Numerical-control machine-tool rectilinear motion shaft geometry precision rapid detection method

A technology of linear motion and CNC machine tools, applied in program control, computer control, general control systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

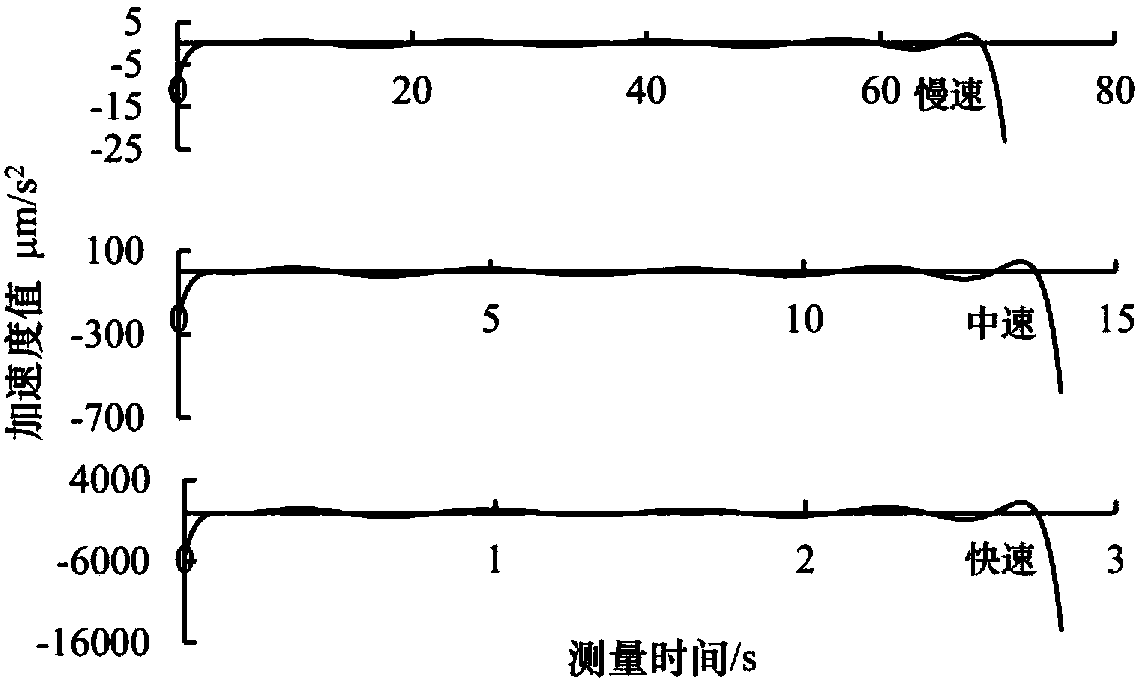

[0060] The specific implementation manners of the present invention will be described in detail below in conjunction with the drawings and technical solutions.

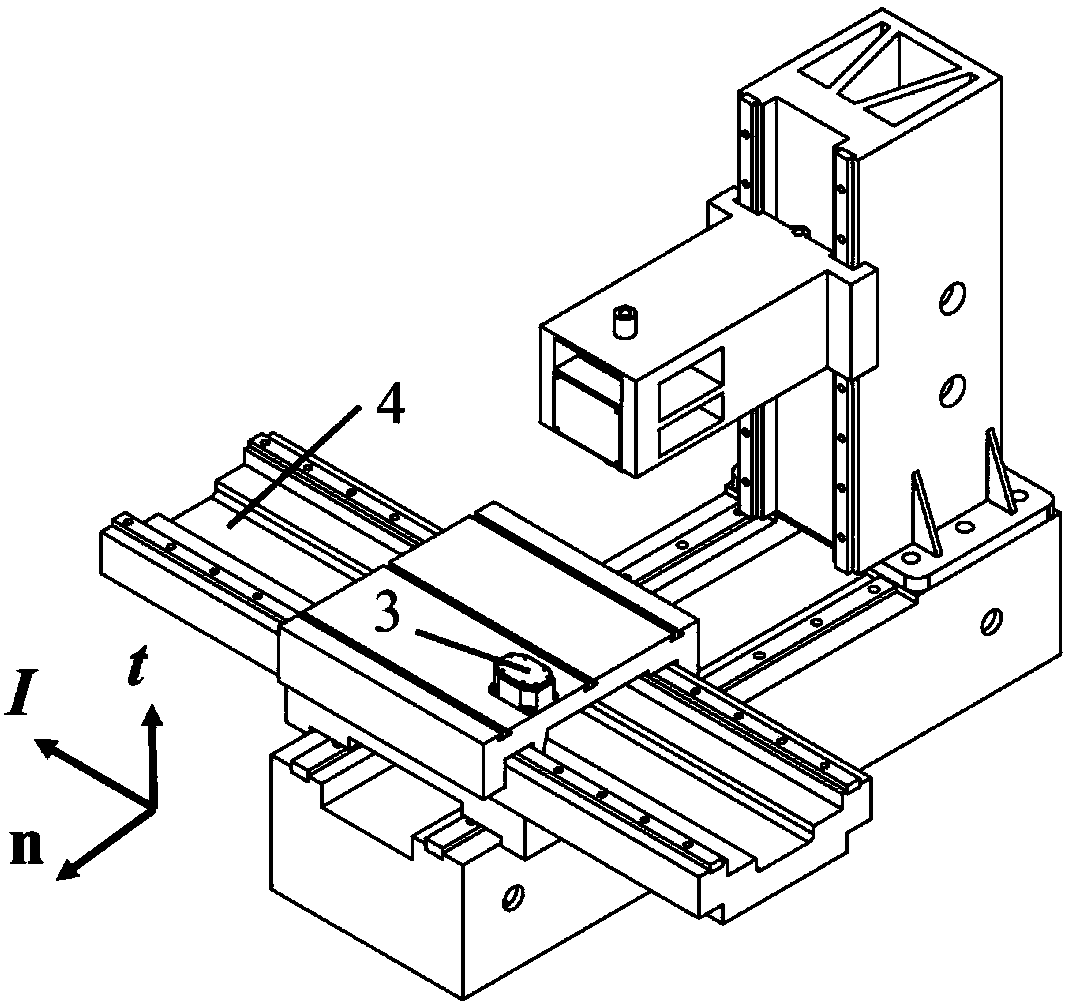

[0061] The CNC machine tool under test is a bed of a vertical machining center, and the stroke length of the guide rail is 1500mm.

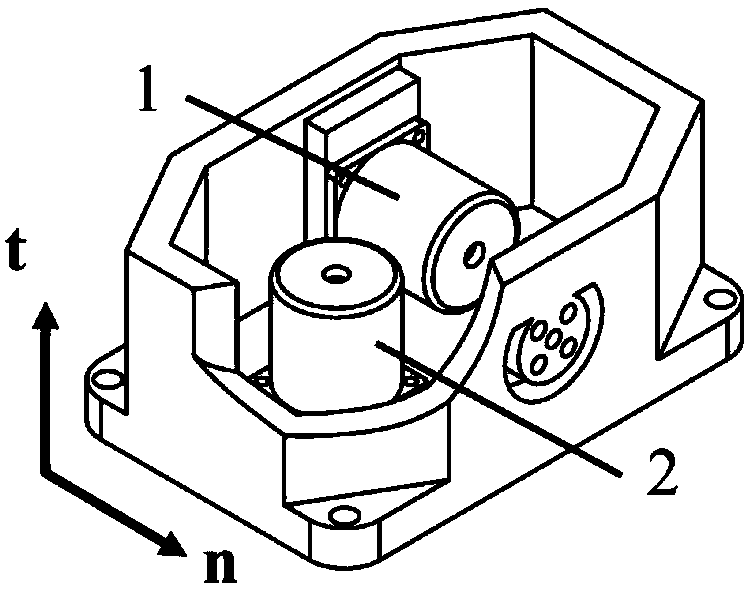

[0062] The first step is to assemble the rapid detection device for the geometric accuracy of the linear motion axis of the CNC machine tool

[0063] Two uniaxial accelerometers: 1 # Single-axis acceleration sensor 1, 2 # A 2-way acceleration sensor group consisting of 2 single-axis acceleration sensors; guarantee 1 # The measurement direction of the uniaxial acceleration sensor 1 is the n direction, 2 # The measurement direction of the uniaxial acceleration sensor 2 is the t direction, and the uniaxial acceleration sensors are respectively fixed in the detection box 3 through nuts; the direction I is the direction of the linear motion axis, and the detection box 3 is fixed on the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com