Vibration inhibiting method of cold continuous rolling unit

A cold tandem rolling mill and vibration suppression technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problem of not taking into account the huge cooling effect of the emulsion, the thermal scratching of rolling production, poor cooling, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

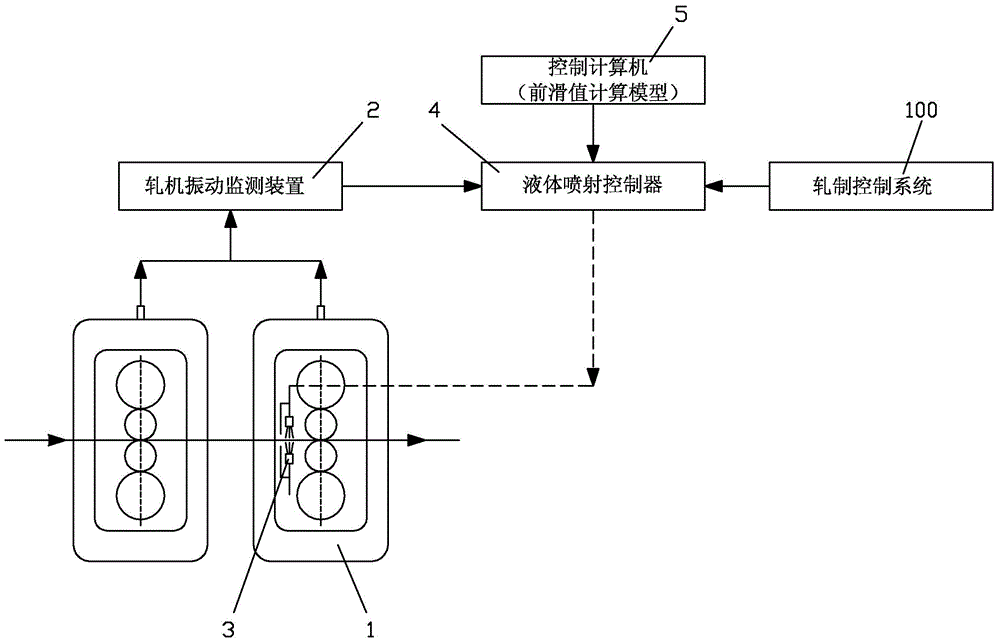

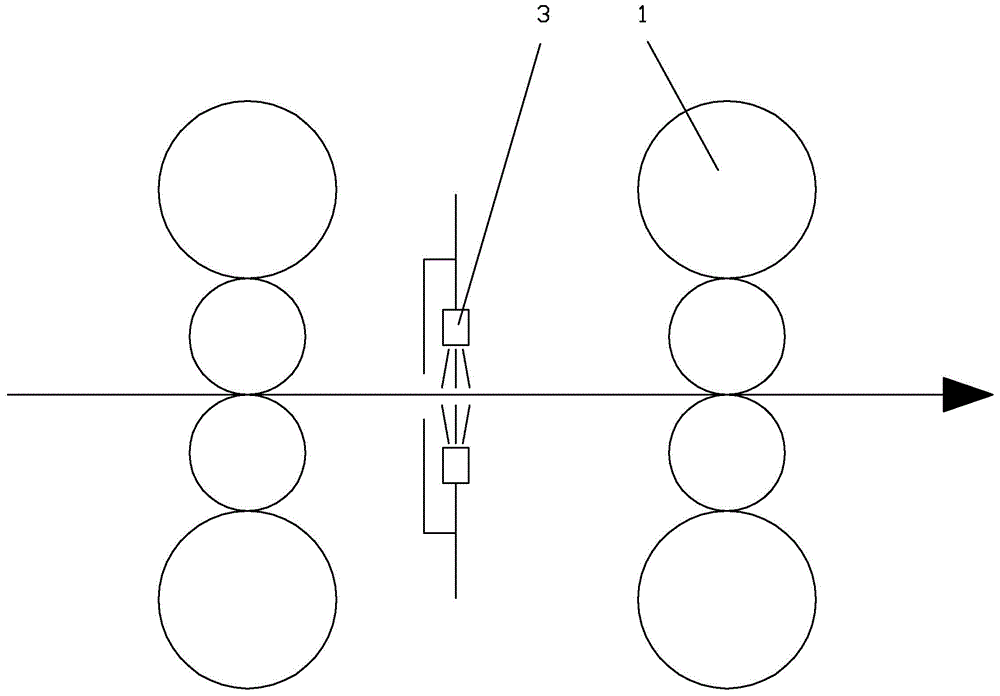

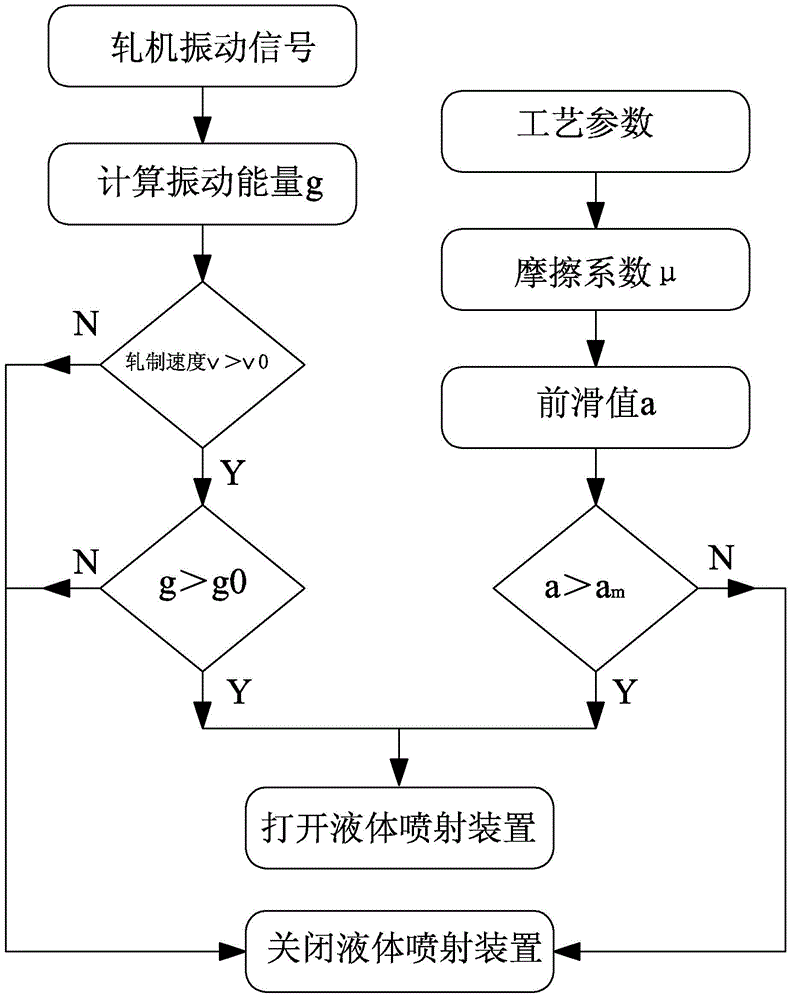

[0063] see Figure 1 to Figure 5 , the method for suppressing the vibration of the tandem cold rolling mill of the present invention, on the 5th or the 4th stand 1 of the five-stand tandem cold rolling mill, the vibration monitoring device 2 of the cold rolling mill is set, that is, a vibration sensor is installed on the top of the frame archway, The vibration signal of the rolling mill is transmitted by the vibration sensor to the data collector in the vibration monitoring device. The data collector collects and processes the vibration signal and provides it to the rolling mill vibration monitoring device 2. The rolling mill vibration monitoring device judges whether the rolling mill needs to Vibration occurs.

[0064] Before the inlet emulsion injection beam of the 5th or 4th stand of the rolling mill, a liquid injection device 3 that can independently adjust the flow rate is installed; the liquid injection device controller 4 is connected to the rolling mill vibration monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com