Safe cylindrical lithium-manganese dioxide battery

A manganese dioxide battery and cylinder technology, which is applied to lithium batteries, secondary batteries, batteries with organic electrolytes, etc., can solve the problems of high probability of batteries flying out of long distances, failure to meet safety requirements of lithium batteries, and severe battery explosions. , to achieve the effect of increasing the volume, eliminating glass corrosion and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

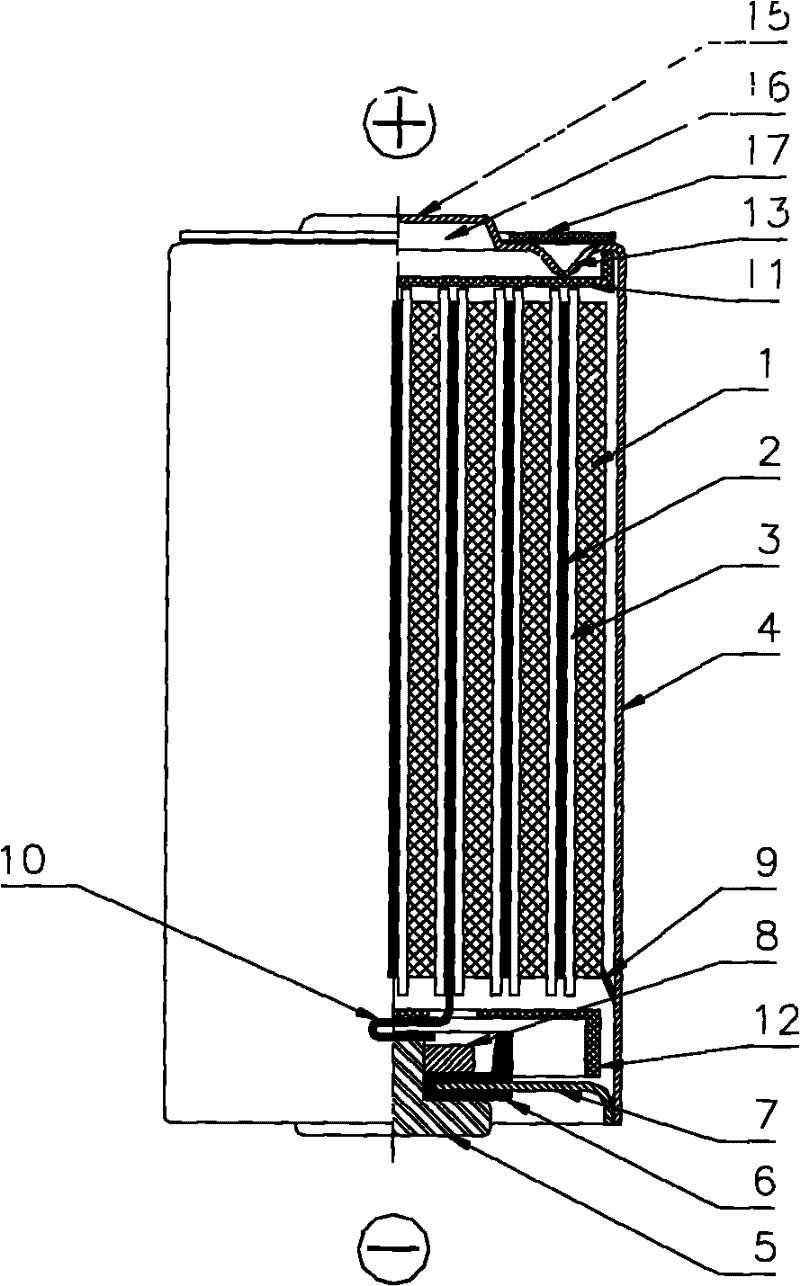

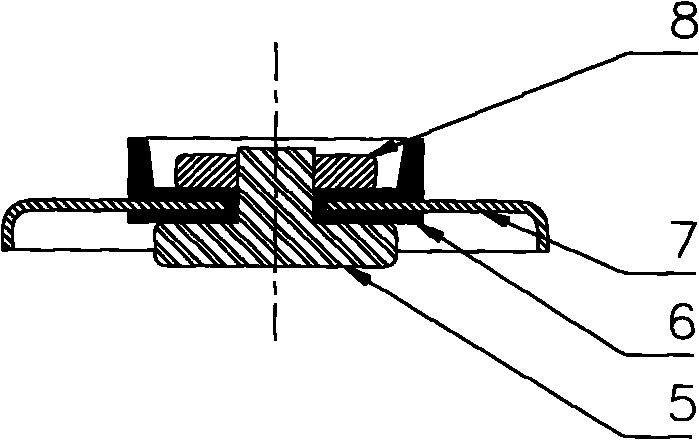

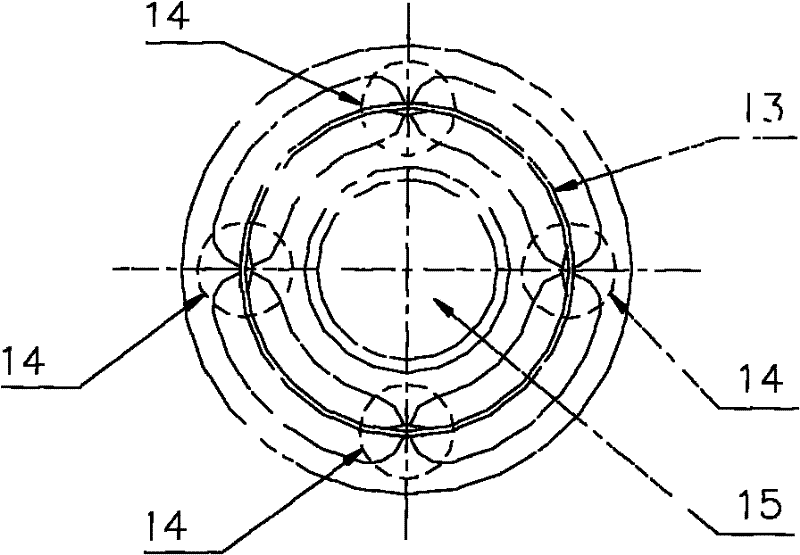

[0033] CR17335 cylindrical lithium-manganese dioxide battery, which includes a positive electrode sheet with manganese dioxide as the active material, and a metal lithium negative electrode sheet. The length ratio of the positive and negative electrodes is 1:0.70, the width ratio is 1:0.80, and the thickness ratio The ratio is 1:0.45, the positive and negative electrodes are separated by an ion-permeable microporous membrane, and wound into a cylindrical core with a safety structure. It is connected with the T-shaped pole of the hot-melt, anti-electrolyte-corroded sealing assembly. The two ends of the winding core are respectively equipped with a polyethylene upper insulating ring and a polytetrafluoroethylene lower insulating ring. The carbon steel battery case is designed with a self-starting explosion-proof The pressure relief device and the sealing assembly are connected to the carbon steel battery casing by argon arc welding.

[0034] The hot-melt, electrolyte-resistant s...

Embodiment 2

[0042] CR17335 cylindrical lithium-manganese dioxide battery, which consists of a positive electrode sheet with manganese dioxide as the active material and a lithium metal negative electrode sheet. The length ratio of the positive and negative electrodes is 1:0.77, the width ratio is 1:0.88, and the thickness The ratio is 1:0.50. The positive and negative electrodes are separated by an ion-permeable microporous membrane, and wound into a cylindrical core with a safe structure. The positive electrode is connected to the 304 stainless steel battery case through tabs, and the negative electrode is connected through The lugs are connected to the T-shaped pole of the hot-melt, electrolyte-resistant sealing assembly, and the two ends of the winding core are respectively equipped with an upper insulating ring made of a mixture of polytetrafluoroethylene and polyethylene and a lower insulating ring made of polystyrene , The 304 stainless steel battery casing is designed with a self-st...

Embodiment 3

[0051] CR17335 cylindrical lithium-manganese dioxide battery, which includes a positive electrode sheet with manganese dioxide as the active material, and a metal lithium negative electrode sheet. The length ratio of the positive and negative electrodes is 1:0.85, the width ratio is 1:0.95, and the thickness ratio The ratio is 1:0.55. The positive and negative electrodes are separated by an ion-permeable microporous membrane and wound into a cylindrical core with a safety structure. The positive electrode is connected to the aluminum battery shell through the tab, and the negative electrode is connected to the T-shaped pole connection of hot-melt, electrolyte-resistant sealing assembly, with plastic PTFE upper insulating rings and lower insulating rings made of polystyrene and polypropylene mixture materials at both ends of the core, aluminum The battery casing is designed with a self-starting explosion-proof pressure relief device, and the sealing assembly is connected to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com