Patents

Literature

33results about How to "Hydraulic pressure reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

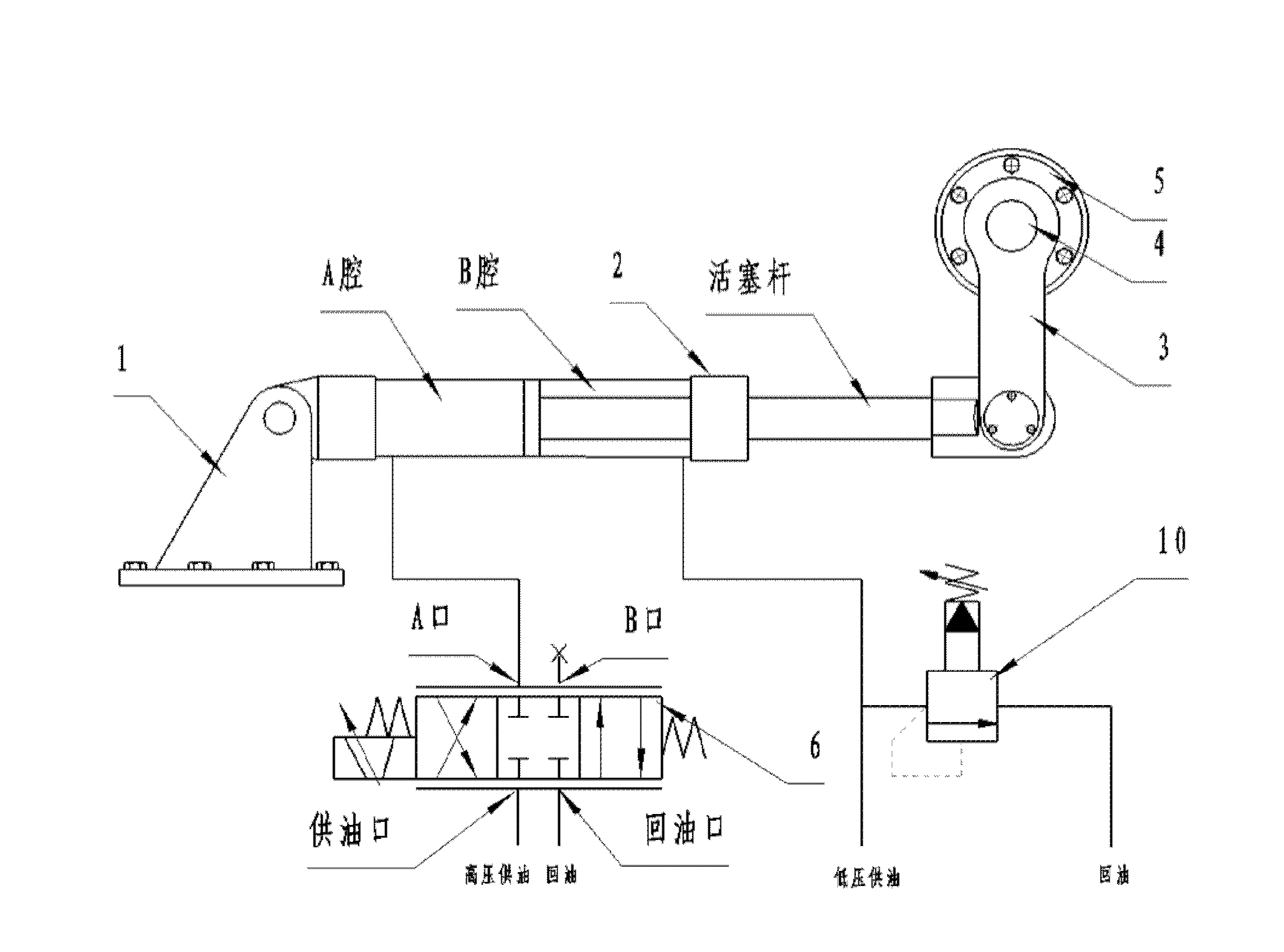

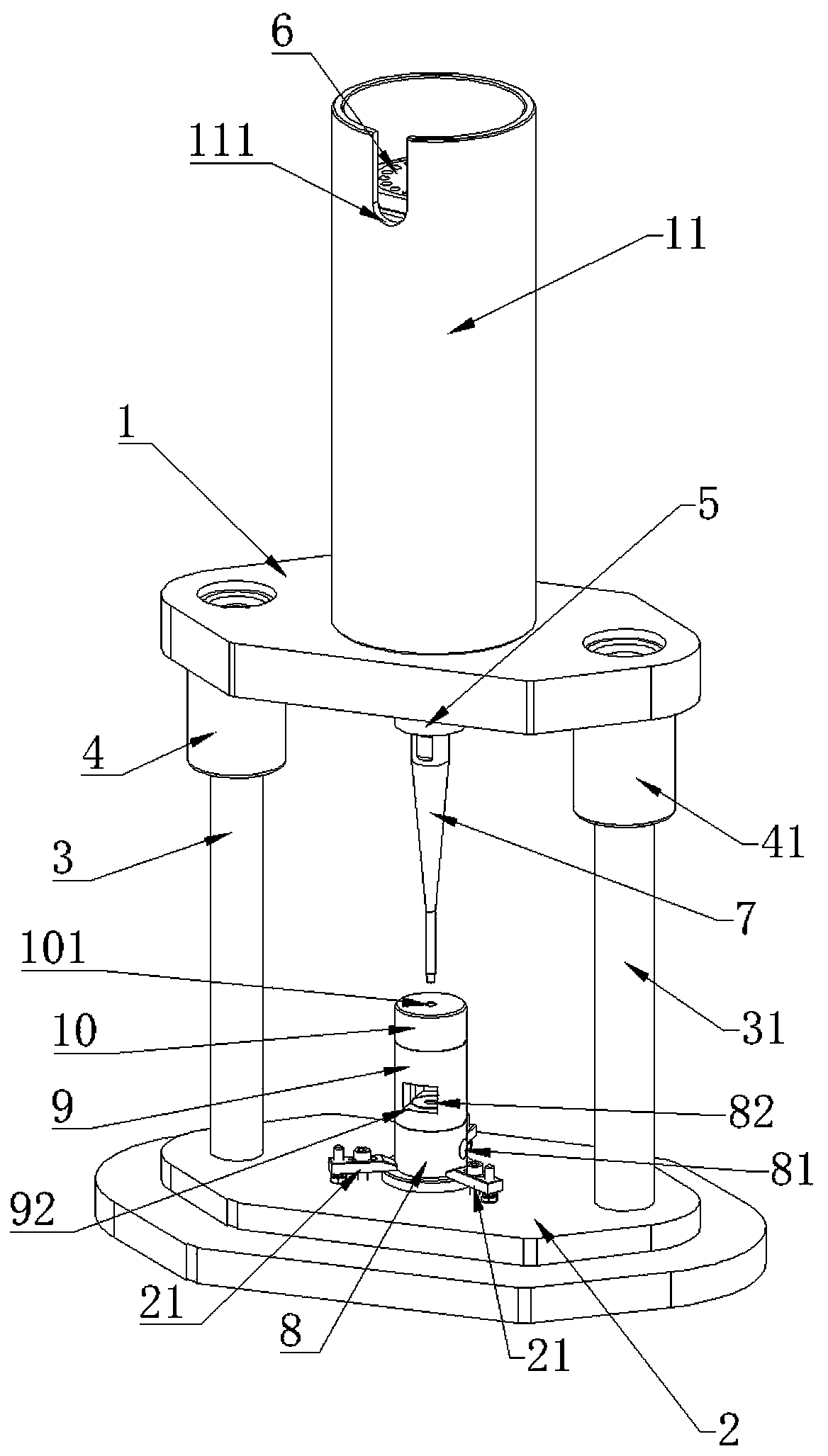

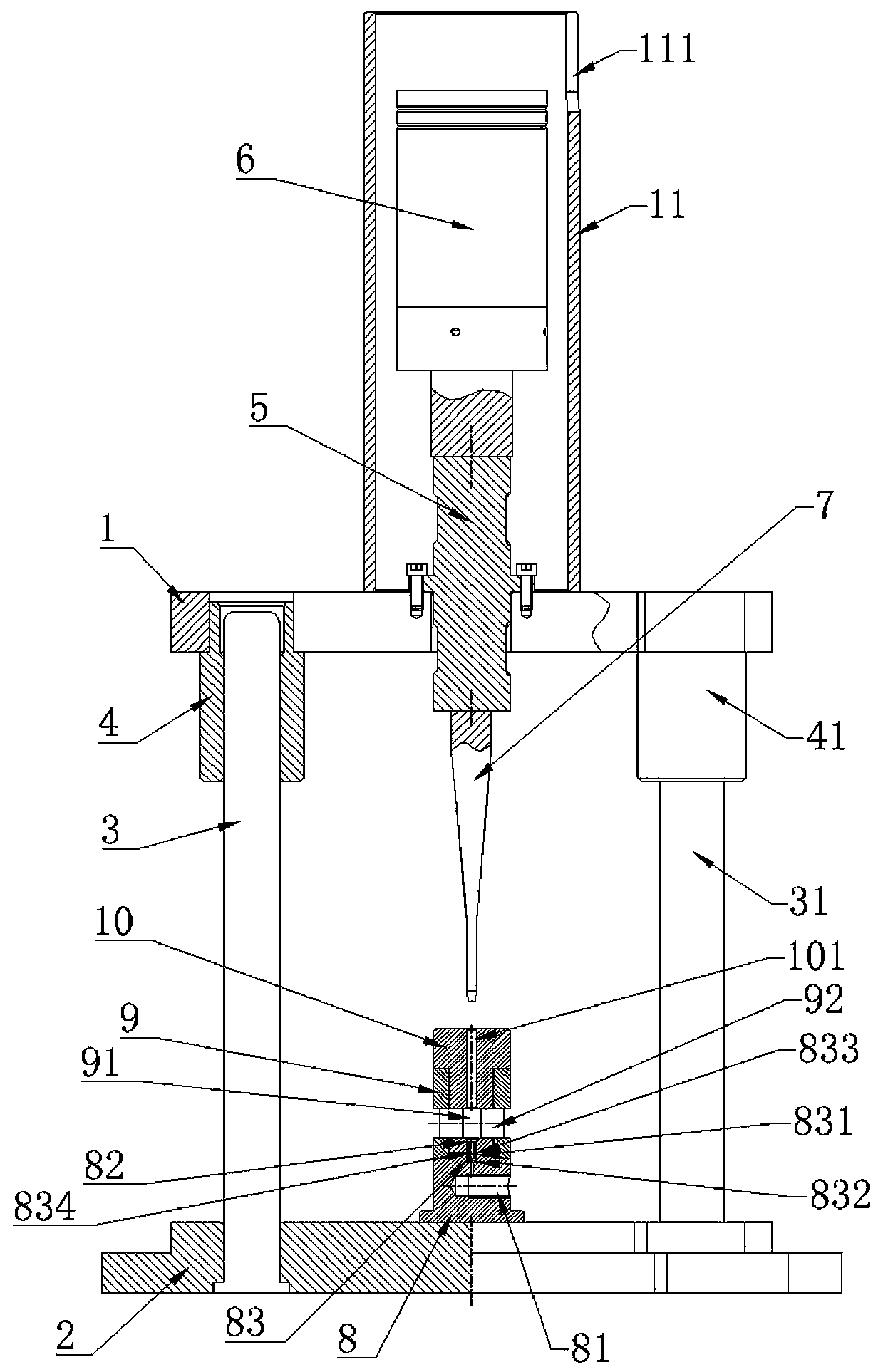

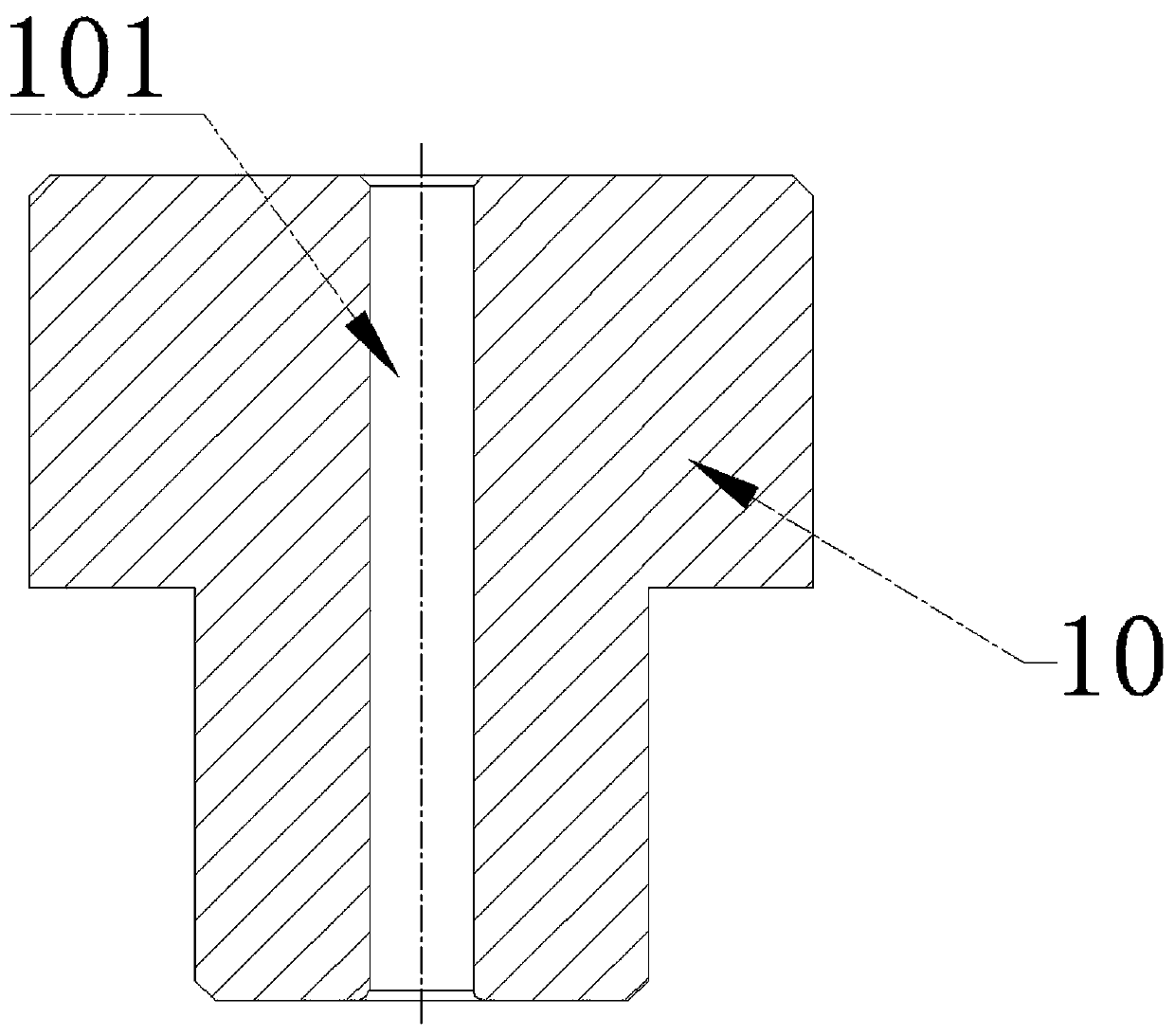

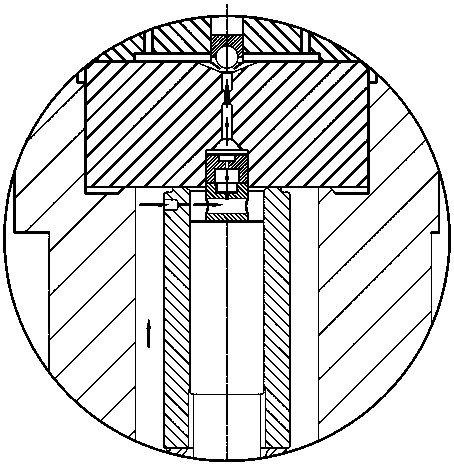

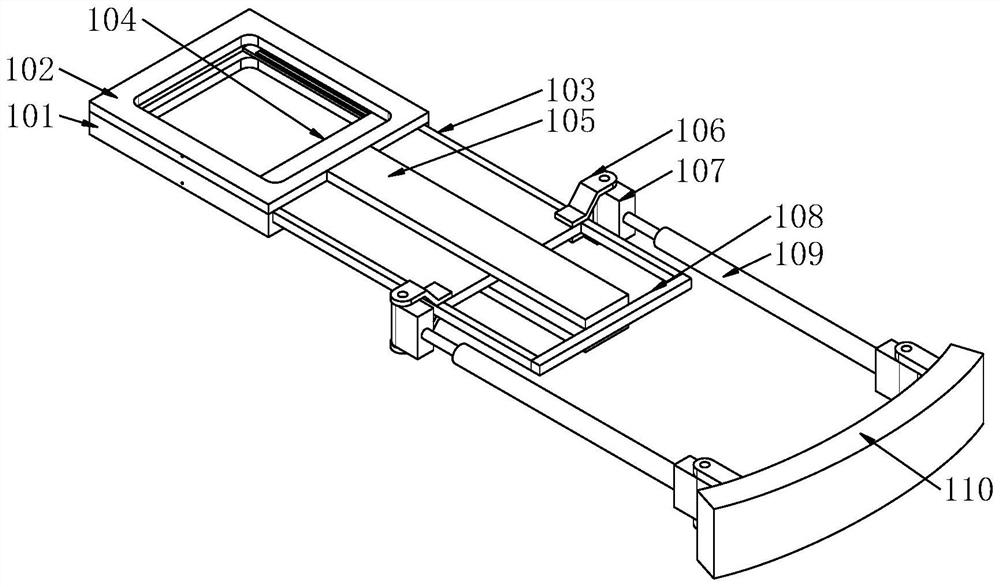

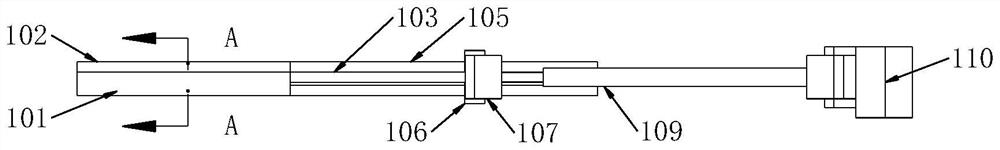

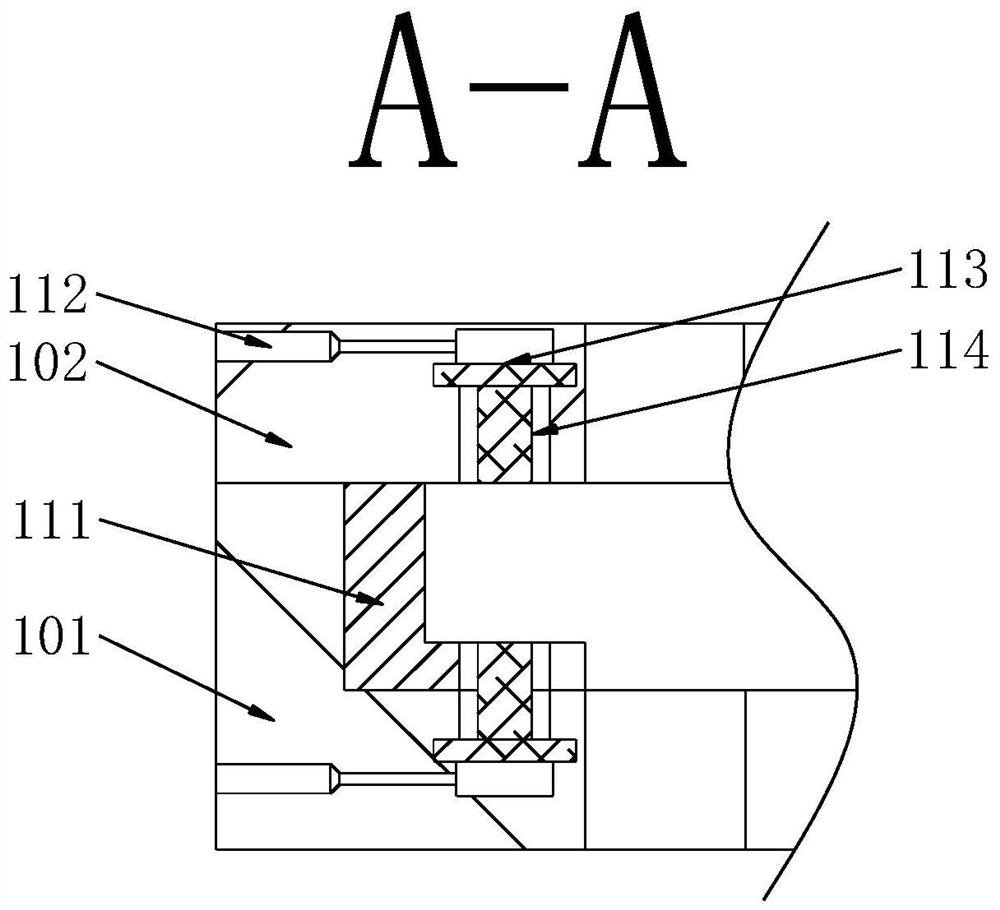

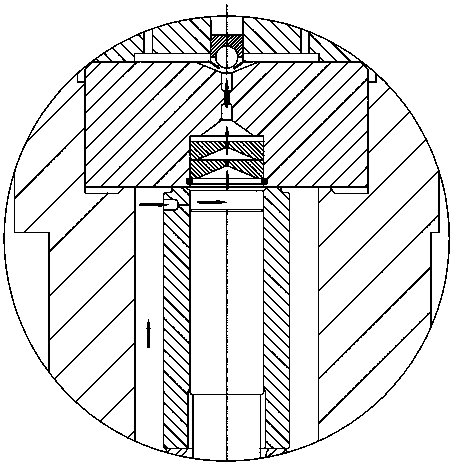

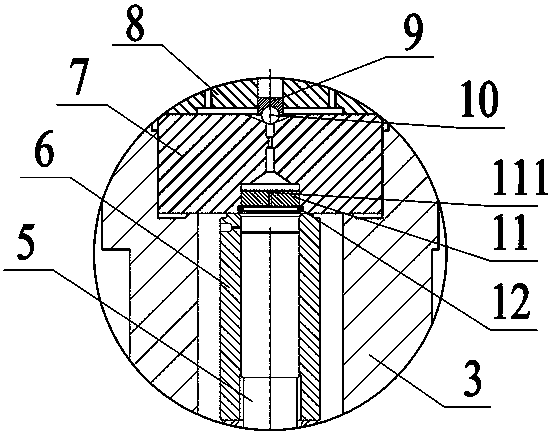

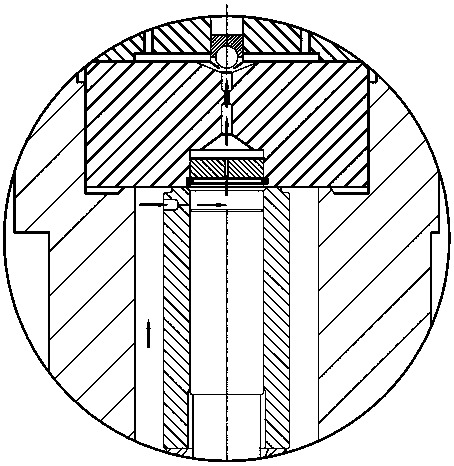

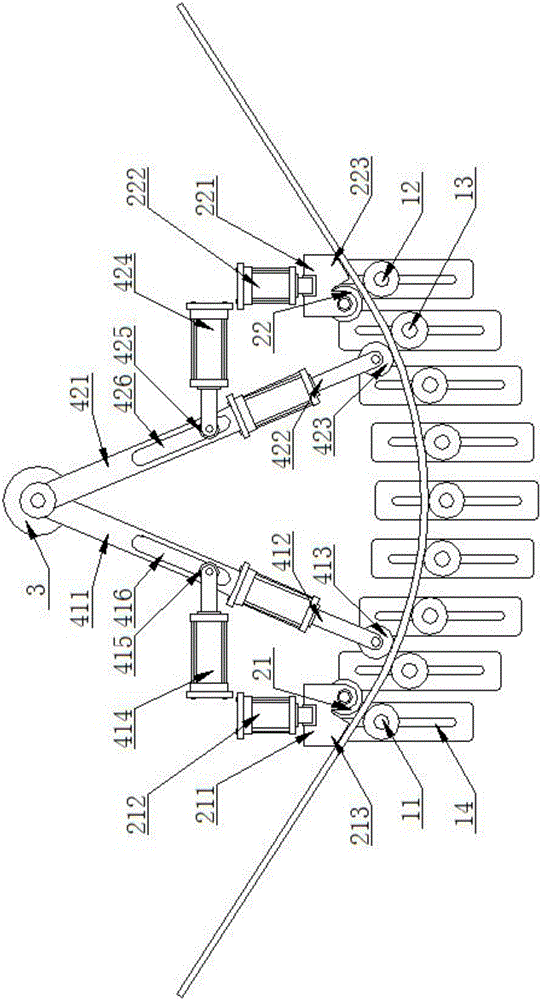

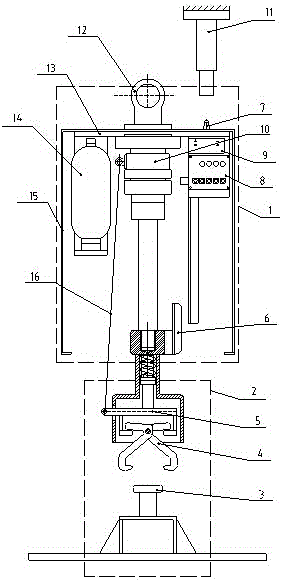

Segmented retardant discharging device

InactiveCN104444756AHydraulic pressure reductionReduce reboundServomotor componentsAccumulator installationsMachining vibrationsHooking

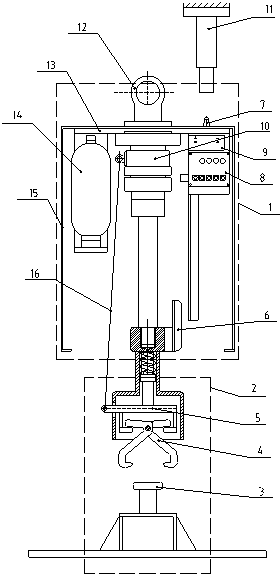

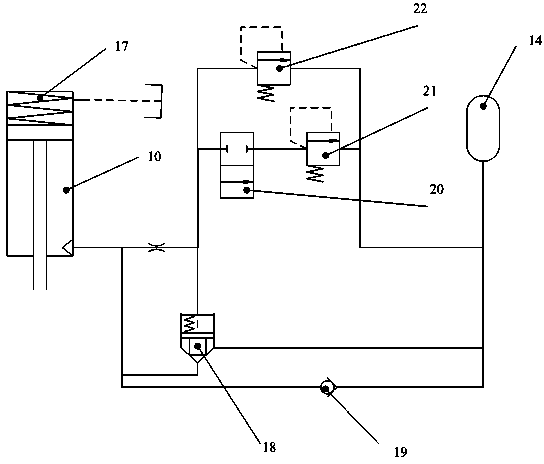

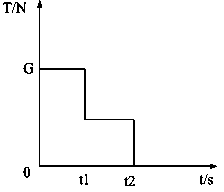

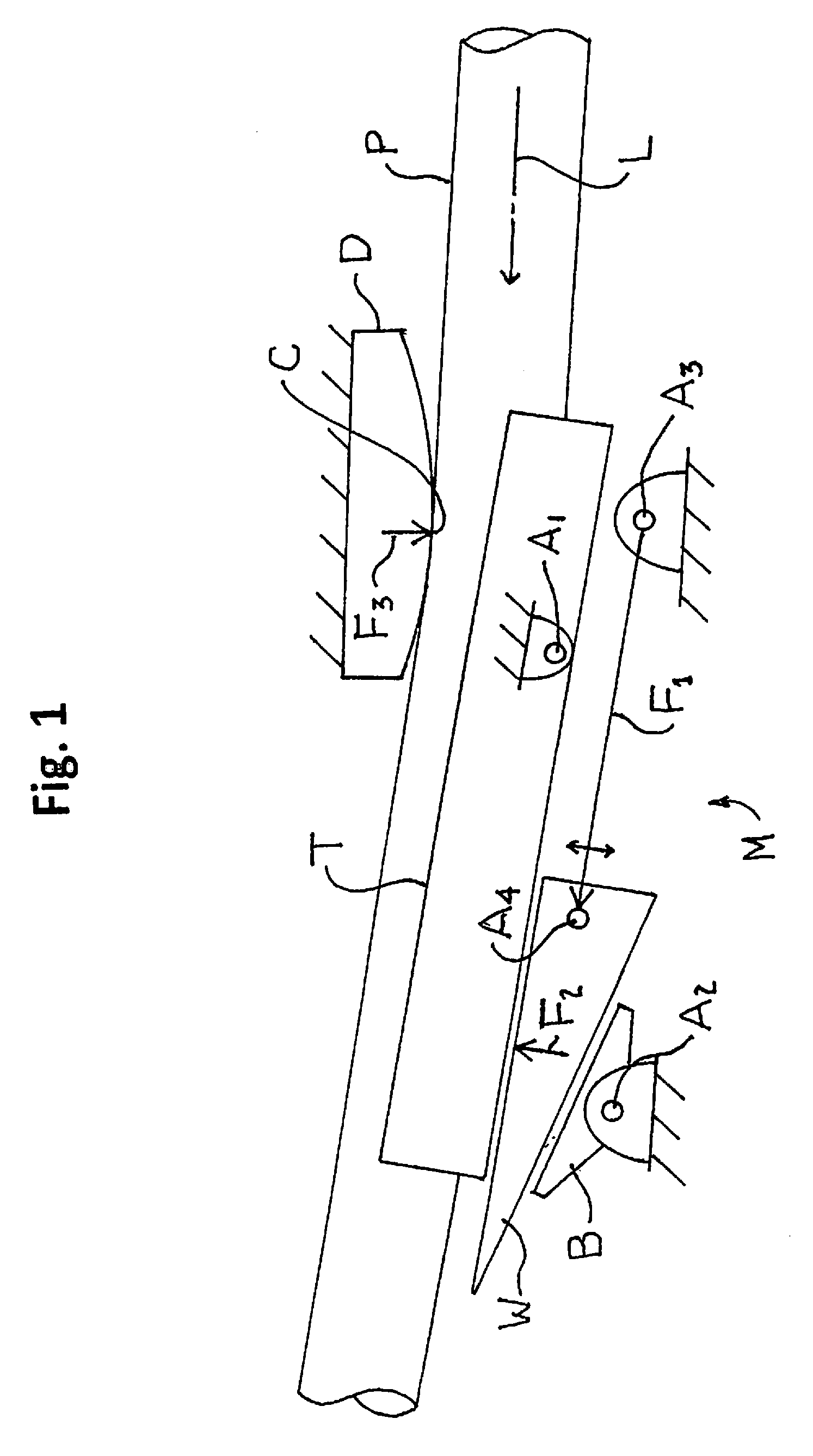

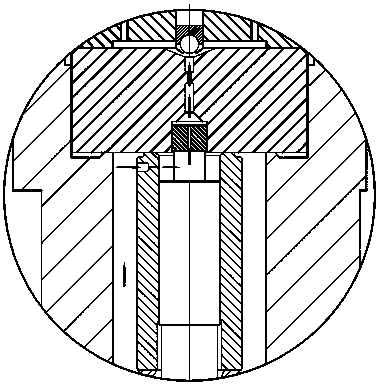

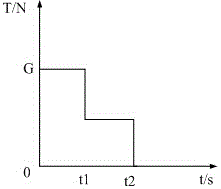

The invention discloses a segmented retardant discharging device. The segmented retardant discharging device comprises an automatic hooking device and a retarder, wherein the automatic hooking device is positioned below the retarder and is connected with the retarder, a spring feeler lever is arranged above the retarder, and the retarder is internally provided with a hydraulic oil path used for controlling hydraulic pressure of the retarder. According to the segmented retardant discharging device disclosed by the invention, by reducing the hydraulic pressure of the retarder in a grading mode, tensile force of a steel wire rope for hanging a heavy hammer is gradually reduced, and the heavy hammer is subjected to putting down in a stair-shaped slow descending mode from a step releasing mode, so that impact to a system due to heavy hammer release is reduced, the rebound of a cargo boom is small, the rope disordering probability of the steel wire rope is low, the abrasion of the automatic hooking device is slight, the whole machine vibration is slight, and the service life is long.

Owner:刘洋

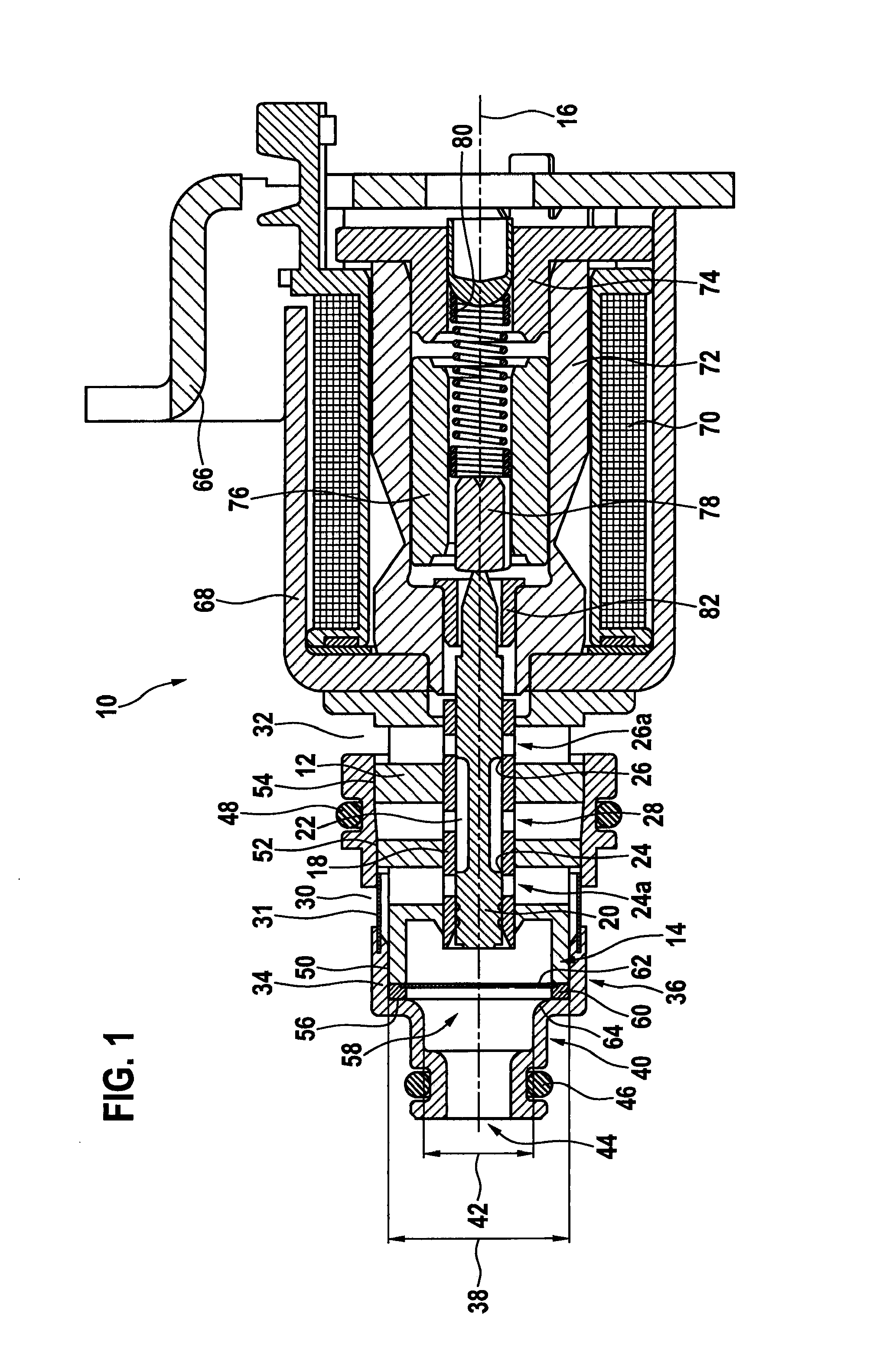

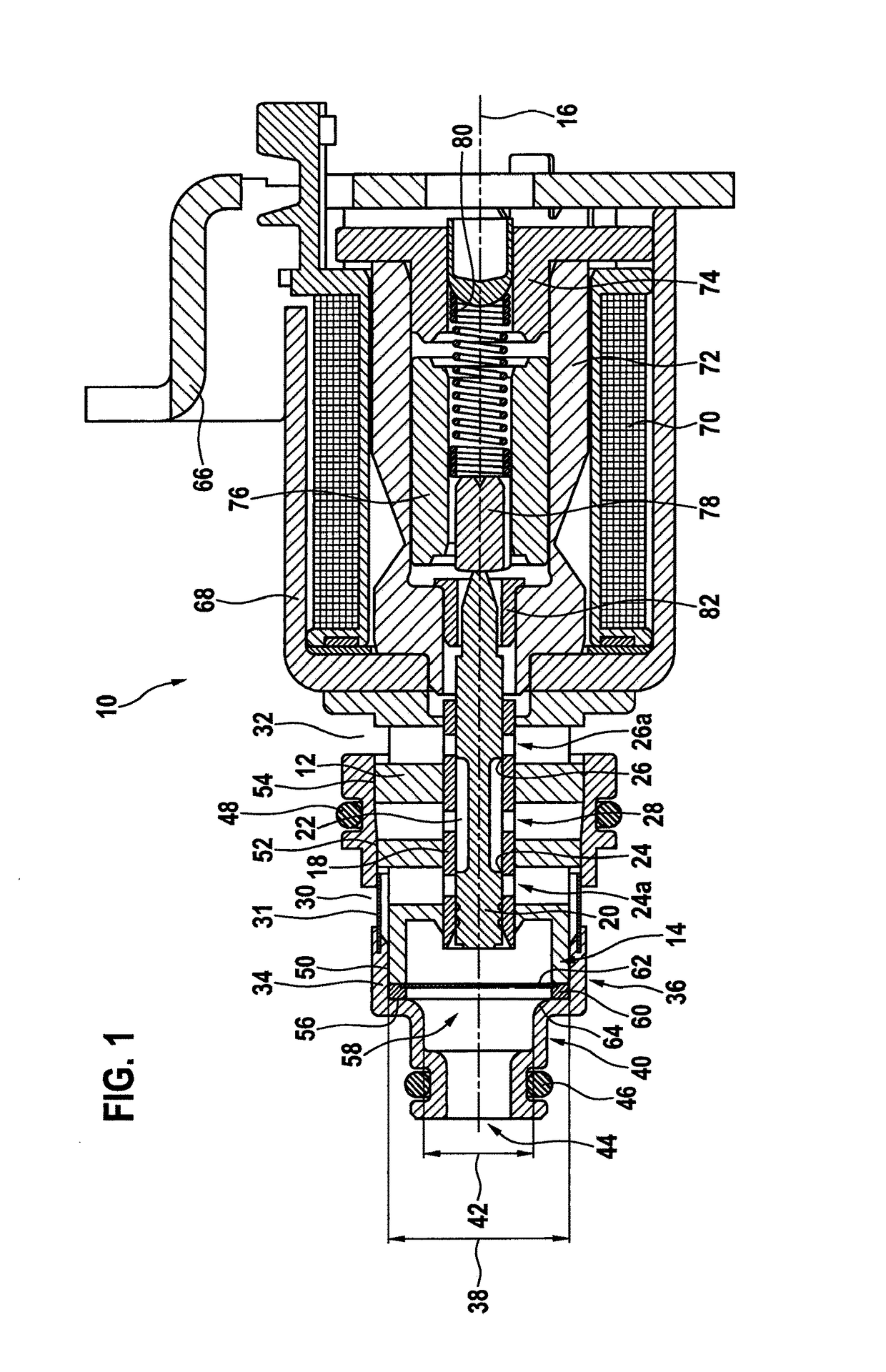

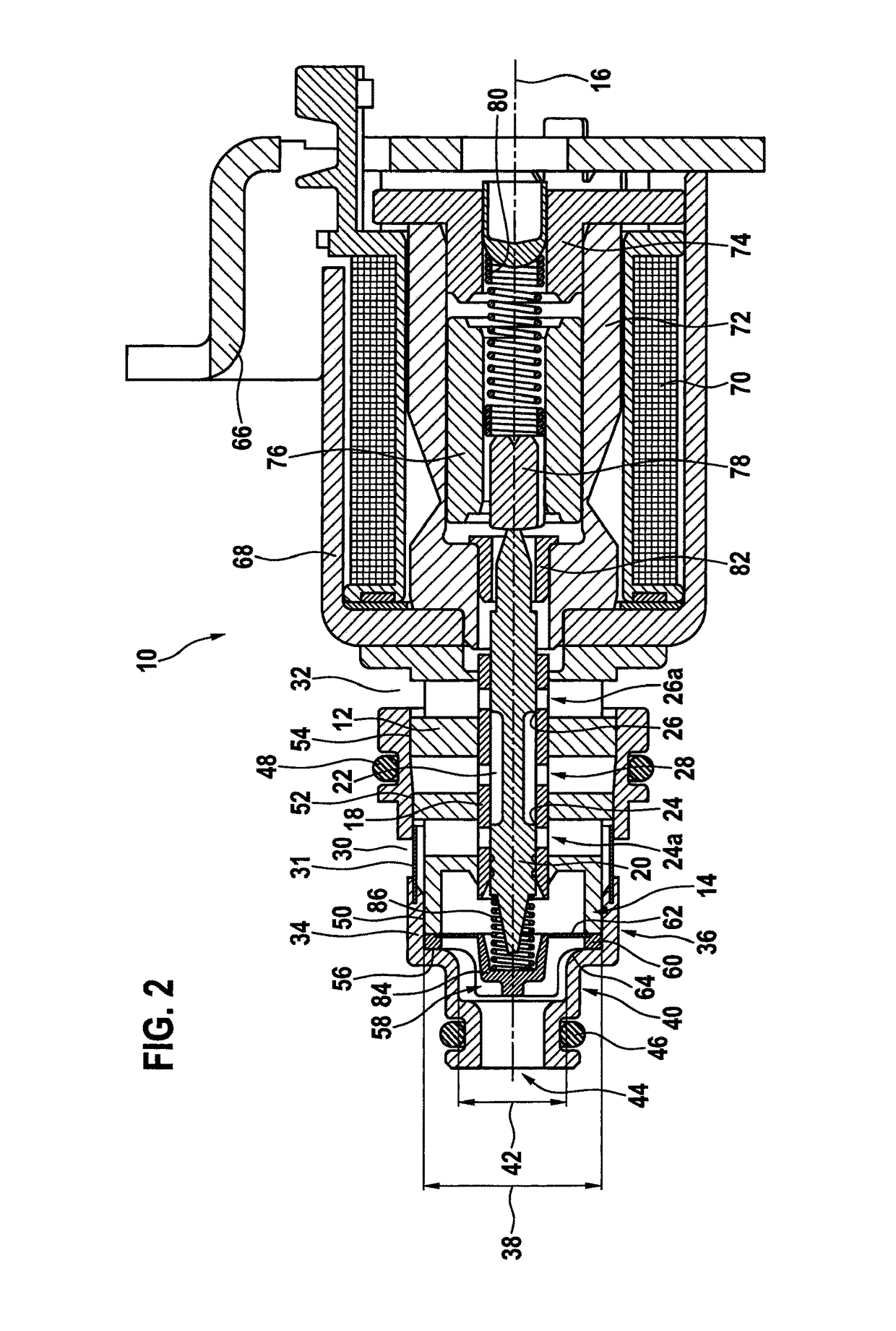

Slide valve, in particular for controlling a motor vehicle automatic transmission

ActiveUS20150354715A1Low costSave spaceOperating means/releasing devices for valvesGearing controlAutomatic controlAutomatic transmission

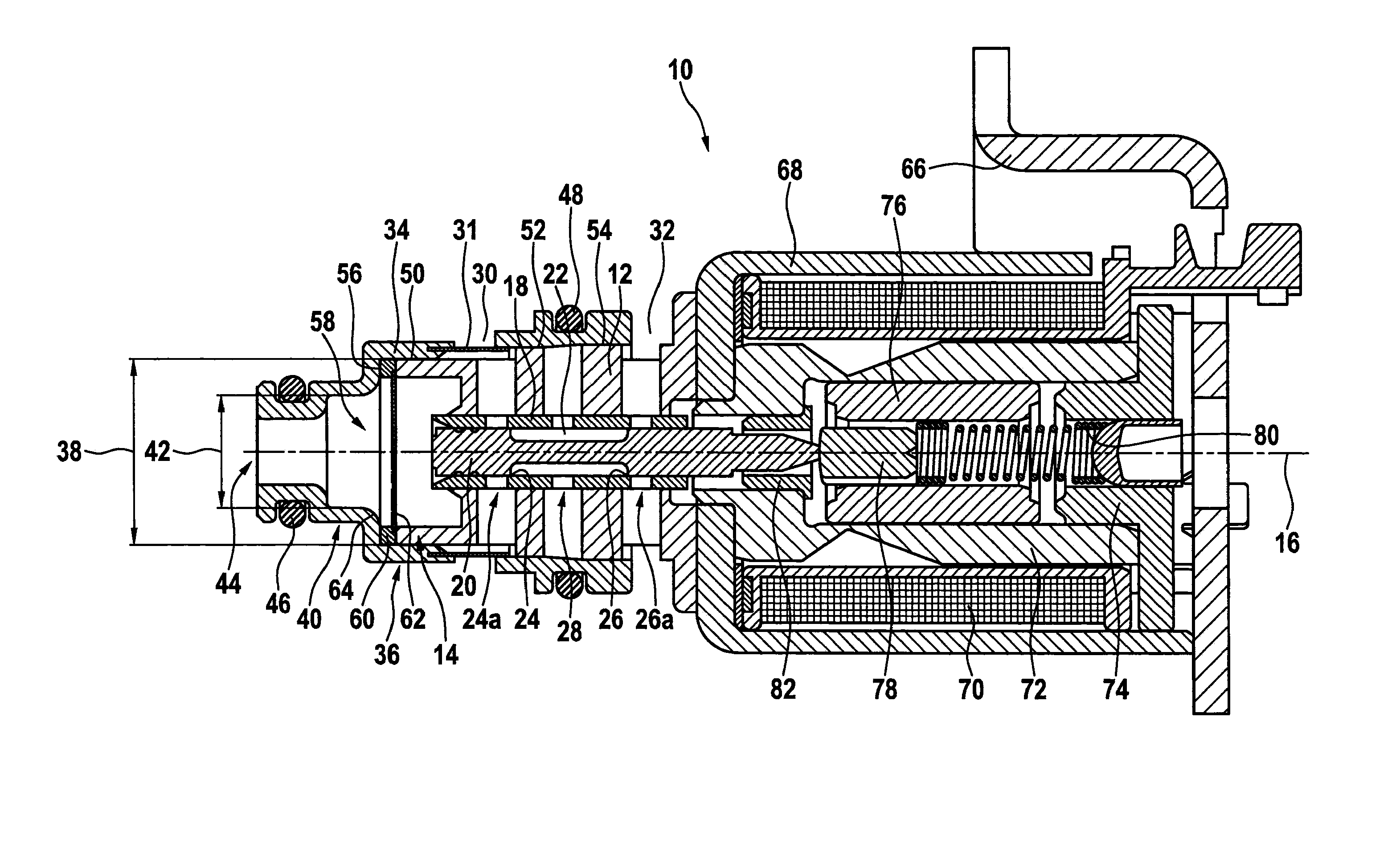

A slide valve, in particular for controlling a motor vehicle automatic transmission, has a housing which includes an axial end section. A connector sleeve is situated on the axial end section of the housing, the connector sleeve having a larger diameter in a first axial area adjacent to the housing and a smaller diameter in a second axial area remote from the housing, a filter device being situated in the first axial area. The second axial area includes a hydraulic connection.

Owner:ROBERT BOSCH GMBH

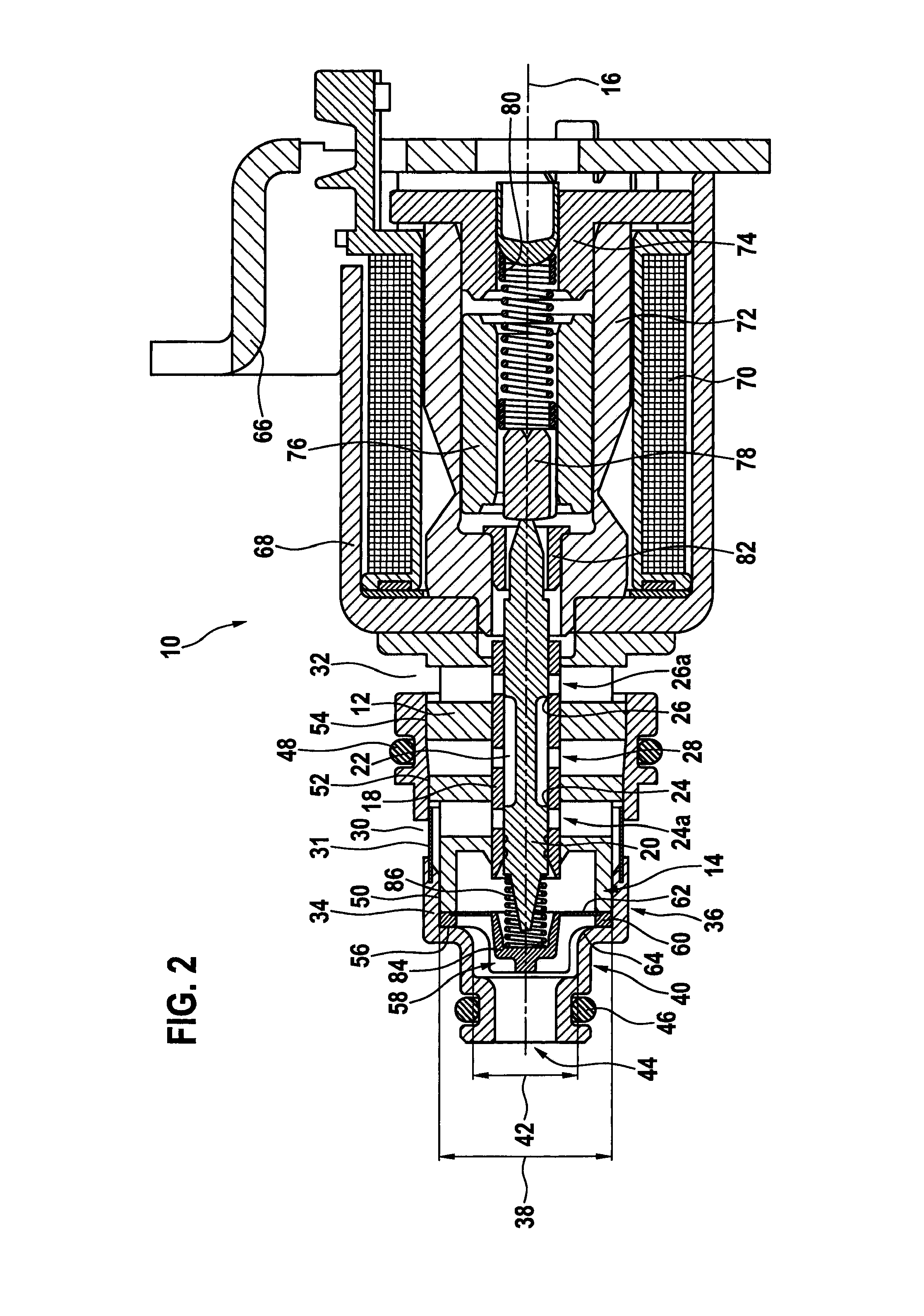

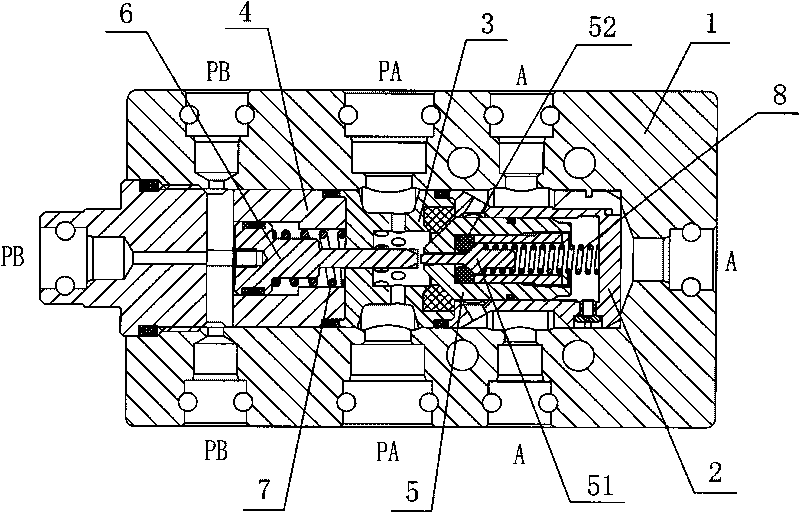

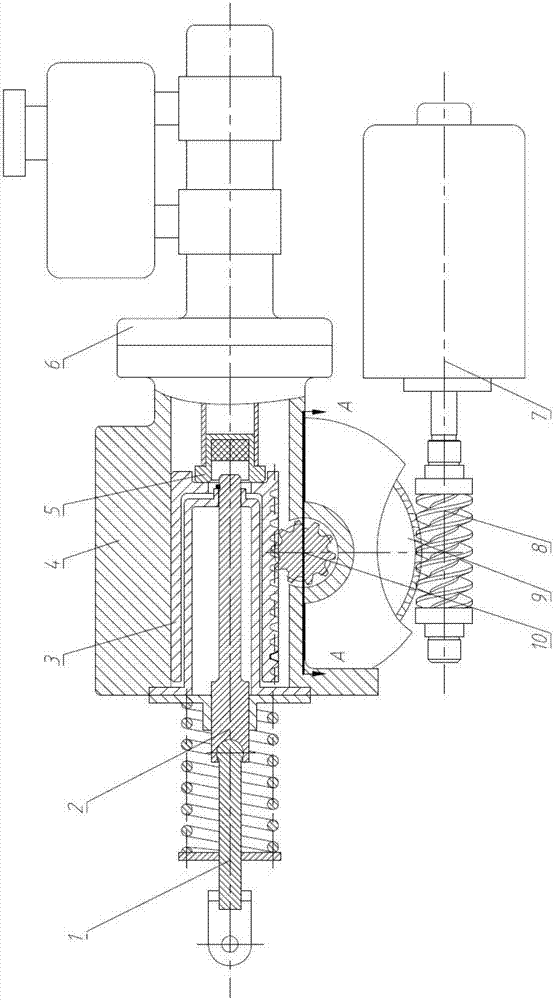

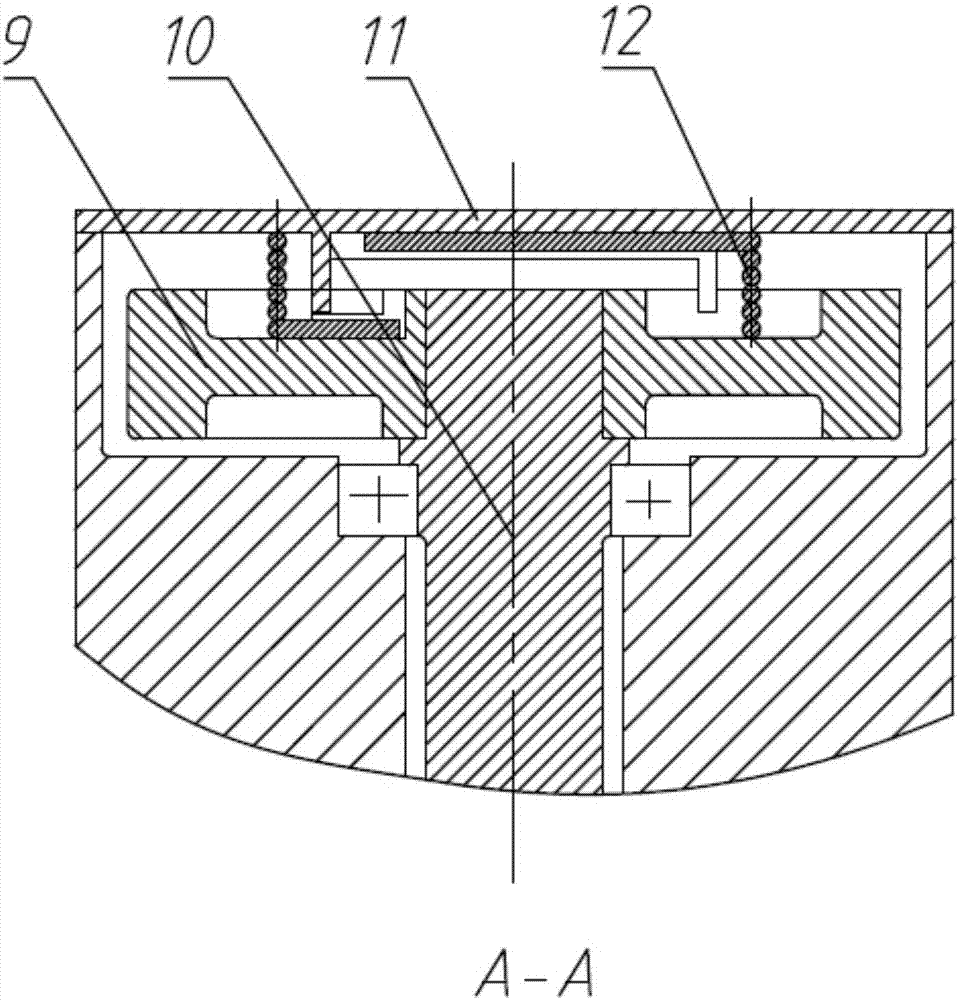

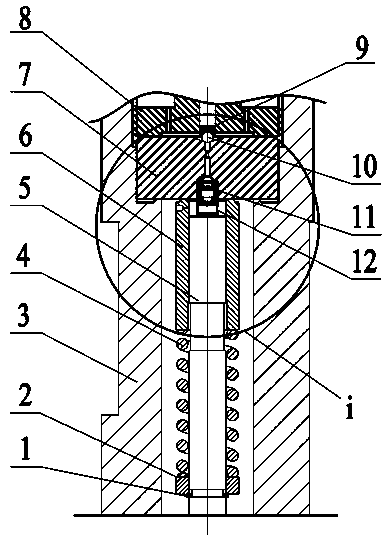

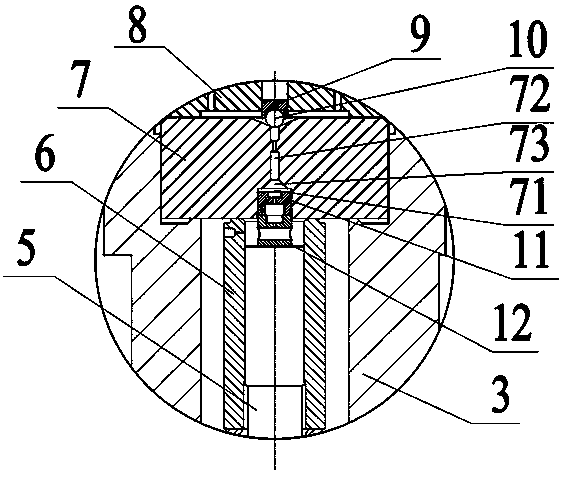

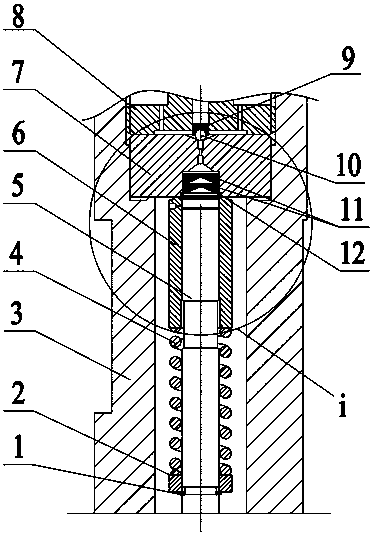

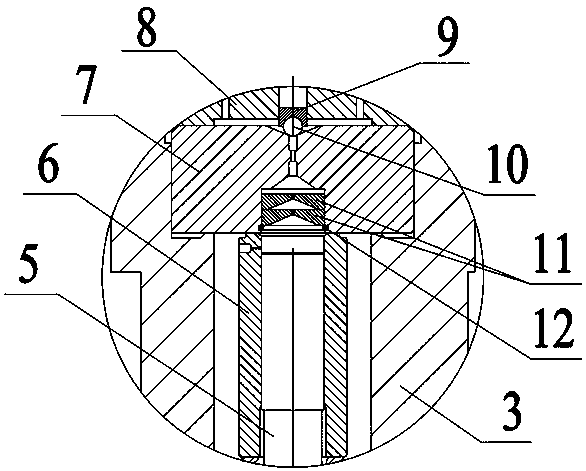

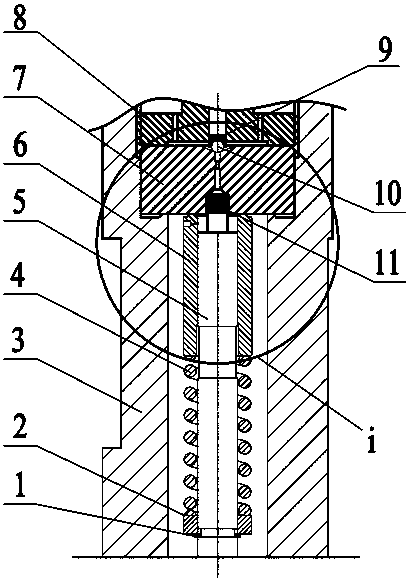

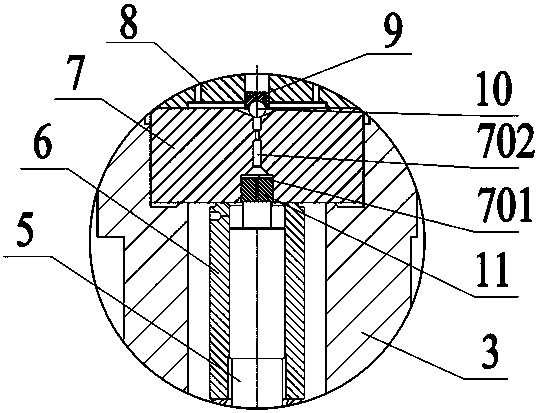

Hydraulic control one-way valve

InactiveCN101706012AReduce impactSmooth startOperating means/releasing devices for valvesCheck valvesPre compressionEngineering

The invention discloses a hydraulic control one-way valve, which comprises a valve body and a guide valve, a valve seat and a valve sleeve hermetically arranged in the valve body, wherein the valve seat is arranged between the guide valve and the valve sleeve; the inside of the guide valve is provided with a valve core; the end of the valve core is pressed against the valve seat; a piston is hermetically arranged in the valve sleeve; the end of the piston penetrates into the valve seat and is opposite to the front end of the valve core; a first spring is connected between the piston and the end face of the valve seat in a pressing way; the valve body is respectively provided with at least one first interface, one second interface and one third interface; the first interface is communicated with the guide valve; the second interface is communicated with the valve seat; and the third interface is communicated with the valve sleeve; the characteristic is that a pre-compression device is arranged in the valve core; and the advantages are that: since the pre-compression device is arranged in the valve core, the hydraulic control one-way valve reduces the impact force of hydraulic pressure on a subsequent connecting piece in the starting process, stabilizes the startup and reset of the subsequent connecting piece and reduces the hydraulic pressure required for starting.

Owner:NINGBO LONG WALL FLUID KINETIC SCI TECH

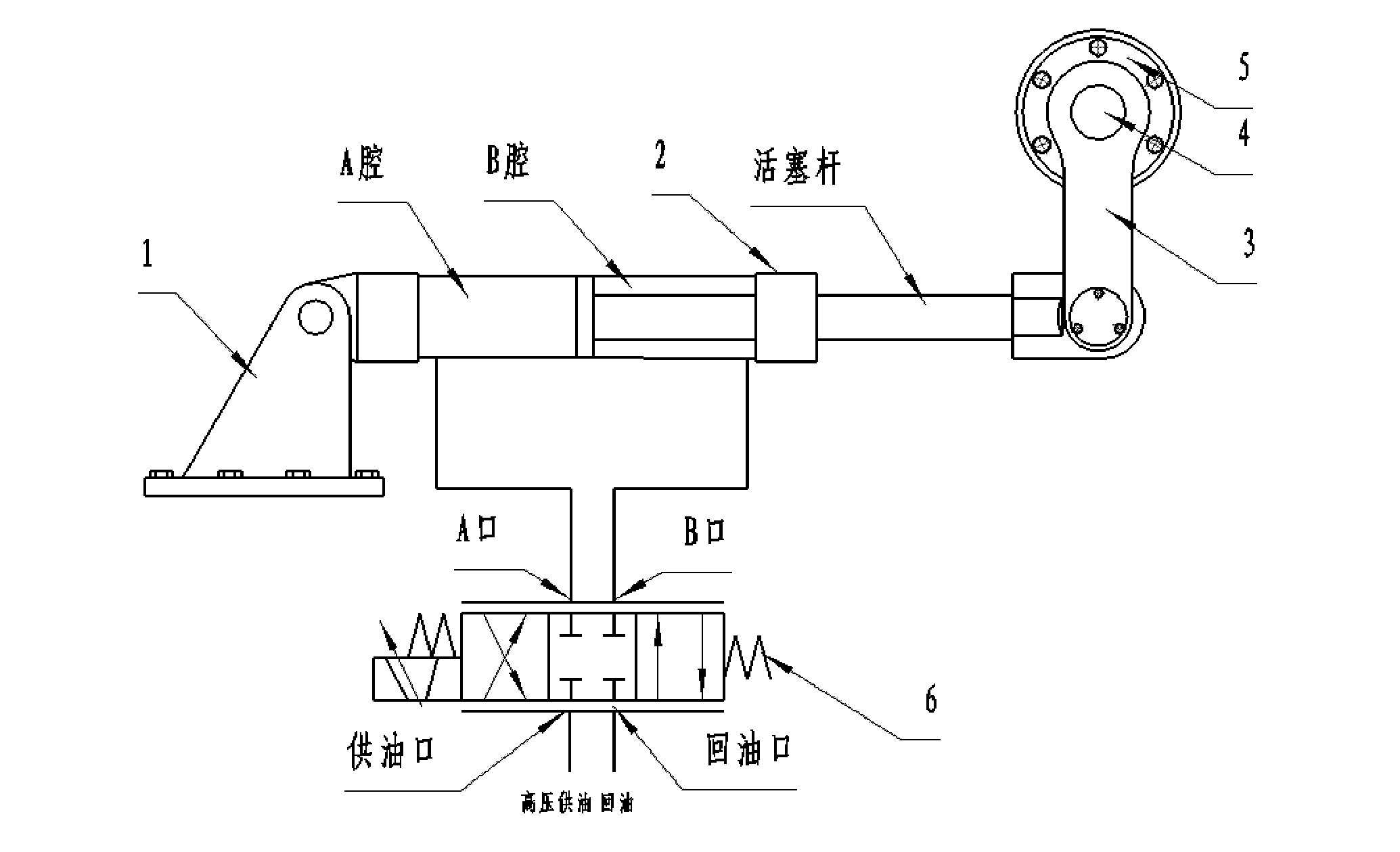

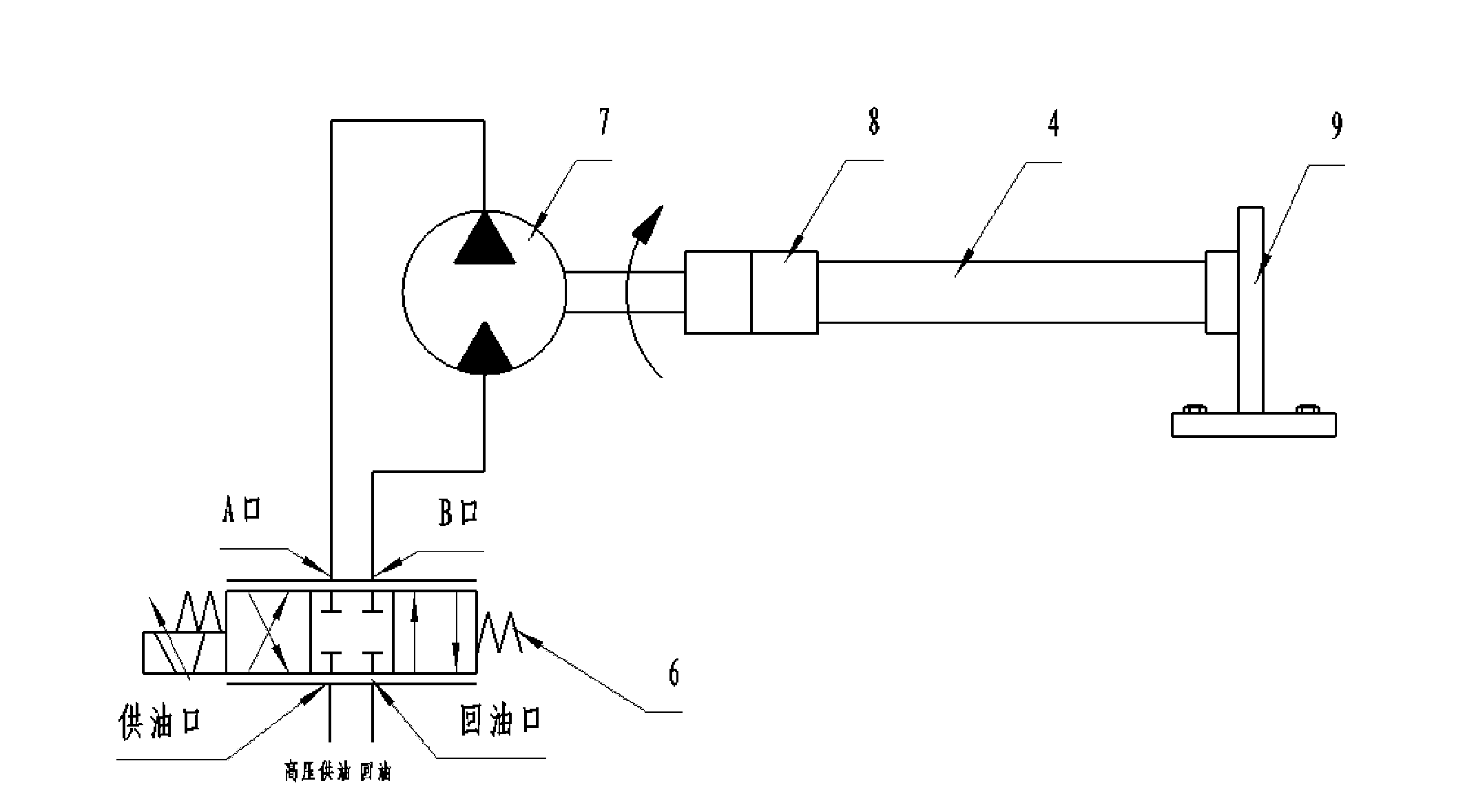

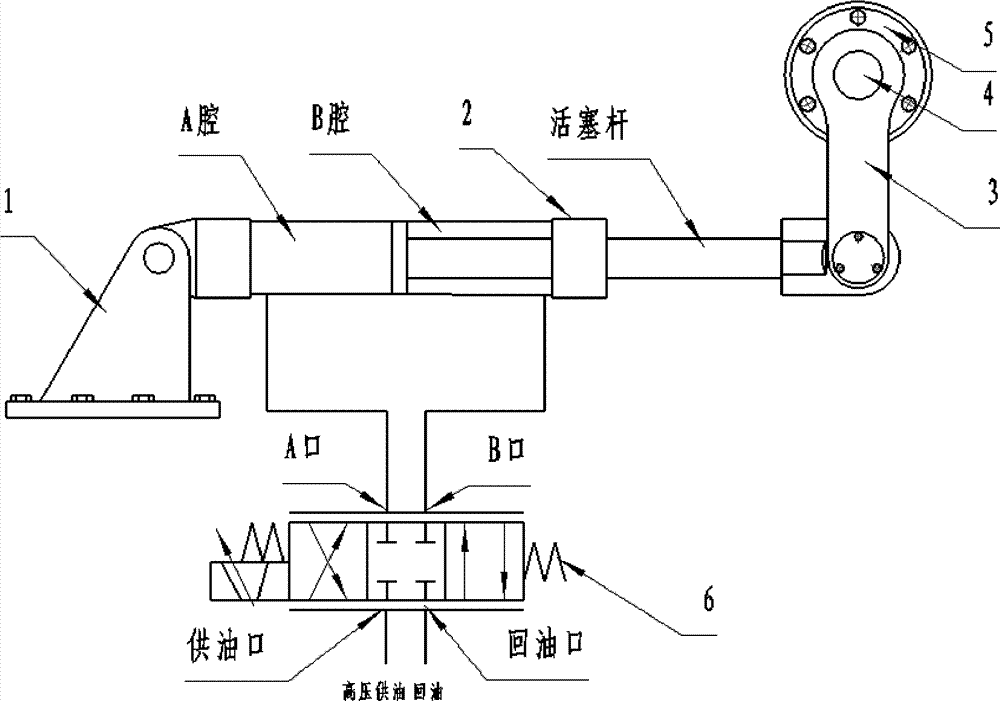

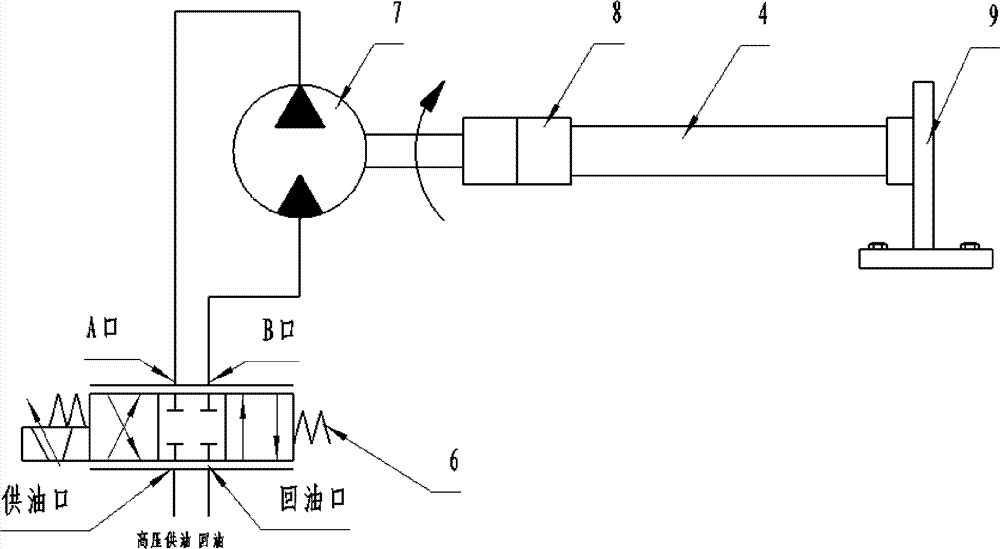

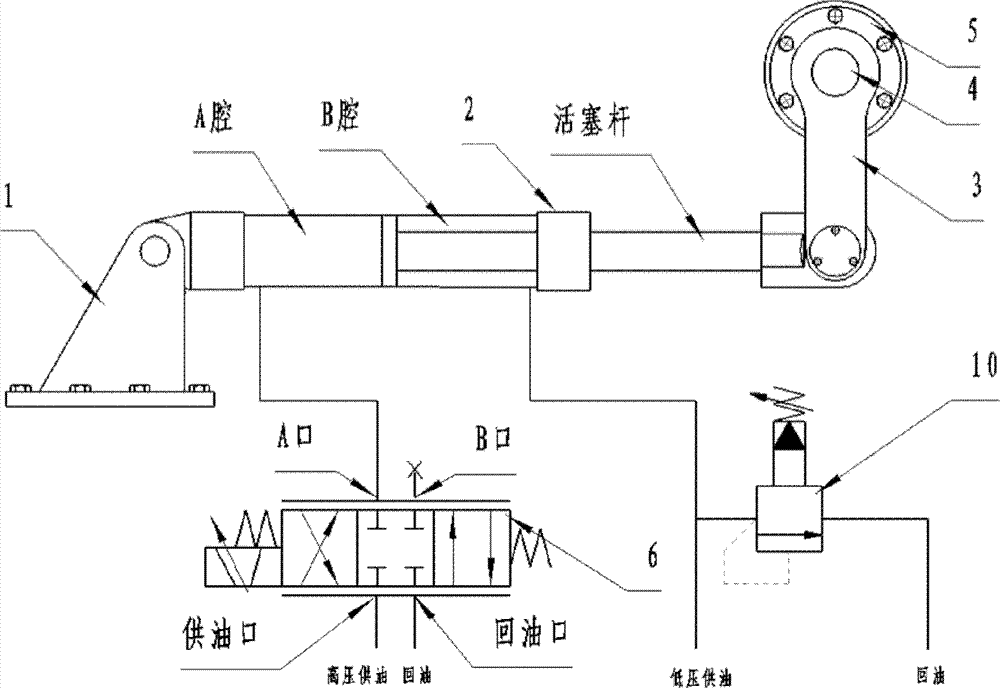

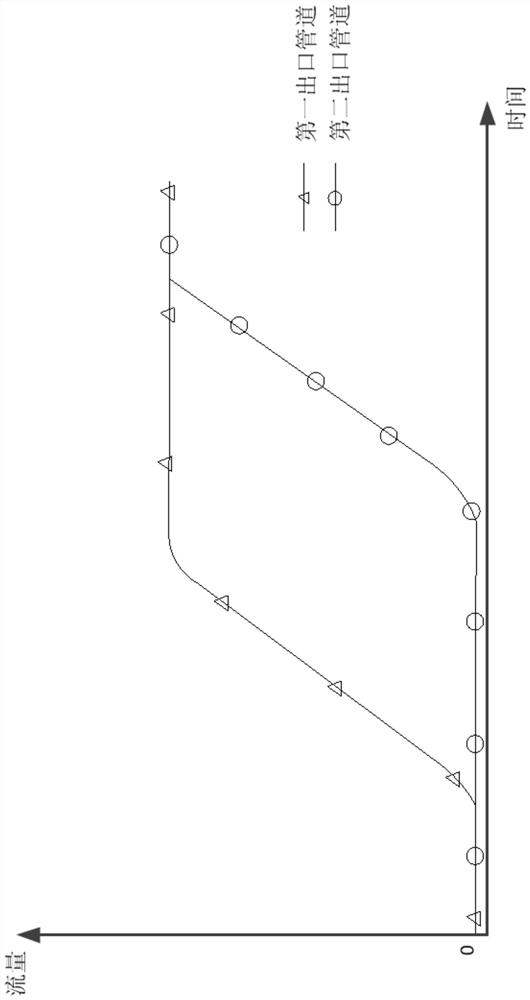

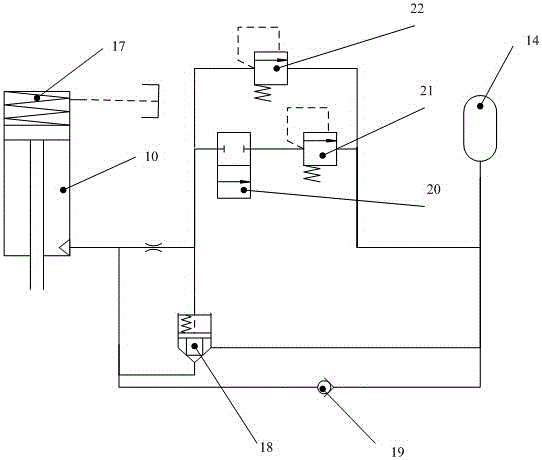

Method and device for energy-saving control of elastic load based on electrohydraulic servo drive

InactiveCN102493968AReduce control difficultyHydraulic pressure reductionServomotor componentsHydraulic cylinderHydraulic motor

The invention provides a method and a device for energy-saving control of an elastic load based on electrohydraulic servo drive. The device comprises a servo valve, a high-pressure oil source, a low-pressure oil source, an overflow valve and an actuating mechanism, wherein the actuating mechanism is a hydraulic cylinder or a hydraulic motor; an oil supply port of the servo valve is connected with the high-pressure oil source, an oil return port of the servo valve is connected with an oil tank, and a B port of the servo valve is blocked; an A port of the servo valve is connected with an A cavity of the actuating mechanism, the low-pressure oil source is connected with a B cavity of the actuating mechanism, the B cavity of the actuating mechanism is connected with an inlet of the overflow valve, and an outlet of the overflow valve is connected with the oil tank; and the actuating mechanism is connected with the elastic load. A setting principle of the pressure of the low-pressure oil source is that: the force generated by the low-pressure oil source in the B cavity of the actuating mechanism can offset the friction of the actuating mechanism. By the method and the device, the problem that the motion law is difficult to control accurately when the elastic load moves from maximum position to zero position, and energy sources can also be saved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

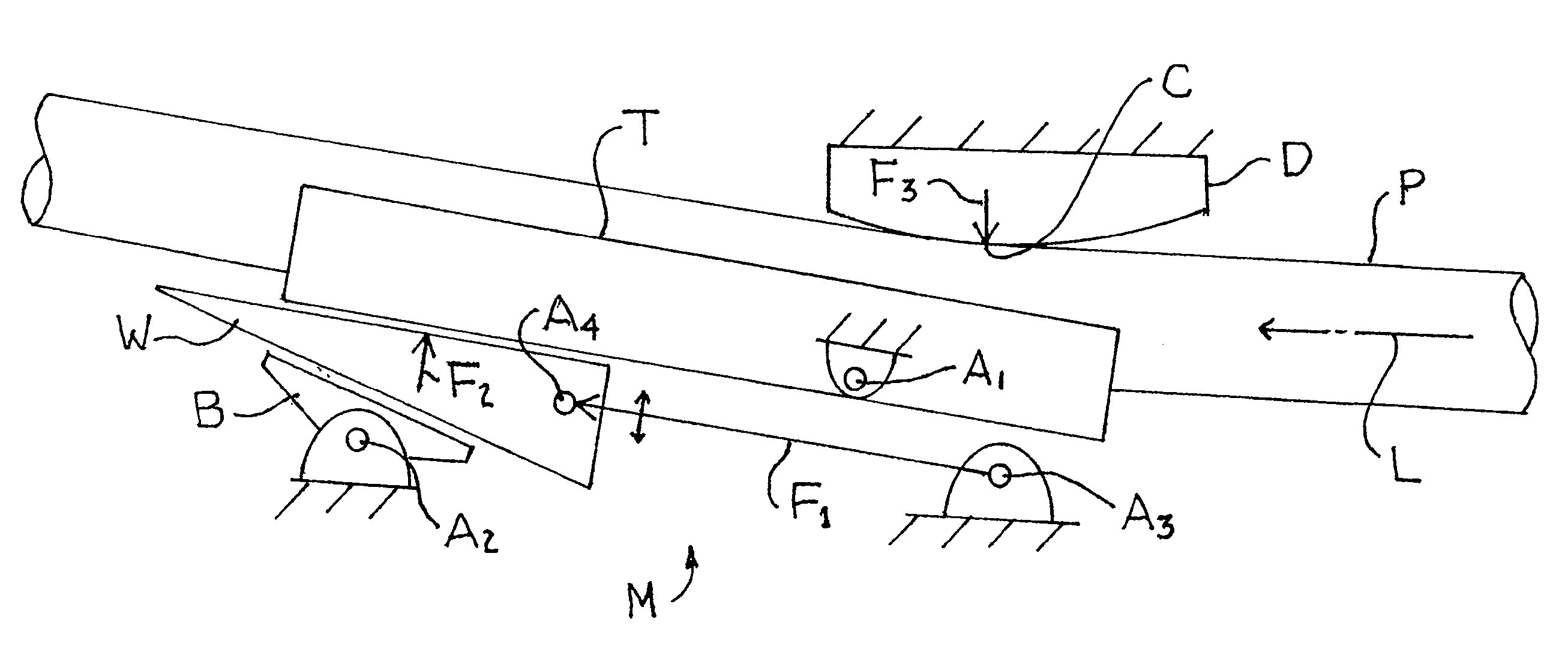

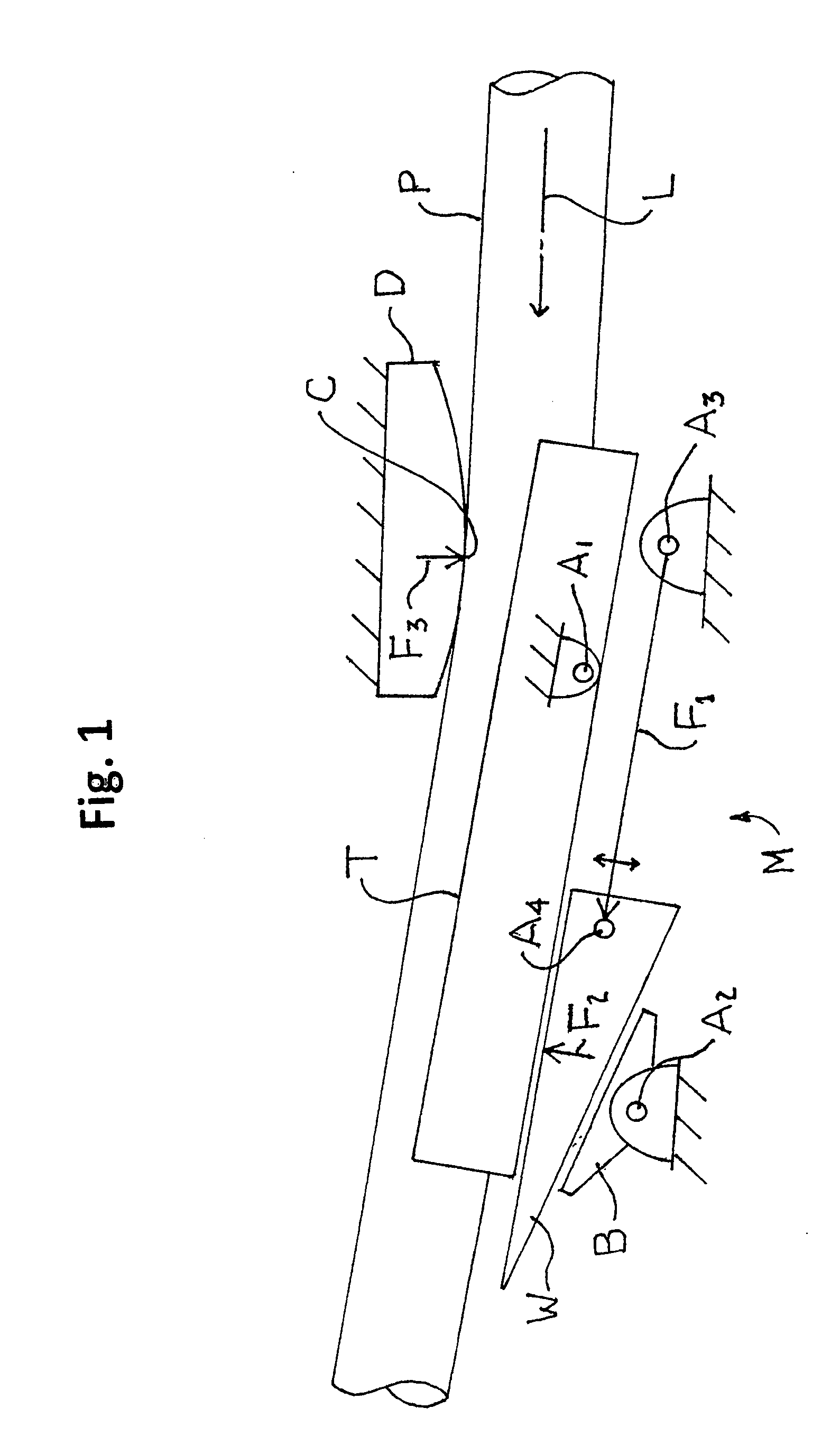

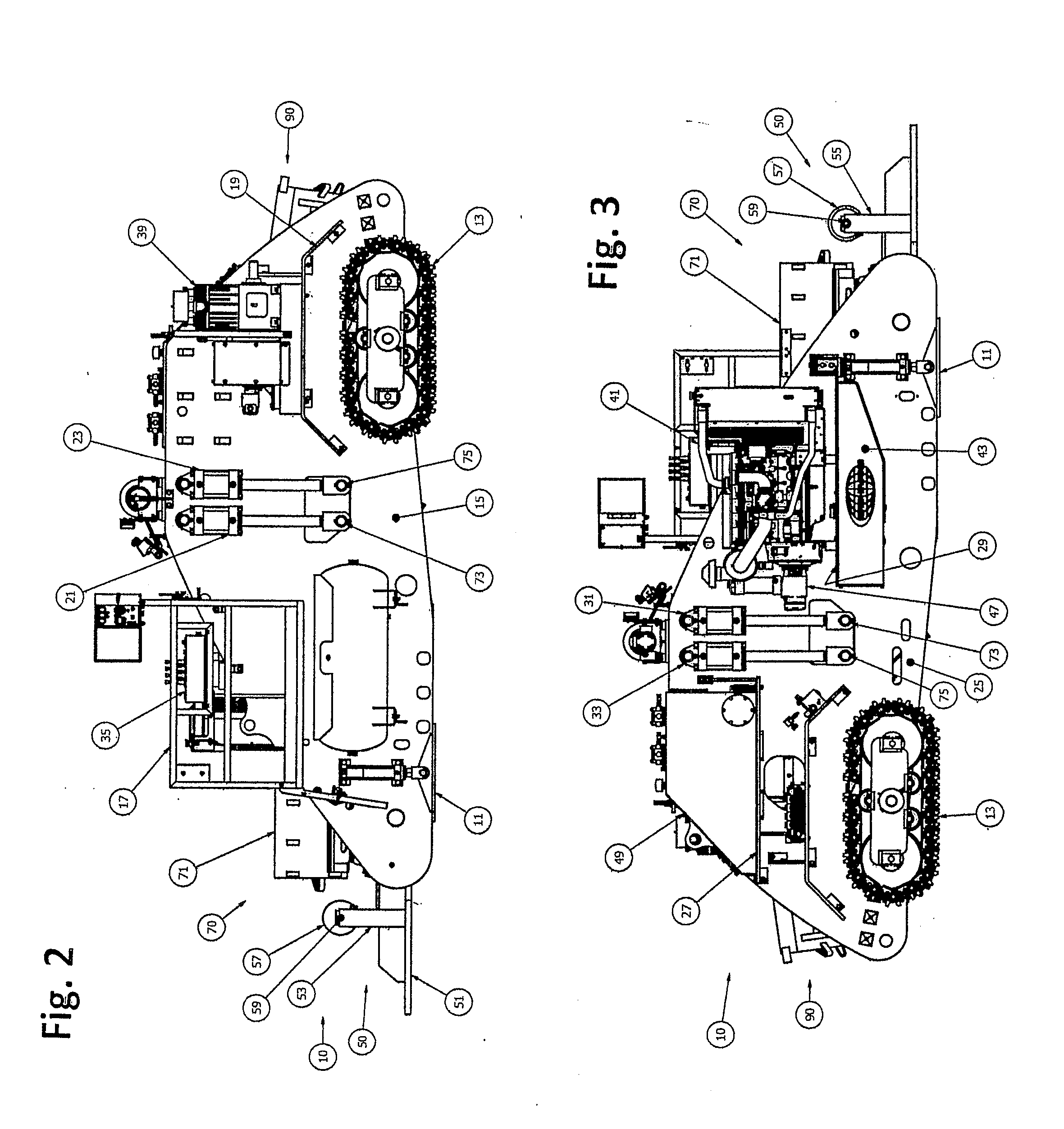

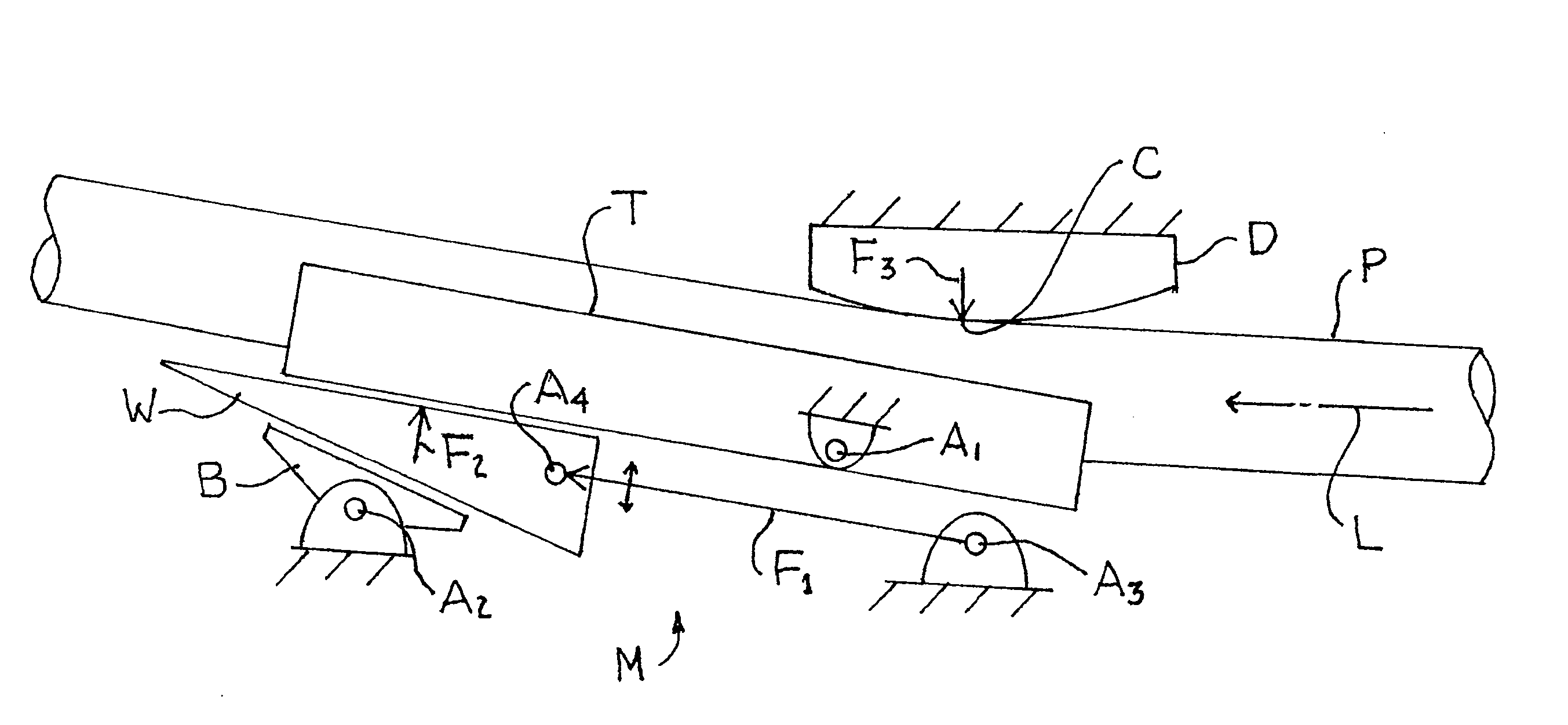

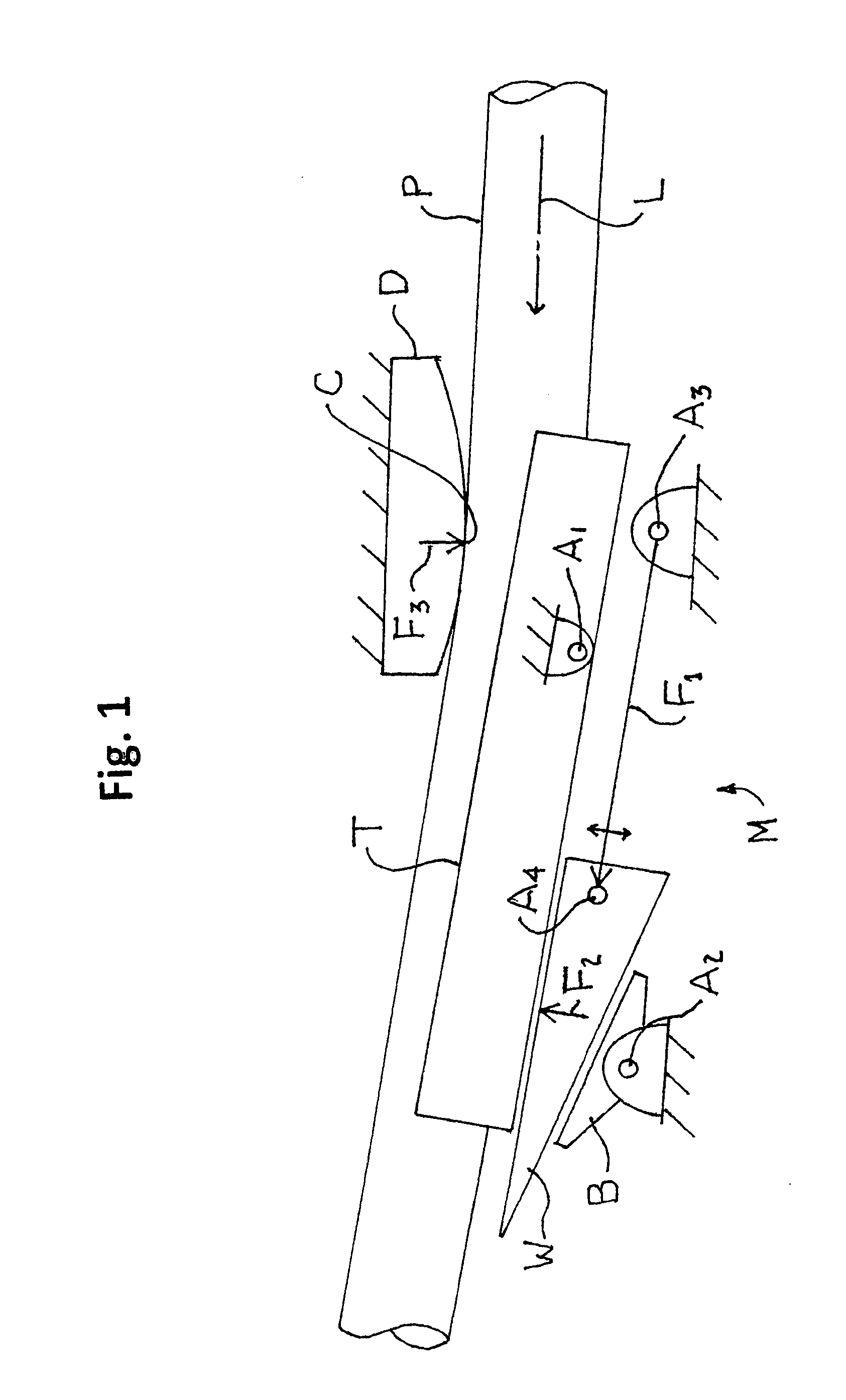

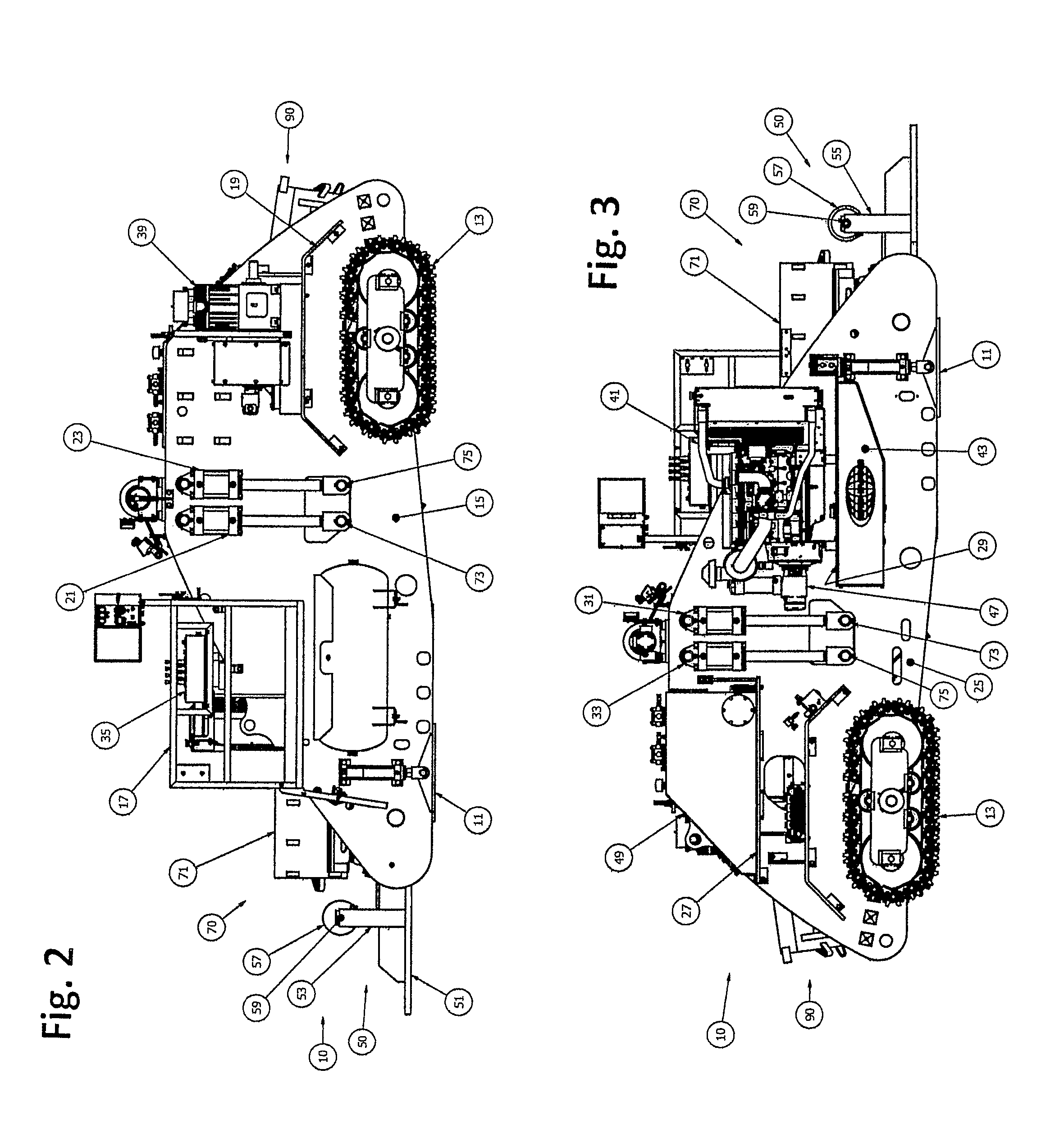

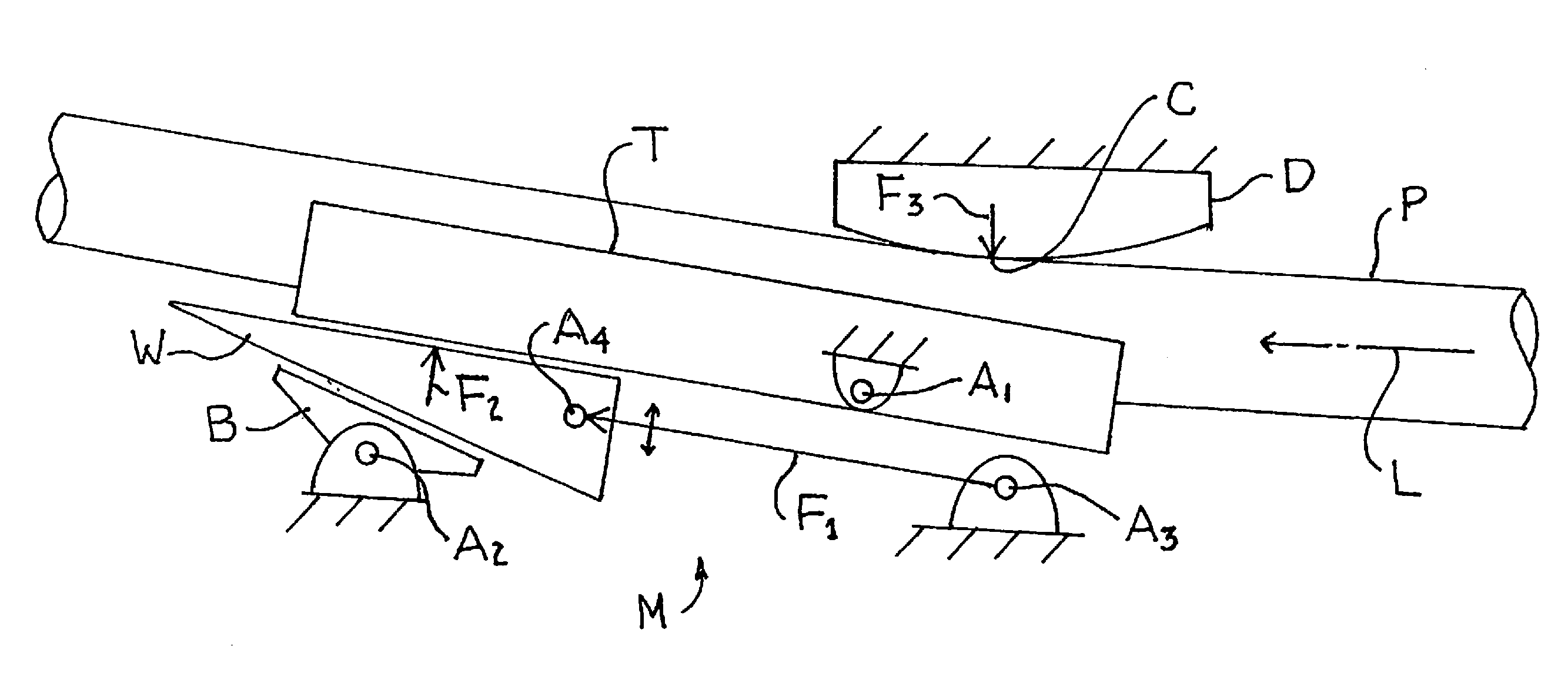

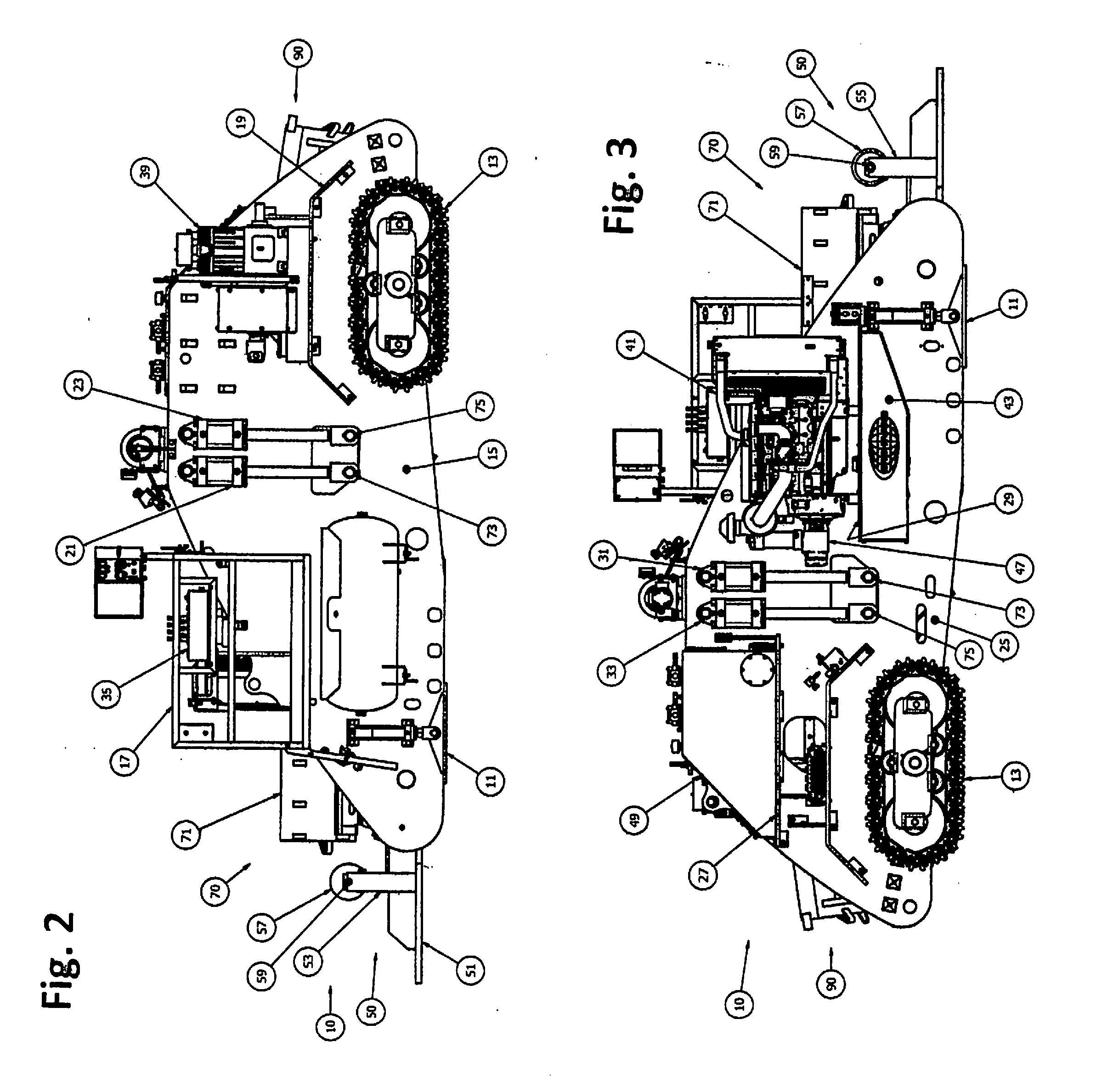

Wedge Driven Pipe Bending Machine

A pipe bending machine has a stiff-back which is driven by a pivoting wedge. A linkage applies force from the actuator to the wedge in a direction parallel to a longitudinal axis of the stiff-back. The stiff-back pivots on a first fulcrum and the wedge slides on a bed which pivots on a second fulcrum. The actuator drives the wedge between the stiff-back and the bed to rotate the stiff-back at the first fulcrum and bend the pipe seated in the stiff-back against the pipe bending face of a die. The conversion of the longitudinal force applied to the wedge into a transverse force applied to the stiff-back provides a significant mechanical advantage which varies directionally as the stiff-back rotates about its fulcrum to maintain a constant force on the stiff-back.

Owner:CRC EVANS PIPELINE INT INC

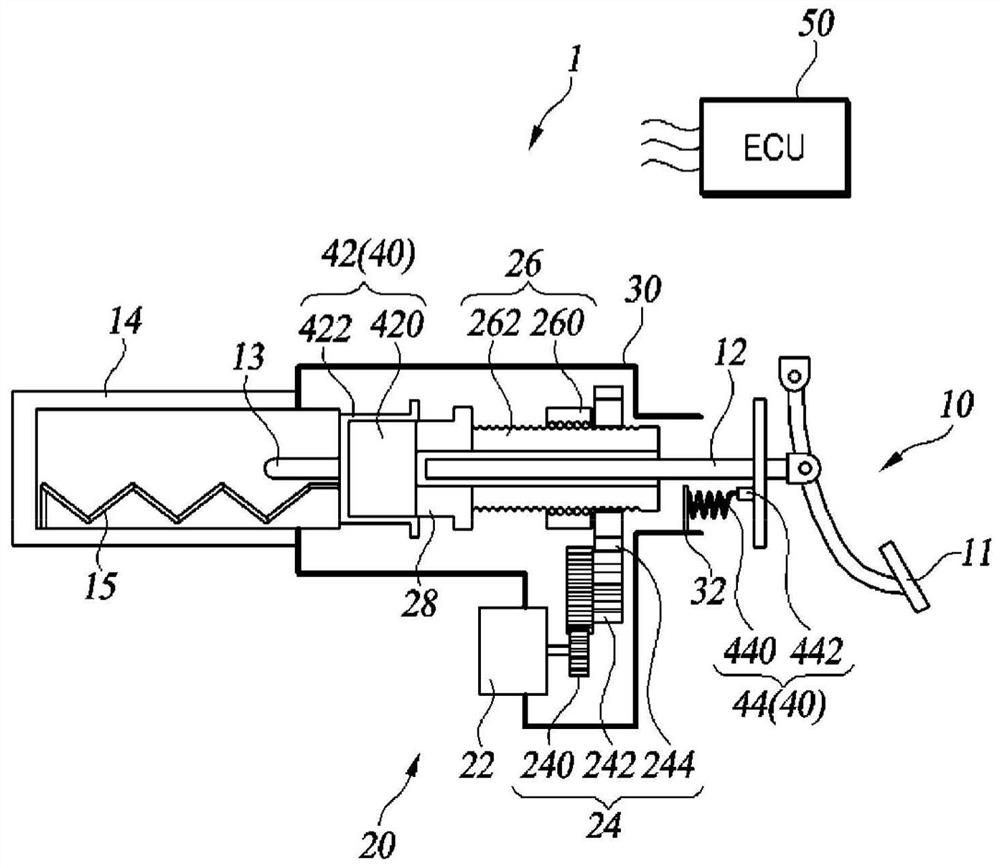

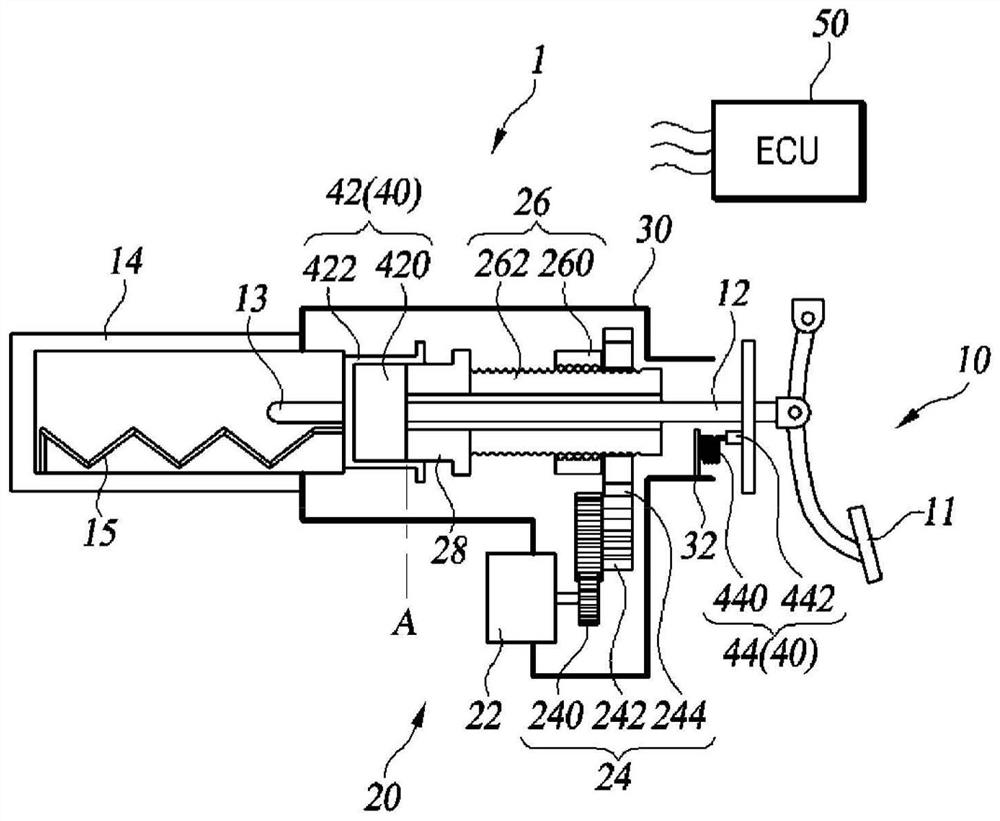

Transmission mechanism achieving rapidly returning and electro-hydraulic brake system

PendingCN106945653AHydraulic pressure reductionIncreased braking safetyBraking action transmissionElastic componentElectric machinery

The invention relates a transmission mechanism achieving rapidly returning. The mechanism is used in an electro-hydraulic brake system and comprises a worm rod(8) and a worm wheel (9) which are meshed with each other, the worm rod(8) is used for transmitting brake assistance power generated by a motor (7) to the worm wheel (9), and the worm wheel (9) is used for transmitting the brake assistance power to a hydraulic brake main cylinder (6) through a secondary transmission mechanism which is connected with the worm wheel (9); the transmission mechanism further comprises elastic components used for providing torsional force, one ends of the elastic components are connected with the worm wheel (9), and the other ends of the elastic components are fixed; and when the transmission mechanism is at an original position, the elastic components exist preload, when the motor (7) generates the brake assistance power, the rotating of the worm wheel (9) enables the elastic components to generate torque, and the torque is opposite to the worm wheel (9) in rotating direction. Compared with prior art, the transmission mechanism achieving rapidly returning has the advantages of high returning speed, compact structure and the like.

Owner:上海同驭汽车科技有限公司

Connector for undersea Christmas tree

InactiveCN105114025AAvoid replacementReduce manufacturing costSealing/packingLine tubingPulp and paper industry

A connector for an undersea Christmas tree comprises an upper body and a lower body mounted below the upper body, wherein an adaptive seal gasket is disposed between the upper body and the lower body, the middle of the upper body and the middle of the lower body are provided with through holes used for receiving a wellhead, a fastener block cooperating with a locking slot of the wellhead is arranged in the through hole of the lower body, a plurality of hydraulic devices are mounted at the bottom of the lower body and are connected with a hydraulic sliding rod disposed in a receiving hole arranged in the lower portion of the lower body, the hydraulic sliding rod is pivoted with an eccentric wheel through an eccentric wheel positioning shaft, and the eccentric wheel is abutted to the fastener block. Each damaged part can be replaced on a platform or land according to damage conditions of the hydraulic devices, thus the overall connector replacement problem caused by failure of a hydraulic system is solved; in addition, sealing reliability is improved, operational difficulty is decreased, and production cost is greatly reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +2

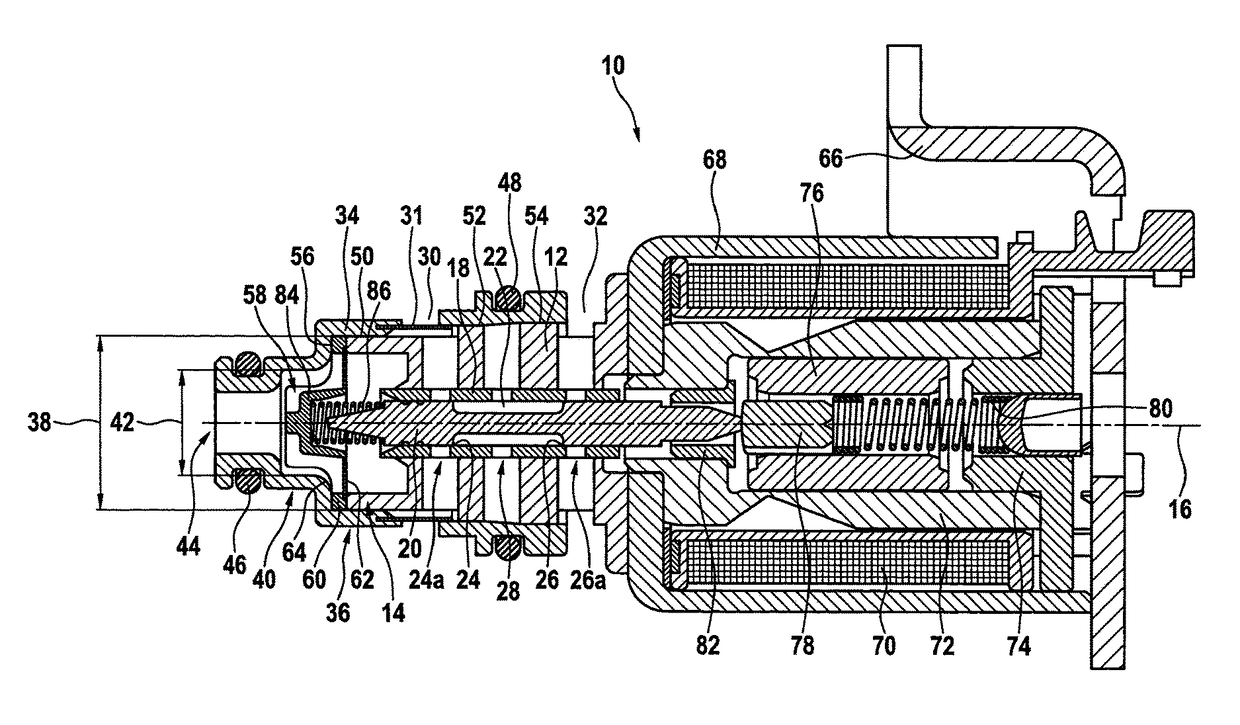

Slide valve, in particular for controlling a motor vehicle automatic transmission

ActiveUS9869399B2Minimize forceSmall diameterOperating means/releasing devices for valvesGearing controlAutomatic transmissionEngineering

A slide valve, in particular for controlling a motor vehicle automatic transmission, has a housing which includes an axial end section. A connector sleeve is situated on the axial end section of the housing, the connector sleeve having a larger diameter in a first axial area adjacent to the housing and a smaller diameter in a second axial area remote from the housing, a filter device being situated in the first axial area. The second axial area includes a hydraulic connection.

Owner:ROBERT BOSCH GMBH

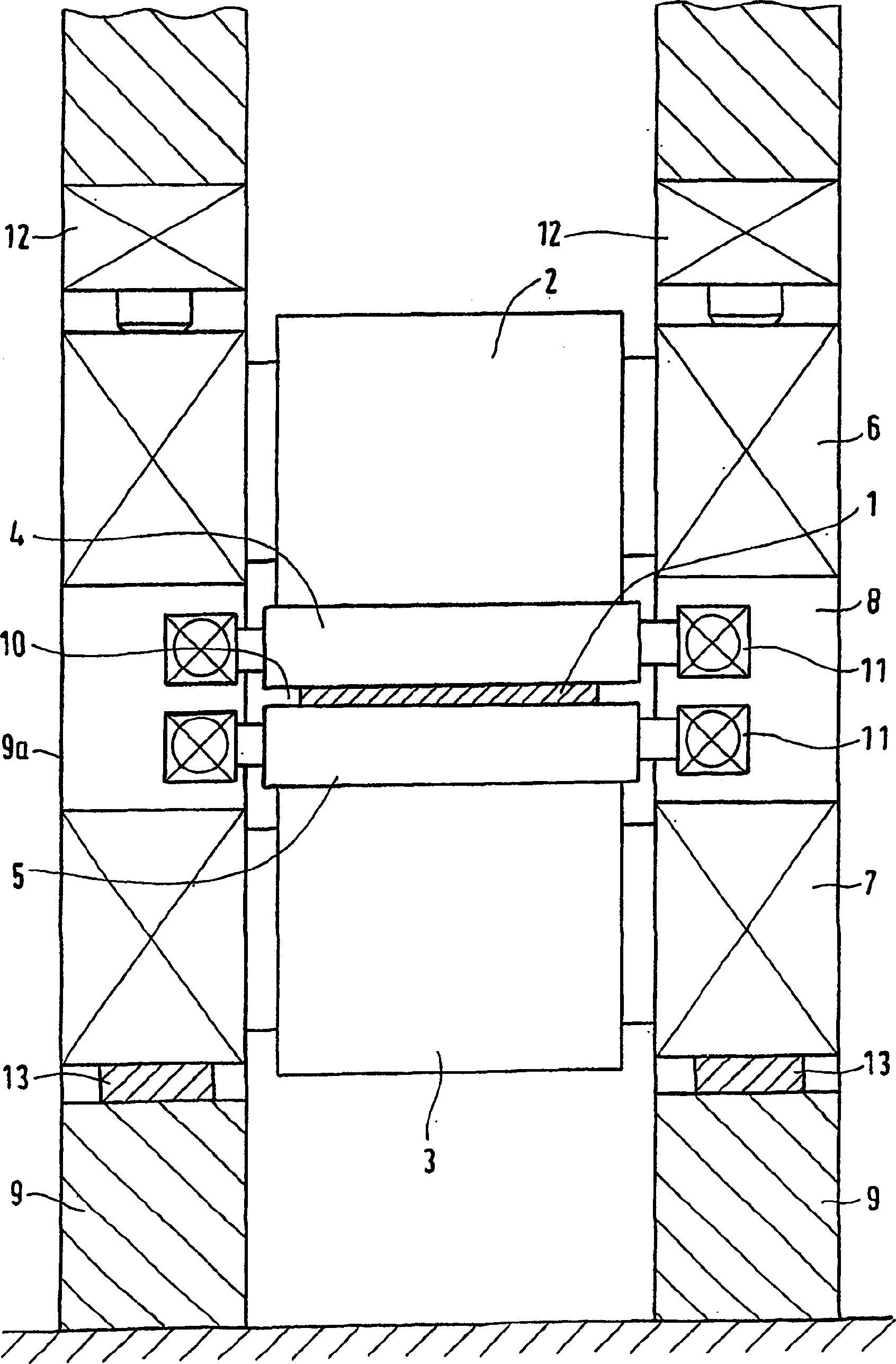

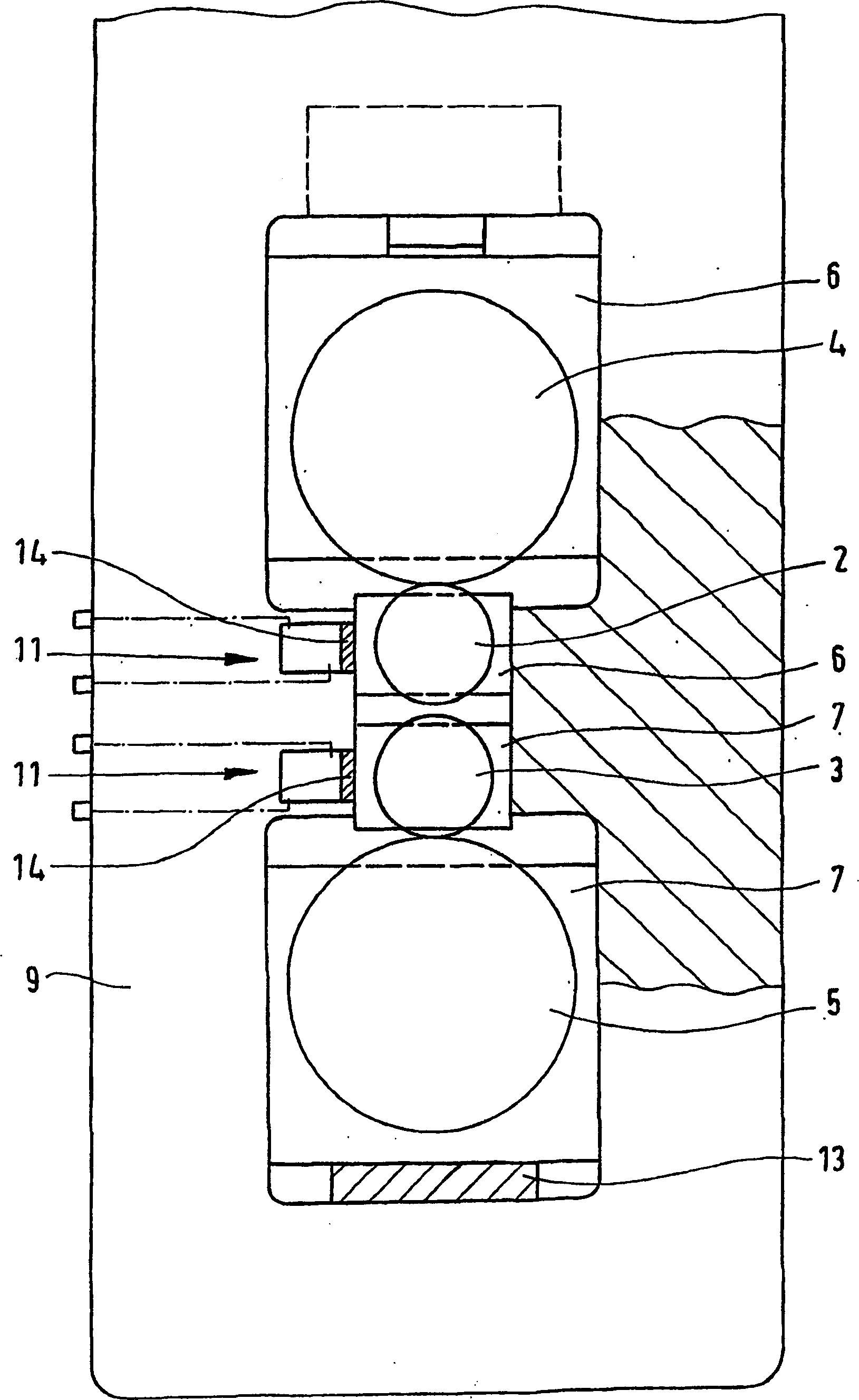

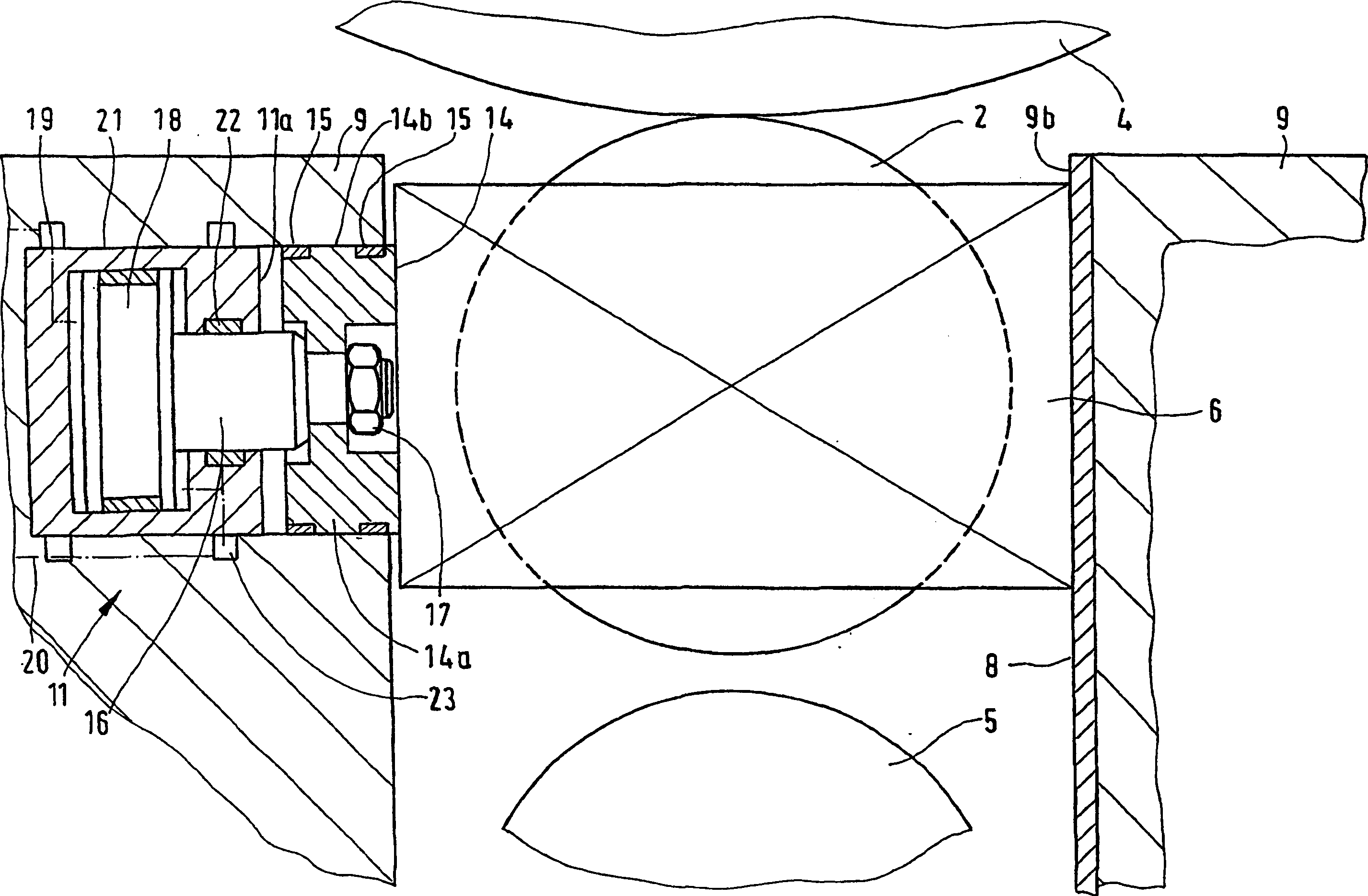

Roll stand for hot-rolling or cold-rolling metallic strips

InactiveCN1245262CSensitive movementEasy to adjustMetal rolling stand detailsCounter-pressure devicesPistonPiston cylinder

The invention relates to a roll stand for hot-rolling or cold-rolling metallic strips. Said roll stand comprises back-up rolls and work rolls (2,3; 4,5) which are respectively positioned in chocks (6; 7) in a rotating manner. Each chock (6; 7) can be displaced on two sides in guiding devices (8) of the column frame (9) for adjusting the roll gap (10) and can be additionally displaced on at least one side for adjusting the play, by means of horizontal piston cylinder units (11) arranged in the column frame (9). The aim of the invention is to completely eliminate the play in the vertical guiding device (8) of the work roll chocks (6; 7) during the rolling. To this end, the chocks which are guided on at least one side of the column (9a) by means of the piston cylinder unit (11) arranged in the column frame (9) and by means of one respective support element (14) which is arranged on the front side of the piston (11a), can be pressed against the other side of the column (9b) and the guiding device (8) thereof without play when the vertical roll positioning drive is stopped, and can be released when the vertical roll positioning drive is switched on.

Owner:SMS DEMAG AG

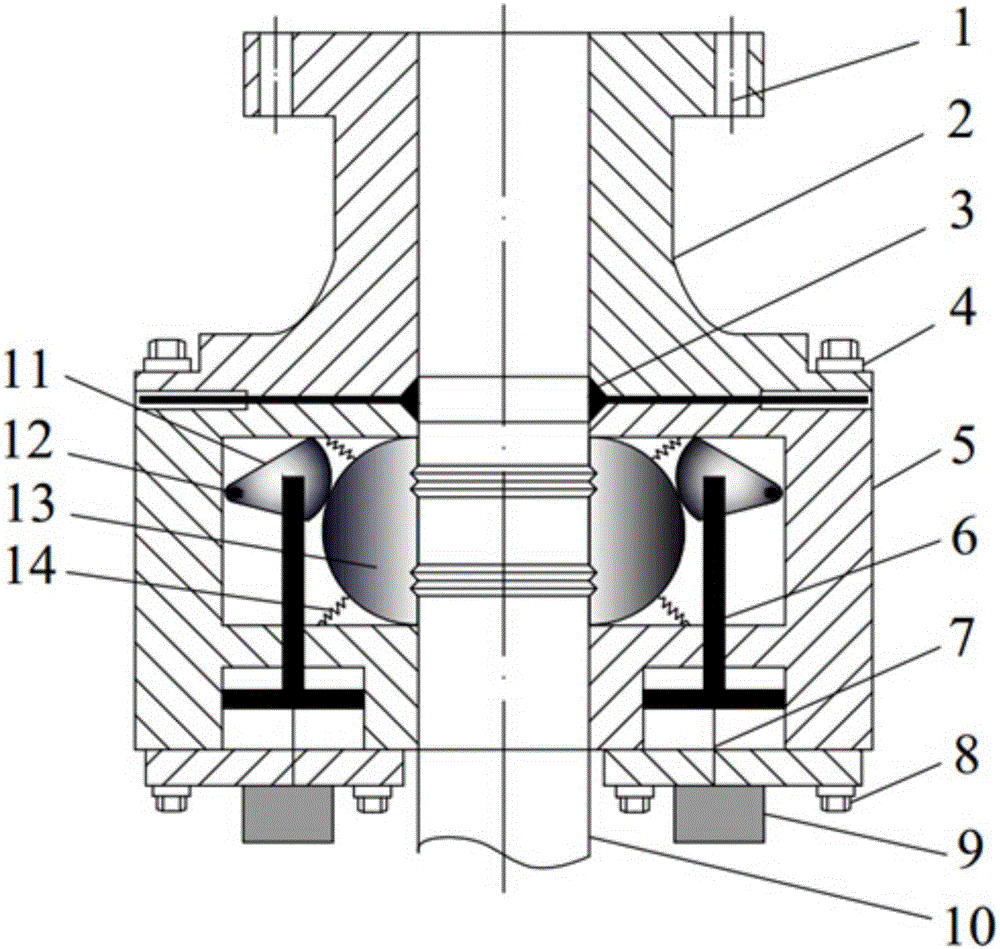

Axial ultrasonic vibration hydraulic bulging structure for tubular product

PendingCN110773622AAdjustable bulging lengthSimple structureShaping toolsStructural engineeringUltrasonic vibration

The invention discloses an axial ultrasonic vibration hydraulic bulging structure for a tubular product. The axial ultrasonic vibration hydraulic bulging structure for the tubular product comprises anupper die base and a lower die base which are arranged in parallel up and down, wherein a first guide column and a second guide column are arranged between the upper die base and the lower die base;the upper die base is provided with a first guide sleeve and a second guide sleeve which are arranged on the first guide column and the second guide column in a sleeving manner correspondingly; the upper die base is provided with an amplitude-change pole penetrating the upper die base; an energy converter is arranged at the end of the upper end of the amplitude-change pole, and a shaft pressing head is arranged at the end of the lower end of the amplitude-change pole; and a liquid filling base, a distance ring and a positioning ring are sequentially arranged on the upper surface of the lower die base from bottom to top. The axial ultrasonic vibration hydraulic bulging structure for the tubular product is simple in structure, convenient to dismount and mount, easy to operate, high in tubular product forming efficiency and low in needed shaft pressure and hydraulic pressure, the bulging length of a tubular product can be adjusted, and bulging of a special-shaped section pipe fitting is achieved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Wedge driven pipe bending machine

A pipe bending machine has a stiff-back which is driven by a pivoting wedge. A linkage applies force from the actuator to the wedge in a direction parallel to a longitudinal axis of the stiff-back. The stiff-back pivots on a first fulcrum and the wedge slides on a bed which pivots on a second fulcrum. The actuator drives the wedge between the stiff-back and the bed to rotate the stiff-back at the first fulcrum and bend the pipe seated in the stiff-back against the pipe bending face of a die. The conversion of the longitudinal force applied to the wedge into a transverse force applied to the stiff-back provides a significant mechanical advantage which varies directionally as the stiff-back rotates about its fulcrum to maintain a constant force on the stiff-back.

Owner:CRC EVANS PIPELINE INT INC

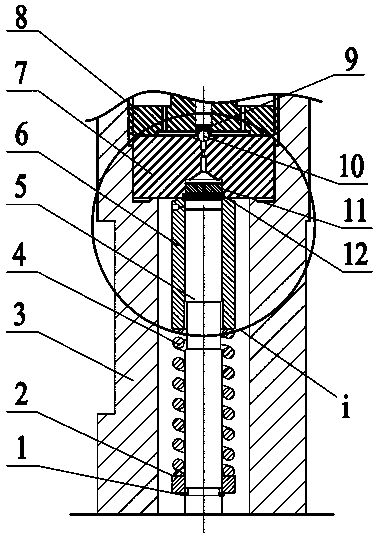

Oil sprayer valve structure

InactiveCN111472913AReduce the damage of cavitationExtend your lifeFuel injection apparatusMachines/enginesInjectorStructural engineering

The invention discloses an oil sprayer valve structure. The oil sprayer valve structure comprises a control plunger, a valve sleeve, a pore plate and a fastening valve seat, wherein the pore plate, the valve sleeve and the control plunger define a control cavity. The oil sprayer valve structure further comprises a first pressure buffering floating column and a second pressure buffering floating column which are vertically stacked on the top surface of the control plunger, and the first pressure buffering floating column and the second pressure buffering floating column are both cylindrical; the pore plate is provided with a pore plate oil outlet and a constraint hole matched with the first pressure buffering floating column and the second pressure buffering floating column; the constrainthole and the pore plate oil outlet communicate through a conical hole section and penetrate through the pore plate; the first pressure buffering floating column is completely arranged in the constraint hole; one part of the second pressure buffering floating column is arranged in the constraint hole; the first pressure buffering floating column and the second pressure buffering floating column canmove up and down in the constraint hole; the first pressure buffering floating column is provided with a first oil channel; the second pressure buffering floating column is provided with a second oilchannel; and the first oil channel is communicated with the control cavity through the second oil channel. The oil sprayer valve structure reduces pressure of oil twice, can solve the problem of cavitation damage of a high-pressure sprayer, prolongs the service life of the sprayer and accelerates action response.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

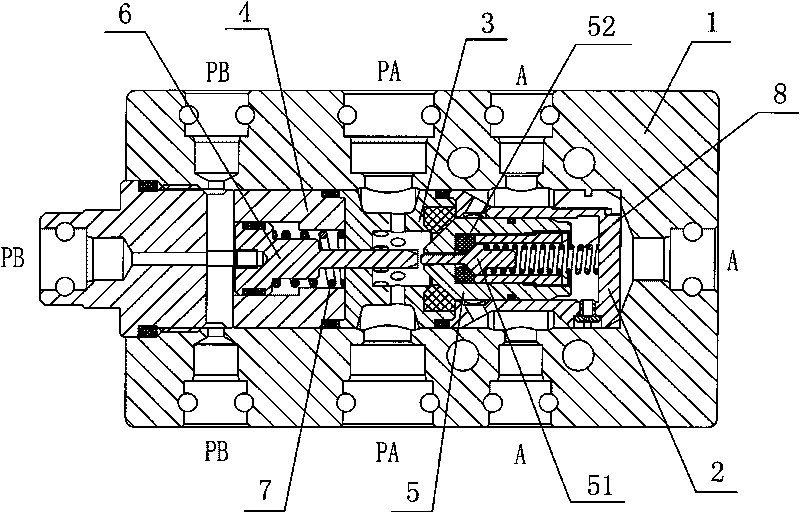

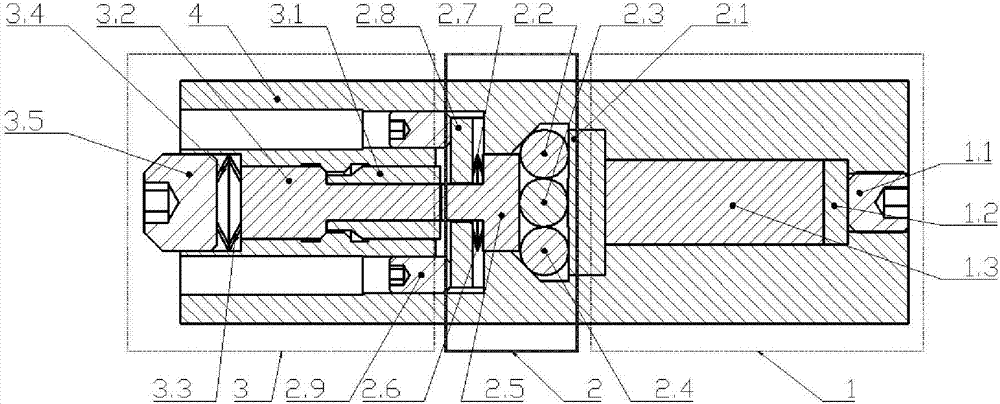

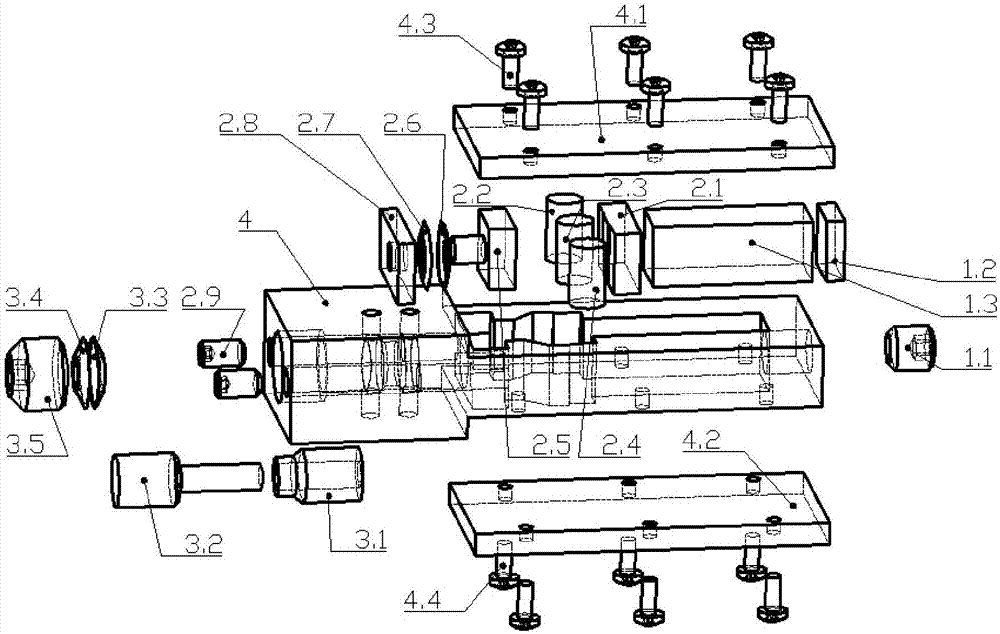

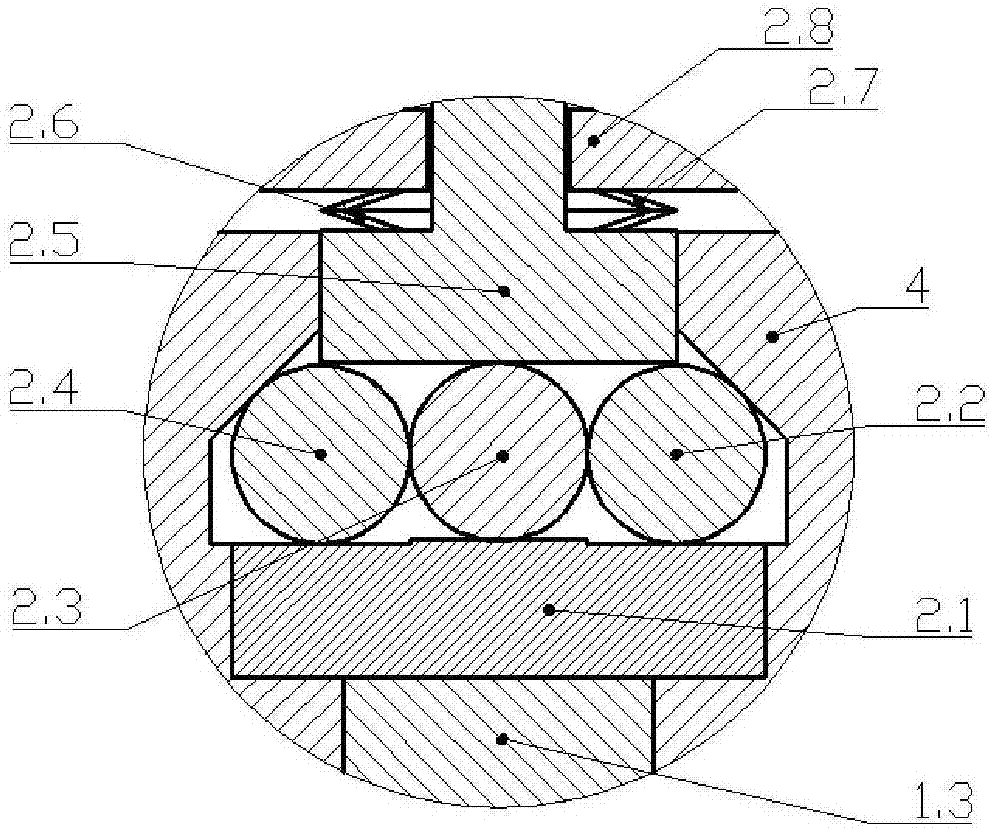

A micro-displacement driven switch valve

ActiveCN106438544BStructural summaryEasy to implementOperating means/releasing devices for valvesServomotor componentsActuatorAmplifier

The invention discloses a micro-displacement driving switching valve. The micro-displacement driving switching valve comprises a micro-displacement driver, a micro-displacement amplifying mechanism, a switching valve element assembly and a valve body base. The micro-displacement amplifying mechanism amplifies micro-displacement output by the micro-displacement driver according to a three-ball and two-triangle-slope combined triangle amplification principle. The switching valve element assembly balances hydraulic pressure and facilitates assembly of a valve element through an upper valve element and lower valve element equal-diameter separation structure. The valve body base integrates a micro-displacement driver mounting space, a micro-displacement amplifying mechanism mounting space and a switching valve element assembly mounting space. A micro-displacement amplifier designed by means of the ball-triangle amplification principle can amplify displacement from a micron grade to a millimeter grade. The micro-displacement driving switching valve is simple in structure and easy to realize. In order to reduce driving resistance, a switching valve is of an equal-diameter separation structure, so that axial hydraulic pressure applied to the valve element is substantially reduced, and assembly is facilitated. The valve body base integrates a micro-displacement driving part, a displacement amplifying part and a switching valve sleeve part, and the structure is compact.

Owner:ZHEJIANG UNIV

Rapid stone removing device for soil bin of shield tunneling machine and construction method of rapid stone removing device

PendingCN114837681AReduce oil pressureIncrease oil pressureTunnelsStructural engineeringShield tunneling

The invention relates to the technical field of shield tunneling machines, in particular to a shield tunneling machine soil bin rapid stone removing device which comprises a gate assembly, the gate assembly comprises a gate body and a driving assembly used for opening and closing a gate, the gate assembly comprises a gate seat and a gate cover plate, and the gate seat and the gate cover plate are each of a rectangular frame structure. A rectangular opening of the gate cover plate is aligned with a rectangular opening of the gate seat, an opening and closing assembly used for the gate seat and the gate cover plate is arranged between the gate seat and the gate cover plate, the opening and closing assembly is installed on a driving assembly, and grooves are formed in the positions, located at the two ends of the rectangular opening, of the outer walls of the two sides, opposite to the gate seat, of the rectangular opening of the gate cover plate. And elastic supporting plates are fixed to the inner walls of the grooves, sealant is fixed to the outer walls of the sides, facing the opening and closing assembly, of the elastic supporting plates, oil channels are formed in the inner walls of the two sides, away from each other, of the two grooves located at the same height, and the service life of the sealant can be prolonged by reducing friction damage.

Owner:江苏旭睿重工科技有限公司

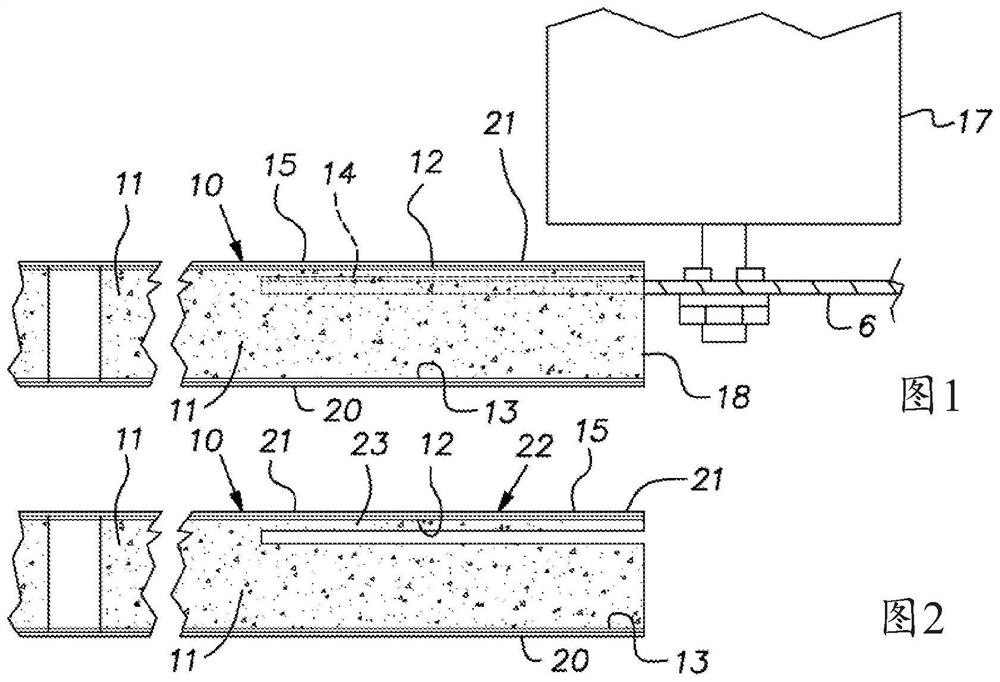

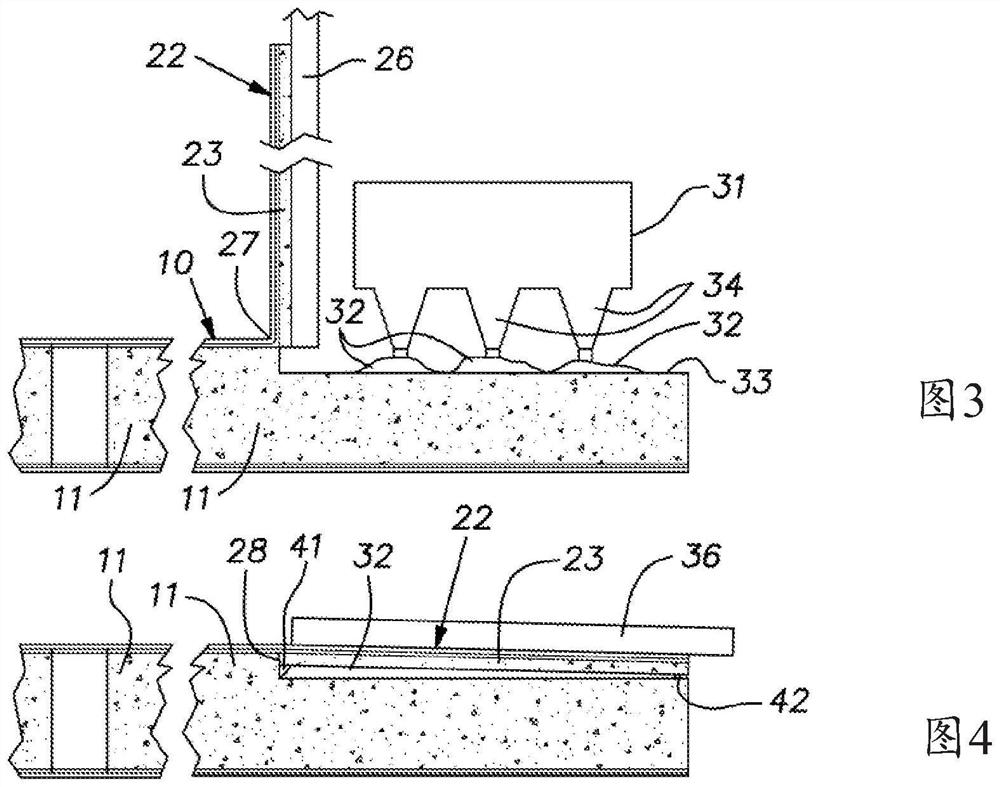

An Adaptive Liquid-Filled Stretch Forming Method to Prevent Inverted Burst

The invention discloses a self-adaptive charging drawing forming method capable of preventing inverse bulging fracturing, and relates to the field of charging drawing of hydraulic drawing presses. The novel self-adaptive charging drawing forming method capable of preventing inverse bulging fracturing is provided for solving the problem that inverse bulging fracturing is prone to occurring in the charging drawing process. Before sheets are thinned to the maximum extent, inverse bulging thinning of the sheets are controlled by controlling the magnitudes of hydraulic pressure (Fy) of a liquid chamber and tensile force (Fn). When the sum of the hydraulic pressure (Fy) of the liquid chamber and the tensile force (Fn) reaches a set value (F0), the sum of the hydraulic pressure (Fy) of the liquid chamber and the tensile force (Fn) increasing as the tensile depth increases is kept at the set value (F0) by reducing the hydraulic pressure (Fy) of the liquid chamber, so that the change law that the hydraulic pressure of the liquid chamber automatically adapts to the tensile force is achieved. When the inverse bulging height drops to a set value (H0) and inverse bulging disappears, the hydraulic pressure (Fy) of the liquid chamber is increased to a set value F1 until the drawing process is completed.

Owner:ZHEJIANG UNIV

Wedge Driven Pipe Bending Machine

A pipe bending machine has a stiff-back which is driven by a pivoting wedge. A linkage applies force from the actuator to the wedge in a direction parallel to a longitudinal axis of the stiff-back. The stiff-back pivots on a first fulcrum and the wedge slides on a bed which pivots on a second fulcrum. The actuator drives the wedge between the stiff-back and the bed to rotate the stiff-back at the first fulcrum and bend the pipe seated in the stiff-back against the pipe bending face of a die. The conversion of the longitudinal force applied to the wedge into a transverse force applied to the stiff-back provides a significant mechanical advantage which varies directionally as the stiff-back rotates about its fulcrum to maintain a constant force on the stiff-back.

Owner:CRC EVANS PIPELINE INT INC

Tapered cutout configuration

PendingCN114423915AHydraulic pressure reductionConstruction materialCovering/liningsThin layerHot-melt adhesive

According to the dry wall board, a gypsum core is wrapped in a front paper layer and a back paper layer, and the edge of the board is conical towards the back. The panel has a taper formed by a flap in the edge region of the face paper and a thin layer of gypsum attached to the inside of the edge of the face paper, folded into a space formed by slots cut to a depth substantially equal to the width of the flap on the edge of the panel, said flap being fixed in place by a continuous layer of hot melt adhesive, the hot melt adhesive occupies the space of the slot that is not occupied by the flap and is resilient, which provides fastener penetration resistance from the associated edge of the front face of the panel.

Owner:USG INTERIORS INC

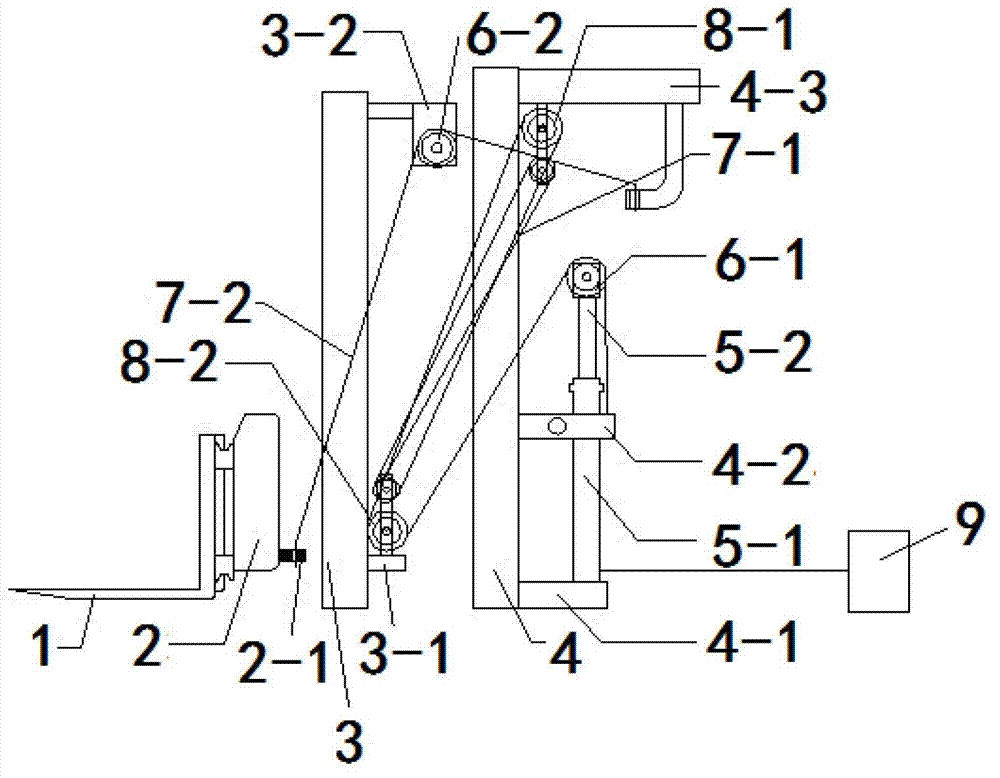

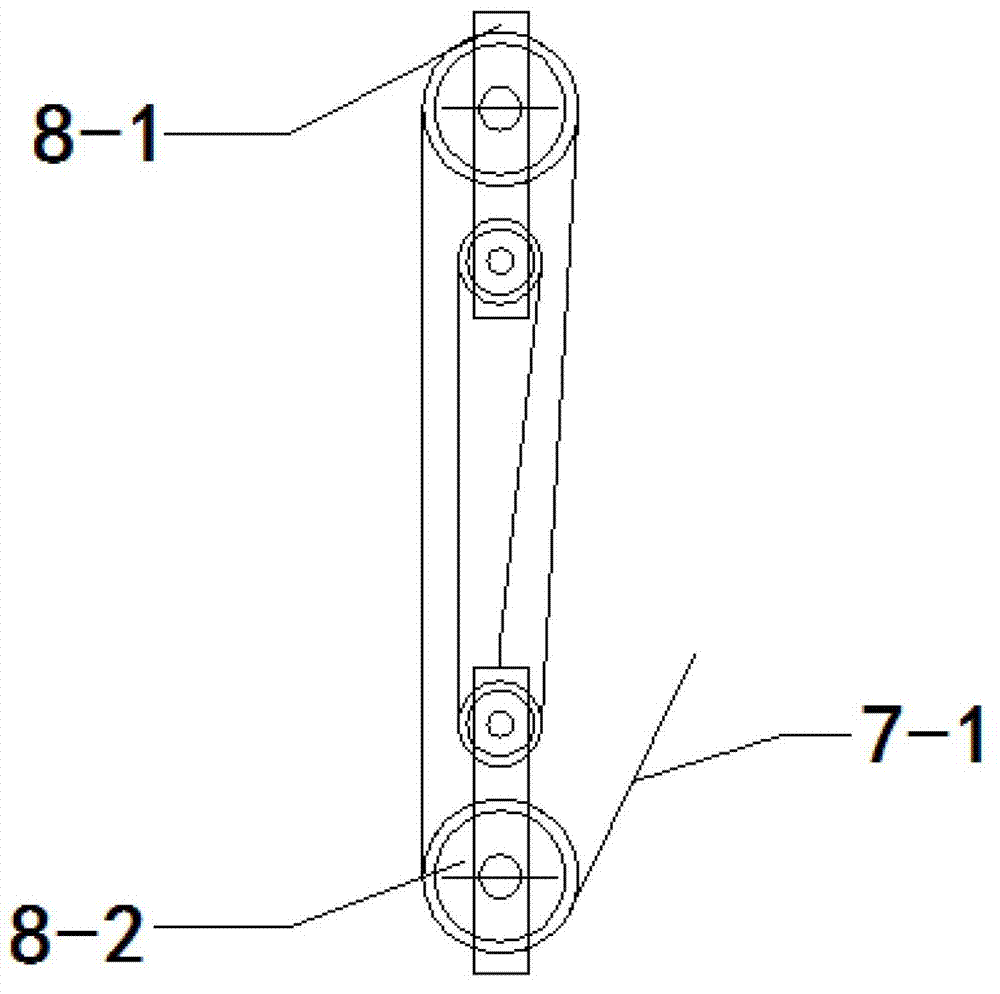

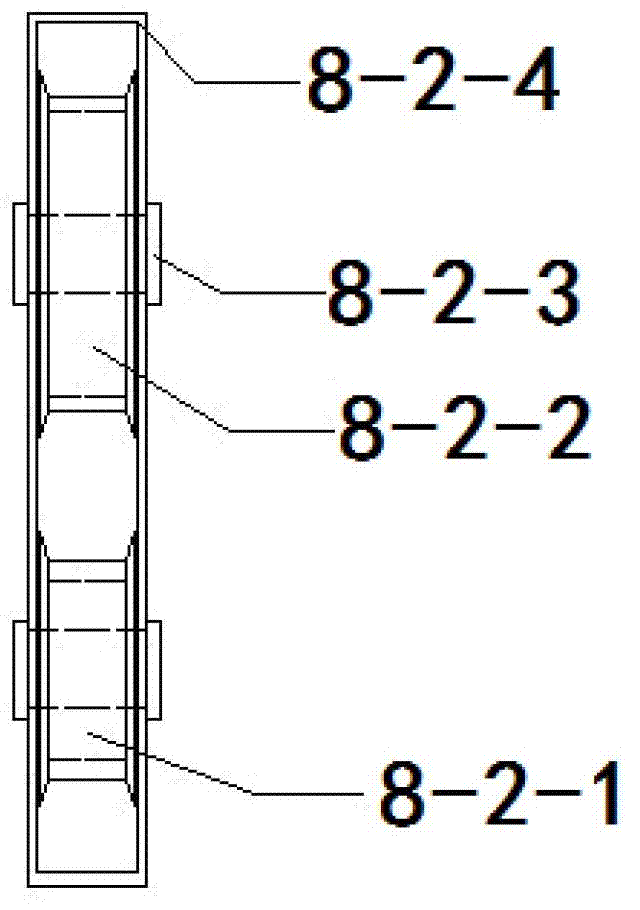

A forklift lifting mechanism

InactiveCN103303846BHydraulic pressure reductionReduce energy consumptionLifting devicesEngineeringMechanical engineering

The invention provides a forklift lifting mechanism applied to the technical field of forklifts. A first chain wheel (6-1) is arranged at the top of a hoisting oil cylinder (5-1) of the forklift lifting mechanism; a second chain wheel group (8-2) is arranged at the lower part of an inner portal (3); a second chain wheel (6-2) is arranged at the top of the inner portal (3); one end of a first chain (7-1) is connected with an outer portal (4); the first chain (7-1) rounds the second chain wheel group (8-2) after rounding the first chain wheel (6-1), and is connected with the second chain wheel group (8-2) after rounding the first chain wheel group (8-1); one end of a second chain (7-2) is connected with the top of the outer portal (4); the other end of the second chain (8-2) is connected with a fork arm carrier (2) after rounding the second chain wheel (6-2); and a fork (1) is arranged on the fork arm carrier (2). With the adoption of the forklift lifting mechanism, the cargo lifting efficiency of a forklift is improved, and the length of the hoisting oil cylinder is decreased.

Owner:上海则轶实业有限公司

An energy-saving control method for elastic loads based on electro-hydraulic servo drive

InactiveCN102493968BReduce control difficultyHydraulic pressure reductionServomotor componentsHydraulic cylinderHydraulic motor

The invention provides a method and a device for energy-saving control of an elastic load based on electrohydraulic servo drive. The device comprises a servo valve, a high-pressure oil source, a low-pressure oil source, an overflow valve and an actuating mechanism, wherein the actuating mechanism is a hydraulic cylinder or a hydraulic motor; an oil supply port of the servo valve is connected with the high-pressure oil source, an oil return port of the servo valve is connected with an oil tank, and a B port of the servo valve is blocked; an A port of the servo valve is connected with an A cavity of the actuating mechanism, the low-pressure oil source is connected with a B cavity of the actuating mechanism, the B cavity of the actuating mechanism is connected with an inlet of the overflow valve, and an outlet of the overflow valve is connected with the oil tank; and the actuating mechanism is connected with the elastic load. A setting principle of the pressure of the low-pressure oil source is that: the force generated by the low-pressure oil source in the B cavity of the actuating mechanism can offset the friction of the actuating mechanism. By the method and the device, the problem that the motion law is difficult to control accurately when the elastic load moves from maximum position to zero position, and energy sources can also be saved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

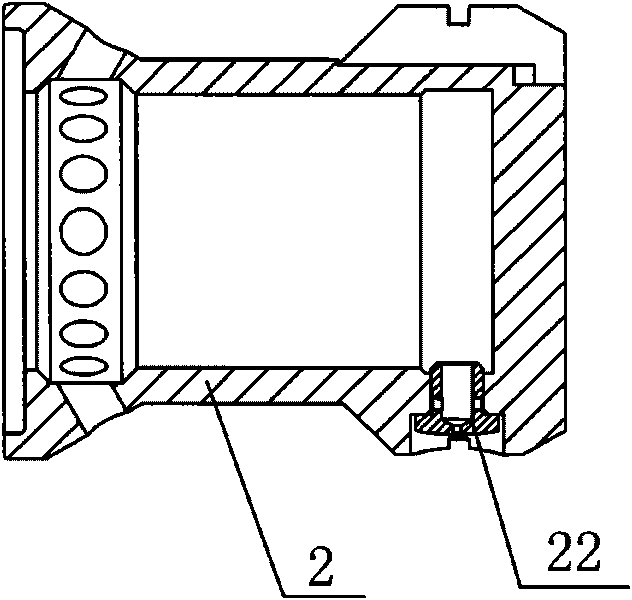

Double-column control valve of ejector

InactiveCN111472909ASpeed up the flowAvoid damageFuel injection apparatusMachines/enginesControl valvesPlunger

The invention discloses a double-column control valve of an ejector. The double-column control valve comprises a control plunger, a valve sleeve, a porous plate and a fastening valve seat. A control cavity is defined by the porous plate, the valve sleeve and the control plunger. The double-column control valve further comprises two vertically-overlapped pressure relief floating columns which are cylindrical. Each pressure relief floating column is provided with a pressure relief oil outlet hole and an inlet conical hole, wherein the inlet conical hole is located at the lower end of the pressure relief oil outlet hole, and the pressure relied oil outlet hole and the inlet conical hole communicate and axially run through the pressure relief floating column. The porous plate is provided witha constraint hole and a porous plate oil outlet hole. The constraint hole is formed in the lower portion of the porous plate and matched with the pressure relief floating columns. The porous plate oiloutlet hole and the constraint hole communicate through a conical pore section and run through the porous plate. The two pressure relief floating columns are arranged in the constraint hole. An opening of the lower end of the constraint hole is provided with an elastic collar. The elastic collar limits the vertical movements of the pressure relief floating columns in the constraint hole. By meansof the double-column control valve, the problem of cavitation damage of a high-pressure ejector can be solved, the service life of the ejector is prolonged, and action response is accelerated.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

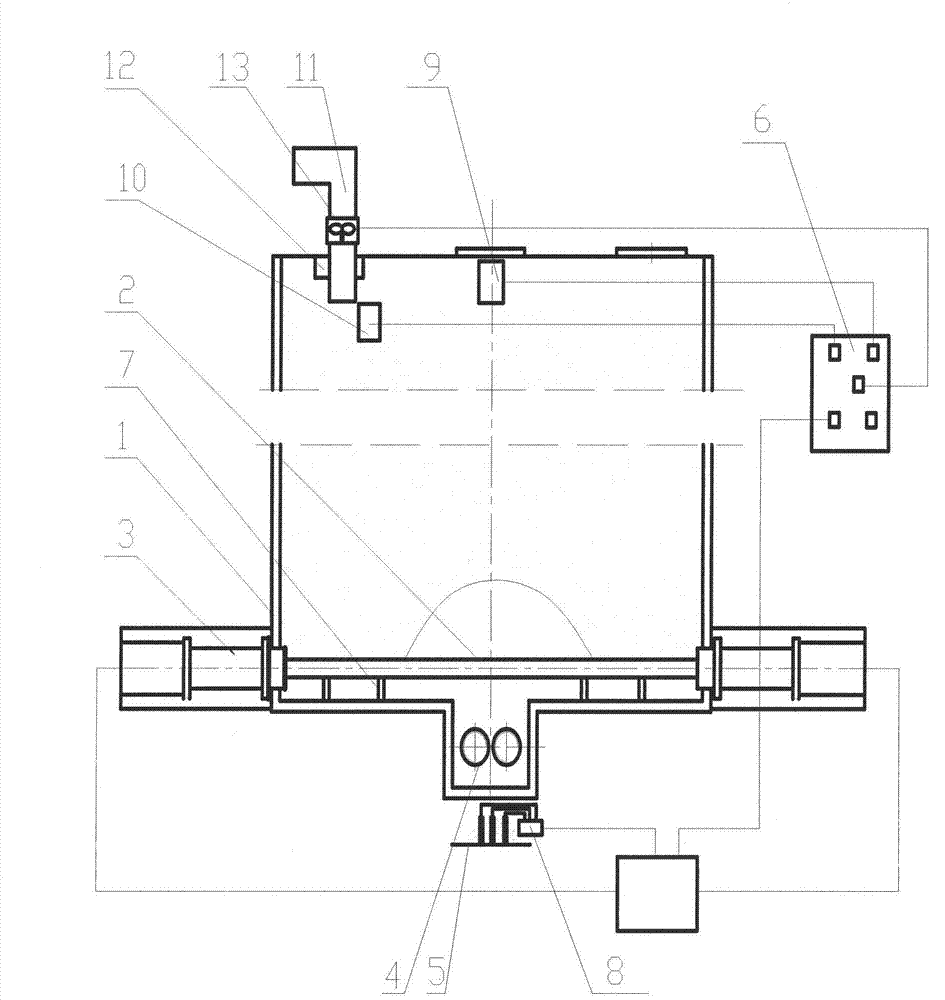

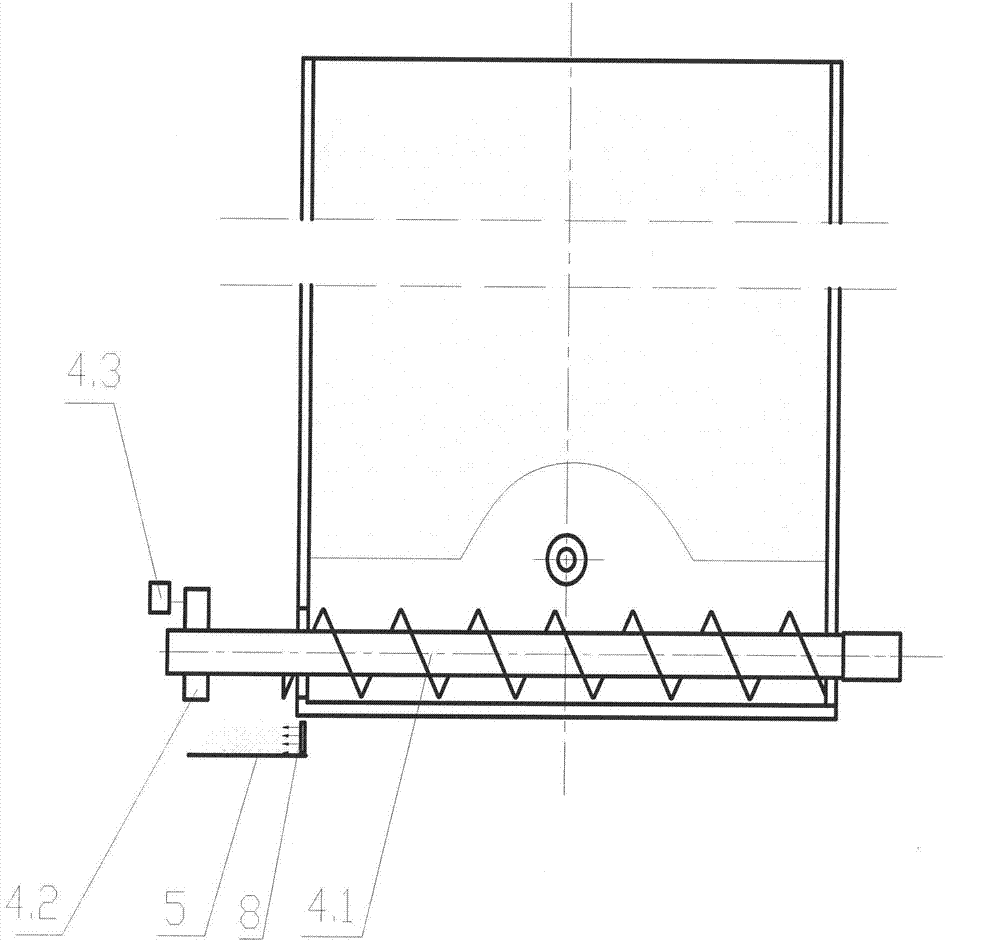

Sludge storage bin system

The invention discloses a sludge storage bin system, which comprises a storage bin body (1), a sliding rack (2), two hydraulic cylinders (3), a screw conveyer (4), a sludge conveying mechanism (5) and a controller (6). The sliding rack (2) is arranged at the bottom of the storage bin body (1), piston ends of the hydraulic cylinders are connected with the sliding rack (2), a guide rail (7) is arranged between the sliding rack and the inner bottom of the storage bin body, the screw conveyer is mounted below the sliding rack, the sludge conveying mechanism is arranged below an outlet of the screw conveyer (4), an infrared sensor (8) is arranged on the sludge conveying mechanism (5), the infrared sensor (8) and the hydraulic cylinders (3) are electrically connected with the controller (6), and the screw conveyer (4) is a two-screw conveyer comprising two screw conveying rods (4.1) and a driving motor (4.2). The sludge storage bin system has the advantages that whether a storage bin bulges or not can be detected in real time, conveying speed can be adjusted, environmental protection is realized, and conveying efficiency is high.

Owner:CHINA JILIANG UNIV

Single-column control valve of ejector

InactiveCN111472907AReduce the damage of cavitationExtend your lifeFuel injection apparatusMachines/enginesInjectorCavitation erosion

The invention discloses a single-column control valve of an ejector. The single-column control valve comprises a control plunger, a valve sleeve, a pore plate and a fastening valve seat, wherein the pore plate, the valve sleeve and the control plunger define a control cavity. The single-column control valve further comprises a pressure-relieving floating column, wherein the pressure-relieving floating column is cylindrical, and is provided with an axially-penetrating pressure-relieving oil outlet hole; the pore plate is provided with a restraining hole and a pore plate oil outlet hole; the restraining hole is formed in the lower part of the pore plate, and is matched with the pressure-relieving floating column; the pore plate oil outlet hole communicates with the restraining hole through aconical hole section, and penetrates through the pore plate; the pressure-relieving floating column is arranged in the restraining hole; an elastic retainer ring is arranged on an opening in the lower end of the restraining hole; and the elastic retainer ring limits up-down movement of the pressure-relieving floating column in the restraining hole. The single-column control valve can solve the problem of cavitation erosion damage of a high-pressure ejector, prolongs the service life of the ejector, and accelerates action response.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

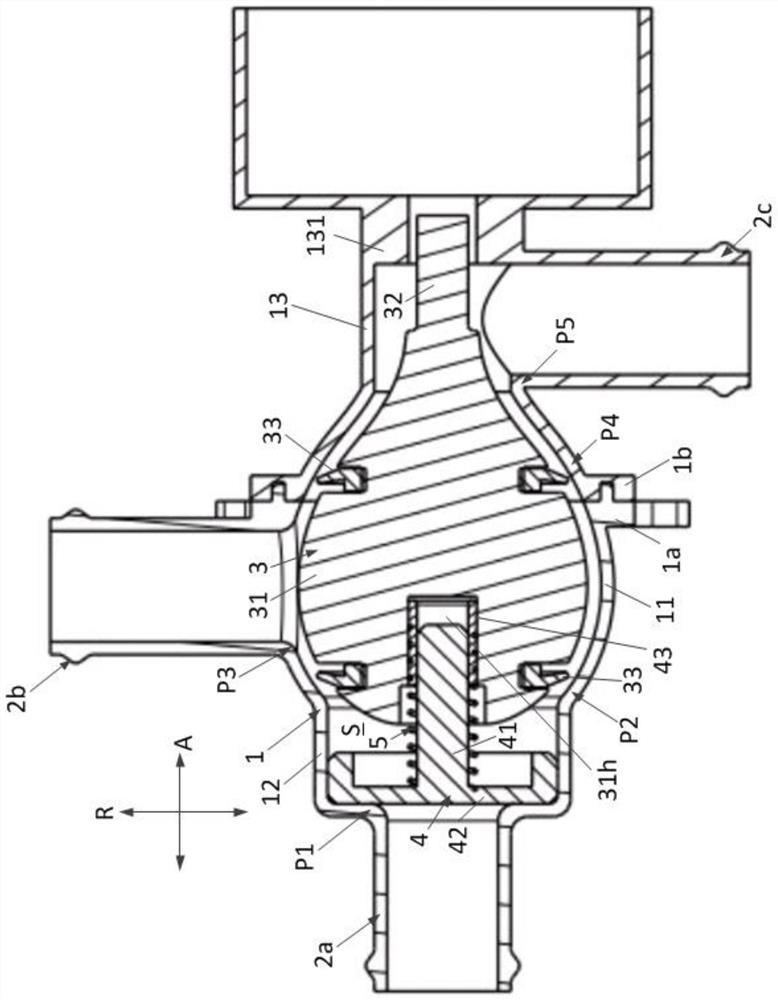

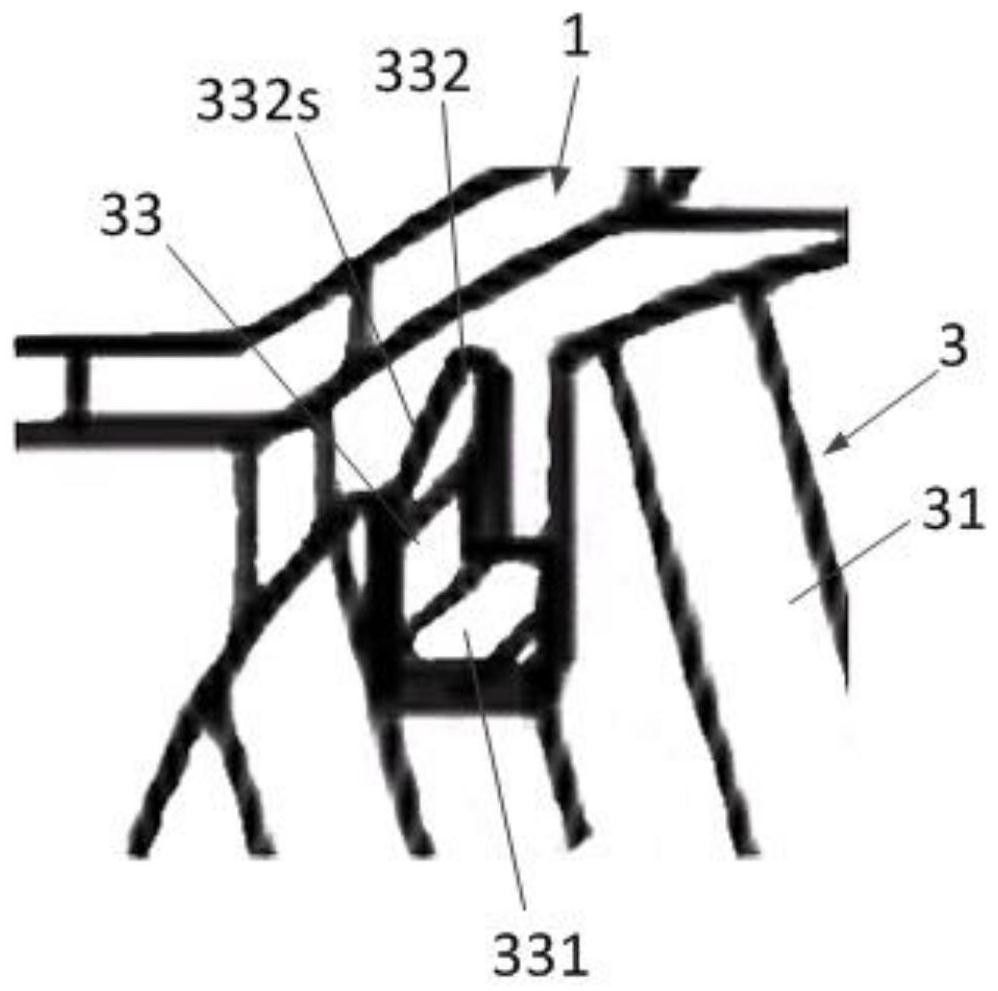

Thermal management module for vehicle and method of operating same

ActiveCN112297751AReduce performanceLower requirementAir-treating devicesVehicle heating/cooling devicesHeat managementReciprocating motion

The invention provides a thermal management module for a vehicle and a method of operating the same. According to the thermal management module for a vehicle, a plunger assembly which reciprocates inthe internal space of a module main body is adopted to control the flow of a fluid medium, and the plunger assembly can be statically sealed with the module main body at different parts. Therefore, compared with the dynamic seal of a rotary valve in the prior art, the static seal realized by the thermal management module for the vehicle has the advantages that the sensitivity to vibration is lower, the requirements on the performance of materials and processing parameters are lower, and the leakage risk is lower. The thermal management module for a vehicle adopts only one plunger assembly, sothat the overall structure is relatively simple, the required space is small, and the cost is low. The plunger assembly of the thermal management module for a vehicle is characterized in that at leastthe outer contour of the section, intercepted in the axial direction, of the plunger head is the curve with the preset curvature, so that the hydraulic pressure, acting on the plunger head, of a fluid medium is reduced, and therefore driving force for driving the plunger assembly is saved.

Owner:SCHAEFFLER TECH AG & CO KG

A continuous bending system of large-scale steel beams for construction

The invention discloses a large-size steel beam continuous bending system for a building. The large-size steel beam continuous bending system for the building comprises a left stress standing limiting wheel, a right stress standing limiting wheel, a left force application limiting wheel and a right force application limiting wheel and further comprises a central bending erection column, a left rolling bending mechanism and a right rolling bending mechanism. The left rolling bending mechanism and the right rolling bending mechanism are symmetrically arranged. The left rolling bending mechanism comprises a left bending oscillation column, a left bending telescopic cylinder, a left bending operation wheel and a left bending oscillation cylinder. The right rolling bending mechanism comprises a right bending oscillation cylinder, a right bending telescopic cylinder, a right bending operation wheel and a right bending oscillation cylinder. According to the large-size steel beam continuous bending system for the building, due to the arrangement of the stress standing limiting wheels, the force application limiting wheels, the central bending erection column and the rolling bending mechanisms, bending operation can be conducted on large-size steel beams, and the demand for large-size steel beam bending operation can be met.

Owner:山东鑫通钢结构工程有限公司

Control valve of injector

InactiveCN111472910AAct as a pressure bufferRelieve pressureFuel injection apparatusMachines/enginesStructural engineeringControl valves

The invention discloses a control valve of an injector. The control valve comprises an ejector body, a control plunger, a valve sleeve, an orifice plate and a fastening valve seat. The orifice plate,the valve sleeve and the control plunger form a control cavity. The control valve of the injector also comprises a pressure relief floating column, and the pressure relief floating column is cylindrical and arranged on the upper end face of the control plunger. The end, close to the control plunger, of the pressure relief floating column is provided with a notch part penetrating through the circumferential surface, and an oil outlet hole is formed in the other end of the pressure relief floating column. The oil outlet hole communicates with the notch part to form a connection channel, the orifice plate is provided with a constraint hole matched with the pressure relief floating column, the constraint hole communicates with an orifice plate oil outlet hole of the orifice plate, and the pressure relief floating column can move up and down in the constraint hole. According to the control valve, the problem of cavitation damage of the high-pressure injector can be solved, the service lifeof the injector is prolonged, and the action response is accelerated.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Self-adaptive charging drawing forming method capable of preventing inverse bulging fracturing

The invention discloses a self-adaptive charging drawing forming method capable of preventing inverse bulging fracturing, and relates to the field of charging drawing of hydraulic drawing presses. The novel self-adaptive charging drawing forming method capable of preventing inverse bulging fracturing is provided for solving the problem that inverse bulging fracturing is prone to occurring in the charging drawing process. Before sheets are thinned to the maximum extent, inverse bulging thinning of the sheets are controlled by controlling the magnitudes of hydraulic pressure (Fy) of a liquid chamber and tensile force (Fn). When the sum of the hydraulic pressure (Fy) of the liquid chamber and the tensile force (Fn) reaches a set value (F0), the sum of the hydraulic pressure (Fy) of the liquid chamber and the tensile force (Fn) increasing as the tensile depth increases is kept at the set value (F0) by reducing the hydraulic pressure (Fy) of the liquid chamber, so that the change law that the hydraulic pressure of the liquid chamber automatically adapts to the tensile force is achieved. When the inverse bulging height drops to a set value (H0) and inverse bulging disappears, the hydraulic pressure (Fy) of the liquid chamber is increased to a set value F1 until the drawing process is completed.

Owner:ZHEJIANG UNIV

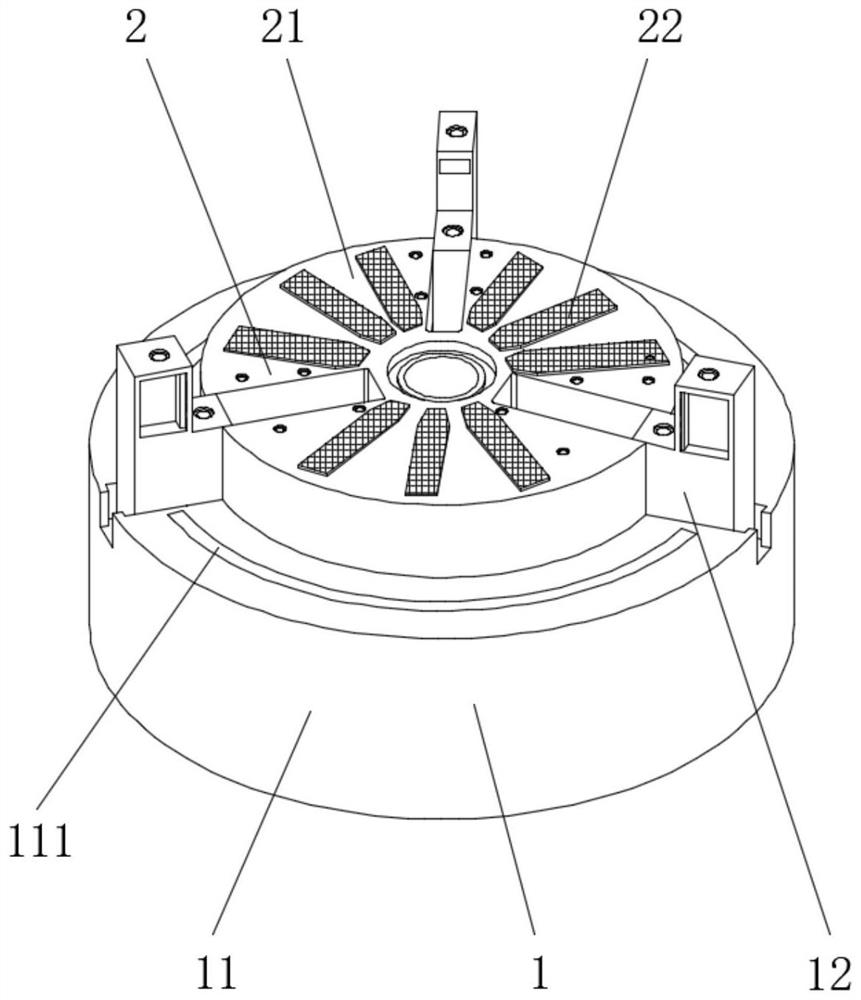

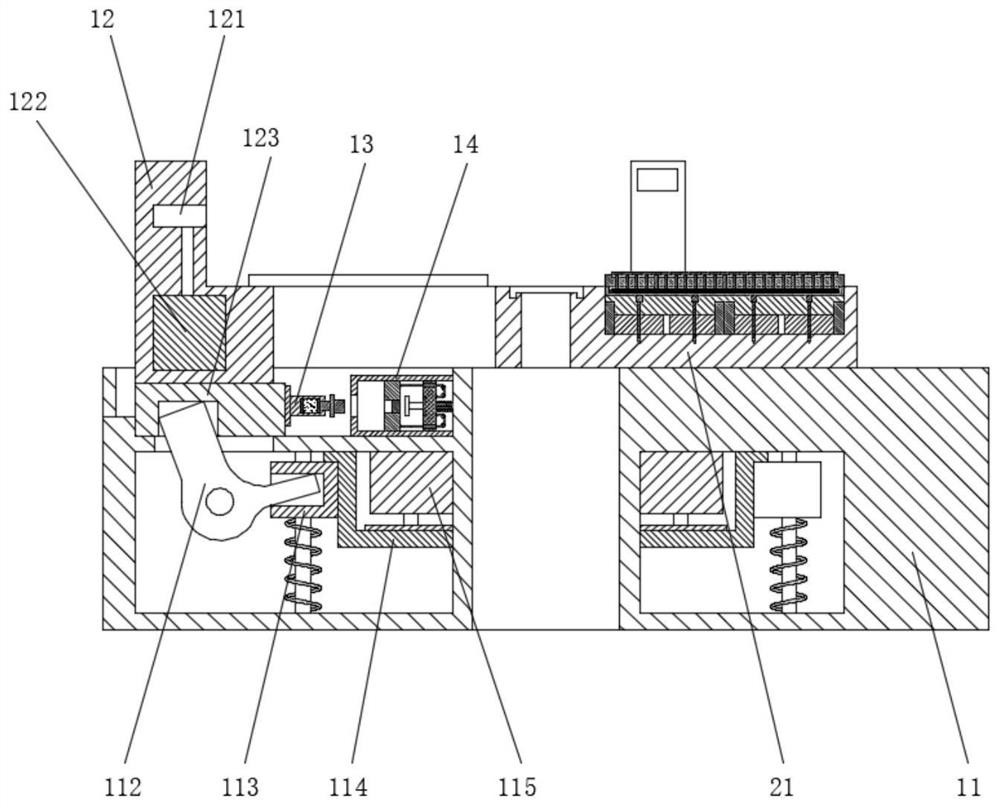

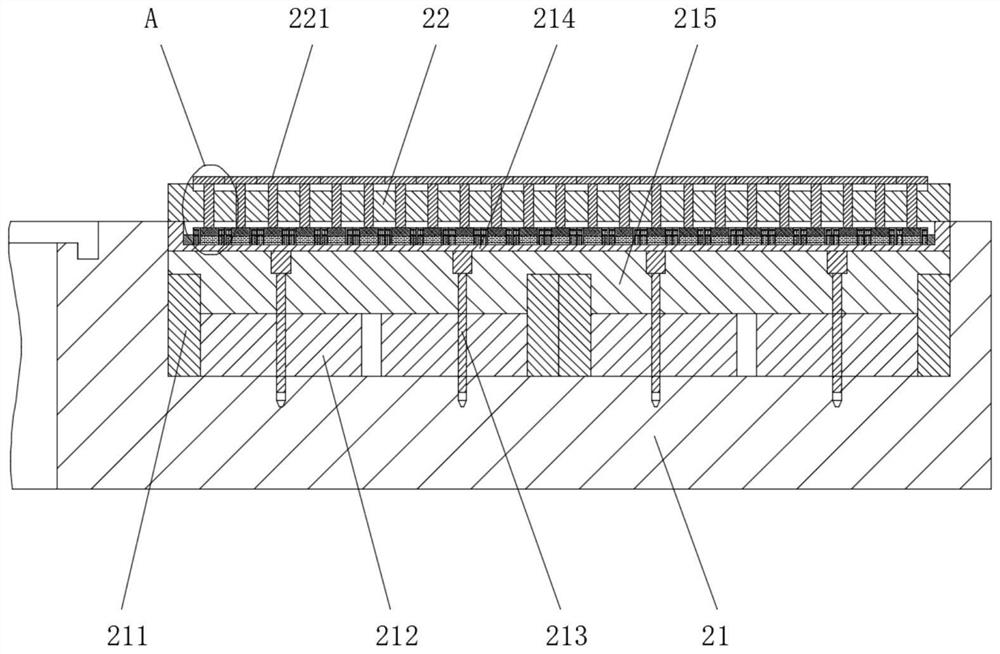

Combined electromagnetic chuck capable of self-centering

ActiveCN114850927APrevent disengagementWill not escape the phenomenonPositioning apparatusMetal-working holdersEngineeringCentrifugal force

The invention discloses a combined electromagnetic chuck capable of self-centering, the combined electromagnetic chuck comprises a positioning device and a magnetic suction device, the magnetic suction device is arranged above the positioning device, the positioning device comprises a chuck and three groups of clamping jaws, the three groups of clamping jaws are arranged on the chuck at equal angles, and the magnetic suction device is arranged above the chuck. Compared with an existing electromagnetic chuck, the electromagnetic chuck is provided with the positioning device, a workpiece can be automatically aligned to the center through the positioning device so that machining can be facilitated, and the deviation prevention mechanism and the compensation mechanism are further arranged; on the other hand, when the electromagnetic chuck rotates at a high speed, a part of centrifugal force of the clamping jaws can be offset through the deviation prevention mechanism and the compensation mechanism, so that hydraulic force generated by the hydraulic device is reduced, and the shifting rod is prevented from being deformed and damaged.

Owner:无锡舰华磁电科技有限公司

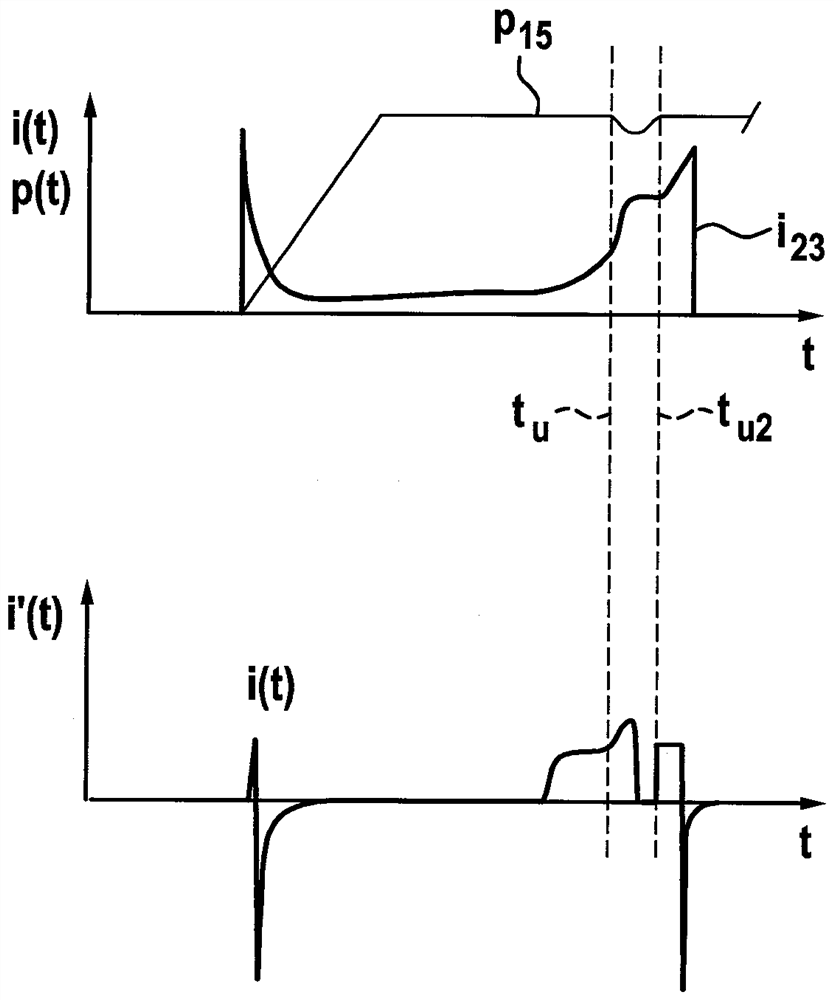

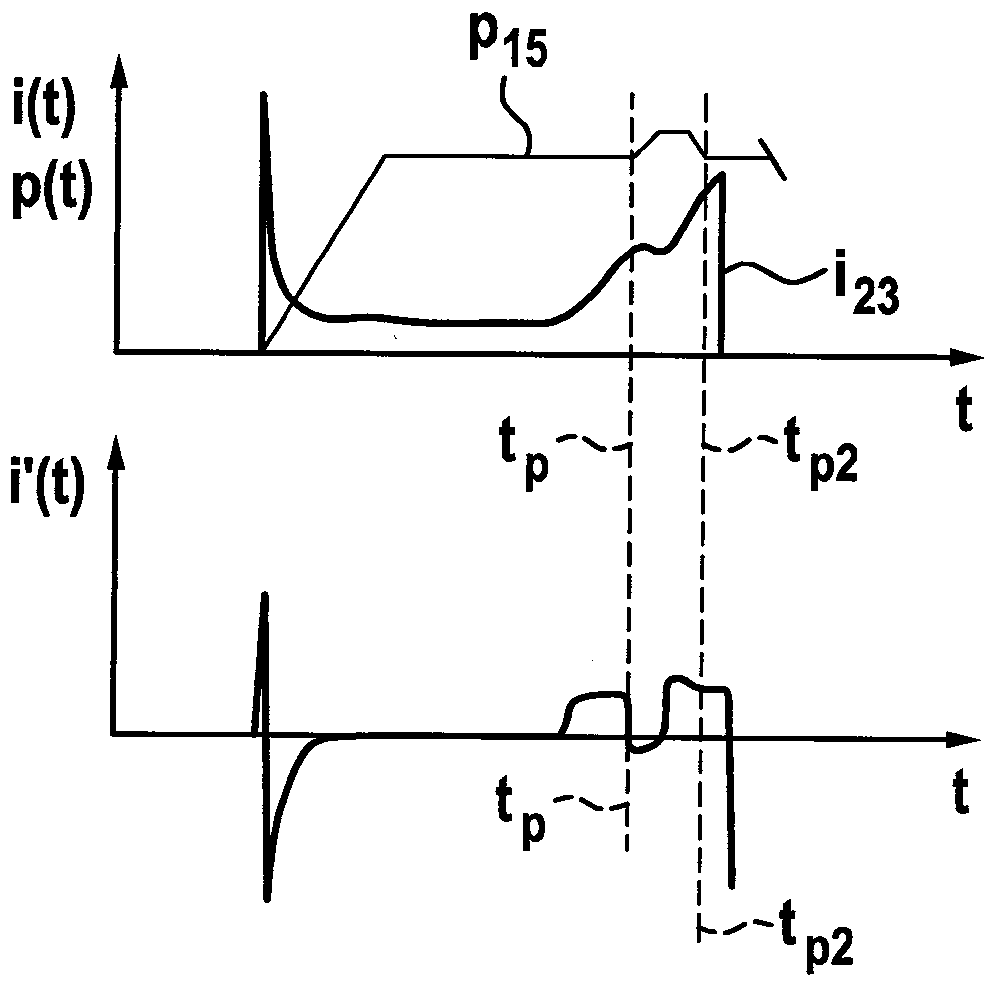

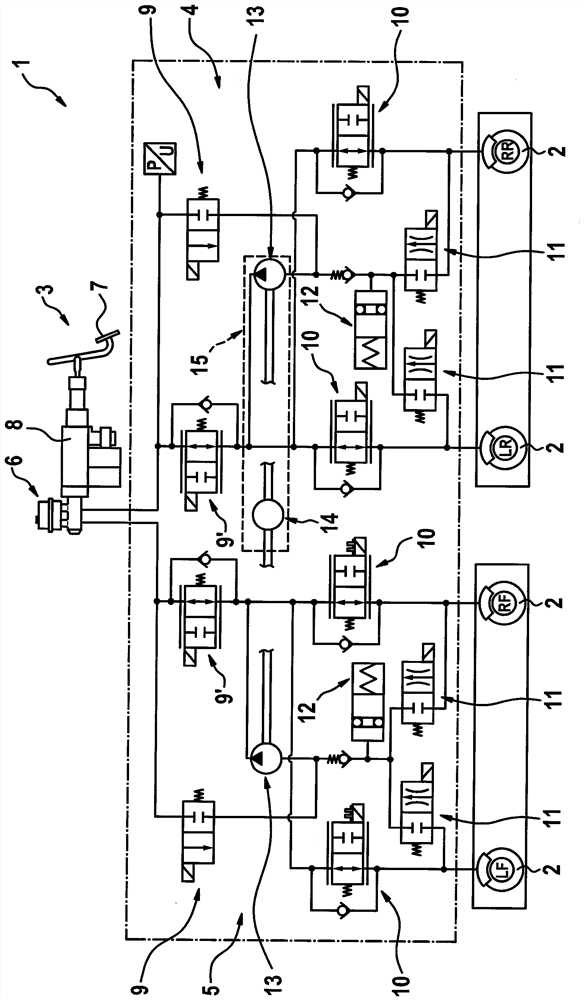

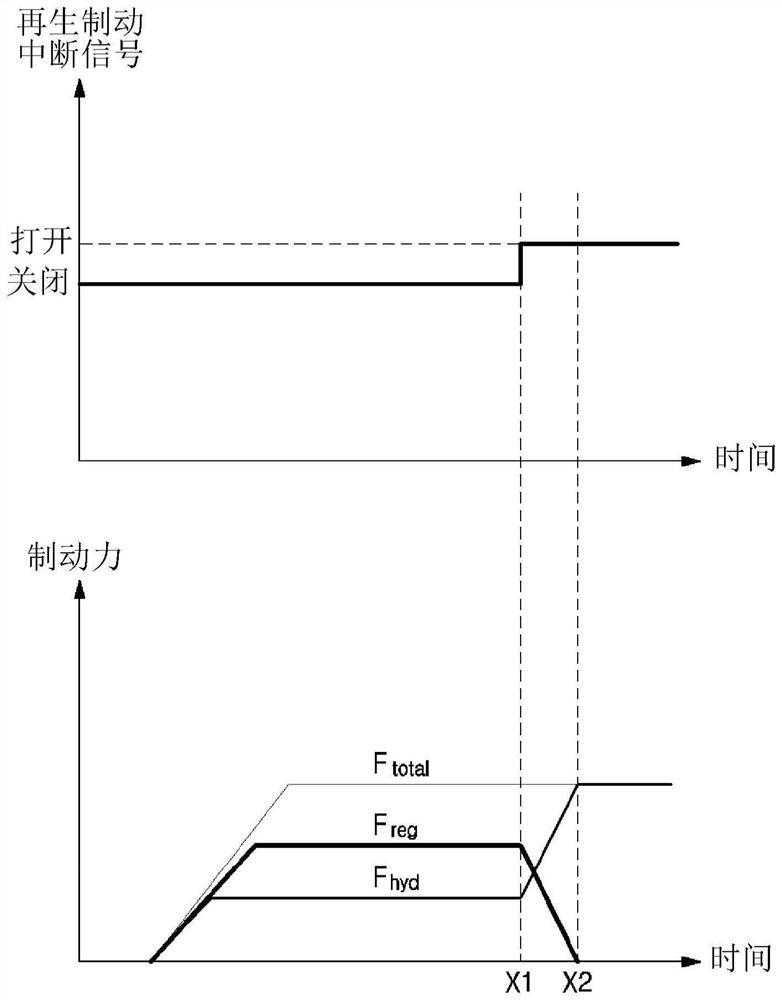

Method and device for operating a hydraulic brake system, brake system

ActiveCN108116393BHydraulic pressure reductionOperating current increasesBraking action transmissionBrake control systemsControl theoryParking brake

The invention relates to a method for operating a hydraulic braking system of a motor vehicle, the braking system having wheel brakes, a brake pedal arrangement and a pressure generator for actuating the wheel brakes, and an electromechanical actuator for actuating the wheels Brakes, by means of pressure generators and actuators that can generate a force that is used to move the brake pistons of the wheel brakes to actuate the wheel brakes, to adjust the parking brake function the pressure generators and actuators are controlled in such a way that they together generate the total clamp tightening force, in order to determine the functional capability of the hydraulic braking system, the operating current of the actuator (i 23 ). It is provided that the pressure generator is actuated during adjustment in such a way that the hydraulic pressure can be maintained for a predetermined duration (tp‑tp 2 ) is modulated in order to de-load or load the actuator, and the operating current of the actuator for this duration is evaluated in order to determine the functional capability of the braking system (i 23 ).

Owner:ROBERT BOSCH GMBH

Brake system of vehicle capable of regenerative braking and hydraulic braking and control method thereof

PendingCN114789715AMinimize unnatural feelingHydraulic pressure reductionBraking element arrangementsBraking action transmissionMaster cylinderTreadle

The invention provides a braking system capable of regenerative braking and hydraulic braking of a vehicle and a control method thereof. The present disclosure provides, in at least one embodiment, a brake system including: a pedal master unit; an electric supercharger unit; a reaction plate that generates a pedal force when compressed by at least one of the operating rod and the motor piston; and a controller that senses a pressure change in the master cylinder after receiving a regenerative braking interrupt signal during cooperative braking of the vehicle, and compensates for a displacement of the motor piston by an amount corresponding to the pressure change.

Owner:HYUNDAI MOBIS CO LTD

A segment slowly unloading device

InactiveCN104444756BHydraulic pressure reductionReduce reboundServomotor componentsAccumulator installationsMachining vibrationsEngineering

The invention discloses a segmented retardant discharging device. The segmented retardant discharging device comprises an automatic hooking device and a retarder, wherein the automatic hooking device is positioned below the retarder and is connected with the retarder, a spring feeler lever is arranged above the retarder, and the retarder is internally provided with a hydraulic oil path used for controlling hydraulic pressure of the retarder. According to the segmented retardant discharging device disclosed by the invention, by reducing the hydraulic pressure of the retarder in a grading mode, tensile force of a steel wire rope for hanging a heavy hammer is gradually reduced, and the heavy hammer is subjected to putting down in a stair-shaped slow descending mode from a step releasing mode, so that impact to a system due to heavy hammer release is reduced, the rebound of a cargo boom is small, the rope disordering probability of the steel wire rope is low, the abrasion of the automatic hooking device is slight, the whole machine vibration is slight, and the service life is long.

Owner:刘洋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com