Control valve of injector

A technology for control valves and injectors, which is applied in the field of control valves and injector control valves. It can solve the problems of limited working pressure of injectors, increased leakage risk of contact surfaces, and high difficulty in manufacturing and processing, so as to reduce opening delay time, The effect of improving the service life and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

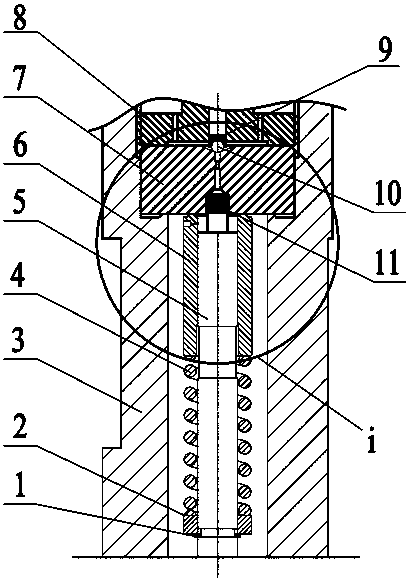

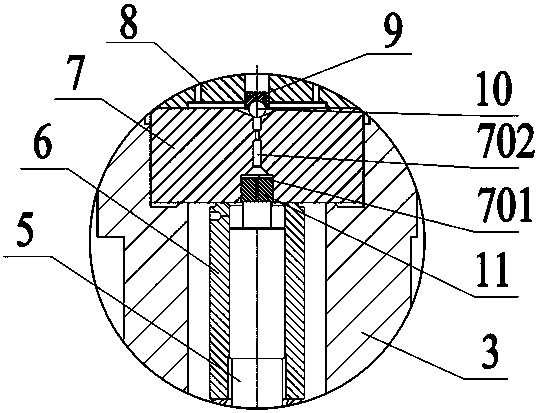

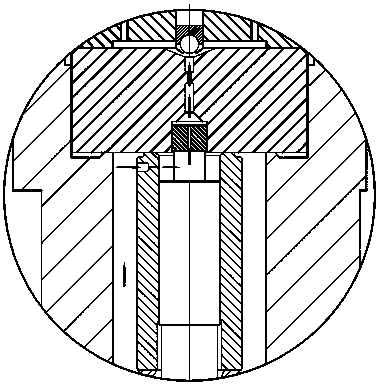

[0037] Example 1, please combine Figure 1 to Figure 3 As shown, the control valve of the injector involved in this embodiment, such as figure 1 As shown, it includes a control plunger 5, a valve sleeve 6, an orifice 7 and a fastening valve seat 8. The fastening valve seat 8 and the injector body 3 are fixed by threaded connection, and the orifice plate 7 is fixed to the injector body 3. Inside, the valve sleeve 6 is sleeved on the outer circumference of the control plunger 5 to cooperate with the control plunger 5 , and the gap between the valve sleeve 6 and the control plunger 5 is between 0.008mm and 0.012mm. The valve sleeve spring 4 acts on the lower end surface of the valve sleeve 6, and the upper end surface of the valve sleeve 6 abuts against the lower end surface of the orifice plate 7. At this time, the control plunger 5, the valve sleeve 6 and the orifice plate 7 form a control cavity. The control valve of the injector also includes a pressure-relief float 11 , wh...

Embodiment 2

[0041] This embodiment 2 is similar to embodiment 1, and the similarities will not be repeated here. The differences of this embodiment are as follows: Figure 10 to Figure 16 As shown, the oil outlet hole 110 of the slow pressure float 11 is a step hole, the near notch end of the oil outlet hole 110 is a large diameter end 112, and the far notch end of the oil outlet hole 110 is a small diameter end 113; 113 aperture ranges from 0.15mm to 0.38mm, preferably ranges from 0.2mm to 0.3mm, and in this embodiment is between 0.2mm to 0.25mm, and the maximum oil outlet aperture range of the slow pressure floating column 11 is from 2mm to 2.5mm; slow pressure The outer peripheral surface of the floating column 11 is provided with a DLC anti-friction coating.

Embodiment 3

[0043] This embodiment 3 is similar to embodiment 1 and embodiment 2, and the similarities will not be repeated here. The differences of this embodiment are as follows: Figure 17 As shown, the diameter of the slow pressure floating column 11 is larger than that in the embodiment 1 and embodiment 2, and the diameter range of the slow pressure floating column 11 is between 3.6mm and 4mm in the present embodiment, and the orifice in the present embodiment is out. The sealing method of the oil hole 701 adopts a planar valve sealing structure in which the sealing column 12 cooperates with the upper end surface of the orifice plate 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com