Vibration-reducing washing machine and vibration-reducing method for washing machine

a washing machine and vibration reduction technology, applied in the field of washing machines, can solve the problems of reducing vibration and unable to efficiently reduce and achieve the effect of reducing the vibration of washing machines efficiently and quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

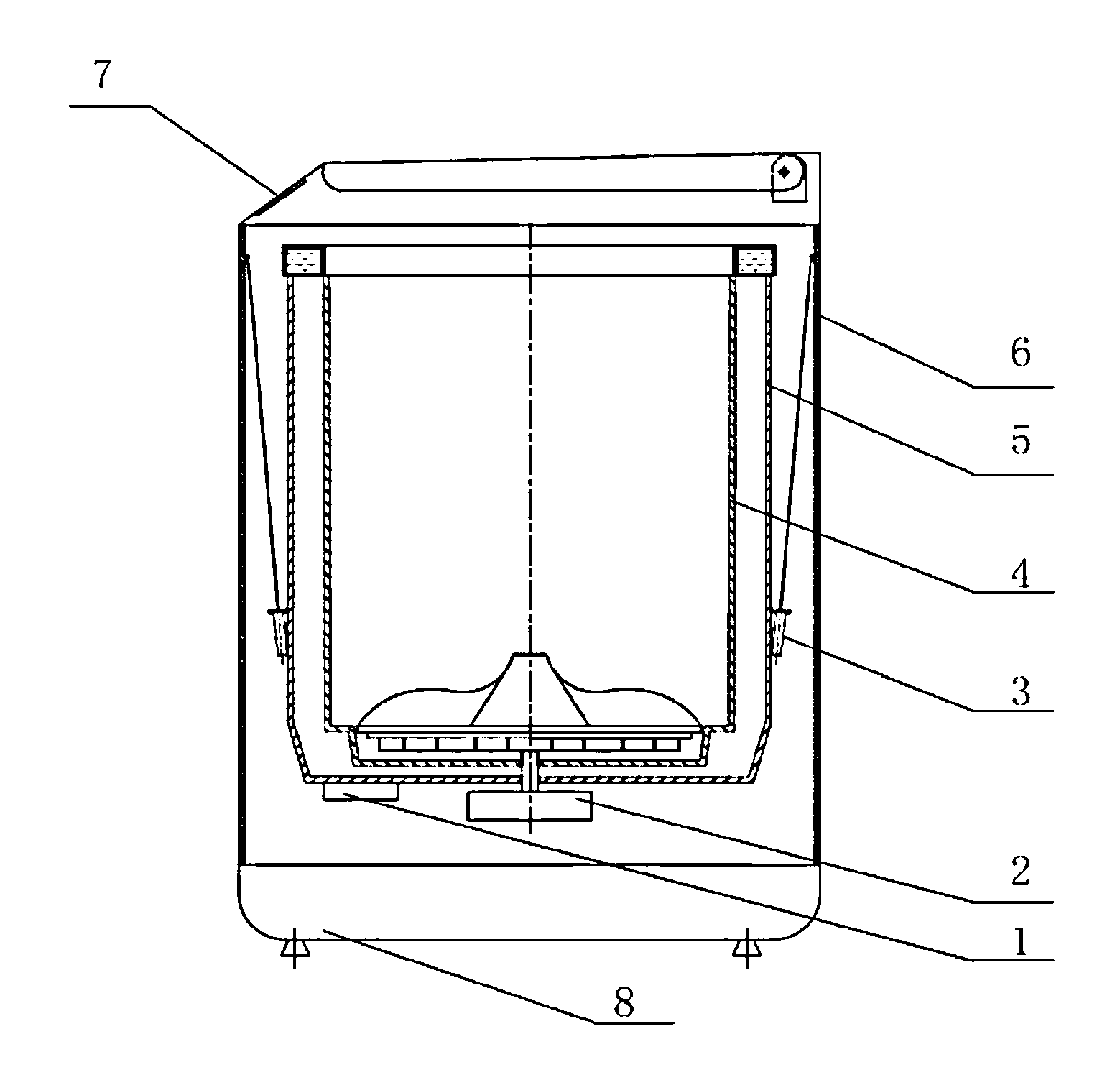

[0020]The present invention provides a vibration-reducing washing machine. Referring to FIG. 1, the vibration-reducing washing machine comprises an outer drum 5, a cabinet 6, a motor 2, a main control panel 7, a damper device 3, and a vibration detection and control module fixed to the washing machine and connected to the main control panel, wherein the vibration detection and control module is configured to detect and calculate vibration data of the washing machine and generate a control signal. The vibration-reducing washing machine and the washing machine vibration reducing method according to the present invention are capable of detecting the vibration data during operation of the washing machine, performing calculation for the vibration data, and generating the control signal. As known from the above, the control signal is generated according to the calculation result of the vibration data, and using the control signal to perform vibration-reducing control for the washing machi...

embodiment 2

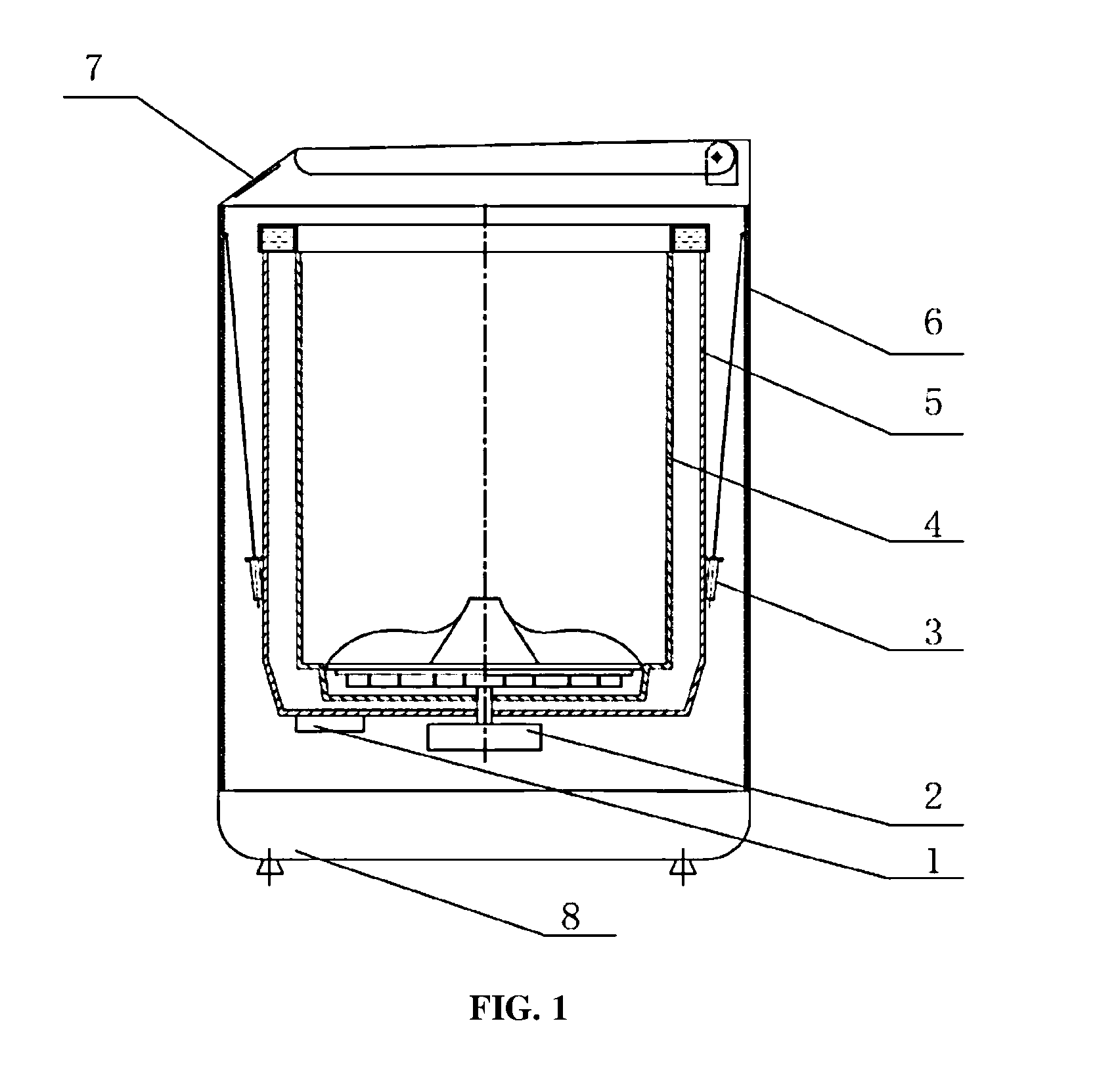

[0048]Corresponding to Embodiment 1, a roller washing machine is described as an example in Embodiment 2. Referring to FIG. 2, different from Embodiment 1, the mounting positions of the motor 2 and detecting unit 1 disposed on the roller washing machine both vary accordingly. In the roller washing machine, a rotation axis of a rotation shaft of the motor 2 is different from the pulsator washing machine. Although the motor is mounted at the bottom of the outer drum, the direction of the bottom of the outer drum here is different from the direction of the bottom of the outer drum of the pulsator washing machine. Briefly, the rotation shaft of the motor mounted at the bottom of the outer drum in the pulsator washing machine is perpendicular to the horizontal surface and the bottom of the outer drum is close to the ground surface; but the rotation shaft of the motor of the roller washing machine in the present embodiment may be parallel to the horizontal surface, with the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com