Super magnetostrictive material driven microdisplacement mechanism

A technology of micro-displacement mechanism and giant magnetostriction, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve high processing and assembly, poor interchangeability, Problems such as large loss of output force achieve the effect of easy processing and installation and good interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

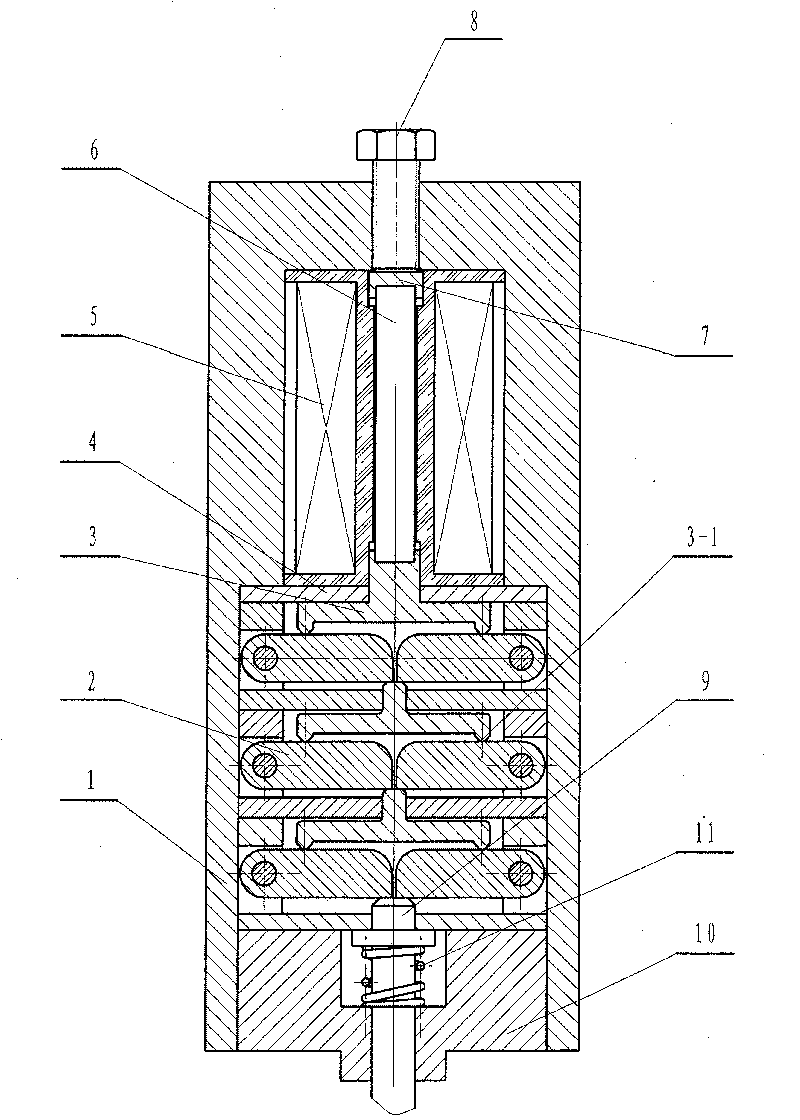

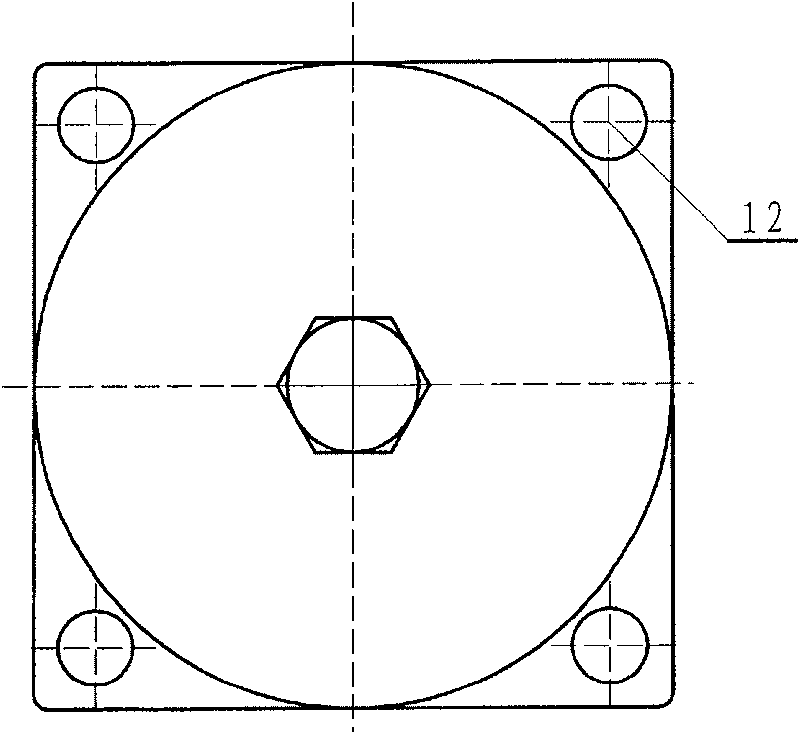

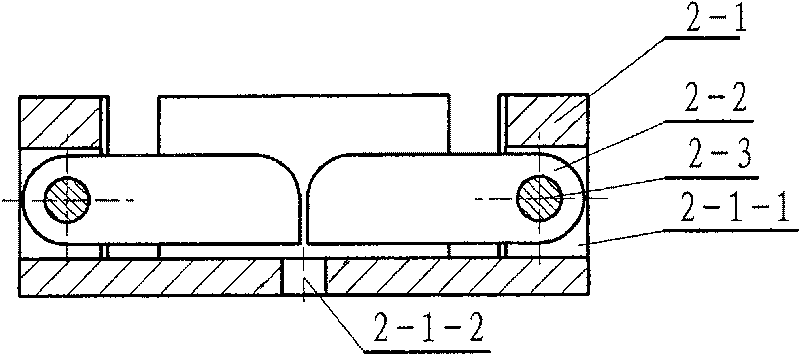

[0021] Micro-displacement mechanism of the present invention such as figure 1 and figure 2 As shown, its main structure includes: cylinder body (1), lever structure (2), transmission plate (3), lower limit ring (4), excitation coil (5), magnetostrictive rod (6), upper limit plate (7), adjusting screw (8), output rod (9), base (10) and return spring (11). An amplification mechanism is arranged between the magnetostrictive rod (6) and the output rod (9) inside the cylinder body (1). The amplification mechanism is composed of a lever member (2) and a transmission disc (3), and the transmission disc (3) is arranged on the lever member (2). Such as image 3 and Figure 4 As shown, the lever structure (2) is composed of a support (2-1), two symmetrical levers (2-2) and two pivot pins (2-3), and the positioning end of the lever (2-2) Be fixed in the through hole (2-1-1) of support (2-1) with axle pin (2-3), the upper side of the end of lever (2-2) has a fillet to facilitate lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com