Metal sulfide electrode with hydrogen reduction activity and preparation method of metal sulfide electrode

A metal sulfide and electrode technology, which is applied to electrodes, electrolysis process, electrolysis components, etc., can solve the problems of expensive equipment and complicated preparation process, and achieve the effects of low cost, good repeatability and simple synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

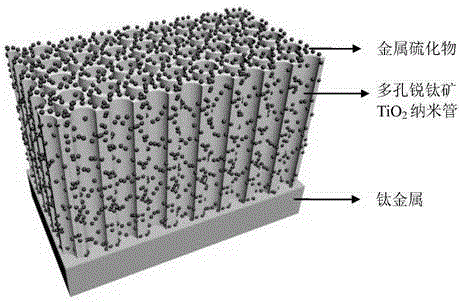

Image

Examples

Embodiment 1

[0032] (1) Put a titanium sheet with a purity of 99.7%, a length of 2.50 cm, a width of 1.00 cm, and a thickness of 0.05 cm into acetone for ultrasonic cleaning for 20 minutes, then transfer it to isopropanol and deionized water in turn, and ultrasonically wash them respectively 20min.

[0033] (2) Put the cleaned and dried titanium sheet into 0.5% HF solution at room temperature, clamp the upper end of the Ti sheet with a clamp, and immerse the lower end in the HF solution, and use the platinum sheet as the counter electrode for anodic oxidation. Among them, the oxidation voltage is 20V, and the oxidation time is 20min. During anodic oxidation, the surface facing the platinum sheet is defined as the front side, and the surface facing away from the platinum sheet is defined as the reverse side. After the oxidation is completed, porous amorphous titanium dioxide nanotubes are obtained on the front and back sides, which are rinsed with deionized water and then dried.

[0034] (3)...

Embodiment 2

[0037] (1) Use the method of step (1) in Example 1 to clean.

[0038] (2) adopt the method for step (2), (3) in the embodiment 1 to prepare porous anatase TiO 2 nanotube.

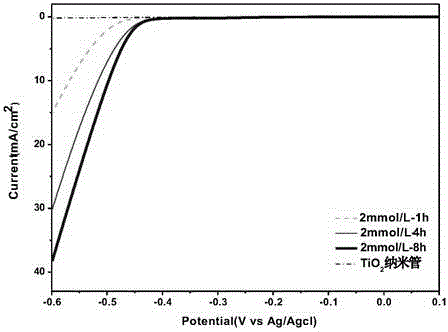

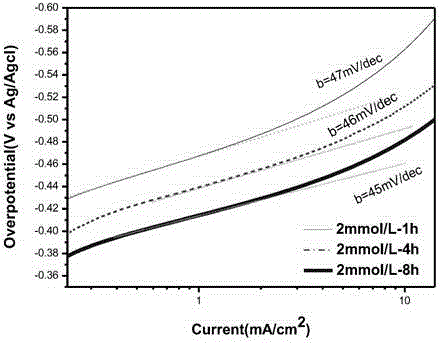

[0039] (3) Prepare 2×10 -3 mol / L (NH 4 ) 2 MoS 4 solution, the solvent is ethanol: water = 1:8, take 10mL of the solution and put it into a petri dish, and the porous anatase TiO obtained in step (2) 2 The nanotubes were placed in the petri dish horizontally, the Ti sheet was facing up, and the TiO was irradiated with ultraviolet light with a light intensity of 10mW. 2 The nanotube material was taken out after 4 hours, rinsed with deionized water and dried to obtain MoS 2 electrode.

Embodiment 3

[0041] (1) Adopt the same cleaning method as step (1) in Example 1 to clean the titanium sheet.

[0042] (2) adopt the method for step (2), (3) in the embodiment 1 to prepare porous anatase TiO 2 nanotube.

[0043] (3) Prepare 2×10 -3 mol / L (NH 4 ) 2 MoS 4 solution, the solvent is ethanol: water=1:8, get 10mL of this solution and put it into a petri dish, and the porous anatase TiO obtained in step (2) 2 Put the nanotubes into the Petri dish horizontally, with the Ti sheet facing up, and use a light intensity of 10mW / cm 2 TiO irradiated with UV light 2 The nanotube material was taken out after 1 hour, rinsed with deionized water and dried to obtain MoS 2 electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com