A Biaxial Stress Fatigue Loading Test Device for Flexible Fiber Reinforced Film

A flexible fiber, fatigue loading technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as difficulty in simulating the real working conditions of flexible film materials, unsuitable flexible fiber reinforced films, and complex system structure. The effect of uniform force, convenient installation and accurate experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

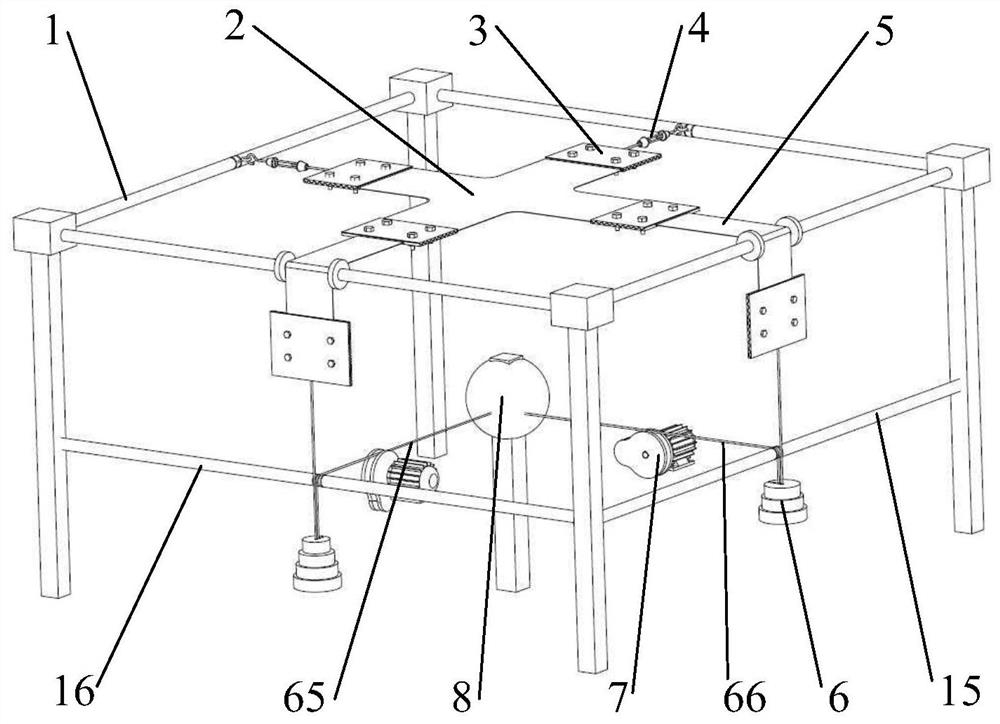

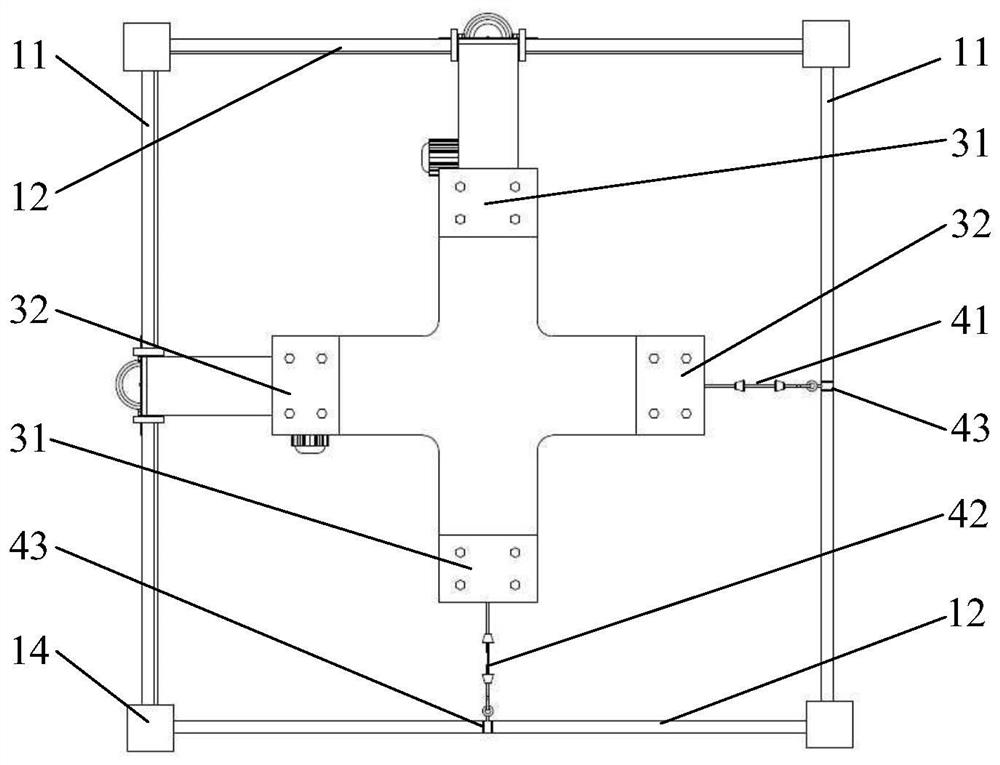

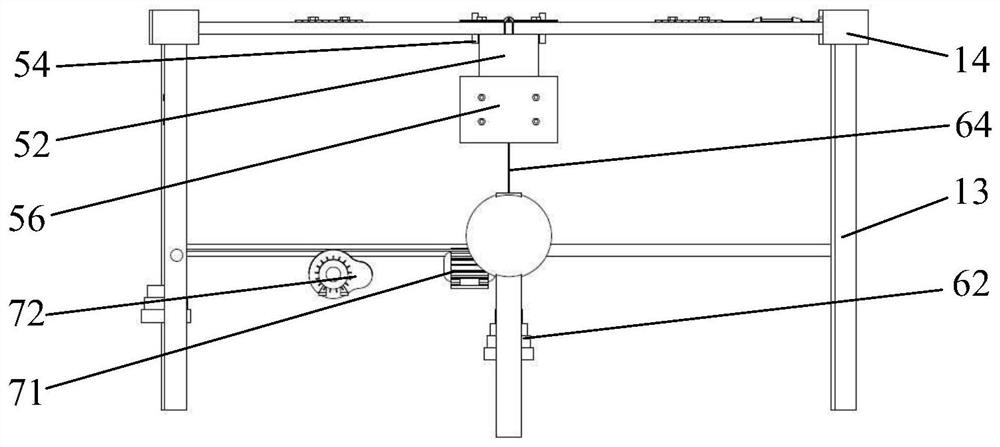

[0040] The present invention is a flexible fiber reinforced film biaxial stress fatigue loading test device, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, it includes: platform (1), upper meridional support beam (11), upper weft support beam (12), vertical column (13), top corner reinforcement joint (14), middle meridional beam (15 ), the middle latitudinal beam (16), the biaxial tensile specimen (2), the specimen fixing chuck (3), the warp direction specimen fixing chuck (31), the weft direction specimen fixing chuck (32 ), position slack adjuster (4), warp position slack adjuster (41), weft position slack adjuster (42), upper beam positioner (43), tensile load transfer belt (5), warp tension Tensile load transmission belt (51), weft tensile load transmission belt (52), longitudinal beam transmission belt stopper (53), latitu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com