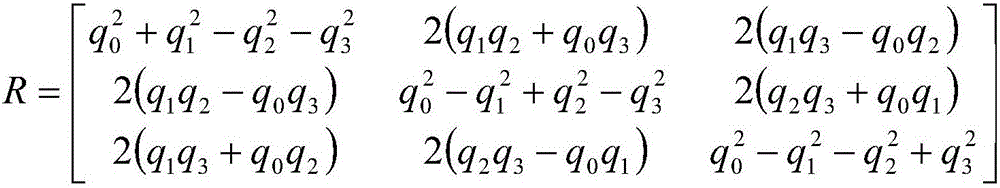

The invention discloses a method for estimating step size of personnel based on inertial sensing. The method comprises the steps of: (1), using a micro electro mechanical system to acquire the movement raw data of an indoor personnel; (2), generating a coordinate transformation matrix by using quaternion; (3), dividing the continuous movement into single steps, and calculating the single step length; and (4) accumulating the total displacement to obtain the length of the whole movement. Compared with the prior art, the invention has the advantages of: 1) the cumulative error caused by the quadratic integral of acceleration is avoided, thereby reducing the cumulative error of step calculation; 2) total displacement calculation by single step length accumulation has good reliability and stability; and 3) the accuracy of zero rate correction is improved, thus to improve the accuracy of the step length calculation.

Owner:TIANJIN UNIV

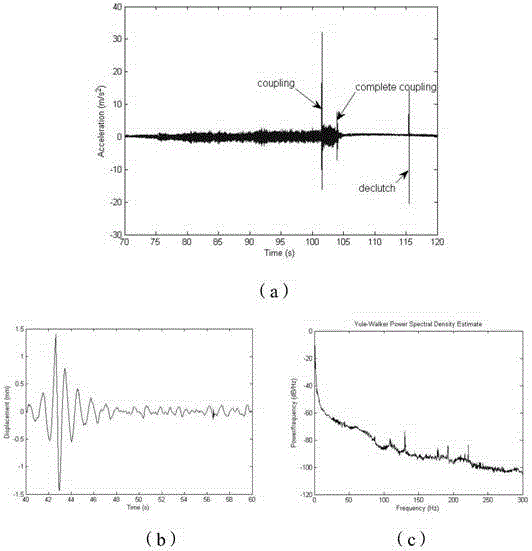

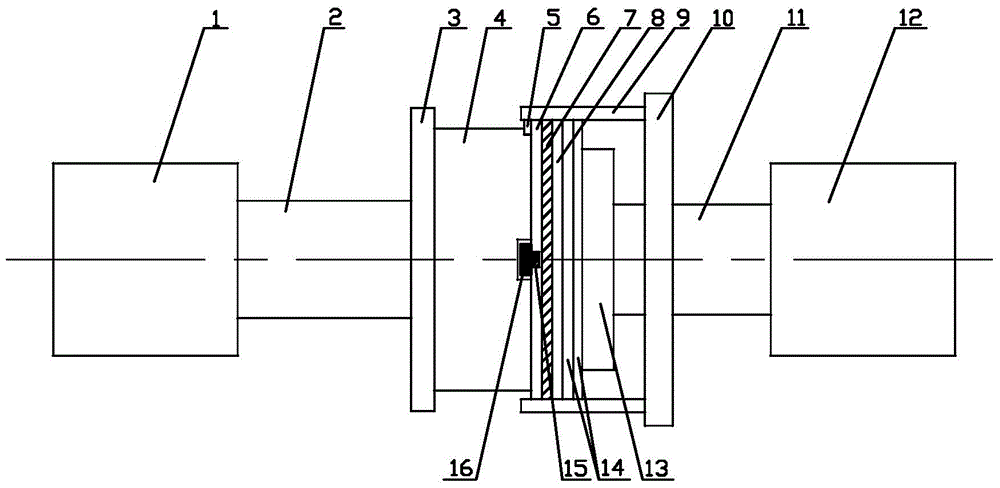

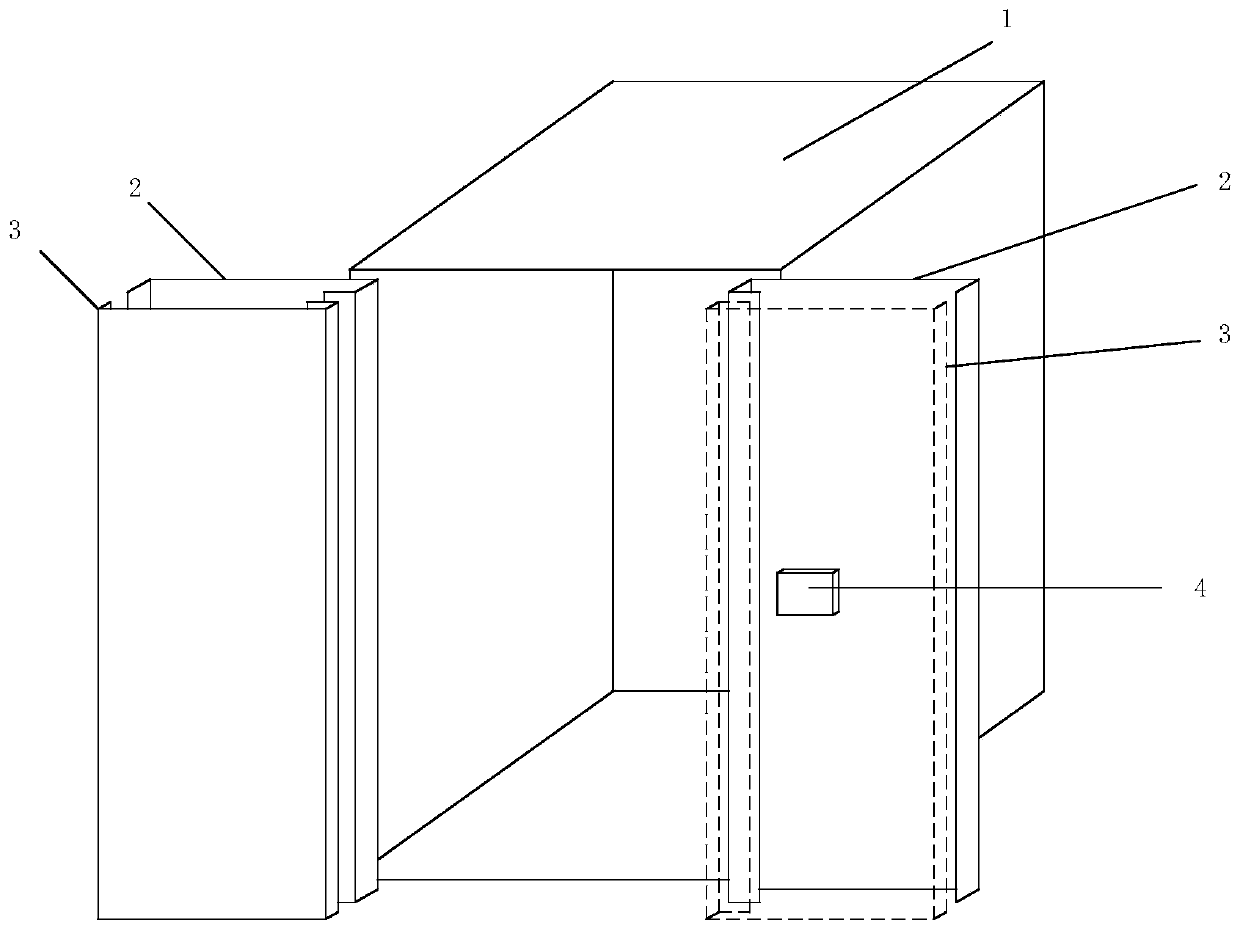

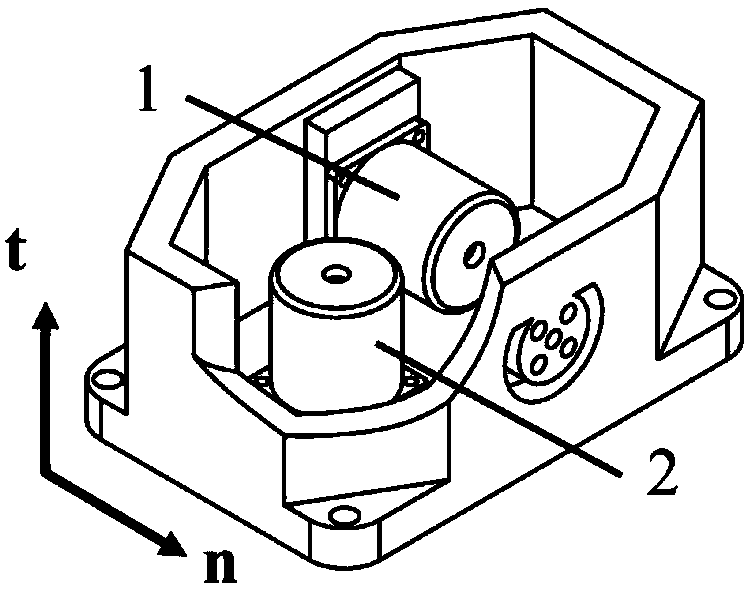

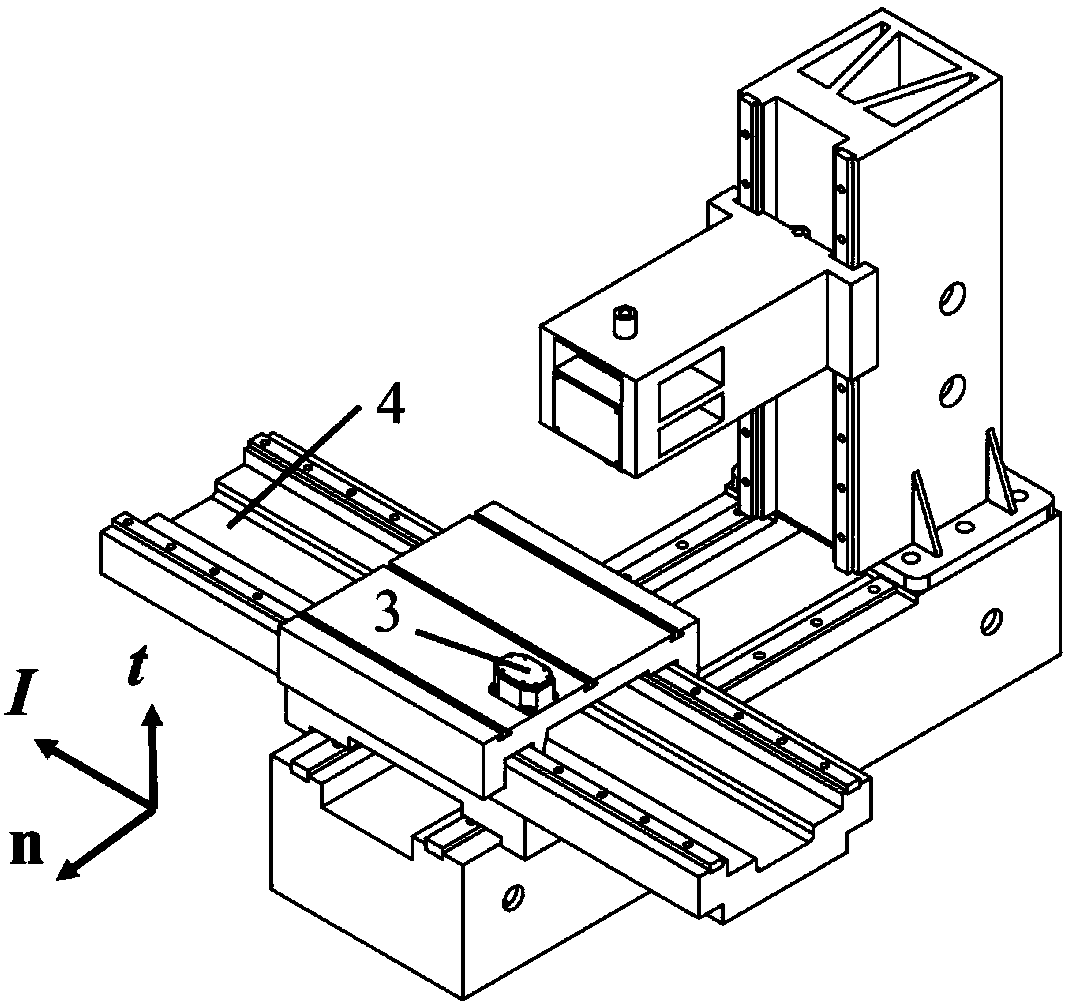

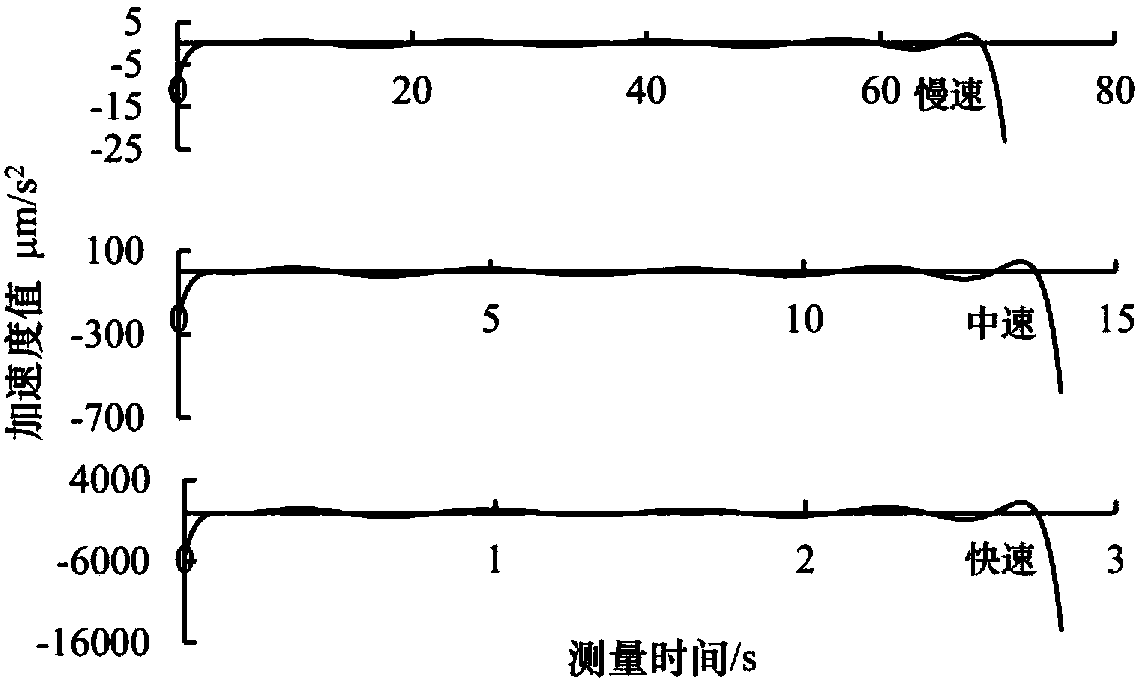

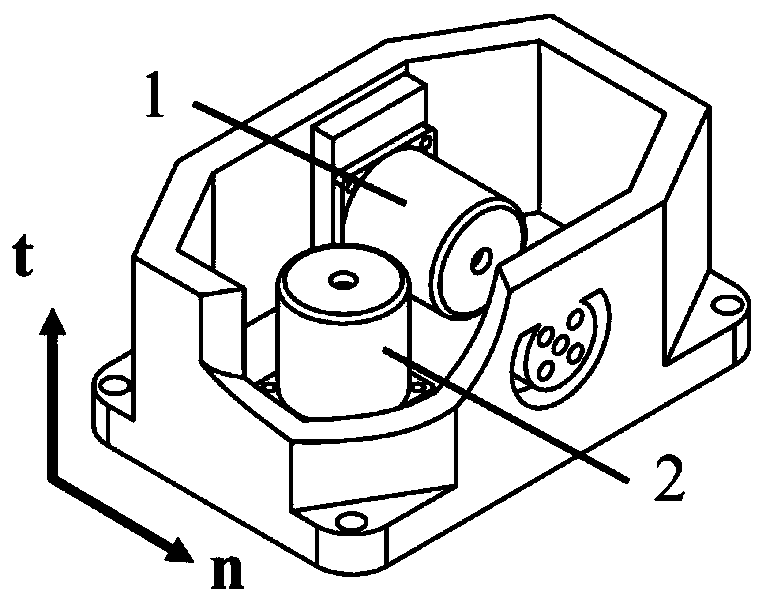

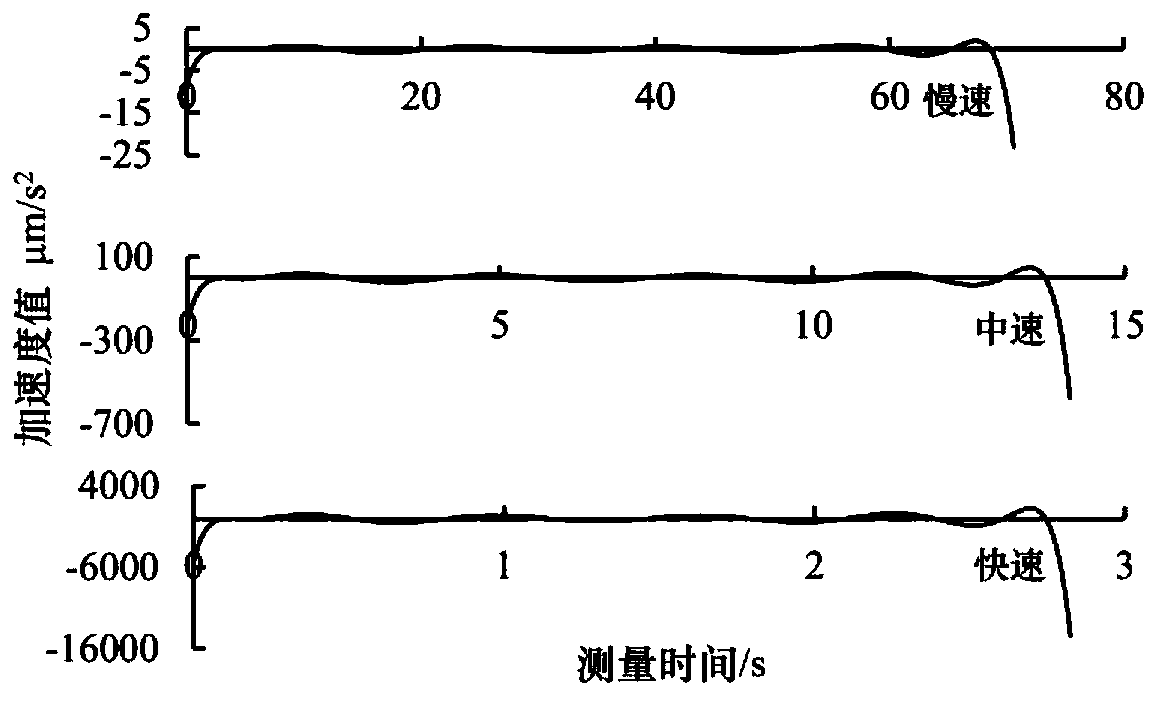

Method for testing thermal-elastic coupled vibration characteristics in friction and sliding process of variable speed friction plate

InactiveCN104931259ASolve the problem that it is difficult to obtain the micro-vibration signal in the process of friction pair frictionSolve the problem of micro-vibration signalVibration measurement in solidsMachine gearing/transmission testingFrequency vectorExperimental testing

The invention belongs to the field of experimental simulation technologies, in particular to a method for testing thermal-elastic coupled vibration characteristics in a friction and sliding process of a variable speed friction plate. The method specifically comprises the steps of testing friction moment characteristics, rotational speed variation characteristics and thermosetting coupling characteristics in the friction and sliding process of a friction element, and then acquiring vibration characteristics. The method can provide theoretical support for the structural strength simulating calculation and optimization design of the friction element, obtains thermal-elastic coupled vibration characteristics of a friction pair during the combination / separation process through a special real-time data processing technology, can remove strong interference signals, can obtain the relation between the moment characteristics and rotational speed variation through accurate circular frequency vector and quadratic integral calculation, further synthesizes results of temperature field analysis and vibration vector spectral analysis, and can obtain the thermal-elastic coupled vibration characteristics. The experimental testing method provided by the invention is simple, practical, and high in precision of test results.

Owner:CHINA NORTH VEHICLE RES INST

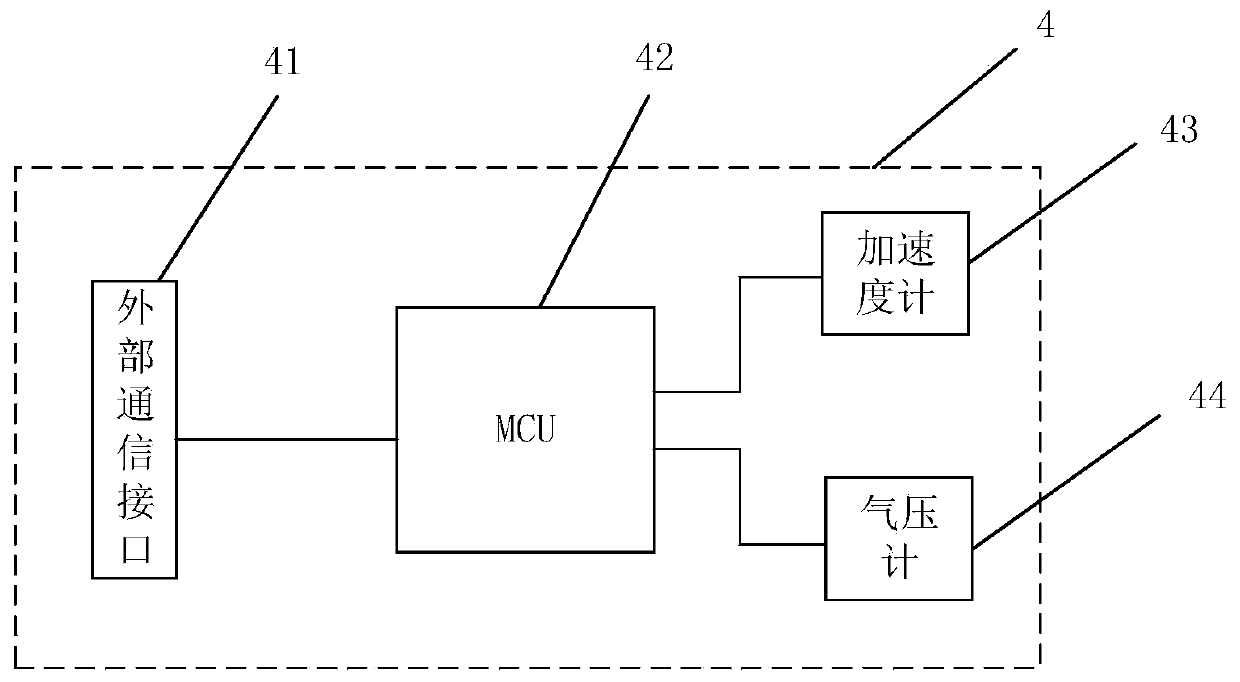

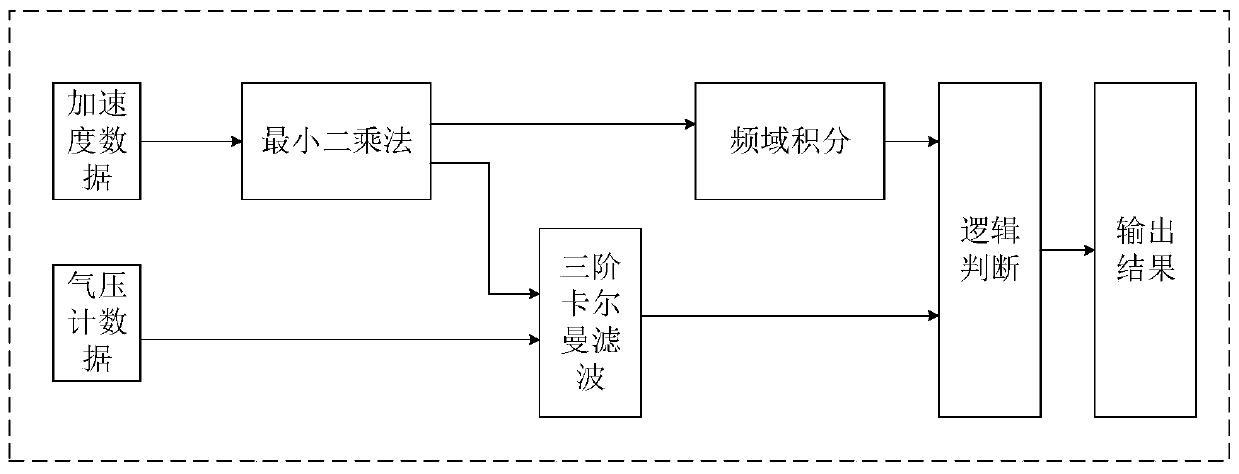

Intelligent detection device for detecting motion state of lift car

The invention provides an intelligent detection device for detecting the motion state of a lift car. The device is installed on the outer side of a lift car door, and the accelerated speed and the airpressure value of a certain position of the lift car door are collected through an accelerometer and an air pressure meter and transmitted to a MCU to be subjected to data processing. After the air pressure value of the accelerometer is corrected through the MCU, third-order Kalman filtering is conducted according to the accelerated speed of the vertical direction of the accelerometer and the airpressure value read by the air pressure meter, the height, the speed and the accelerated speed of the current lift car are obtained, and the rising, falling and stopping states of the lift car are judged; and after the accelerated speed of the horizontal direction of the accelerometer is corrected and subjected to Kalman filtering, the speed and the displacement of the lift car door are obtainedthrough a frequency-domain quadratic integral method, and the door opening, the door closing, the door opening in-place and door closing in-place states of the lift car door are judged. According to the device, the installing position is hidden, and the precision of the obtained detection results is high.

Owner:ZHEJIANG UNIV

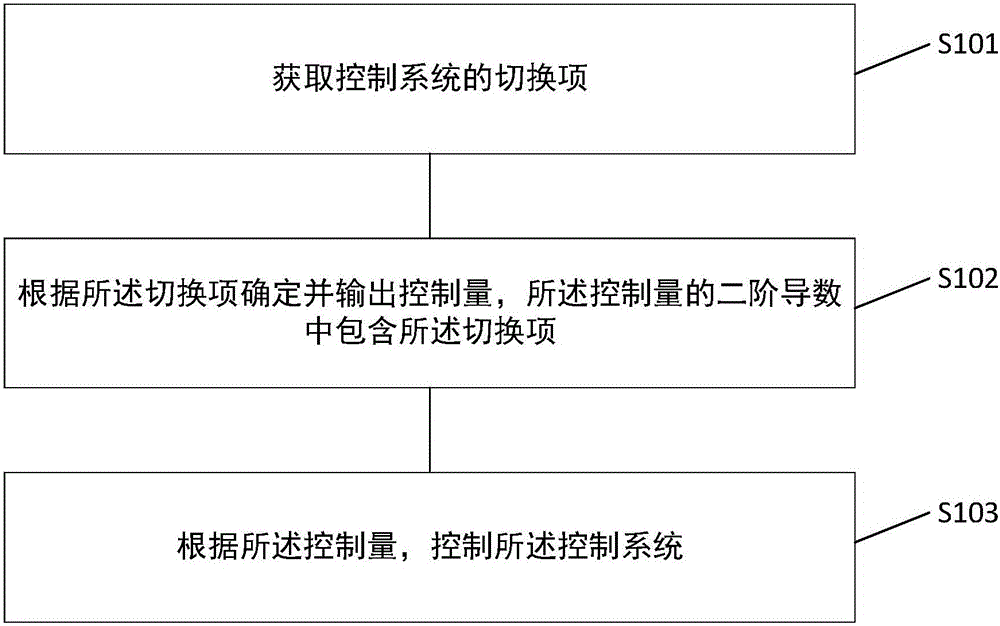

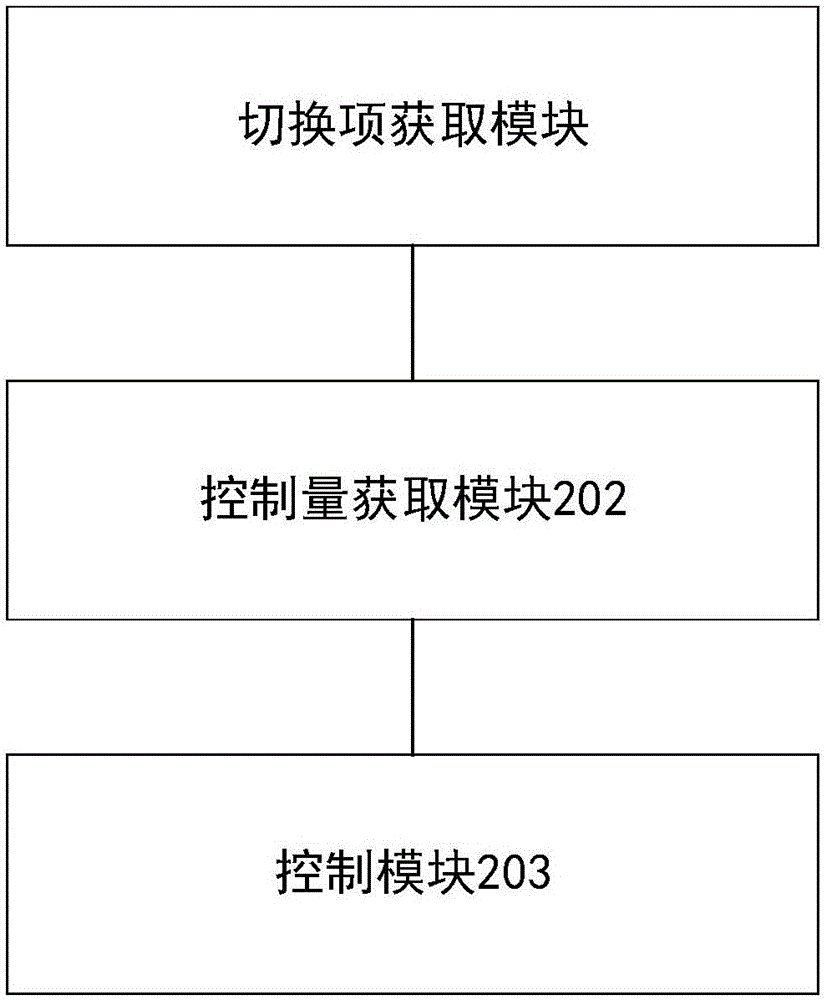

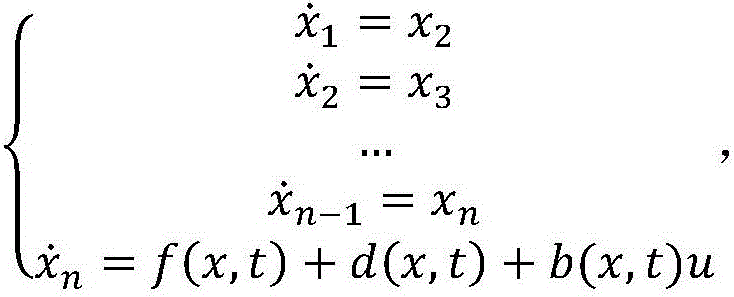

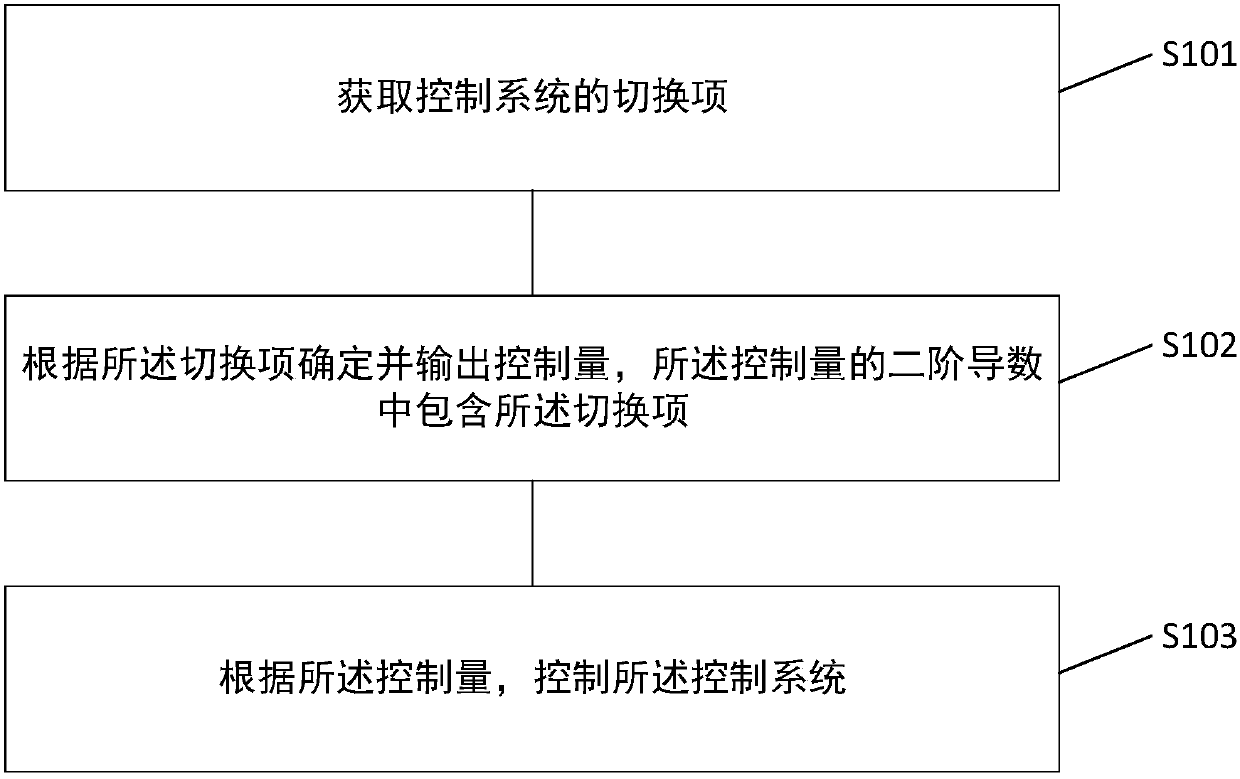

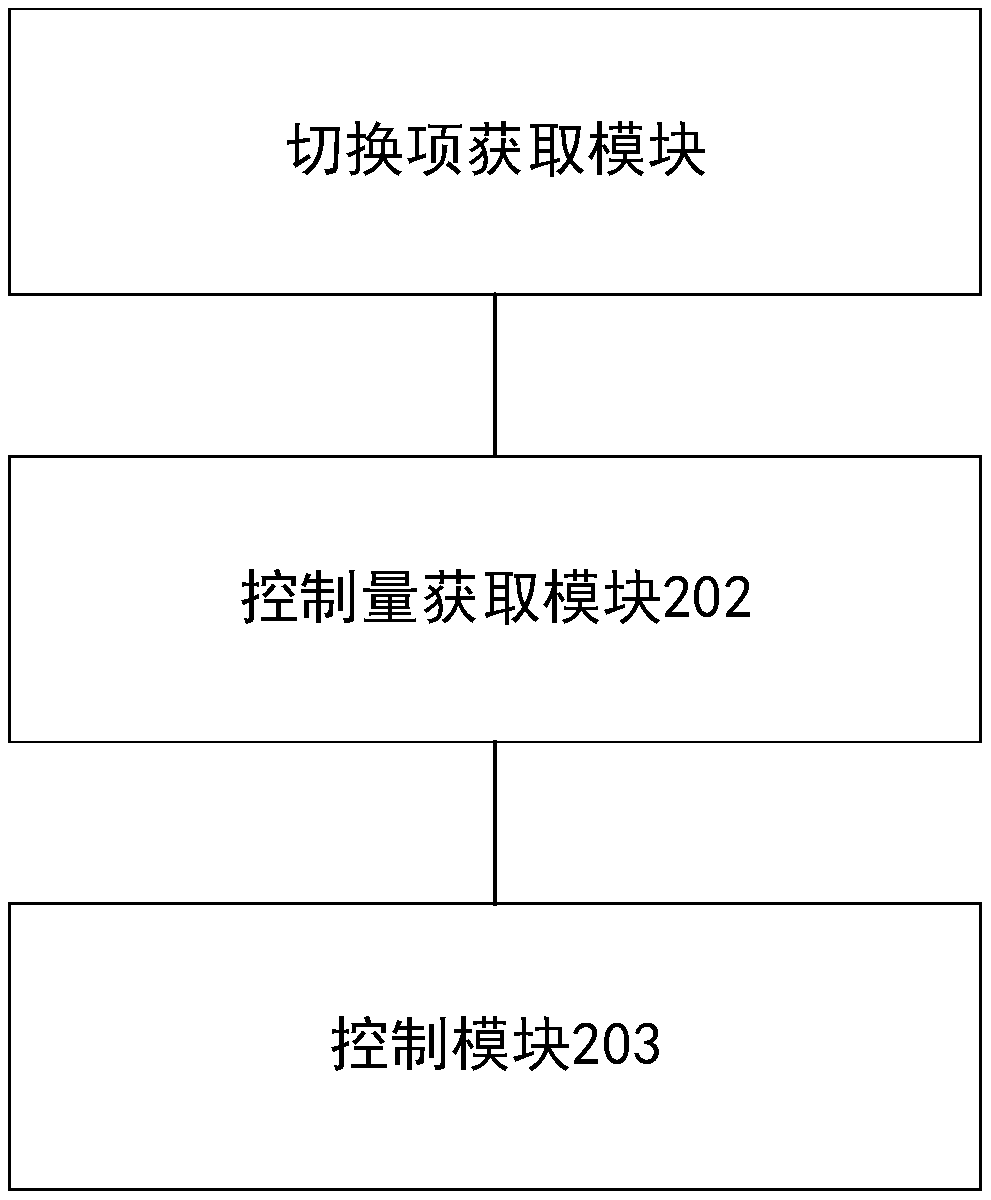

Sliding mode control method and apparatus

InactiveCN105843078AResolve continuitySolve the disadvantage of discontinuitySimulator controlControl systemQuadratic integral

The invention provides a sliding mode control method and apparatus. The method comprises: a switching item of a control system is obtained; according to the switching item, a control quantity is determined and outputted, wherein a second derivative of the control quantity includes the switching item; and according to the control quantity, the control system is controlled. According to the method, because the switching item is included by the second derivative of the control quantity, the control quantity is a quadratic integral of the switching item and the changing rate of the control quantity is a once integral of the switching item; and the switching item becomes continuous after integration and thus the control quantity and the control quantity changing rate become continuous. Therefore, the sliding mode control method is suitable for control of the process without control quantity and derivative mutation; a defect that the traditional sliding mode control quantity and the derivative are not continuous can be overcome; and a problem that buffeting exists in sliding mode control under the circumstance that the control system is in a non-linear mode and the model is not accurate can be solved.

Owner:HARBIN ENG UNIV

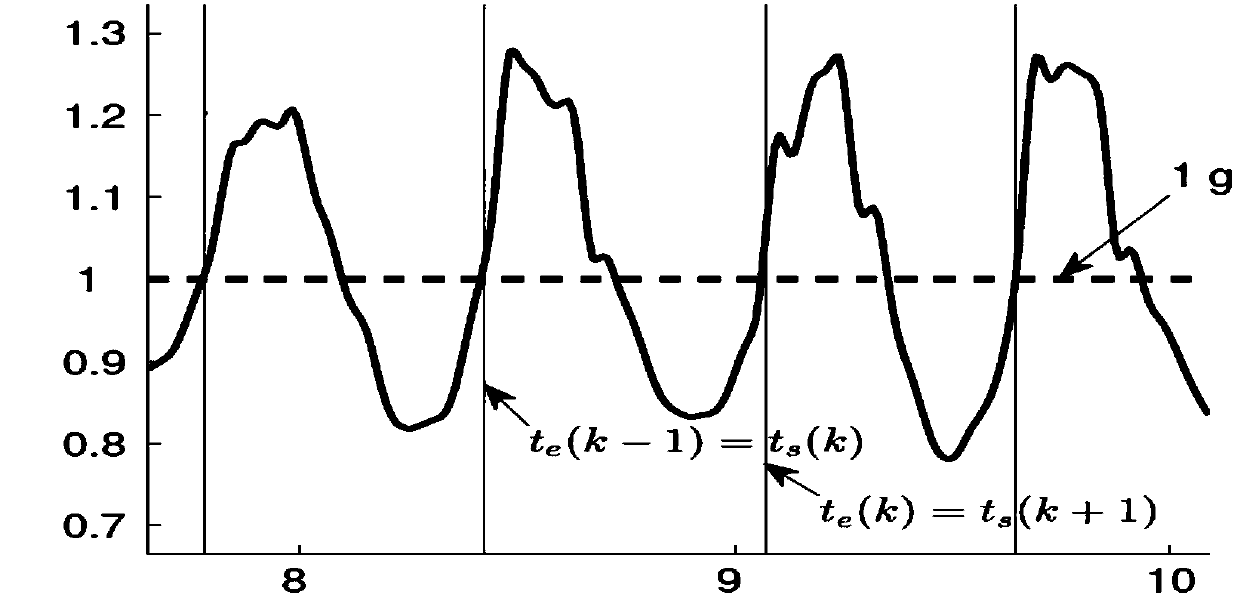

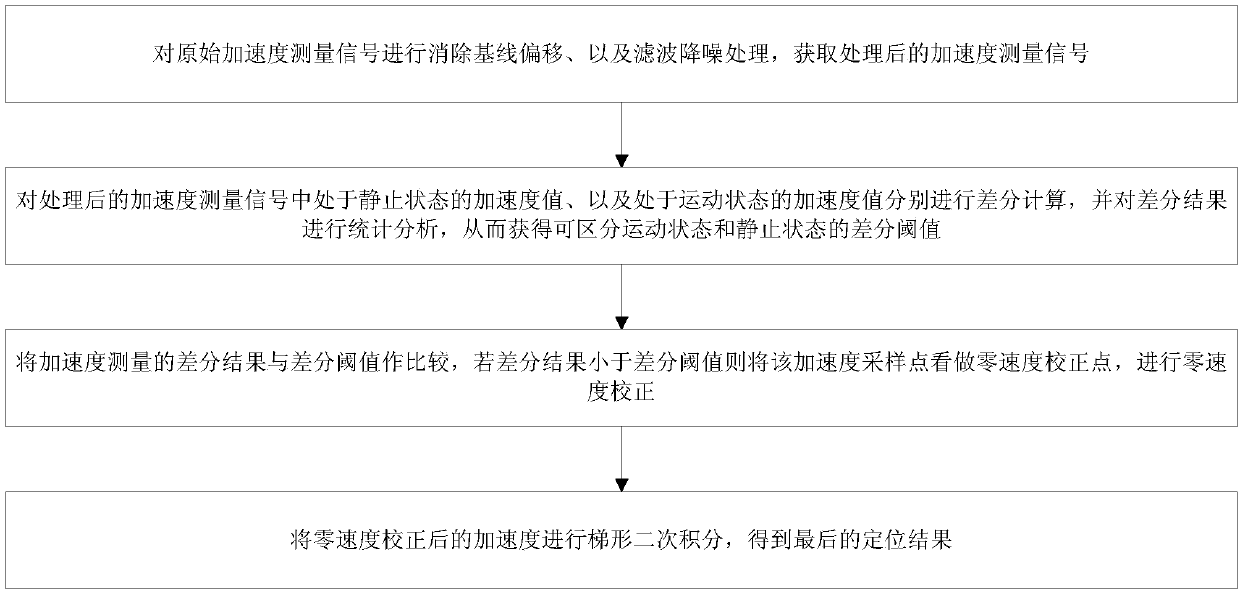

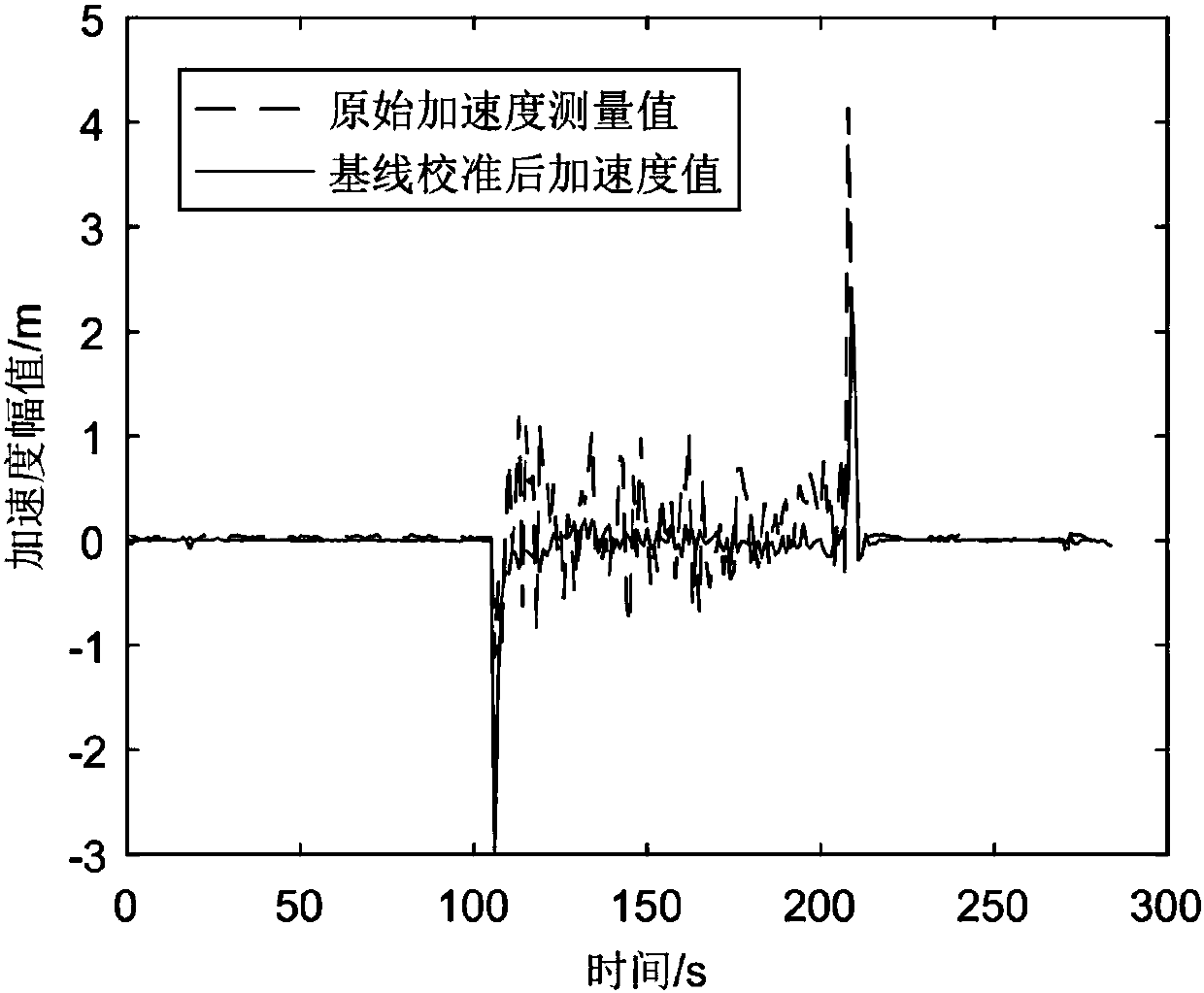

Zero-speed correcting and locating method based on difference statistics

InactiveCN108519105APrecise positioningImprove indoor positioning accuracyMeasurement devicesStatistical analysisNoise reduction

The invention discloses a zero-speed correcting and locating method based on difference statistics. The zero-speed correcting and locating method comprises the following steps: performing base line shift elimination and smoothing and noise reduction treatment on original acceleration measurement signals to obtain treated acceleration measurement signals; respectively performing difference calculation on static-state acceleration magnitudes and motion-state acceleration magnitudes in the treated acceleration measurement signals and performing statistic analysis on a difference result to obtaina difference threshold value capable of distinguishing a dynamic state and a static state; comparing the acceleration measurement difference result with the difference threshold valve and utilizing anacceleration sampling point as a zero-speed correcting point to perform zero-speed correction if the difference result is smaller than the difference threshold value; performing trapezoid quadratic integral on the zero-speed corrected acceleration to obtain a final locating result. The zero-speed correcting and locating method disclosed by the invention can find the zero-speed correcting point more accurately, so that inertial errors are effectively controlled; thus, the zero-speed correcting and locating method can be widely applied to varieties of service based on positions.

Owner:TIANJIN UNIV

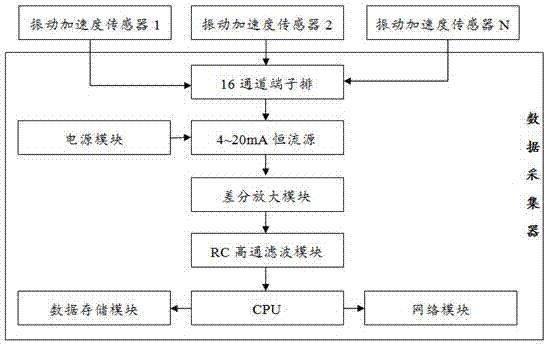

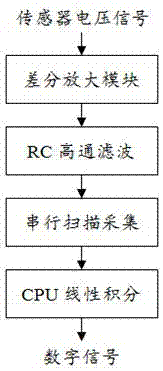

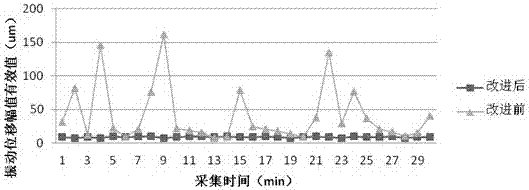

Data collection and signal processing method and data collector

InactiveCN107883996AAvoid Cumulative ErrorsImprove accuracy and repeatabilitySubsonic/sonic/ultrasonic wave measurementData collectorLinear operation

The present invention discloses a data collection and signal processing method and a data collector. According to the method, after collected original signals are subjected to denoising, and the signals are subjected to quadratic linear integral operation to obtain an integral value, namely a signal final processing result; and the original signals are acceleration signals, and the integral valueobtained through the quadratic linear integral operation is a displacement amplitude. The linear integral operation is employed to perform processing of signal data to obtain the displacement amplitude, and therefore, accumulative errors caused by traditional integration can be effectively avoided.

Owner:NANJING GUODIAN ENVIRONMENTAL PROTECTION TECH

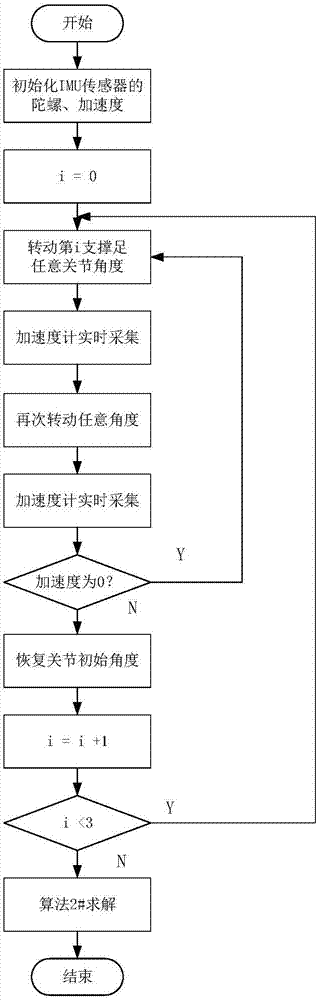

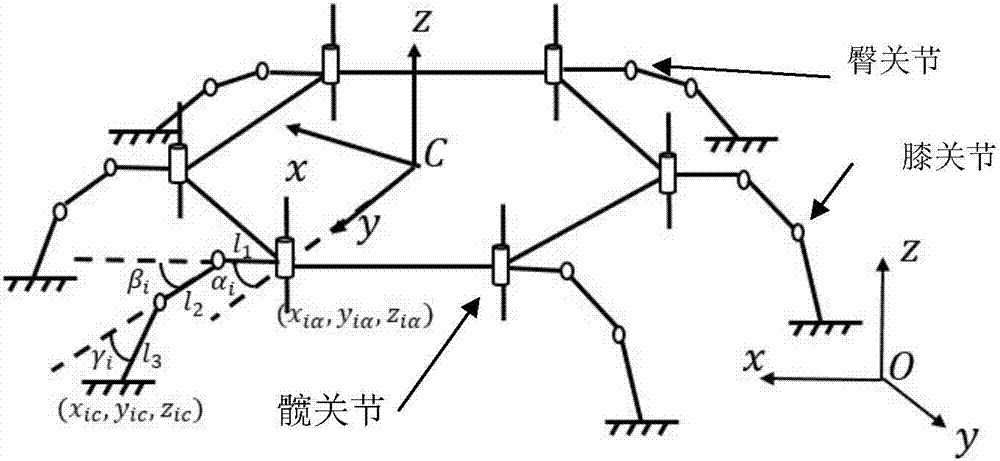

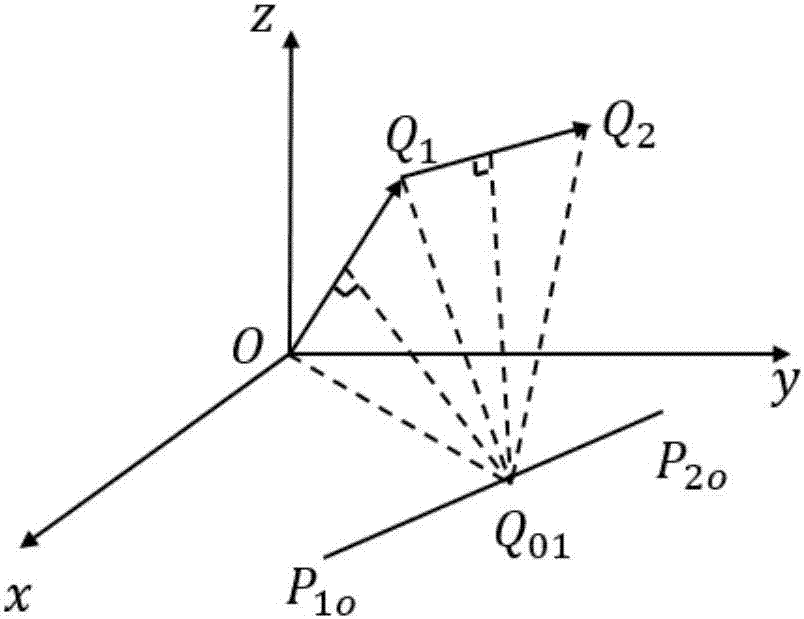

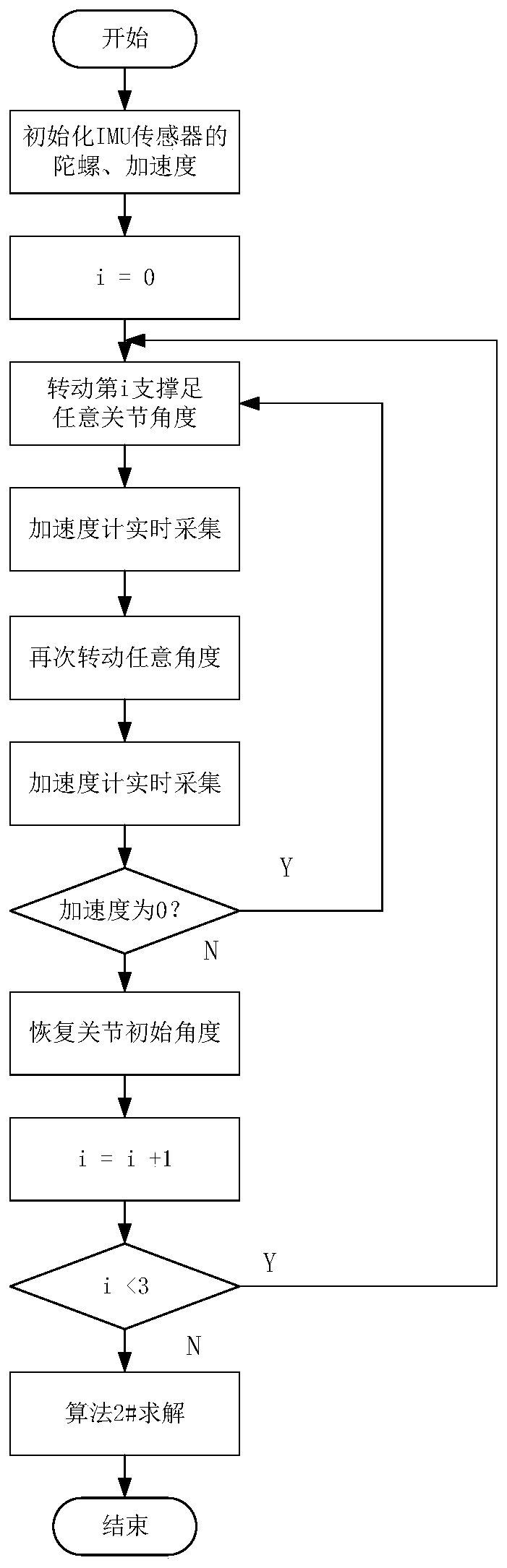

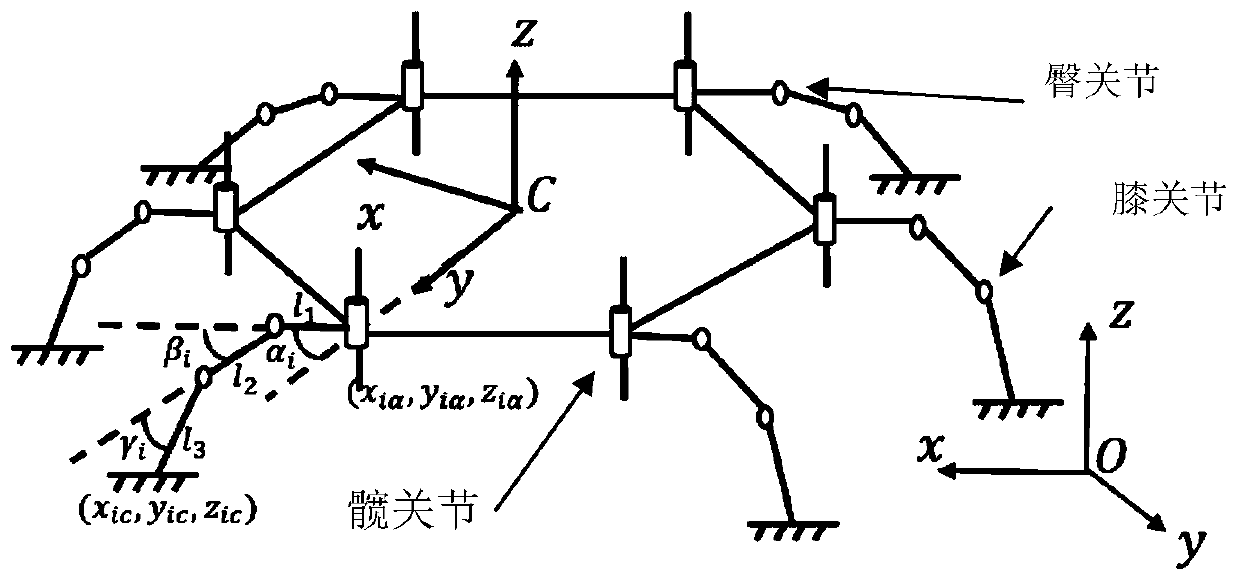

Body gravity center displacement correction-based six-foot robot joint angle calibration method

InactiveCN107214698AEnsure coordinationGuaranteed accuracyProgramme-controlled manipulatorAdaptive controlAngular degreesDecision taking

The invention provides a body gravity center displacement correction-based six-foot robot joint angle calibration method. The method comprises the following steps: driving a robot to support the ground with any three feet, and keeping the other three feet uplifted and not in contact with the ground all the time; selecting one of the supporting feet, and driving a certain joint on the foot to rotate an angle, thus enabling the sole to slide and the other two soles to not slide relative to the ground; and by building a function relation between the angle of the joint and a body gravity center moving track, measuring a three-degree-of-freedom acceleration through a body IMU (Inertial Measurement Unit), calculating a relative moving track of a body through quadratic integral, and calculating coordinates of the tail end of the supporting foot relative to the body according to a multi-foot moving robot kinematic model, thus correcting angles of all joints of the supporting foot. The calibration method provided by the invention can quickly and accurately complete correction of the angles of the joints of a multi-foot moving robot, so as to guarantee multi-foot coordinating motion of the robot and the precision of the moving track; and the calibration method also can be used for checking faults of the foot joints of the robot to provide a basis for a robot motion decision.

Owner:SHANGHAI JIAO TONG UNIV

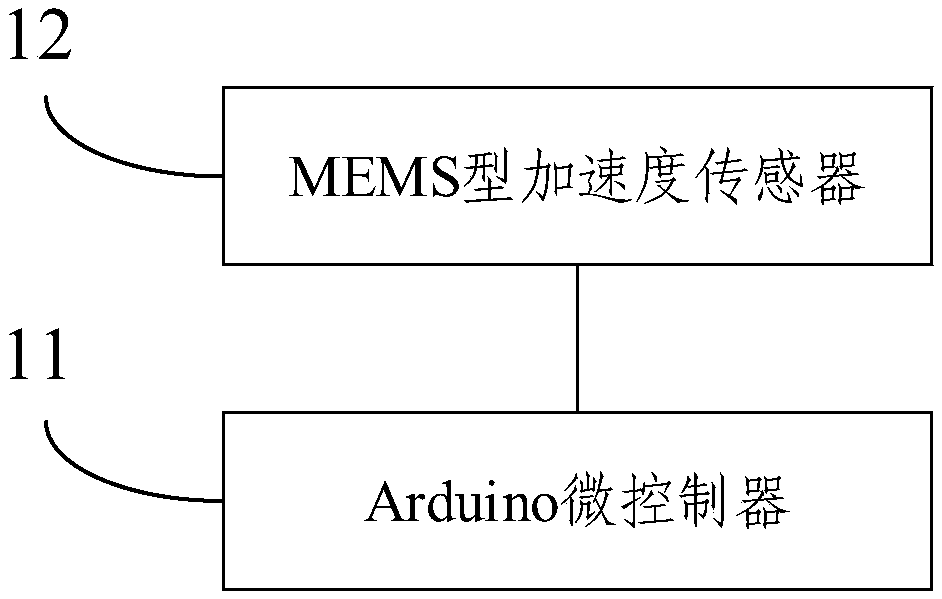

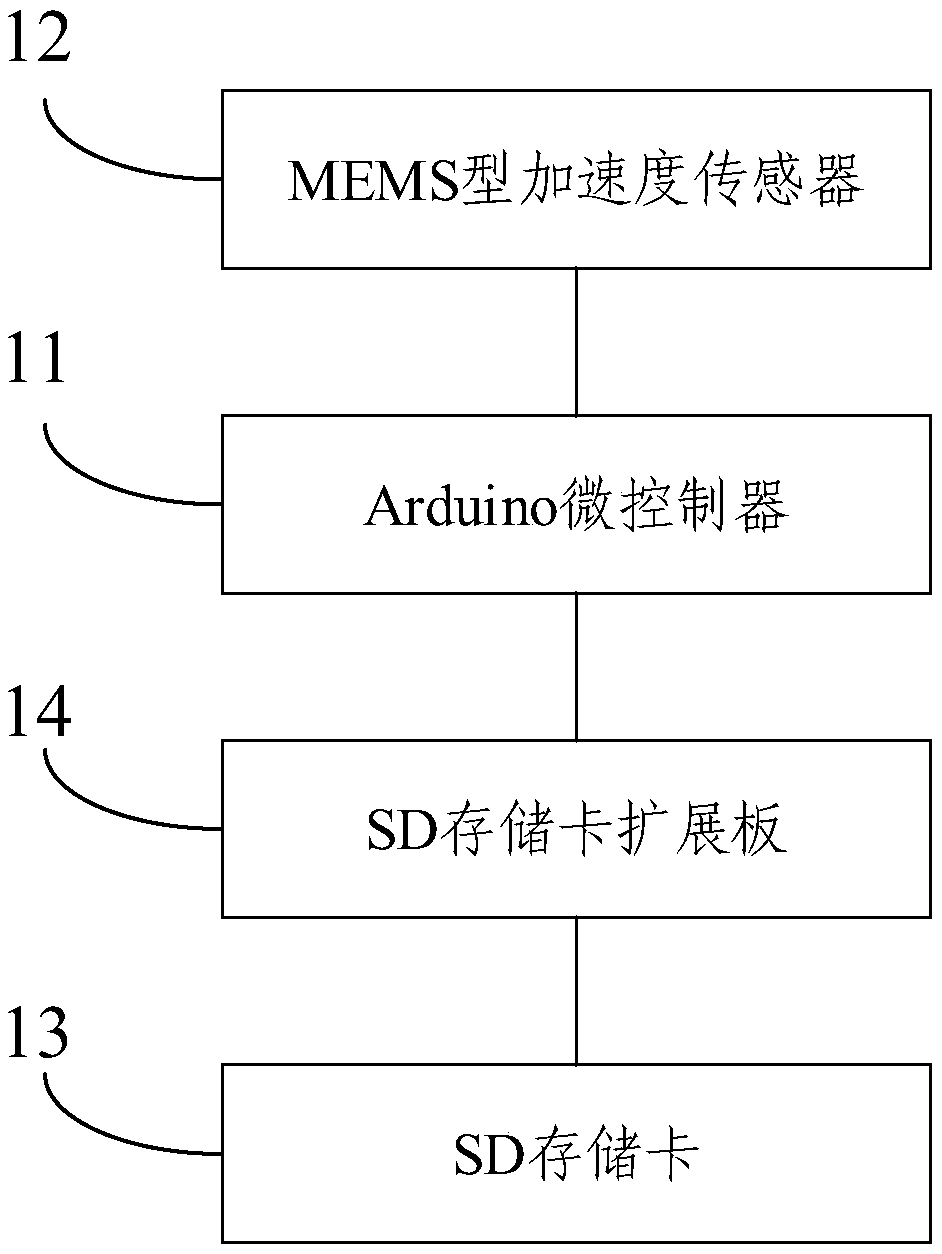

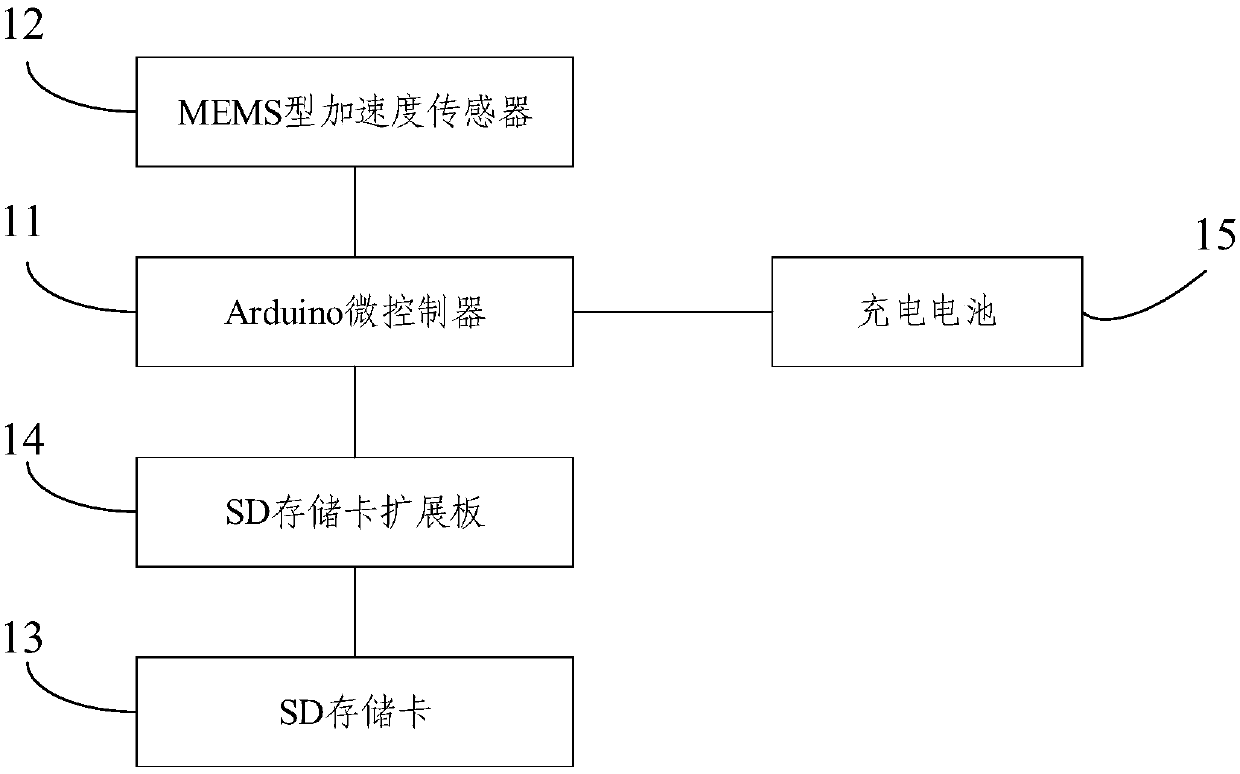

Arduino-based dynamic displacement real-time collection system and method

PendingCN109099828AEasy to moveSolve the problem that real-time acquisition of displacement cannot be realizedSubsonic/sonic/ultrasonic wave measurementUsing electrical meansArduino microcontrollerStructural dynamics

The embodiment of the invention provides an Arduino-based dynamic displacement real-time collection system and method. The system comprises an Arduino microcontroller, an MEMS (Micro Electro Mechanical System) acceleration sensor, a safety data SD (Secure Digital) memory card and an SD memory card expansion board, wherein the MEMS acceleration sensor acquires an acceleration of a to-be-measured target; the Arduino microcontroller determines a displacement of the to-be-measured target according to the acceleration of the to-be-measured target and a built-in preset displacement reconfiguration algorithm; and the displacement of the to-be-measured target is stored through the SD memory card and the SD memory card expansion board. The displacement is reconfigured through the acceleration by use of the preset displacement reconfiguration algorithm, the quadratic integral of the acceleration is not needed, the displacement of the to-be-measured target can be determined more conveniently andrapidly without depending on any initial condition, boundary condition and structural dynamic characteristic. Meanwhile, the displacement of the to-be-measured target is stored through the SD memory card and the SD memory card expansion board, thus the problem that the displacement cannot be stored in an offline manner by an existing system is solved.

Owner:BEIJING MUNICIPAL INST OF LABOUR PROTECTION

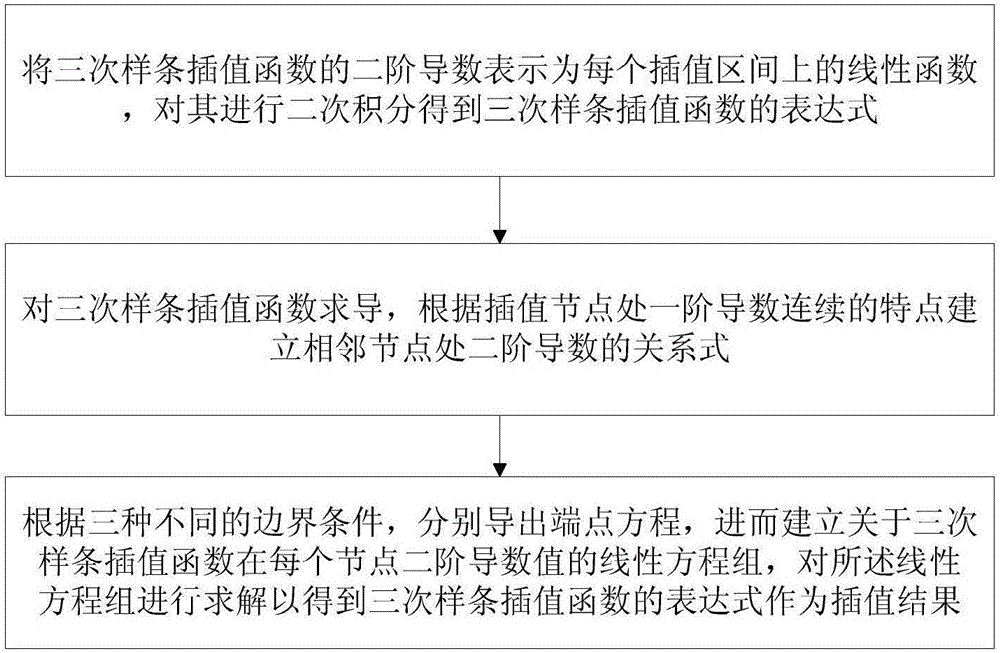

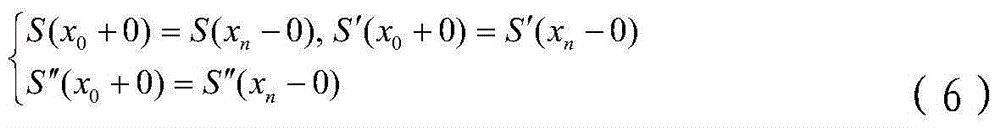

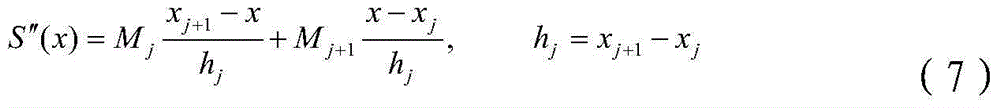

Method of determining boundary of drag acceleration corridor of glide vehicle

InactiveCN105022858ASolve the problem that can only be calculated point by point by numerical calculationSpecial data processing applicationsComputer scienceQuadratic integral

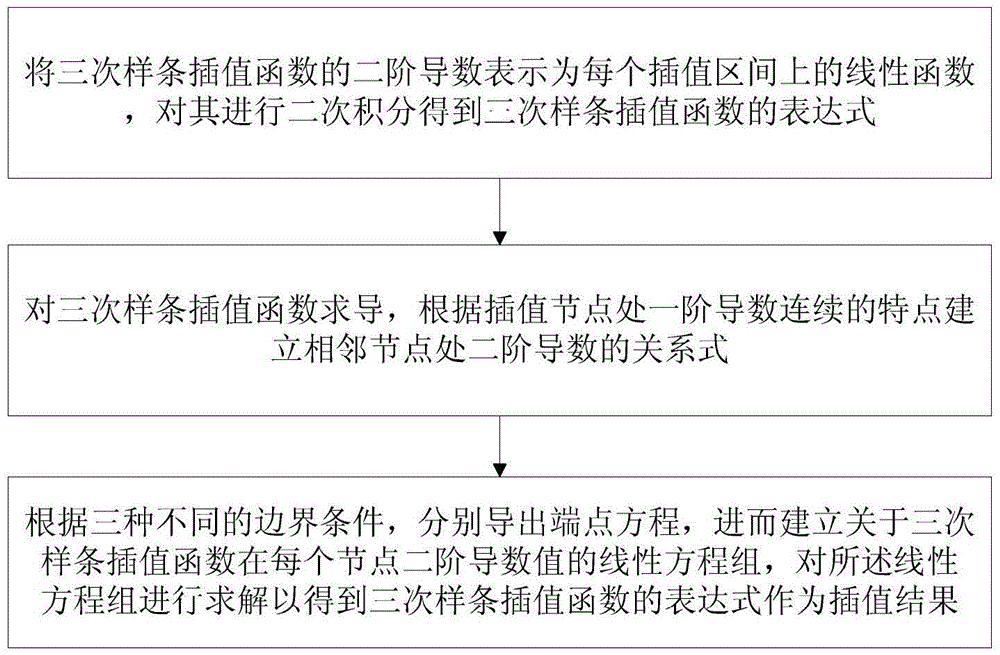

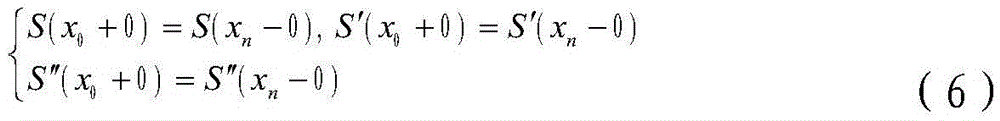

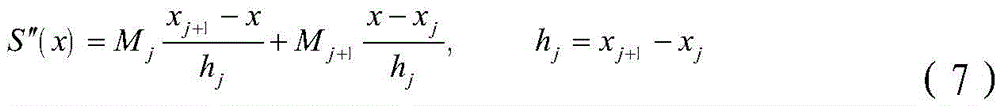

The invention discloses a method of determining a boundary of a drag acceleration corridor of a glide vehicle. The method comprises the following steps: expressing a second derivative S'' (x) of a cubic spline interpolation function S (x) as a linear function on each interpolation interval, and performing quadratic integral on the second derivative S'' (x) to obtain an expression of the cubic spline interpolation function S (x); taking the derivative of the cubic spline interpolation function S (x), and establishing a relation of a second derivative at the adjacent nodes according to the characteristic that a first derivative is continuous at an interpolation node; respectively deriving endpoint equations according to three different boundary conditions, so as to establish a system of linear equations for the cubic spline interpolation function S (x) at each node second derivative value Mj (j=0,1, to n), solving the system of linear equations to obtain the expression of the cubic spline interpolation function S (x) as the interpolation result.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST

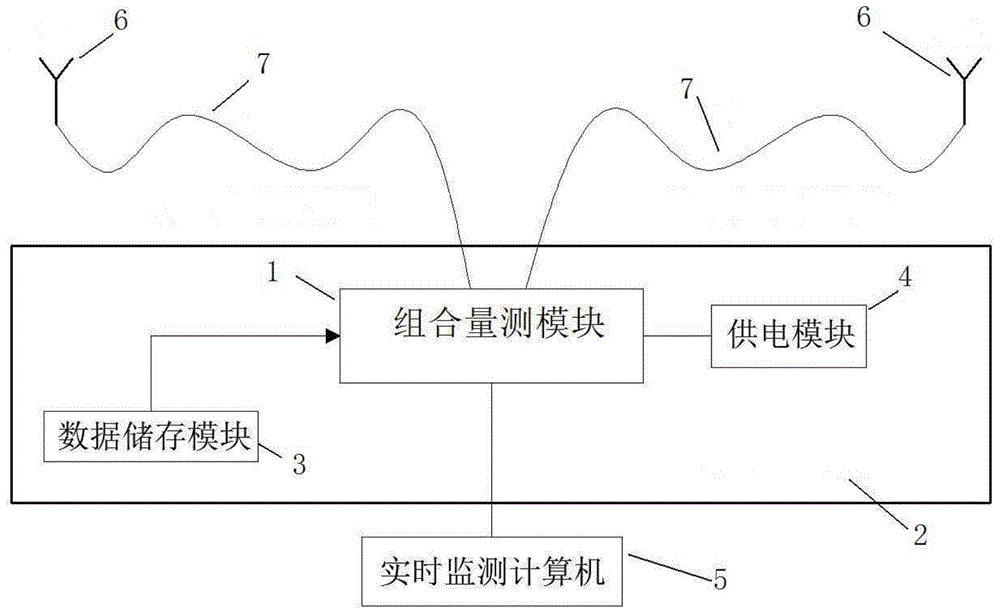

Movement actual measurement method and system of jacket platform water entering process

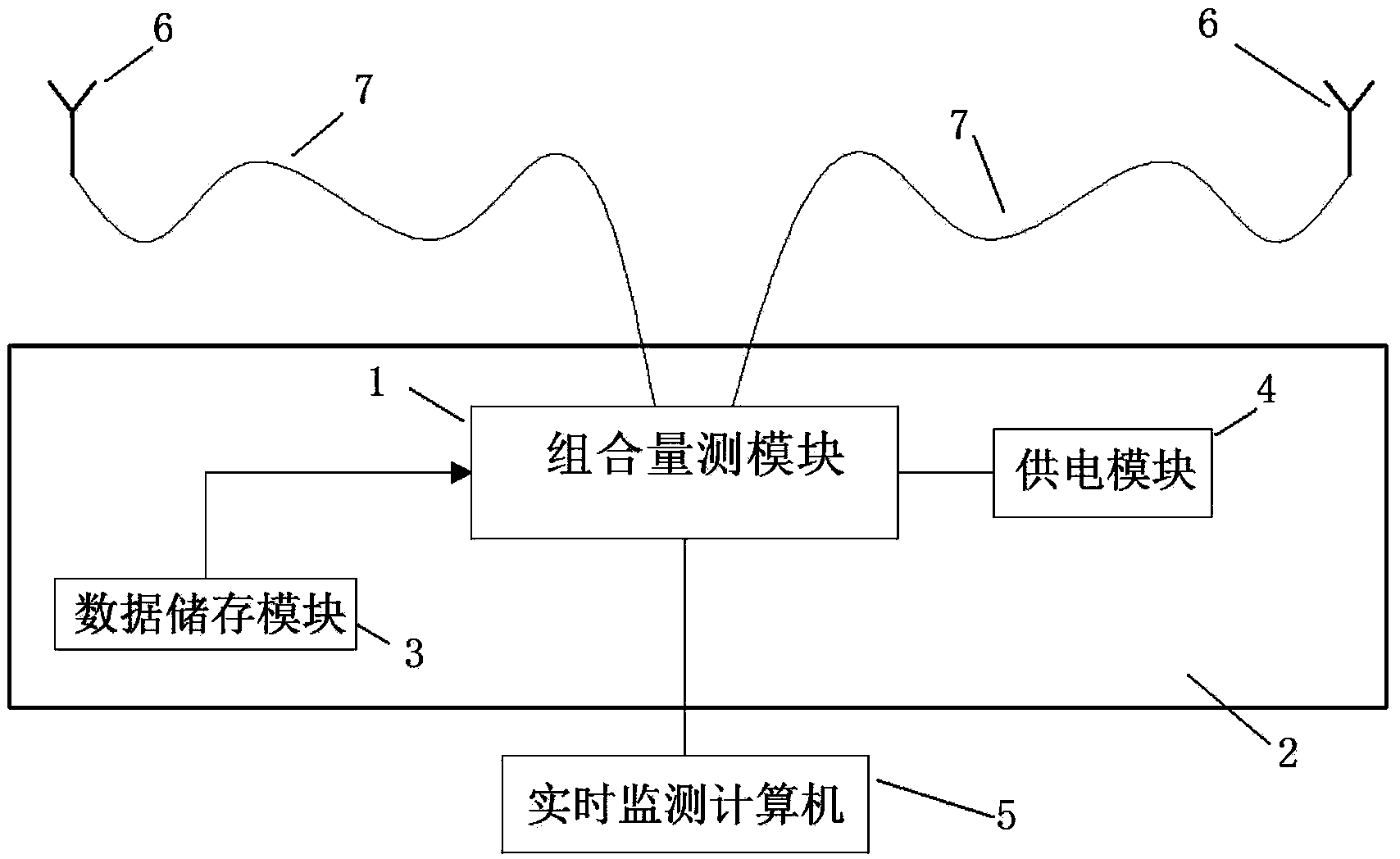

ActiveCN103616709ACorrection errorReal-time outputNavigation by speed/acceleration measurementsSatellite radio beaconingGps measurementRadio frequency signal

The invention discloses a movement actual measurement method of a jacket platform water entering process and a movement actual measurement system of the jacket platform water entering process. The movement actual measurement system includes a combined measurement module, a watertight module, a data storage module, a power supplying module, a real-time monitoring computer, a GPS antenna and a radio frequency signal transmission line, wherein the combined measurement module includes a GPS measurement system and an inertial navigation system, and the combined measurement module, the data storage module and the power supplying module are arranged in the watertight module. According to the movement actual measurement method and system of the jacket platform water entering process of the invention, the combined measurement module system is adopted; the GPS system and the inertial navigation system are combined with each other; when signals exist in the GPS system; the GPS system can output position signals to the inertial navigation system in a real-time manner; errors of the inertial navigation system caused by quadratic integral can be corrected, and measurement precision can be ensured; and therefore, difficulties in actual parameter measurement in the jacket platform water entering process can be eliminated.

Owner:SHANGHAI JIAO TONG UNIV

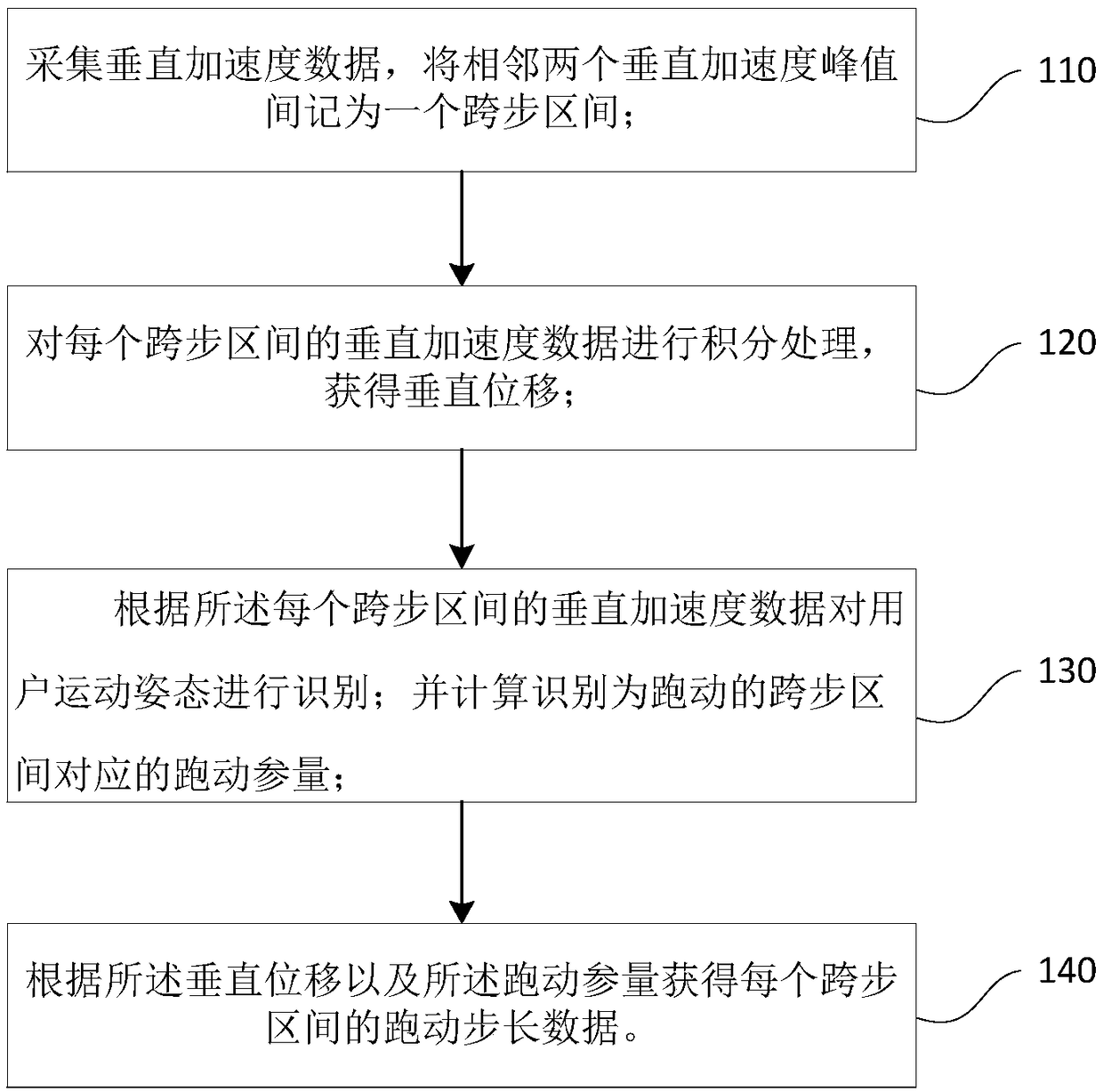

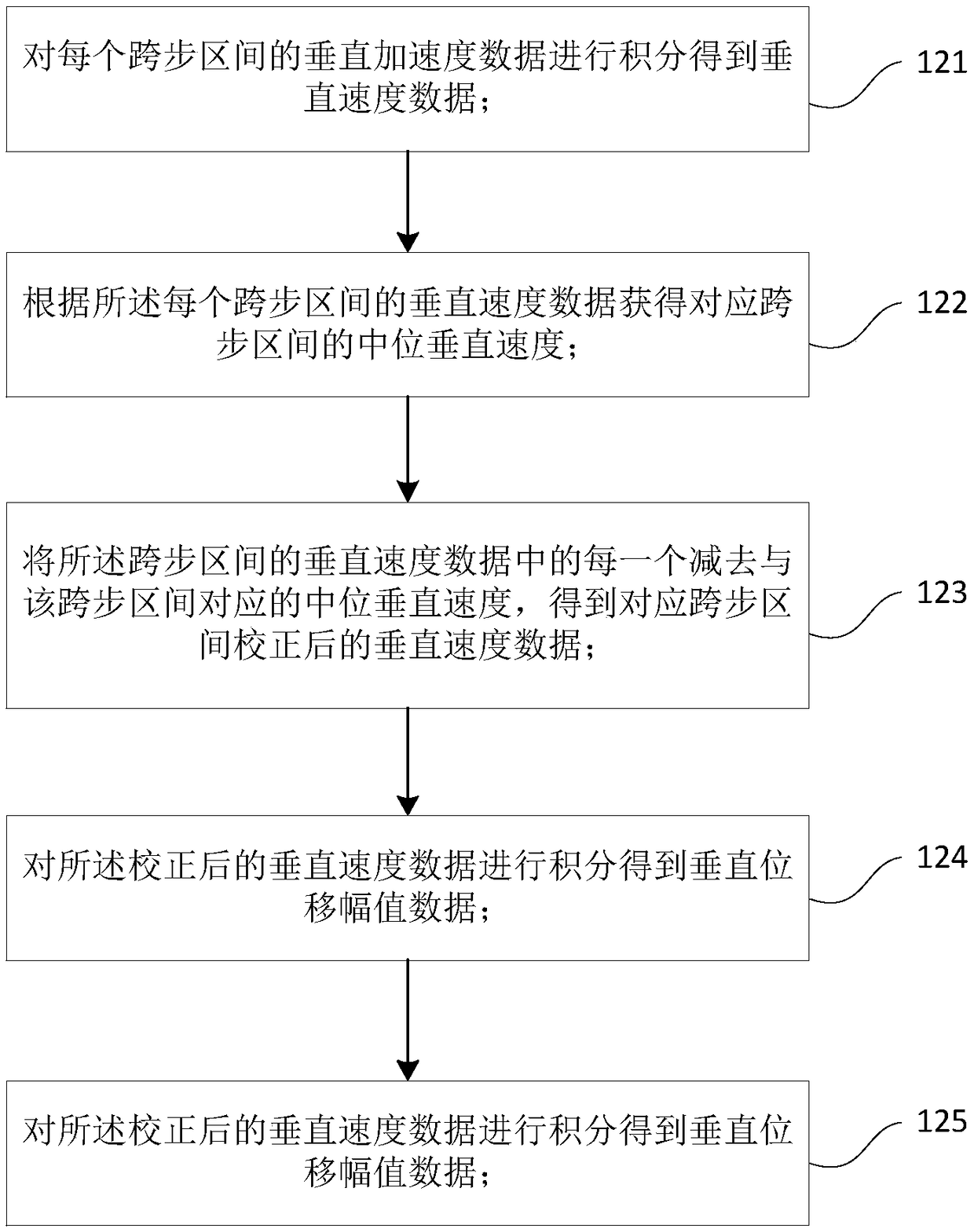

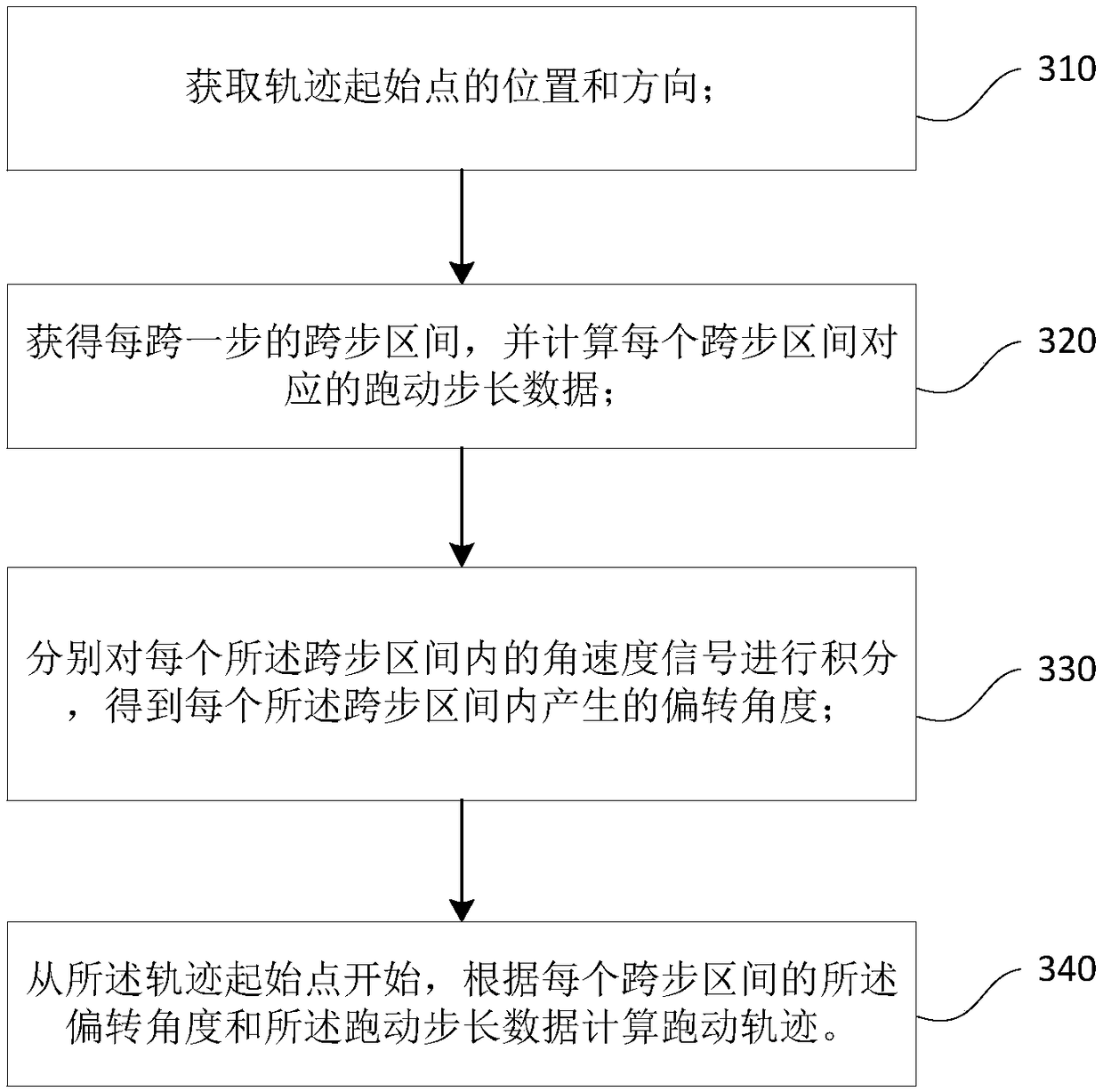

Method and device for estimating running step size

ActiveCN108871331AAccurate estimateAvoid inaccurate positioningNavigational calculation instrumentsInstabilityPeak value

The invention discloses a method and a device for estimating a running step size. The method comprises: acquiring vertical acceleration data, detecting a plurality of peak values of vertical acceleration data, and recording an interval between two adjacent vertical acceleration peak values as a step interval; performing quadratic integral processing on the vertical acceleration data of each step interval to obtain a vertical displacement; identifying the motion posture of a user according to the vertical acceleration data of each step interval; and calculating running parameters correspondingto the step interval identified as the running; obtaining running step size data of each step interval according to the vertical displacement and the running parameters; the method and device obtain reference data through hardware of the device self, thereby avoiding inaccurate positioning due to instability of positioning signal; at the same time, the running step is compensated for running dynamically by identifying the posture to obtain a more accurate step size estimation; the method and device can be further used for indoor motion trail estimation.

Owner:BEIJING FINE WAY TECH CO LTD

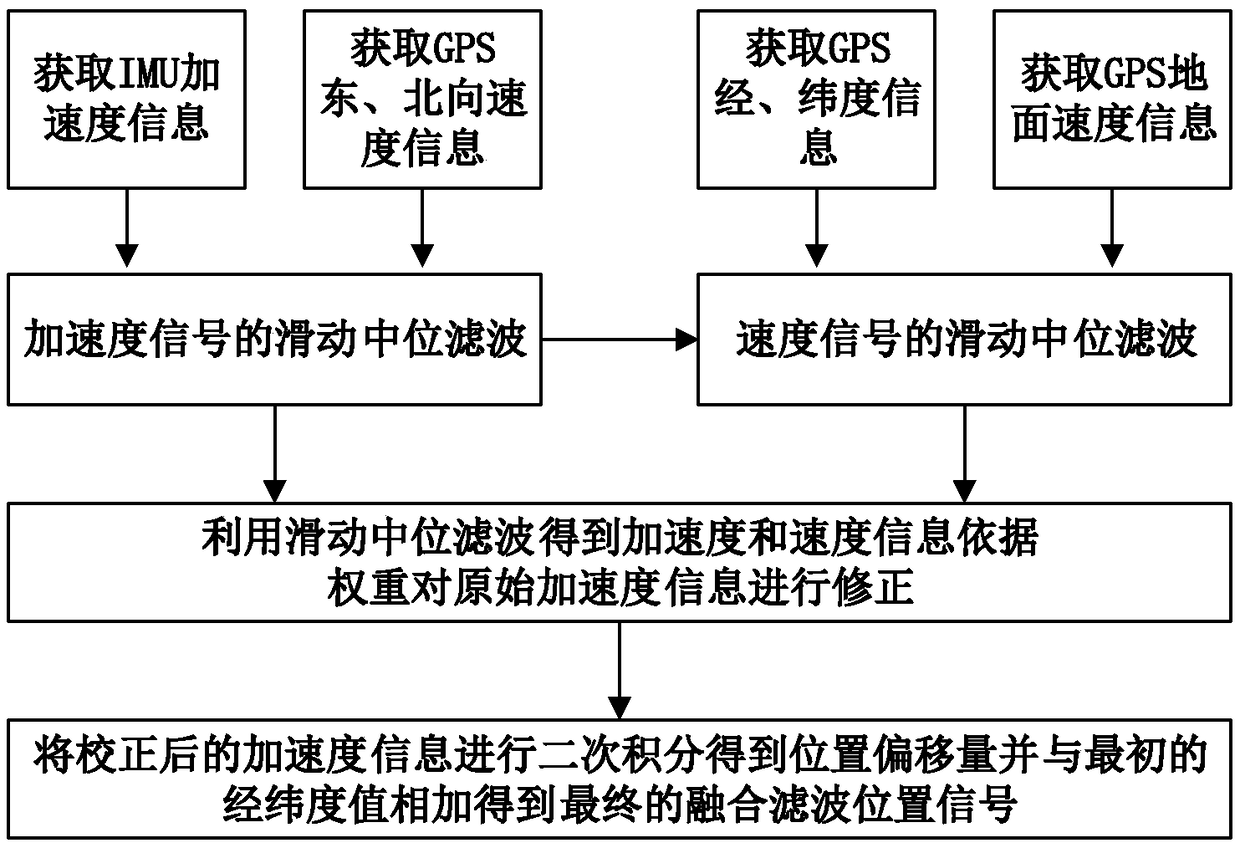

Aircraft position signal fusing and filtering method

PendingCN109459772ASpeed blockSmall latitude and longitude deviationSatellite radio beaconingBody axisLongitude

The invention discloses an aircraft position signal fusing and filtering method. The method includes the steps of collecting eastern and northern speed information output by a GPS, collecting acceleration information output by an inertial measurement unit under a vehicle body axis and magnetic course angle information output by a magnetometer, conducting sliding median filtering on the eastern andnorthern speed information output by the GPS, collecting longitude and latitude position information output by the GPS, collecting ground speed information output by the GPS, conducting sliding median filtering on the position information output by the GPS in combination with the obtained eastern and northern speed information subjected to sliding median filtering, conducting fusing and correcting on the acceleration information output by an IMU under the aircraft body axis through the eastern and northern speed information subjected to sliding median filtering and the obtained position information subjected to sliding median filtering, converting the corrected acceleration under a body coordinate system into acceleration under an inertial coordinate system, and conducting quadratic integral on the acceleration. The reliable aircraft position information can be obtained.

Owner:JIANGSU UNIV OF TECH

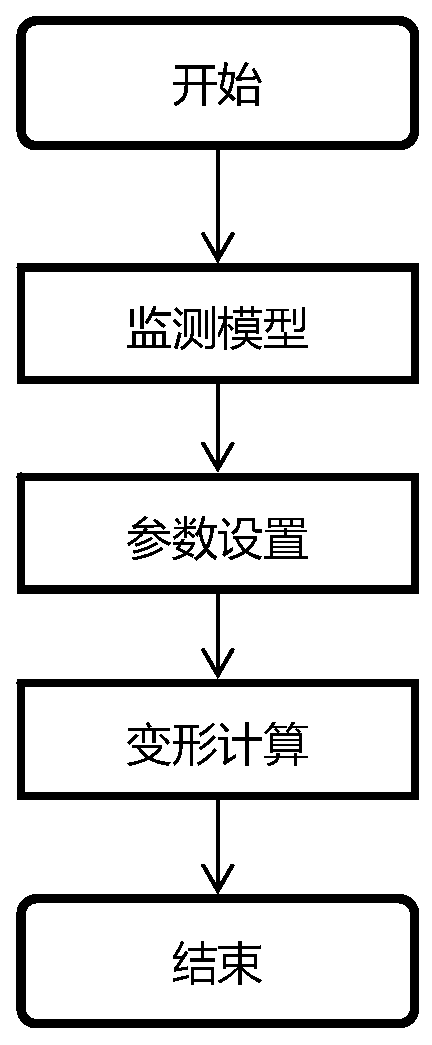

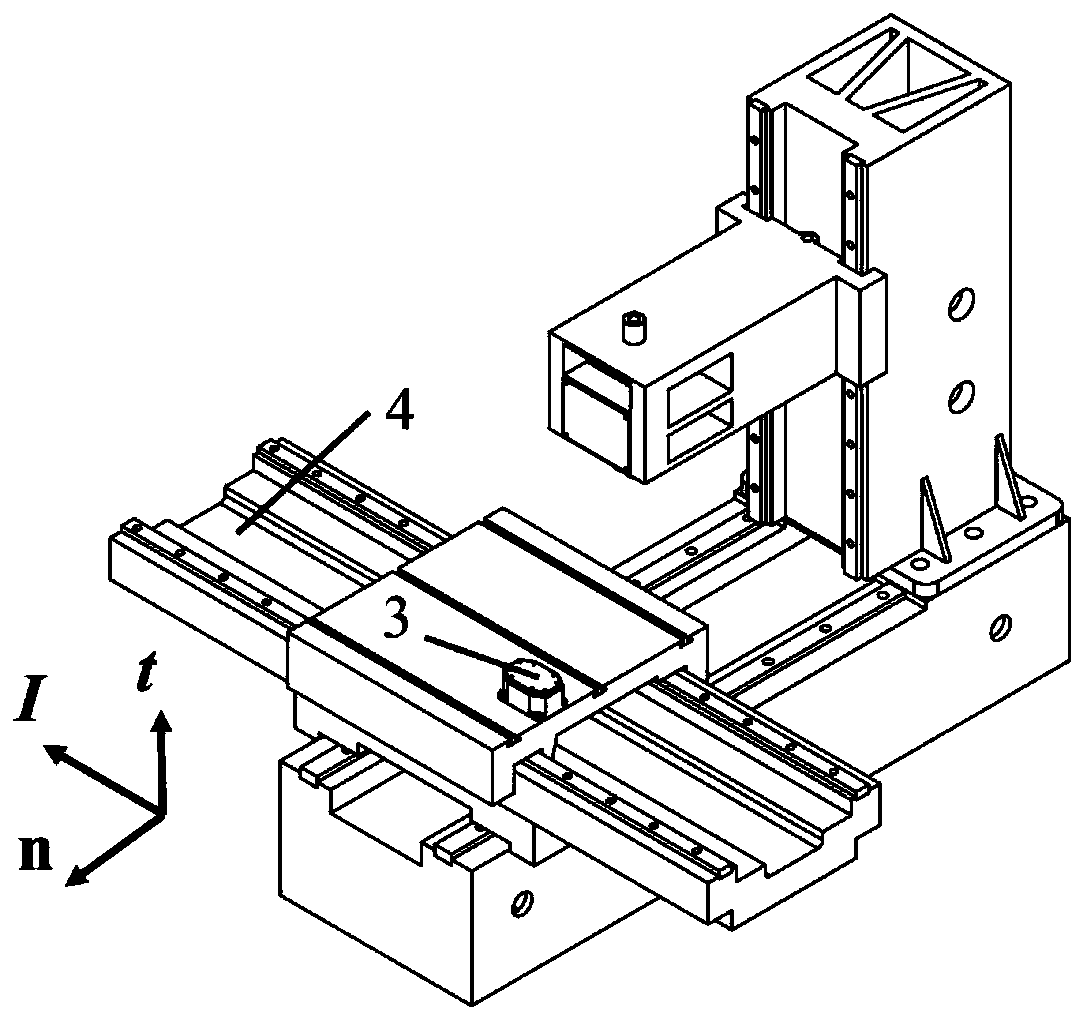

Numerical-control machine-tool rectilinear motion shaft geometry precision rapid detection method

ActiveCN108415368AQuick measurementProgramme controlComputer controlGeometric errorNumerical control

A numerical-control machine-tool rectilinear motion shaft geometry precision rapid detection method belongs to the numerical-control machine-tool detection technology field. The method is characterized by firstly, installing a measurement device on a rectilinear motion shaft, carrying out uniform motion at three different speeds along with the rectilinear motion shaft, and carrying out multichannel acquisition automatically and storing motion measurement point acceleration data by an upper layer measurement system; then, based on a condition that a same geometric error signal can be decomposedinto different frequency components, filtering acceleration signals under different measurement speeds; and finally, carrying out time-domain quadratic integral on each filtered acceleration data andacquiring displacement data, carrying out data superposition on the displacement data under three kinds of measurement speeds till that rectilinear motion shaft deformation calculation is completed;and through an endpoint line connection method, calculating the linearity of a rectilinear motion shaft, and completing the rapid linearity measurement of the machine tool rectilinear motion shaft. The method has advantages that debugging is convenient; measurement efficiency is high; and data processing capability is good. The rapid measurement of the geometric accuracy of machine-tool rectilinear motion shaft can be realized, an equipment integration level is high and automation can be conveniently realized.

Owner:DALIAN UNIV OF TECH

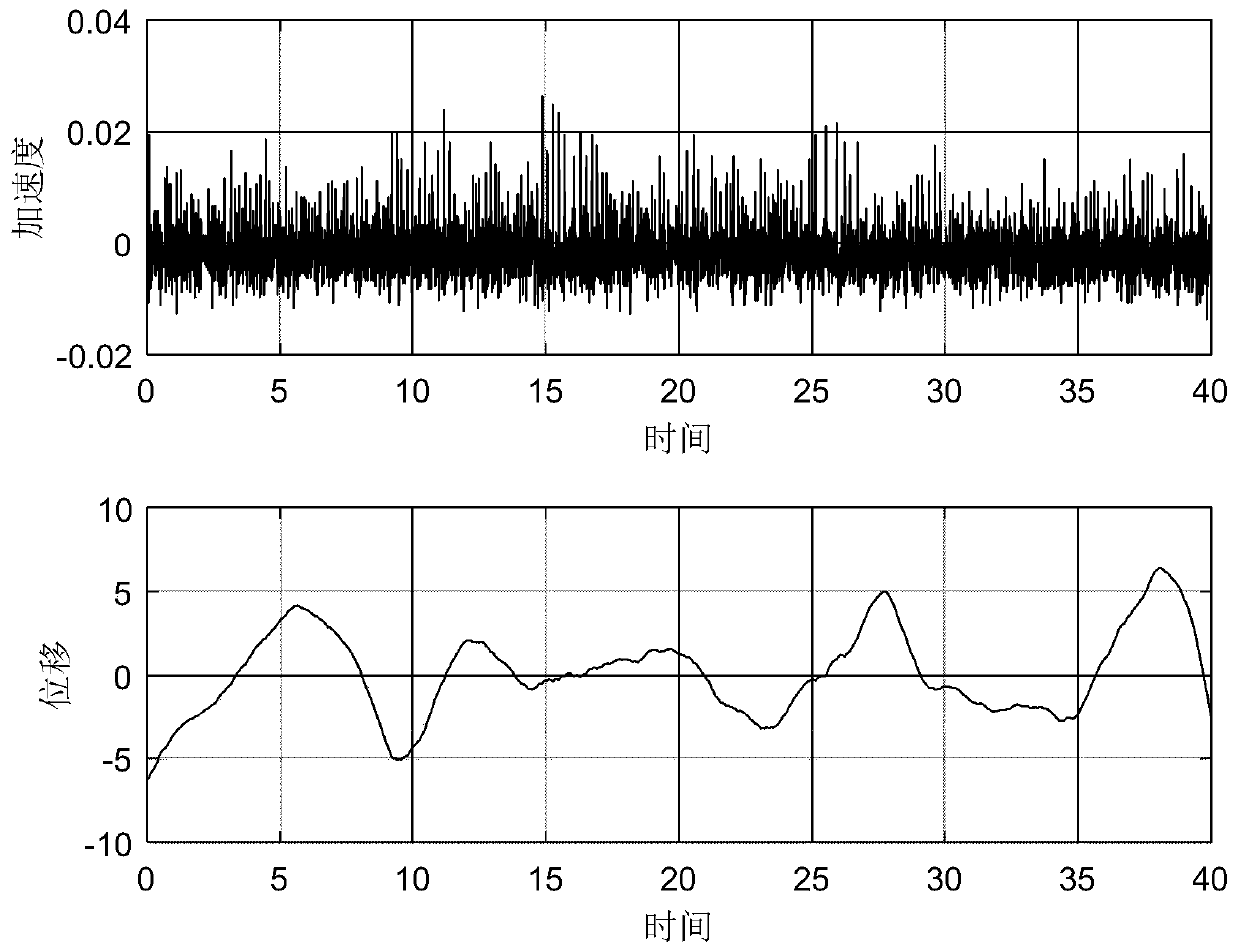

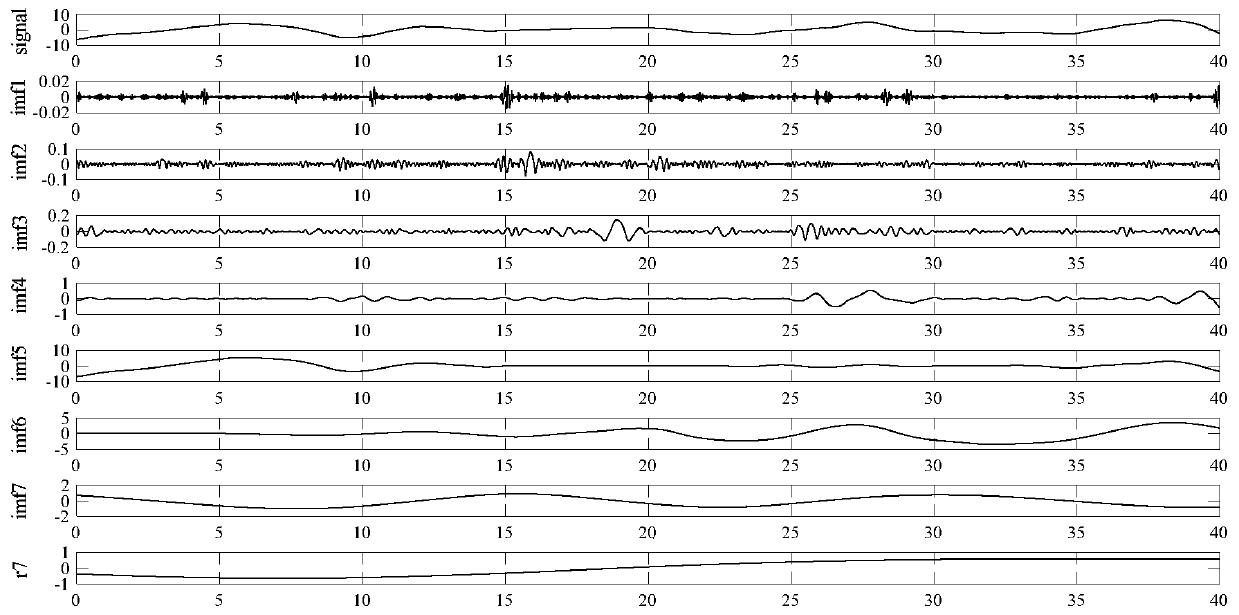

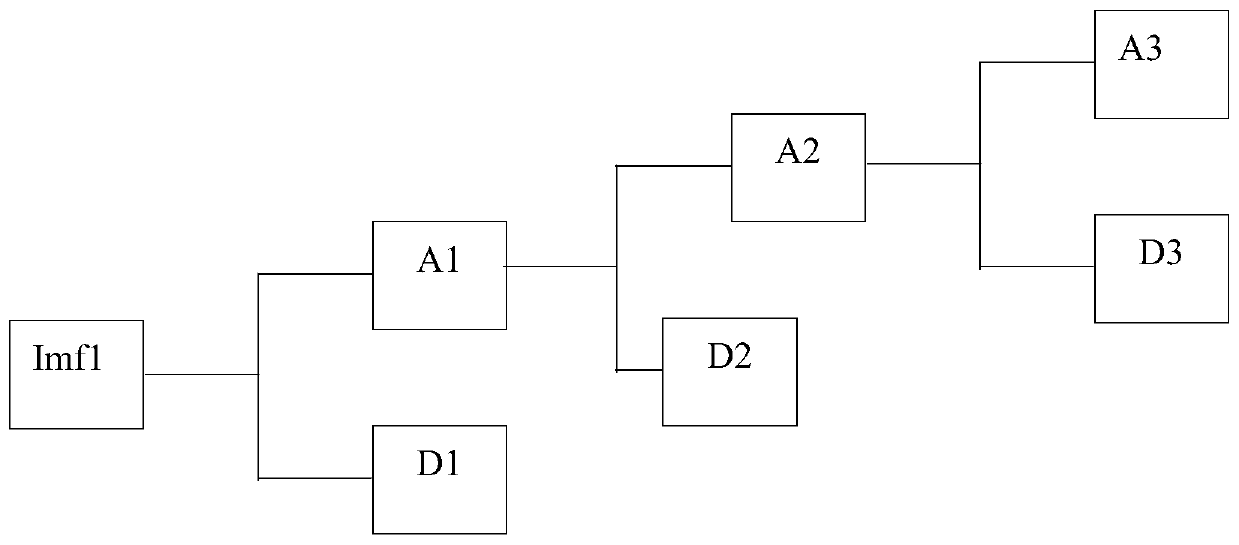

Air floatation plate vibration signal processing method based on empirical mode decomposition

ActiveCN110207811AEfficient removalImprove signal-to-noise ratioSubsonic/sonic/ultrasonic wave measurementVibration accelerationDecomposition

The invention relates to an air floatation plate vibration signal processing method based on empirical mode decomposition. The air floatation plate vibration signal processing method comprises the following steps: acquiring vibration acceleration data of an air floatation plate; performing Fourier transform on the acceleration data to be converted into a frequency domain and performing quadratic integral, and then performing inverse transformation to be converted into a time domain and obtaining vibration displacement data; performing empirical mode decomposition, obtaining multiple intrinsicmode functions and a residual error, and according to characteristics of the air floatation plate, screening a first intrinsic mode function as a vibration mode function of the air floatation plate; performing wavelet thread denoising on the vibration mode function of the air floatation plate; and performing Hilbert spectral analysis and Hilbert marginal spectral analysis on a denoised signal. Thevibration signal processing method provided by the invention can effectively denoise, and a signal-to-noise ratio is increased.

Owner:CHANGZHOU UNIV

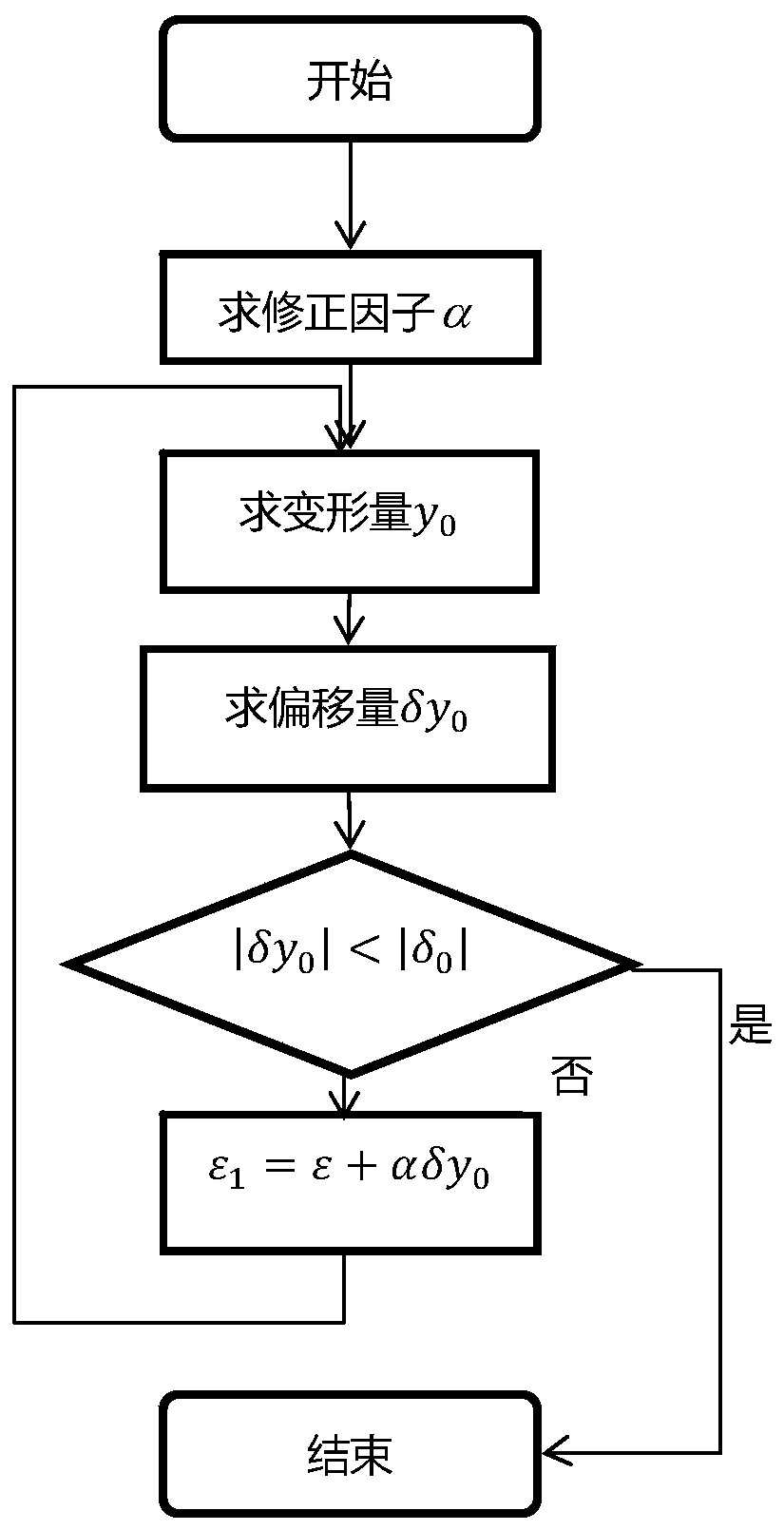

A Subway Tunnel Settlement and Deformation Monitoring Method Based on Adaptive Quadratic Integral

ActiveCN108168508BReduce mistakesAvoid strain error accumulation effectsHeight/levelling measurementAlgorithmStructural engineering

Owner:ZHEJIANG UNIV CITY COLLEGE

Sliding mode control method and device

InactiveCN105843078BSolve chattering problemsResolve continuitySimulator controlControl systemQuadratic integral

The invention provides a sliding mode control method and apparatus. The method comprises: a switching item of a control system is obtained; according to the switching item, a control quantity is determined and outputted, wherein a second derivative of the control quantity includes the switching item; and according to the control quantity, the control system is controlled. According to the method, because the switching item is included by the second derivative of the control quantity, the control quantity is a quadratic integral of the switching item and the changing rate of the control quantity is a once integral of the switching item; and the switching item becomes continuous after integration and thus the control quantity and the control quantity changing rate become continuous. Therefore, the sliding mode control method is suitable for control of the process without control quantity and derivative mutation; a defect that the traditional sliding mode control quantity and the derivative are not continuous can be overcome; and a problem that buffeting exists in sliding mode control under the circumstance that the control system is in a non-linear mode and the model is not accurate can be solved.

Owner:HARBIN ENG UNIV

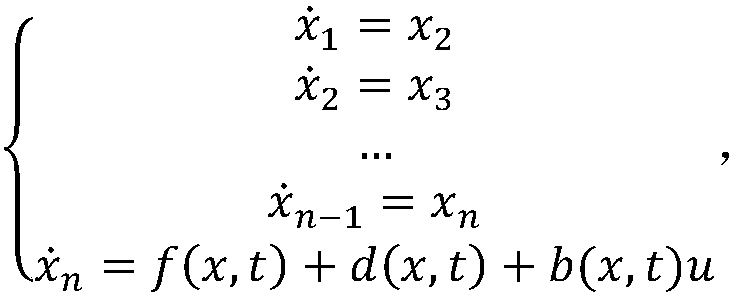

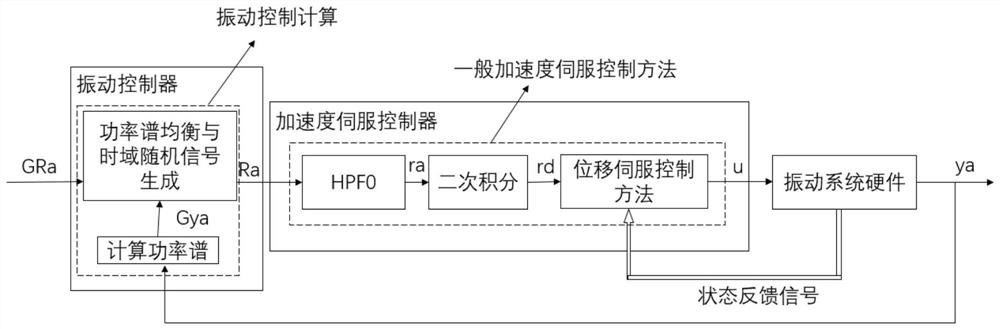

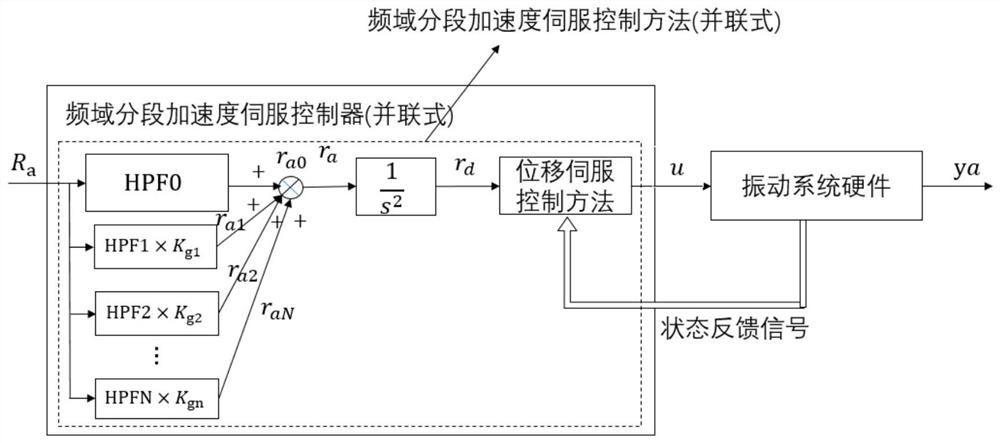

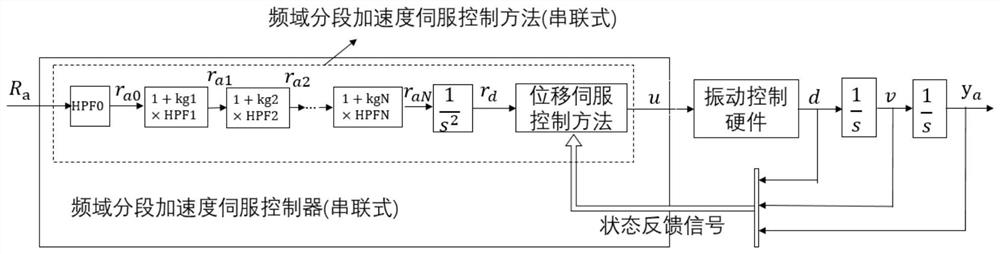

A kind of acceleration frequency domain segmental servo control method and controller

ActiveCN112947615BImprove high frequency componentsReduced Acceleration Power Spectral Density Reproduction Process TimeMechanical oscillations controlInner loopClassical mechanics

The invention discloses an acceleration frequency domain segmentation servo control method and a controller. Methods After the time domain reference acceleration is processed by the frequency domain segmentation processing method, the synthetic reference acceleration is obtained, and the reference displacement is obtained after the secondary integral calculation of the synthetic reference acceleration, and the reference displacement and the state feedback of the vibration system hardware are fed back by the displacement servo control method. The signal is calculated to obtain the control output voltage. The acceleration servo controller applying the above method uses the acceleration frequency domain subsection servo control method to process the time domain reference acceleration and state feedback signals to obtain the control output voltage. The invention improves the high-frequency component of the frequency response function H, improves the control accuracy of the acceleration power spectrum density, and reduces the reproduction process time of the acceleration power spectrum density of the electro-hydraulic random vibration system; the initial state sampling ratio in the controller is generally given to the initial state The way of setting zero reduces the time-domain response error of the acceleration servo control inner loop at startup.

Owner:ZHEJIANG UNIV

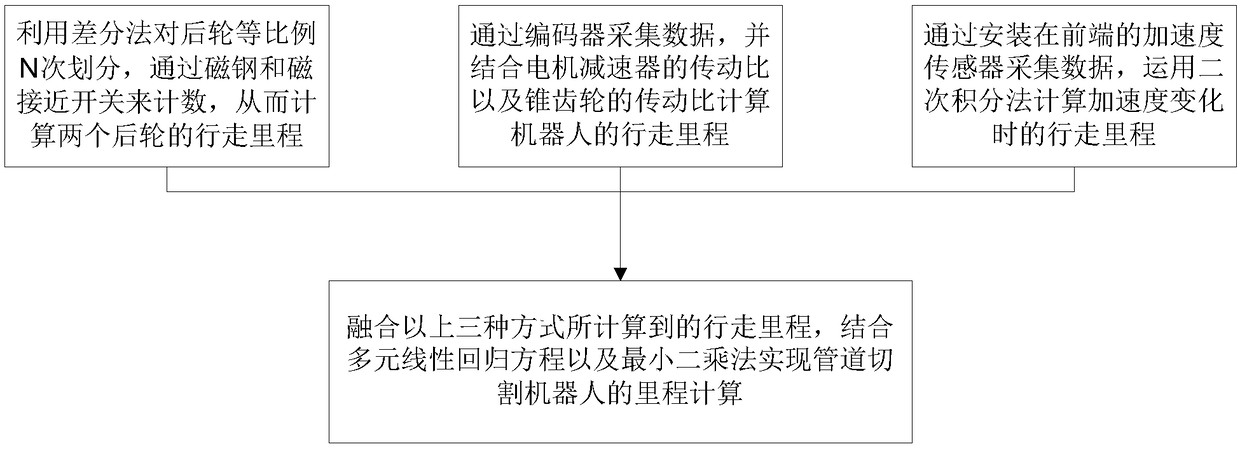

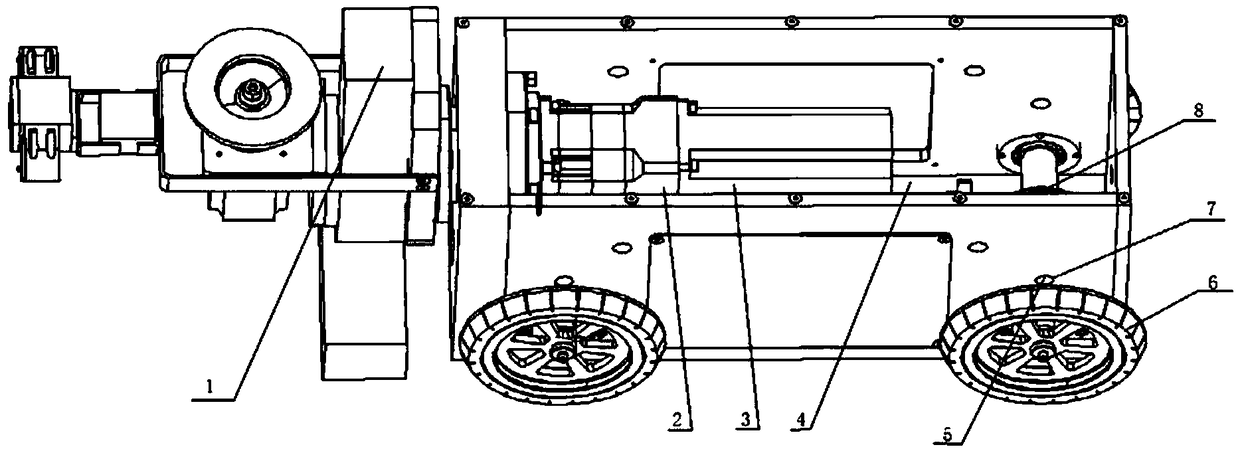

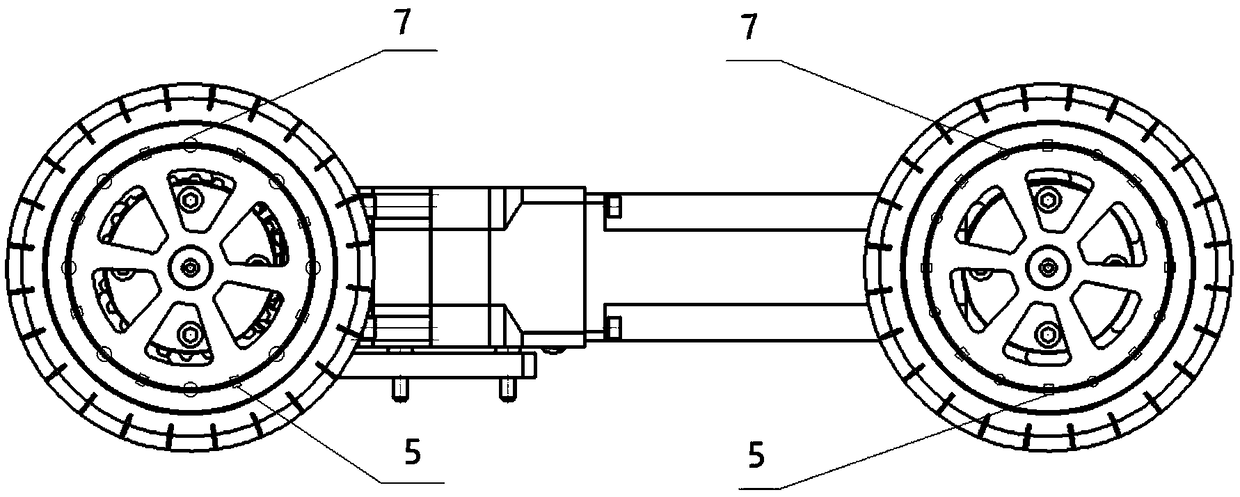

Mileage calculation method for pipeline cutting robot

ActiveCN108759856AAccurate calculationEliminate calculation errorsDistance measurementCalculation errorData acquisition

The invention discloses a mileage calculation method for a pipeline cutting robot. The mileage calculation method comprises dividing rear wheels in an equal proportion N times through a difference method, carrying out counting by magnetic steel and a magnetic proximity switch, calculating the walking mileage of the two rear wheels, acquiring data through an encoder, calculating the walking mileageof the robot through combination of a transmission ratio of a motor reducer and a transmission ratio of a bevel gear, acquiring data through an acceleration sensor installed at the front end, calculating the walking mileage at acceleration change time through a quadratic integral method, fusing the calculated walking mileages, and calculating the mileage of the pipe cutting robot through the multiple linear regression equations and the least square method. Through fusion of the calculation data of the above three methods, the calculation error produced by the single mode data acquisition is eliminated, the walking mileage of the robot is accurately calculated and the accuracy of the mileage calculation is improved. The mileage calculation method has high credibility, a simple calculationmethod and a low cost.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

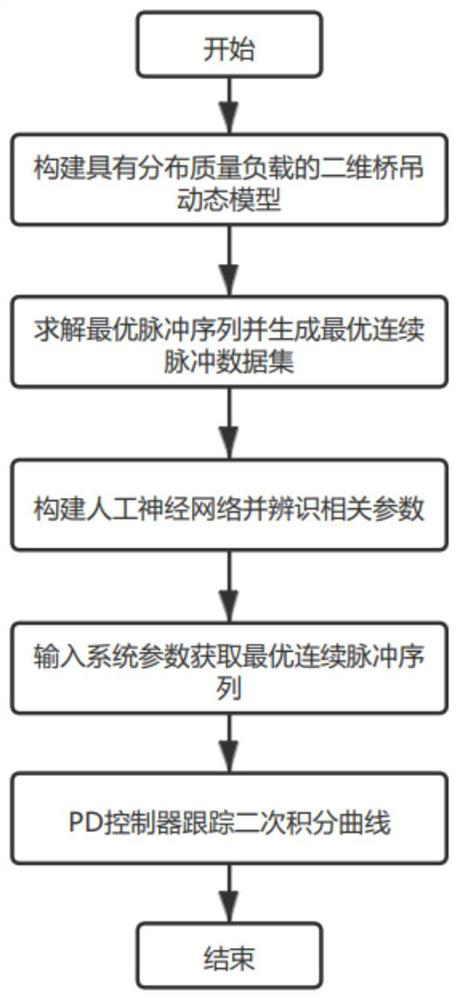

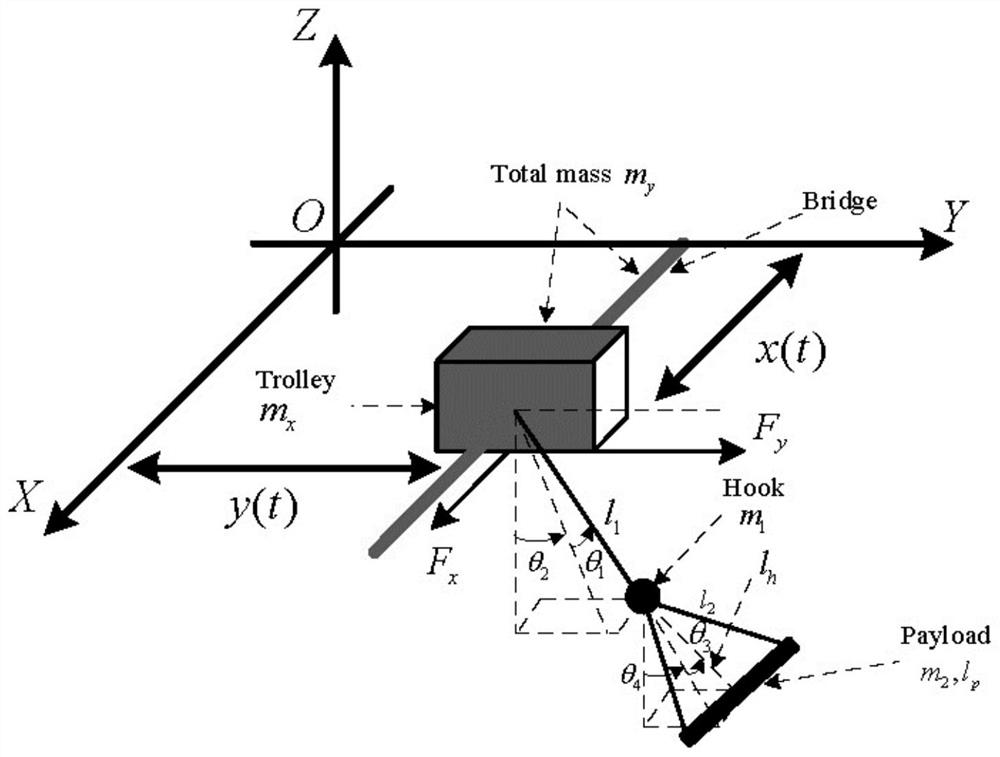

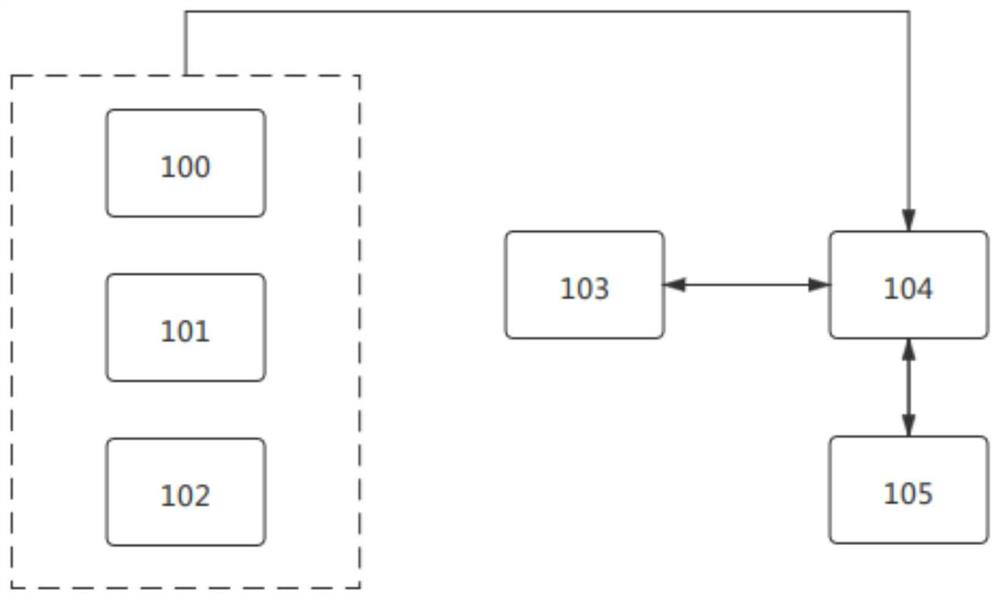

Multi-modal bridge crane swing suppression control method based on artificial neural network

The invention discloses a multi-modal bridge crane swing suppression control method based on an artificial neural network. The method comprises the steps of constructing a bridge crane multi-modal dynamic model with a distributed mass load; calculating a first optimal continuous pulse sequence under different parameters, and constructing an optimal continuous pulse data set; calculating a weight and a bias parameter of the artificial neural network, and constructing an artificial neural network identification related parameter; and calculating a second optimal continuous pulse sequence under the current real-time measured parameters by using the artificial neural network, and obtaining a final acceleration signal. According to the multi-modal bridge crane swing suppression control method, a PD controller tracks a final acceleration signal quadratic integral curve to realize positioning and anti-swing, a continuous pulse sequence is optimized through a particle swarm optimization algorithm, the bad performance of a traditional open-loop controller for a nonlinear system is solved, an optimal parameter set is learned, tedious offline iteration steps are avoided, the required optimal pulse sequence is generated in real time, and the efficiency of the controller is improved.

Owner:NANJING UNIV OF TECH

Calibration method of joint angle of hexapod robot based on displacement correction of fuselage center of gravity

InactiveCN107214698BEnsure coordinationGuaranteed accuracyProgramme-controlled manipulatorAdaptive controlEngineeringGravity center

The invention provides a body gravity center displacement correction-based six-foot robot joint angle calibration method. The method comprises the following steps: driving a robot to support the ground with any three feet, and keeping the other three feet uplifted and not in contact with the ground all the time; selecting one of the supporting feet, and driving a certain joint on the foot to rotate an angle, thus enabling the sole to slide and the other two soles to not slide relative to the ground; and by building a function relation between the angle of the joint and a body gravity center moving track, measuring a three-degree-of-freedom acceleration through a body IMU (Inertial Measurement Unit), calculating a relative moving track of a body through quadratic integral, and calculating coordinates of the tail end of the supporting foot relative to the body according to a multi-foot moving robot kinematic model, thus correcting angles of all joints of the supporting foot. The calibration method provided by the invention can quickly and accurately complete correction of the angles of the joints of a multi-foot moving robot, so as to guarantee multi-foot coordinating motion of the robot and the precision of the moving track; and the calibration method also can be used for checking faults of the foot joints of the robot to provide a basis for a robot motion decision.

Owner:SHANGHAI JIAOTONG UNIV

Motion measurement method and system for jacket platform launching process

ActiveCN103616709BCorrection errorReal-time outputNavigation by speed/acceleration measurementsSatellite radio beaconingGps measurementComputer module

The invention discloses a movement actual measurement method of a jacket platform water entering process and a movement actual measurement system of the jacket platform water entering process. The movement actual measurement system includes a combined measurement module, a watertight module, a data storage module, a power supplying module, a real-time monitoring computer, a GPS antenna and a radio frequency signal transmission line, wherein the combined measurement module includes a GPS measurement system and an inertial navigation system, and the combined measurement module, the data storage module and the power supplying module are arranged in the watertight module. According to the movement actual measurement method and system of the jacket platform water entering process of the invention, the combined measurement module system is adopted; the GPS system and the inertial navigation system are combined with each other; when signals exist in the GPS system; the GPS system can output position signals to the inertial navigation system in a real-time manner; errors of the inertial navigation system caused by quadratic integral can be corrected, and measurement precision can be ensured; and therefore, difficulties in actual parameter measurement in the jacket platform water entering process can be eliminated.

Owner:SHANGHAI JIAOTONG UNIV

A Method for Determining the Boundary of Drag Acceleration Corridor of Gliding Vehicle

InactiveCN105022858BSolve the problem that can only be calculated point by point by numerical calculationSpecial data processing applicationsComputer scienceQuadratic integral

The invention discloses a method of determining a boundary of a drag acceleration corridor of a glide vehicle. The method comprises the following steps: expressing a second derivative S'' (x) of a cubic spline interpolation function S (x) as a linear function on each interpolation interval, and performing quadratic integral on the second derivative S'' (x) to obtain an expression of the cubic spline interpolation function S (x); taking the derivative of the cubic spline interpolation function S (x), and establishing a relation of a second derivative at the adjacent nodes according to the characteristic that a first derivative is continuous at an interpolation node; respectively deriving endpoint equations according to three different boundary conditions, so as to establish a system of linear equations for the cubic spline interpolation function S (x) at each node second derivative value Mj (j=0,1, to n), solving the system of linear equations to obtain the expression of the cubic spline interpolation function S (x) as the interpolation result.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST

A kind of real-time navigation method of data processing computer system for distributed POS

ActiveCN104698486BOvercoming the deficiency of low alignment accuracyReduce mistakesSatellite radio beaconingSpecial data processing applicationsReal time navigationReal-time data

The invention provides a real-time navigation method of a data processing computer system for a distributed POS. The method comprises the steps of acquiring three IMU original data at the same time by the PPS actual calibration and frequency division time synchronizing method; fusing the main IMU data with the GPS data to obtain the main POS real-time navigation result; initially aligning a shaking base through the secondary IMU by the inertia vector quadratic integral based analysis aligning method; performing the transmission aligning of the distributed POS by the multi-stage lever arm compensation based kalman filtering method so as to obtain the real-time navigation result of the secondary IMU and the relative spatial relationship between the main IMU and the secondary IMU. The method achieves the real-time data processing of the distributed POS with one main IMU and two secondary IMUs and is applicable to high-precision distributed inertia measurement, navigation and combined navigation systems.

Owner:BEIHANG UNIV

A method for detecting vibration displacement data of washing machine based on mems sensor

ActiveCN104947371BEliminate vibration interference signalsImprove efficiencyControl devices for washing apparatusTextiles and paperIir filteringMachining vibrations

The invention relates to a method for detecting washing machine vibration displacement data based on an MEMS sensor. The method comprises the steps that triaxial acceleration data of a washing machine external barrel are collected by the MEMS sensor; the triaxial acceleration data are converted into corresponding displacement data through the quadratic integral; before conversion, an IIR filter is adopted for filtering away data with the signal frequency lower than the preset frequency; after conversion, the rotating speed of a washing machine is judged, and different IIR filter coefficients and filter gains are selected based on the rotating speed of the washing machine for carrying out correcting and compensation on the displacement data obtained in the previous step, so that various vibration interference signals existing in the washing machine running process are eliminated, and vibration displacement data output with the high precision is obtained. Vibration displacement data are filtered two times, so that the vibration displacement data with the high precision are obtained, the current vibration displacement data are output to a washing machine computer controller in real time, the rotating speed of a washing machine running motor is controlled, the washing program is optimized, the washing machine working noise is lowered, and the washing efficiency is improved.

Owner:厦门翰普电子有限公司

A rapid detection method for the geometric accuracy of linear motion axes of CNC machine tools

ActiveCN108415368BQuick measurementProgramme controlComputer controlGeometric errorNumerical control

A numerical-control machine-tool rectilinear motion shaft geometry precision rapid detection method belongs to the numerical-control machine-tool detection technology field. The method is characterized by firstly, installing a measurement device on a rectilinear motion shaft, carrying out uniform motion at three different speeds along with the rectilinear motion shaft, and carrying out multichannel acquisition automatically and storing motion measurement point acceleration data by an upper layer measurement system; then, based on a condition that a same geometric error signal can be decomposedinto different frequency components, filtering acceleration signals under different measurement speeds; and finally, carrying out time-domain quadratic integral on each filtered acceleration data andacquiring displacement data, carrying out data superposition on the displacement data under three kinds of measurement speeds till that rectilinear motion shaft deformation calculation is completed;and through an endpoint line connection method, calculating the linearity of a rectilinear motion shaft, and completing the rapid linearity measurement of the machine tool rectilinear motion shaft. The method has advantages that debugging is convenient; measurement efficiency is high; and data processing capability is good. The rapid measurement of the geometric accuracy of machine-tool rectilinear motion shaft can be realized, an equipment integration level is high and automation can be conveniently realized.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com