Method for detecting washing machine vibration displacement data based on MEMS sensor

A vibration displacement, washing machine technology, applied in the control device of washing machine, washing device, textile and paper making, etc., can solve the problems of distortion and deformation of displacement value digital signal waveform, and can not be used to control the vibration of washing machine, etc., to improve efficiency, Avoid hitting the barrel and speed up the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

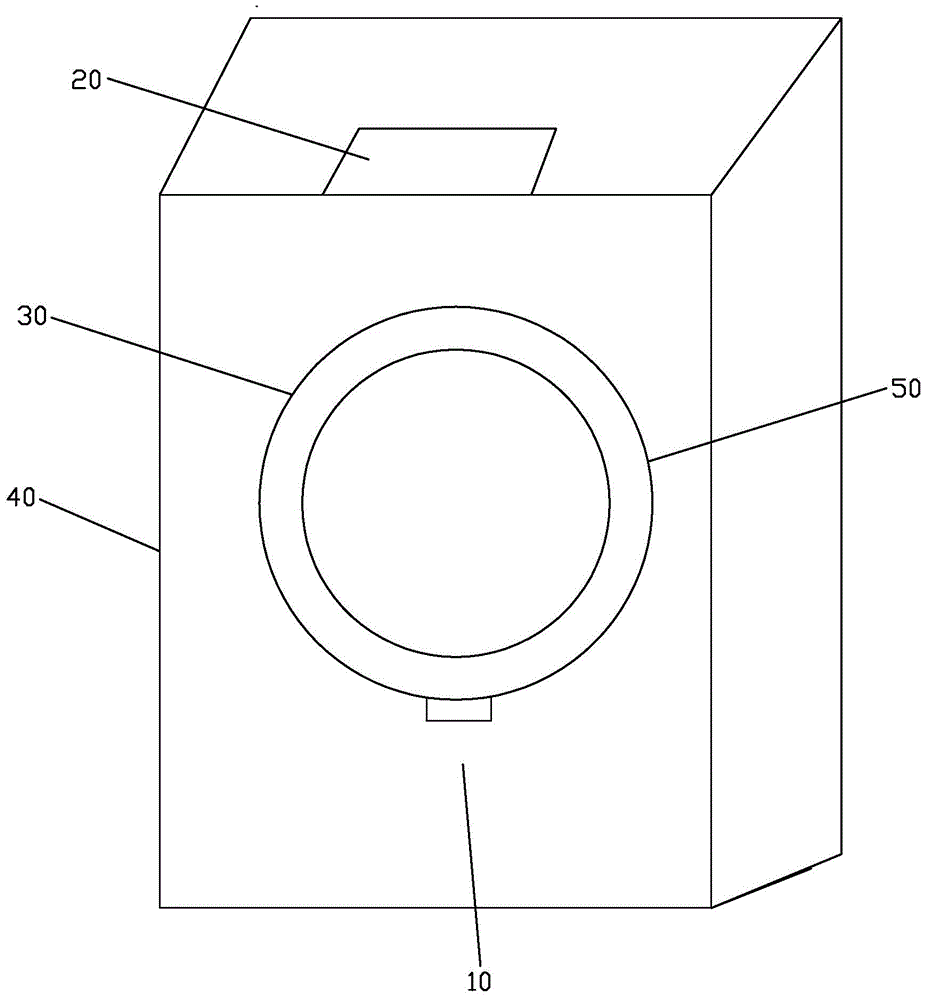

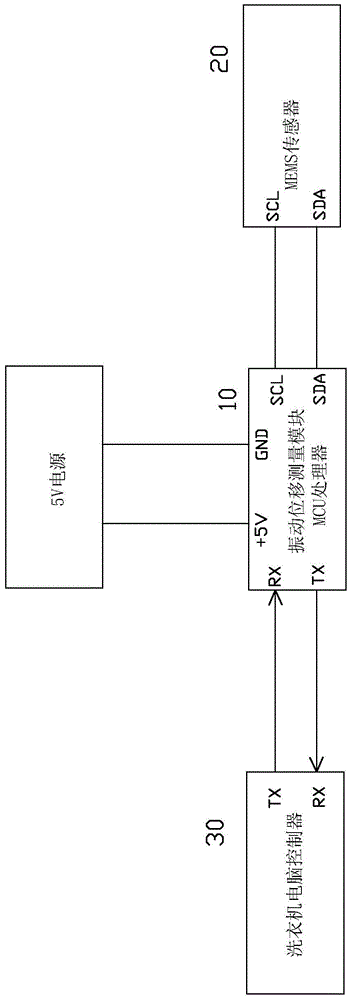

[0043] see figure 1 , figure 2 As shown, a method for detecting vibration displacement data of a washing machine based on a MEMS sensor in the present invention requires first installing the vibration displacement measurement module 10 on the outer tub 30 of the washing machine, and communicating the communication line of the vibration displacement measurement module 10 with the computer controller 20 of the washing machine line connection; the inner barrel 50 of the washing machine is enclosed within the outer barrel 30, and the computer controller 20 of the washing machine can be contained on the outer case 40 of the washing machine.

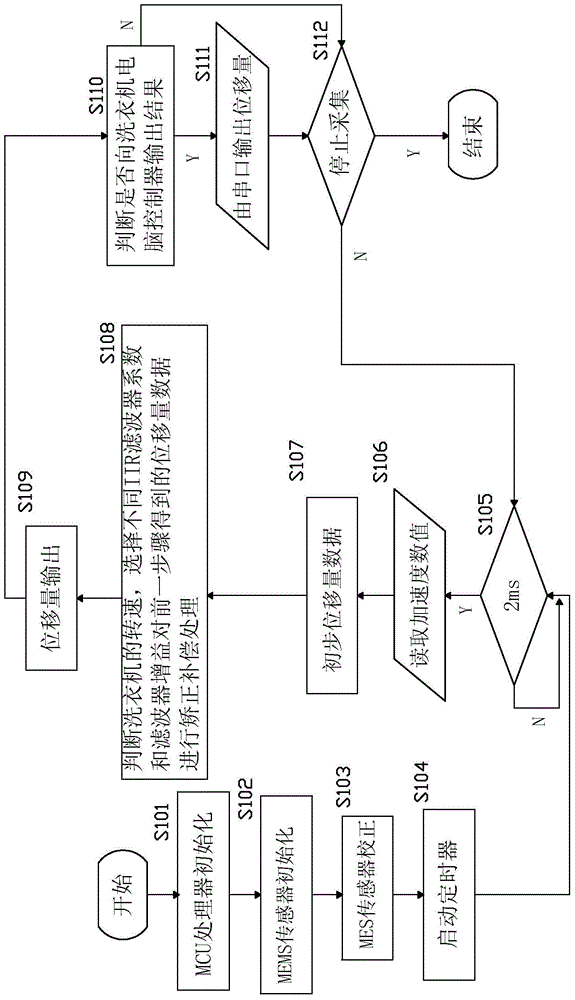

[0044] see image 3 Shown, a kind of method based on MEMS sensor of the present invention detects the vibration displacement data of washing machine, comprises the steps:

[0045] When the washing machine is powered on, the vibration displacement measurement module 10 is powered on simultaneously;

[0046] MCU processor initialization; suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com