Single-column control valve of ejector

A technology of injectors and control valves, which is applied in fuel injection devices, machines/engines, engine components, etc., can solve the problems of high difficulty in manufacturing and processing, many sealing contact surfaces, and short service life, so as to reduce the opening delay time and reduce the Destruction of cavitation and effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

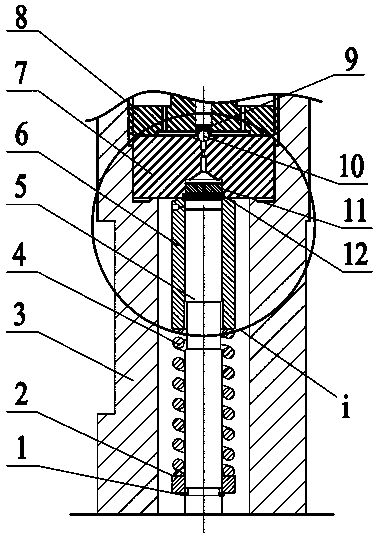

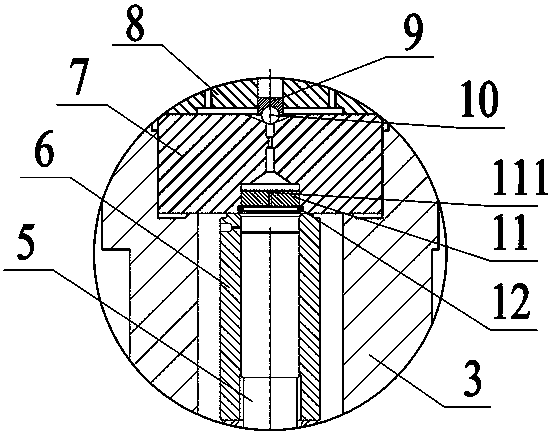

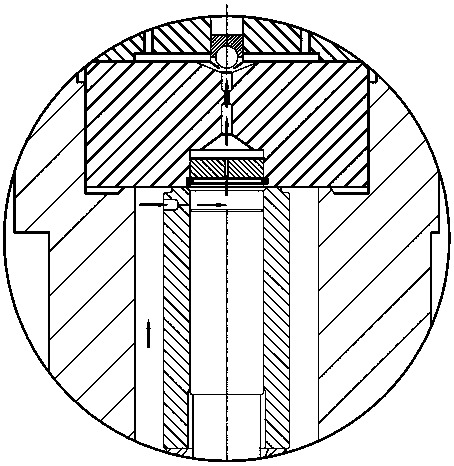

[0024] Example 1, please combine Figure 1 to Figure 3 As shown, the single-column control valve of the injector involved in this embodiment, such as figure 1 As shown, it includes a control plunger 5, a valve sleeve 6, an orifice 7 and a fastening valve seat 8. The fastening valve seat 8 and the injector body 3 are fixed by threaded connection, and the orifice plate 7 is fixed to the injector body 3. Inside, the valve sleeve 6 is sleeved on the outer circumference of the control plunger 5 to cooperate with the control plunger 5 , and the gap between the valve sleeve 6 and the control plunger 5 is between 0.005 mm and 0.012 mm. The control plunger 5, the valve sleeve 6 and the orifice 7 form a control chamber. The single-column control valve of the injector also includes a pressure-relief floating column 11, which is cylindrical, and a pressure-relief oil outlet hole 111 penetrating in the axial direction is opened in the center of the pressure-relief float 11. The diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com