Hard rock road-header damping design method based on multi-tuning mass damper

A technique for tuning mass damping, hard rock roadheaders, used in computer-aided design, design optimization/simulation, instrumentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

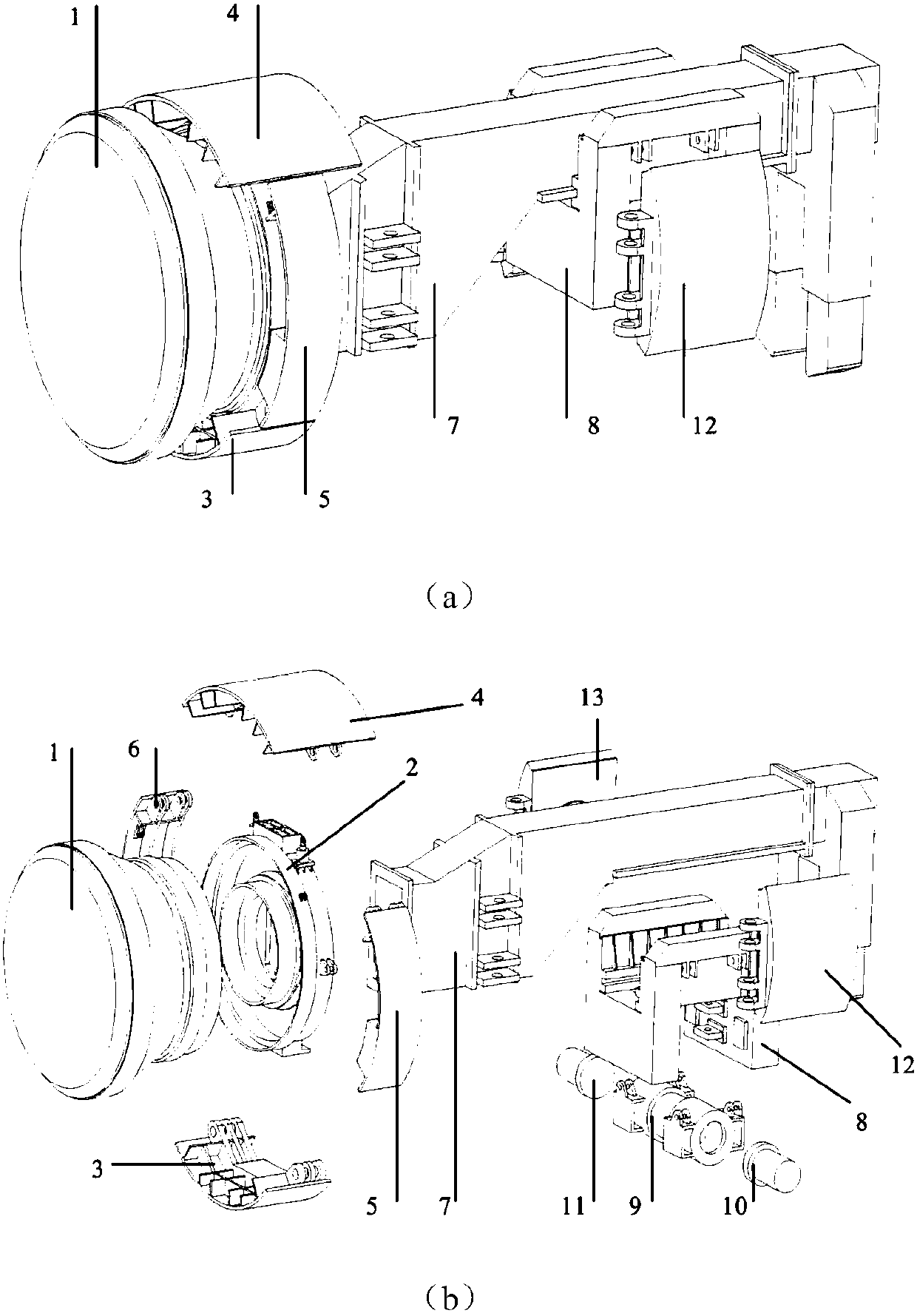

[0034] Such as figure 1 As shown, the main large parts of the open main beam hard rock tunneling machine of this embodiment include: cutter head, gear box, bottom shield, top shield, left shield, right shield, main beam assembly, saddle frame , support cylinder body, support cylinder left piston rod, support cylinder right piston rod, left support shoe and right support shoe, etc. The main structural parameters are: total mass 135t, cutter head diameter 4m, main engine length 10m, pinion number 8, disc hob number 24, knife spacing 84mm, hob diameter 432mm, hob blade width 9.2mm.

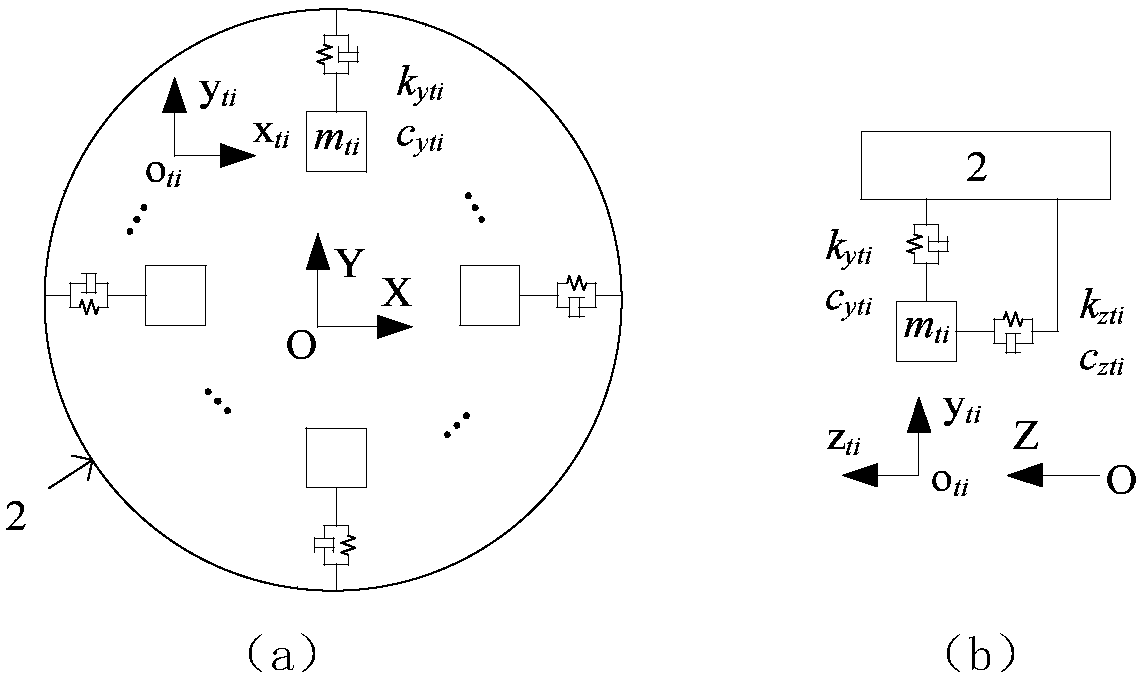

[0035] According to the design method for vibration reduction of hard rock roadheader based on multi-tuned mass dampers in this embodiment, the multi-tuned mass dampers are arranged on the gear box of hard rock roadheader, and the specific steps are as follows:

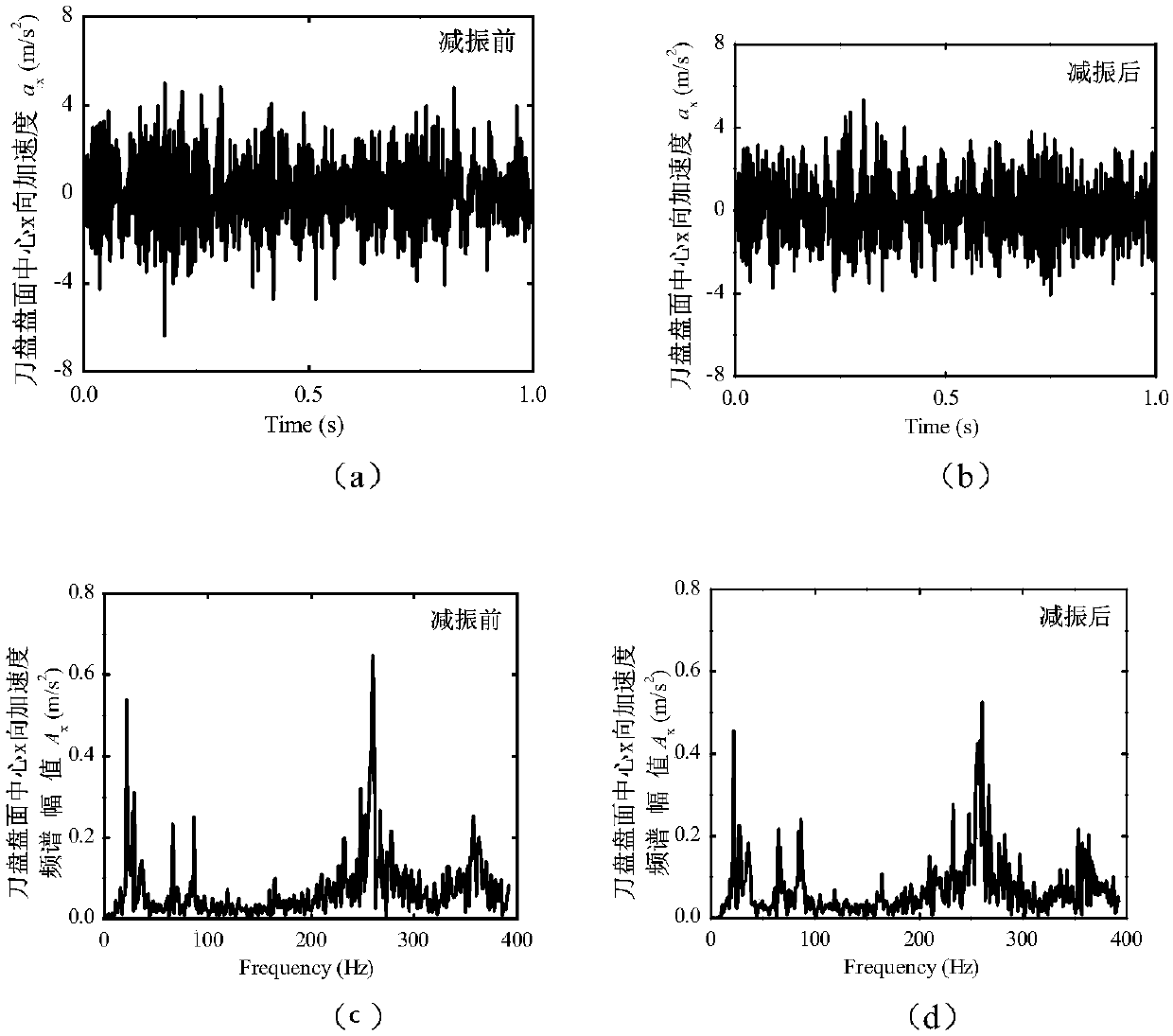

[0036] (1) According to figure 1 The schematic diagram of the structure of the open main beam hard rock roadheader is shown, and the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com