Segmented retardant discharging device

A retarder and retarder technology, applied in the field of segmented retarder unloading devices, can solve the problems of crane impact and slow action, and achieve the effects of long working life, reduced impact and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

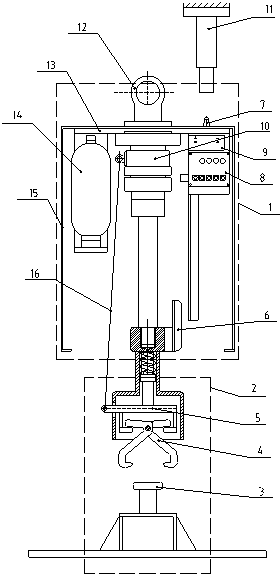

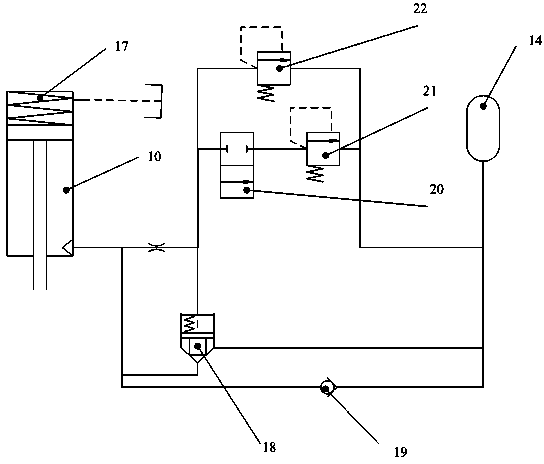

[0041] Reference figure 1 , The segmented retarder discharge device of this embodiment includes a retarder 1 and an automatic hooker 2. The automatic hooker 2 is located below the retarder 1, and the automatic hooker 2 is connected to the retarder 1, and the retarder 1 A spring contact rod 11 is provided above the retarder 1; a hydraulic oil circuit for controlling the hydraulic pressure of the retarder 1 is provided in the retarder 1.

[0042] The retarder 1 includes a base 13, and the top of the base 13 is provided with a lifting ring 12 and a first switch 7. Below the base 13 are provided an accumulator 14, an oil cylinder 10, a battery 9, and an oil cylinder. A wedge-shaped striker 6 is provided below 10, and the wedge-shaped striker 6 is connected to the piston rod of the oil cylinder 10; a valve block 8 is provided under the battery 9, and the first switch 7 is electrically connected to the valve block 8.

[0043] The number of the oil cylinder 10 is one.

[0044] A sun shield...

Embodiment 2

[0059] Reference Figure 4 The difference between this embodiment and embodiment 1 is only that: a switch is provided under the valve block 8, which is the second switch 23; refer to Figure 5 , The number of control oil circuits is two, divided into the first control oil circuit and the second control oil circuit. The second switch 23 is electrically connected to the electromagnetic directional valve 20 of the second control oil circuit for controlling the second control oil. The power supply of the electromagnetic directional valve 20 of the circuit is on and off. The number of oil cylinders 10 is two, and the two oil cylinders 10 are connected in parallel. The first switch 7 and the second switch 23 are travel switches. The rest is the same as in Example 1.

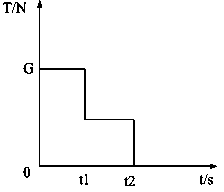

[0060] When this embodiment is used, the steel wire rope is first connected to the hoisting ring 12, and then the entire sectioned slow-speed discharge device is suspended under the crane hook through the wire rope; the ...

Embodiment 3

[0066] Reference Figure 7 The difference between this embodiment and the first embodiment is only: two switches are provided under the valve block 8, namely the second switch 23 and the third switch 24, the second switch 23 is located above the third switch 24 and in the same vertical In the straight direction, the vertical length of the wedge-shaped striker 6 is greater than the distance between the second switch 23 and the third switch 24; reference Figure 8 , The number of control oil circuits is three, which are divided into the first control oil circuit, the second control oil circuit and the third control oil circuit. The second switch 23 is electrically connected to the electromagnetic directional valve 20 of the second control oil circuit for The electromagnetic directional valve 20 of the second control oil circuit is turned on and off; the third switch 24 is electrically connected to the electromagnetic directional valve 20 of the third control oil circuit, and is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com