On-line gas-solid kinetic testing method and device

A test method and kinetic technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low efficiency, inaccurate experimental data, and inability to monitor in real time, and achieve high efficiency and accurate experimental data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

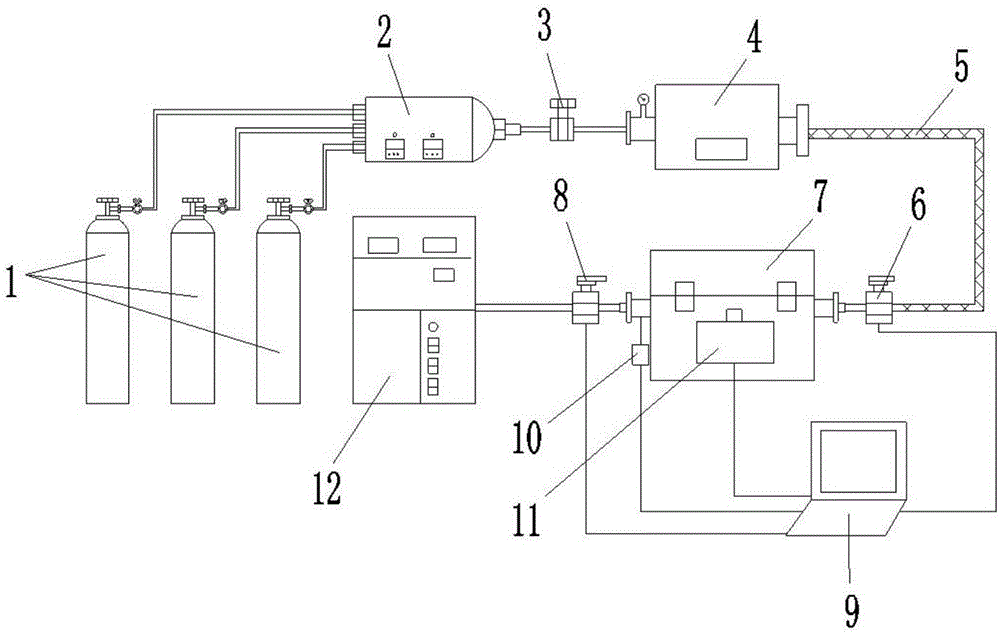

[0023] Embodiment of the present invention: the structure diagram of online gas-solid dynamics testing method and device is as follows figure 1 As shown, it includes a mass gas mixing system 2 and more than one gas cylinder 1 connected to the mass gas mixing system 2. The mass gas mixing system 2 is connected to a preheating vacuum furnace 4 through an inlet valve 3, and the preheating vacuum The furnace 4 is connected to the reaction vacuum furnace 7 through the heat preservation pipeline 5 and the controllable solenoid valve 6, and the reaction vacuum furnace 7 is connected to the vacuum system 12 through the controllable exhaust valve 8, and a pressure sensor 10 and a temperature sensor are arranged in the reaction vacuum furnace 7 11. The controllable solenoi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com