Method for preparing titanium-alloy super-hydrophobic surface with low roughness

A super-hydrophobic surface, low-roughness technology, applied in surface reaction electrolytic coatings, electrolytic coatings, coatings, etc., can solve the problems of large surface roughness, high cost, low efficiency, etc., and achieve a simple and easy process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) Cut both the titanium alloy (Ti-6Al-4V) plate and the graphite plate into 20mm×30mm, but the actual processing area is 20mm×20mm, and the rest is used for clamping and conduction. Before processing, sand the titanium alloy plate with 1500# sandpaper, then ultrasonically clean it in acetone, ethanol, and deionized water for 3 minutes to remove oil stains.

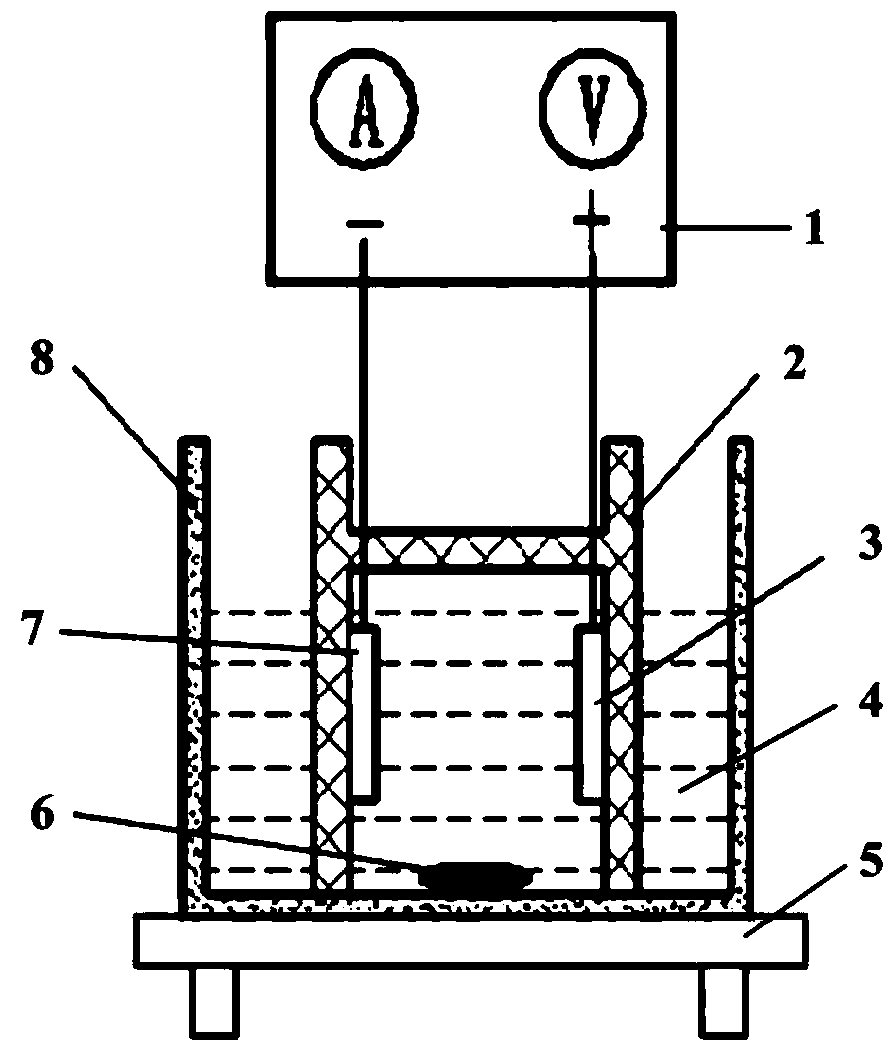

[0016] 2) Place the titanium alloy plate and the graphite plate in parallel and face to face, with an interval of 15mm, connect the two plates to the DC power supply with a wire, the titanium alloy plate is connected to the positive electrode, and the graphite plate is connected to the negative electrode. At the same time, put the two plates into the mixed solution containing 1.5mol / L NaOH and 0.15mol / L H2O2, turn on the magnetic stirrer (1000r / min), connect the DC power supply, and the voltage is fixed at 10V. The oxidation time was 30 min, and the solution temperature during processing was about room temperature ...

Embodiment 2

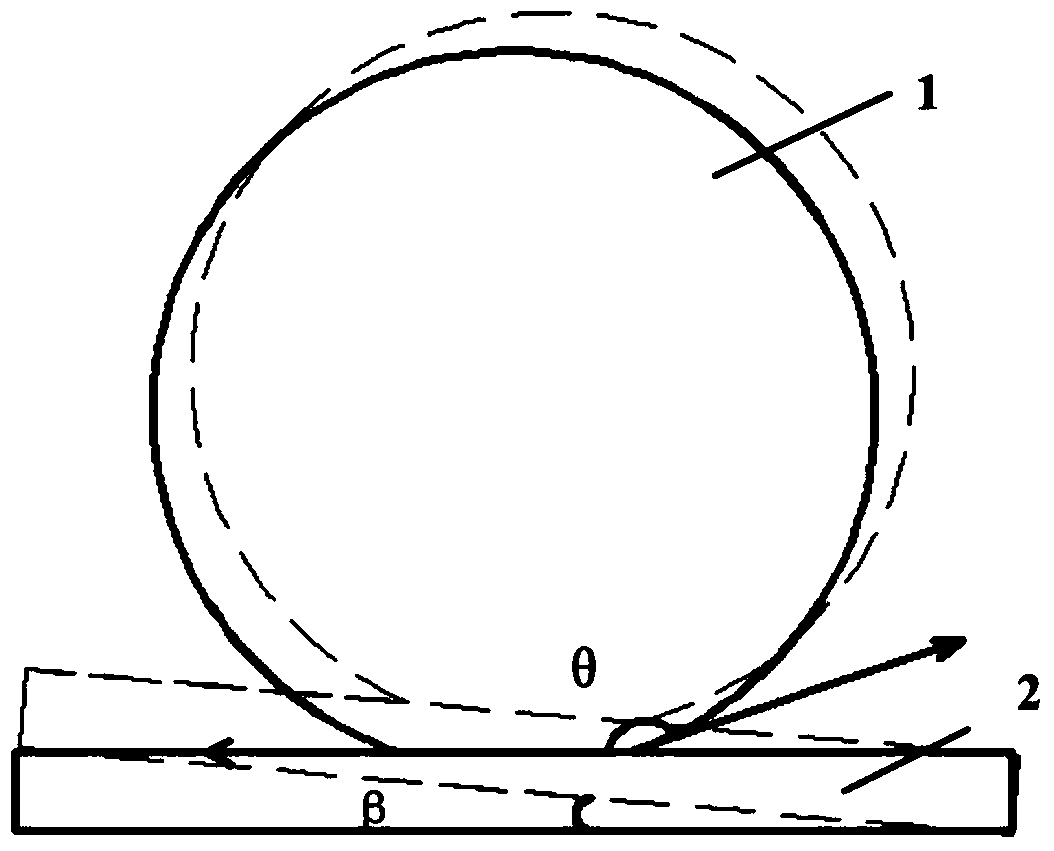

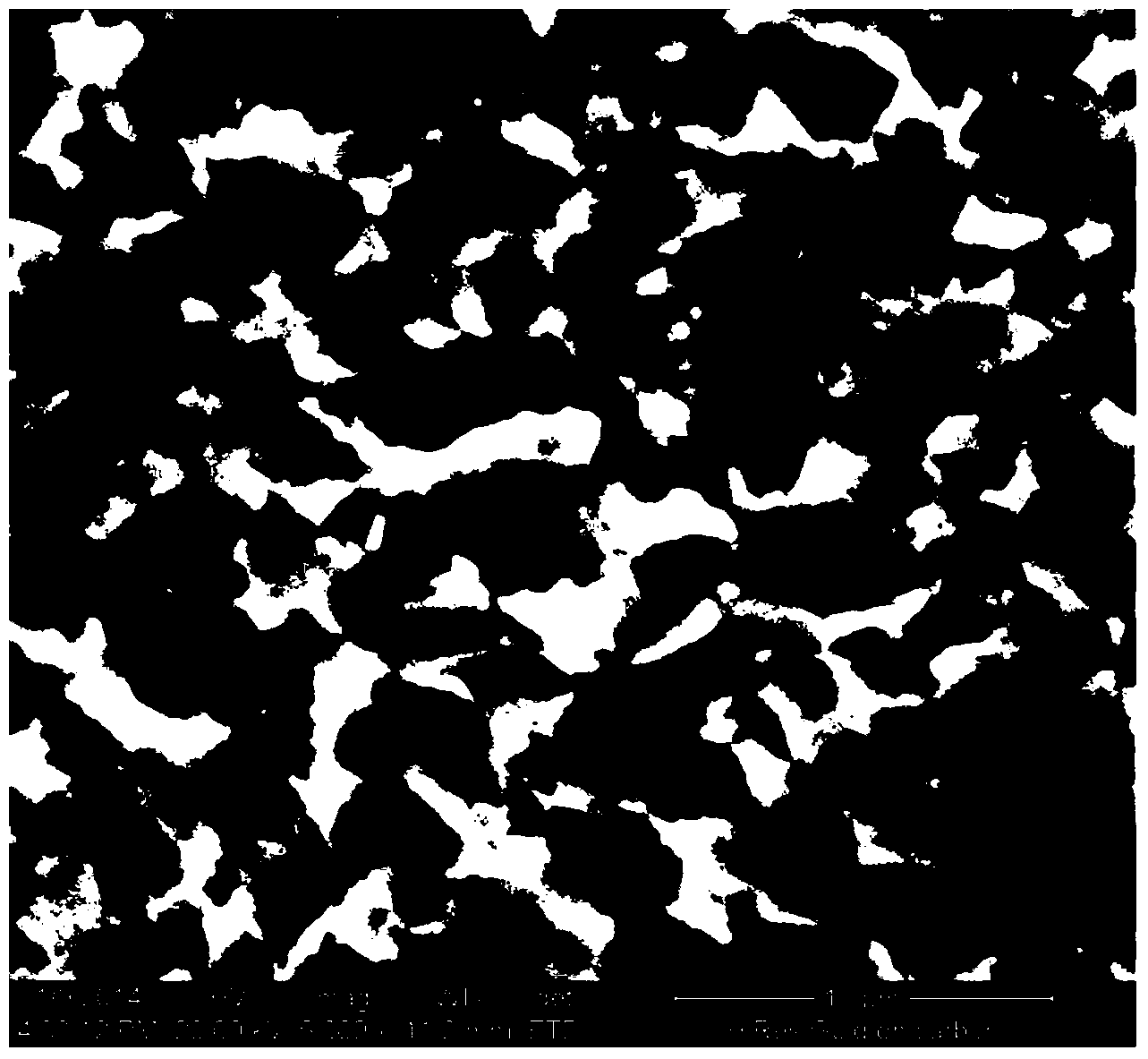

[0020] According to the operation and steps of Example 1, the oxidation time was changed to 60min. The obtained superhydrophobic surface of the titanium alloy has no obvious change in the microscopic morphology, and has a pore structure, and the pore size is also 5-10 μm. The superhydrophobic surface roughness Ra is 0.822 μm, the contact angle to water droplets is 158.8°, and the rolling angle is 5.1°.

Embodiment 3

[0022] According to the operation and steps of Example 1, the constant voltage was changed to 15V. The obtained superhydrophobic surface of the titanium alloy still has a randomly distributed hole structure, and the hole size is 5-10 μm. The superhydrophobic surface roughness Ra is 0.785 μm, the contact angle to water droplets is 157.8°, and the rolling angle is 5.6°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com