Method for micro-processing patterned surface based on super hydrophilic-super hydrophobic characteristic template

A surface pattern and super-hydrophobic technology, which is applied in the field of super-hydrophobic/super-hydrophobic templates, can solve problems that are difficult to widely apply in scientific research and high-tech fields, complex and expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: First obtain a layer of nano-ordered TiO on the surface of the substrate by electrochemical anodic oxidation 2 The nanotube array film was heat-treated at 450°C for 2 hours, and then cooled in a furnace for standby use. Self-assemble a PTES monomolecular layer on the surface of the obtained film layer, then cover the surface of the film layer with a photomask, and irradiate with ultraviolet light for a certain period of time to obtain a superphobic-superhydrophilic pattern. figure 1 Fluorescence micrographs of several prepared surface-modified sodium fluorescein with different superphilic / superhydrophobic patterns. Depend on figure 1 It can be seen that the introduced sodium fluorescein is mainly aggregated and adsorbed in the superhydrophilic region, which emits obvious green light under the excitation of blue light (450-490nm). In the superhydrophobic area, due to its superhydrophobicity, the adsorption of sodium fluorescein is effectively prevented, ther...

Embodiment 2

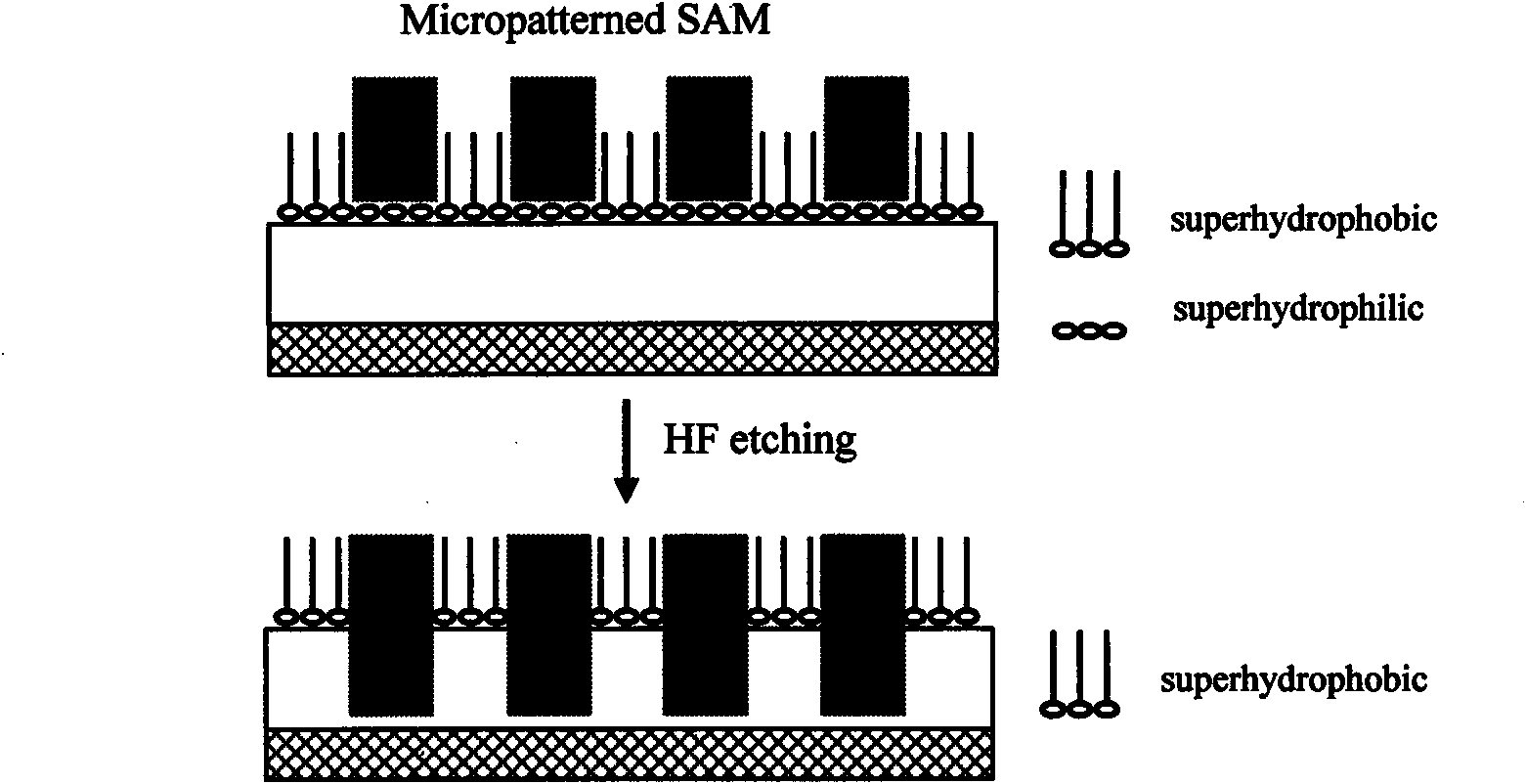

[0027] Example 2: figure 2 Schematic diagram of the preparation of micro-nano composite structures by wet chemical etching using superphilic / superhydrophobic patterns as templates. image 3 and Figure 4 Respectively, using superphilic / superhydrophobic micropatterns as templates, after etching with 0.1wt% HF solution for 120s, the TiO 2 Laser confocal micrographs and optical micrographs of micro-nano patterns were obtained on the surface of the nanotube array film. The square block in the figure is the superhydrophilic region etched by hydrofluoric acid, which is obviously different from the superhydrophobic region protected by the PTES film layer. Two types of micropatterns with significant differences in region composition are basically consistent in shape and size with the photomask. Figure 5 A field emission scanning electron microscope image of the micropattern. from Figure 5 a, b It can be seen that the micropattern morphology is clearly visible, and the boundari...

Embodiment 3

[0029] Example 3: similar to Example 2, the difference is that etching in 0.5wt% HF solution for 30s can construct a clear surface micropattern on the titanium substrate by three-dimensional ultramicromachining. Figure 7 is an optical micrograph of the micropattern prepared after etching in 0.5 wt% HF solution for 30 s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com