A micro-displacement driven switch valve

A technology of micro-displacement driver and driving switch, applied in the field of hydraulic components, can solve the problems of insufficient valve core driving force, ingenious mechanism design, affecting the function of the switch valve, etc., and achieves the effect of compact structure, easy assembly and reduced resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

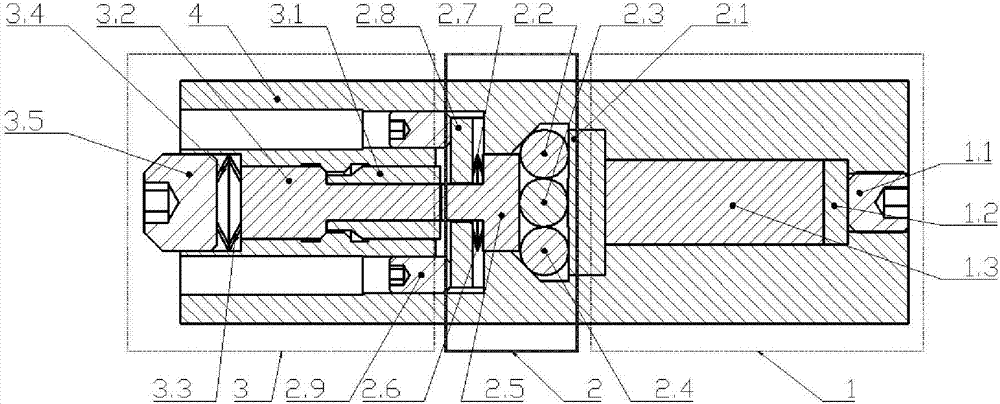

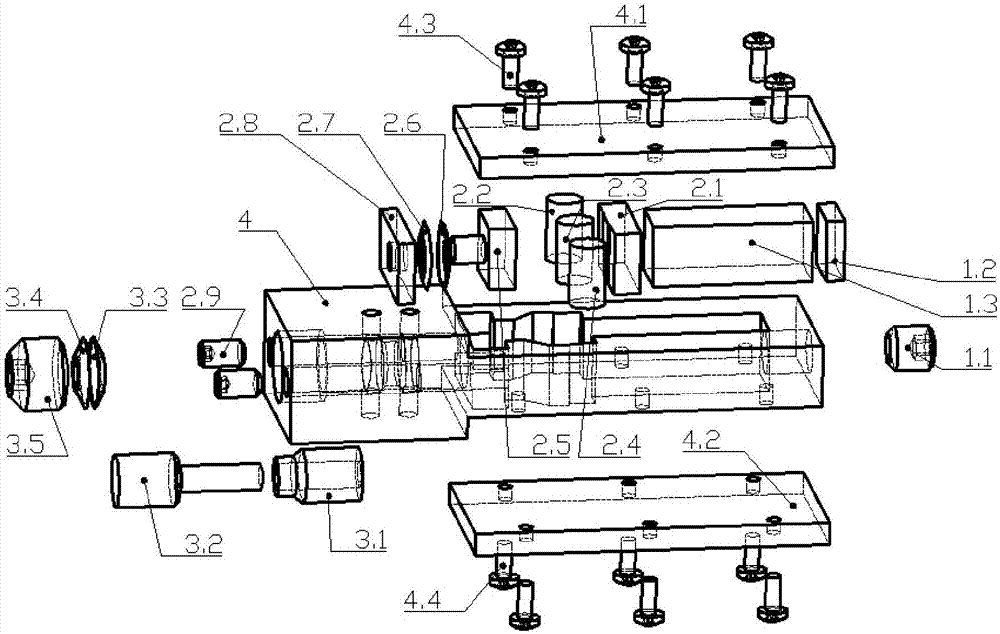

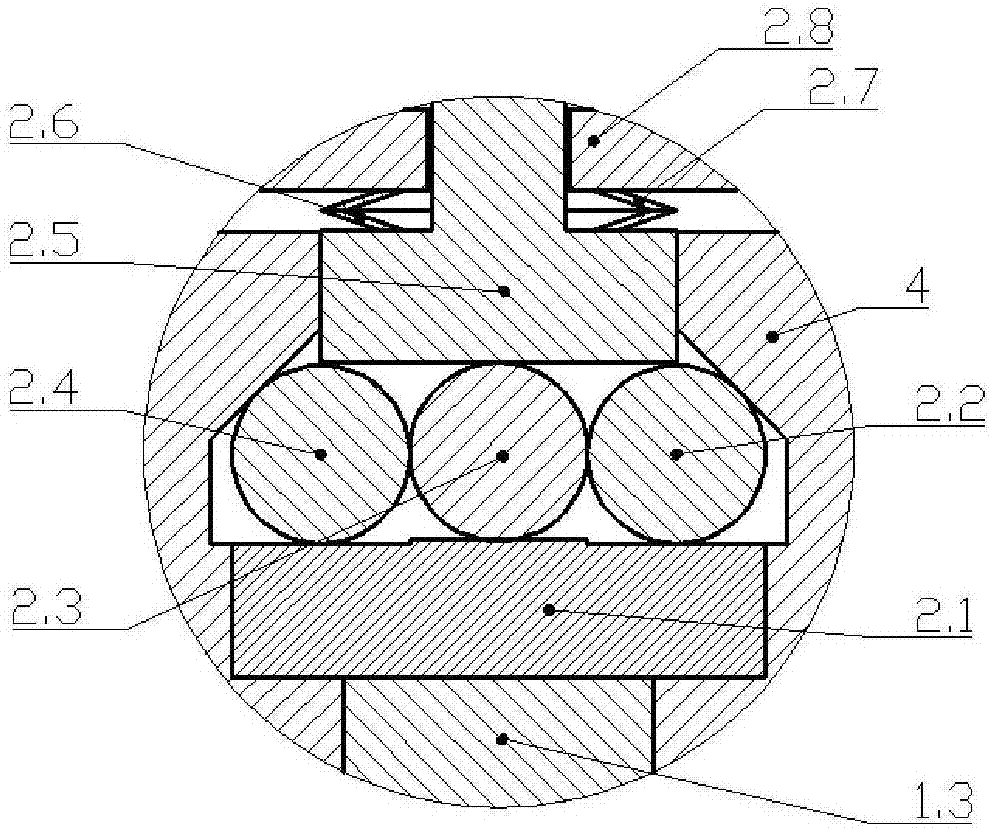

[0021] Such as Figure 1-5 As shown, a kind of micro-displacement driving switching valve provided by the present invention includes a micro-displacement driver 1, a micro-displacement amplification mechanism 2, a switching valve spool assembly 3 and a valve body base 4; the micro-displacement amplification mechanism 2 adopts three balls The triangular amplification principle combined with two triangular slopes amplifies the micro-displacement output by the micro-displacement driver 1; the switch valve spool assembly 3 adopts an equal-diameter separation structure of the upper and lower spools to balance the hydraulic pressure and facilitate the assembly of the spool; the valve body base 4. Integrate the installation space of the micro-displacement driver 1, the installation space of the micro-displacement amplification mechanism 2, and the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com