Transmission mechanism achieving rapidly returning and electro-hydraulic brake system

A transmission mechanism and hydraulic braking technology, applied in the direction of brake, brake transmission, transportation and packaging, etc., can solve the problems of low inverse efficiency, occupying the axial space of the brake master cylinder, large transmission resistance, etc. To the effect of size, small footprint and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

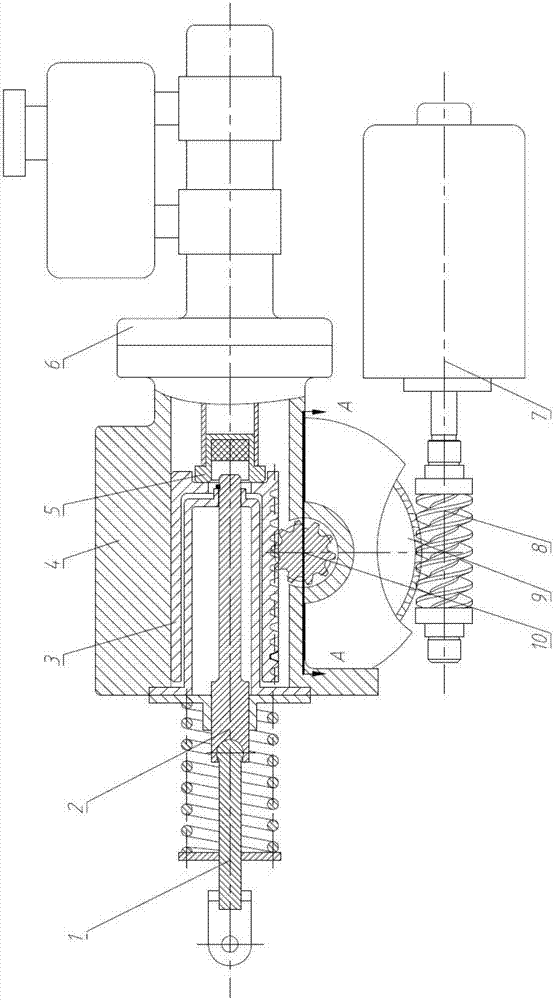

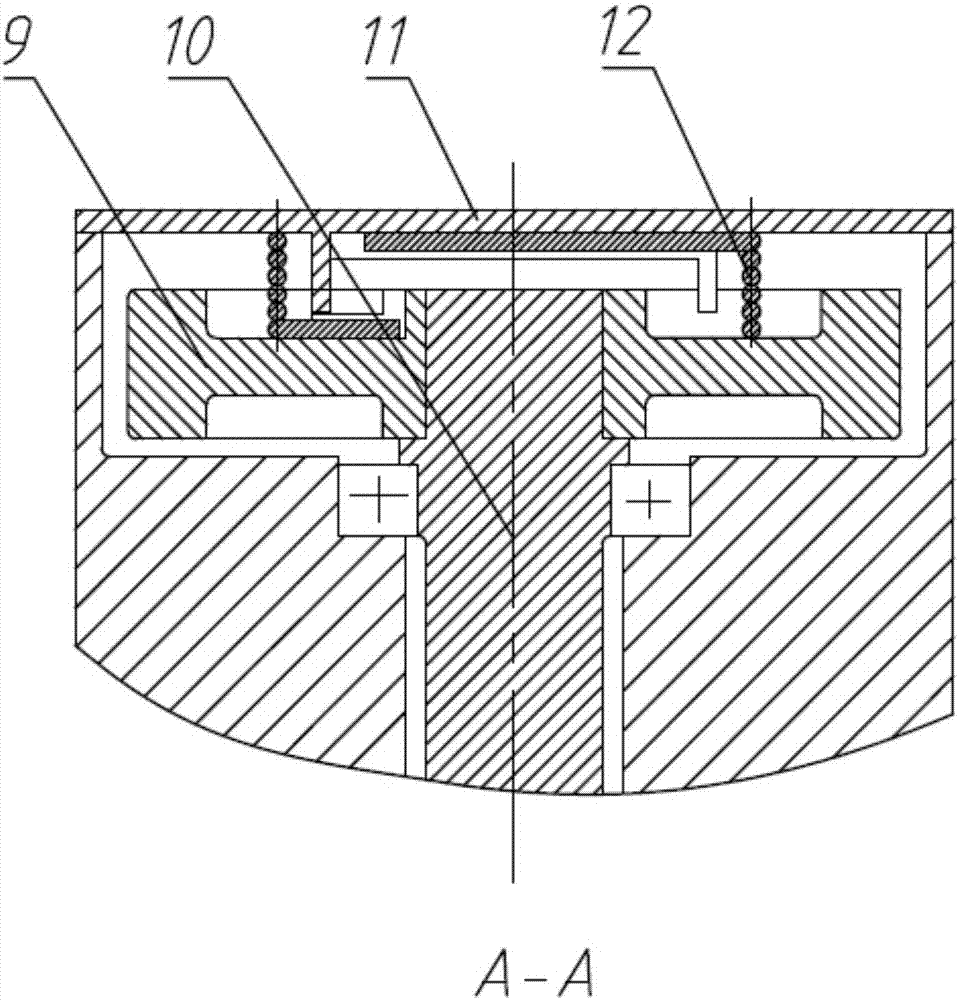

[0026] A quick-return transmission mechanism, including a worm 8 and a worm gear 9 that mesh with each other, the worm 8 is used to transmit the braking boost of the motor 7 to the worm gear 9, and the worm gear 9 is used to transmit the braking boost to the secondary drive connected to it The structure is transmitted to the hydraulic brake master cylinder 6. The transmission mechanism also includes a worm gear end cover 11 and a torsion spring 12 for providing torsional force. The worm gear end cover 11 is parallel to the worm wheel 9 and its position is fixed. One end of the torsion spring 12 is connected to the worm wheel 9. The other end is fixed on the worm gear end cover 11. In the initial position of the transmission mechanism, the torsion spring 12 has a pre-tightening force. When the motor 7 generates braking boost, the rotation of the worm wheel 9 makes the elastic element generate torque, which is opposite to the direction of rotation of the worm wheel 9. .

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com