Sludge storage bin system

A sludge and silo technology, which is applied in containers, packaging, transportation and packaging, etc., can solve the problems of affecting the transmission efficiency, the conveying mechanism is not finished conveying, and the warehouse is full, so as to achieve smooth operation of the carriage, uniform force, and prevent transmission. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

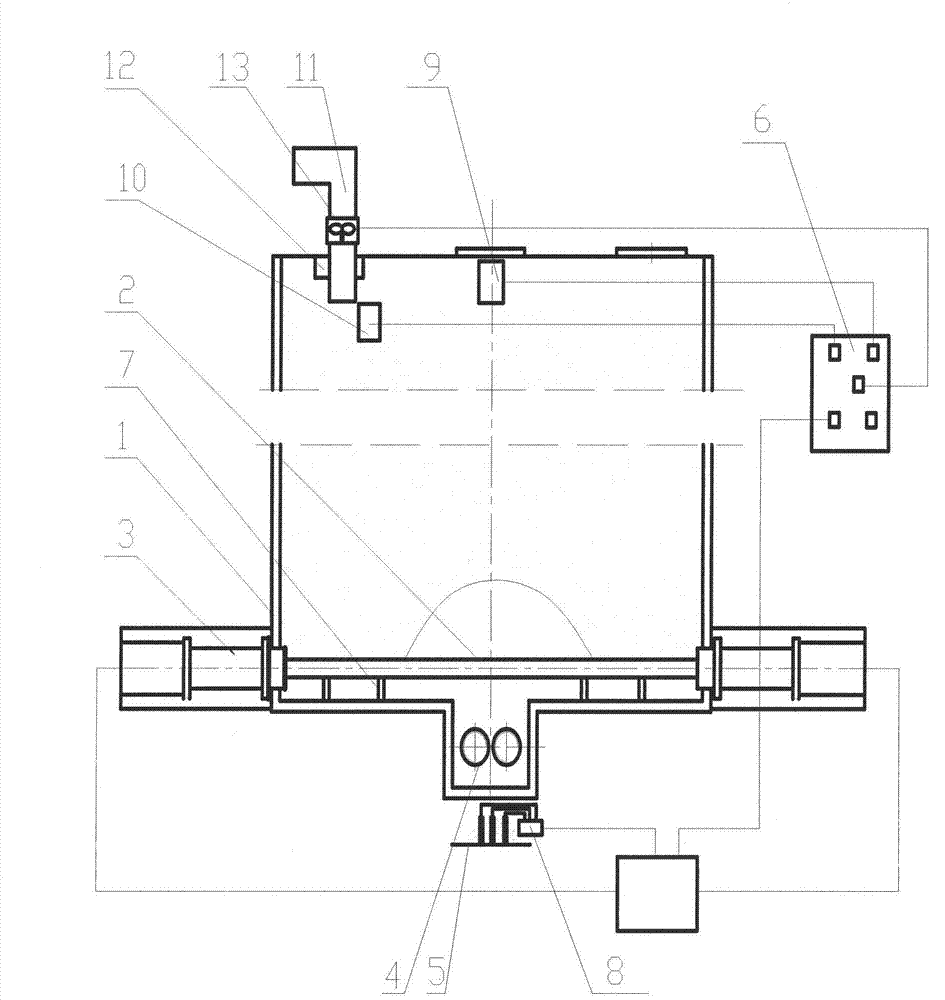

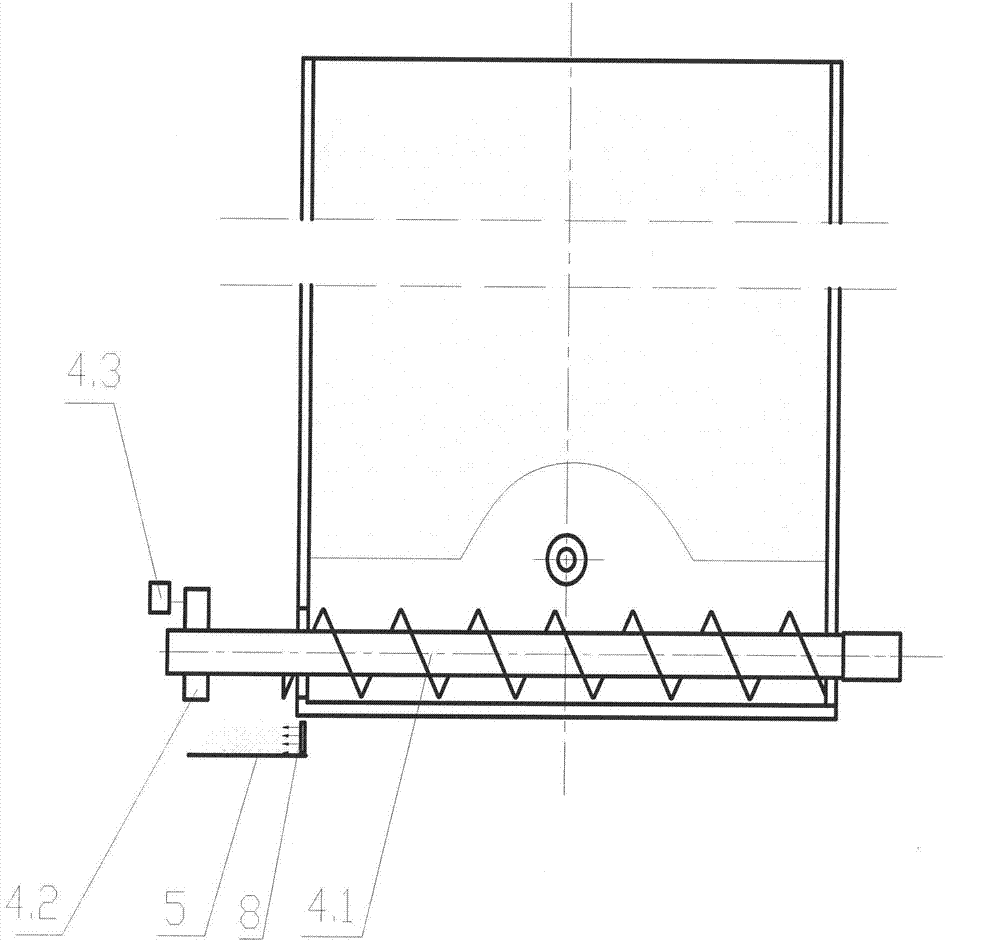

[0017] Such as figure 1 , 2 As shown, the sludge silo system of the present invention includes a silo body 1, a carriage 2, a hydraulic cylinder 3, a screw conveyor 4, a sludge transmission mechanism 5 and a controller 6, and the carriage 2 is arranged on the material At the bottom of the bin body 1, there are two hydraulic cylinders 3, which are respectively installed on both sides of the carriage 2, and the piston end of the hydraulic cylinder 3 is connected with the carriage 2; the carriage 2 is connected to the inner bottom surface of the bin body 1 There are guide rails 7 between them, the screw conveyor 4 is installed under the slide frame 2, the sludge transfer mechanism 5 is arranged under the outlet of the screw conveyor 4, and an infrared conveyor is installed on the sludge transfer mechanism 5. The sensor 8, the infrared sensor 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com