Preparation method of nanometer ordered structure biomaterial membranous layer based on super hydro philic/hydro phobic characteristic template

A technology of ordered structure and biomaterials, applied in medical science, prosthesis, etc., to achieve the effect of precise and controllable preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

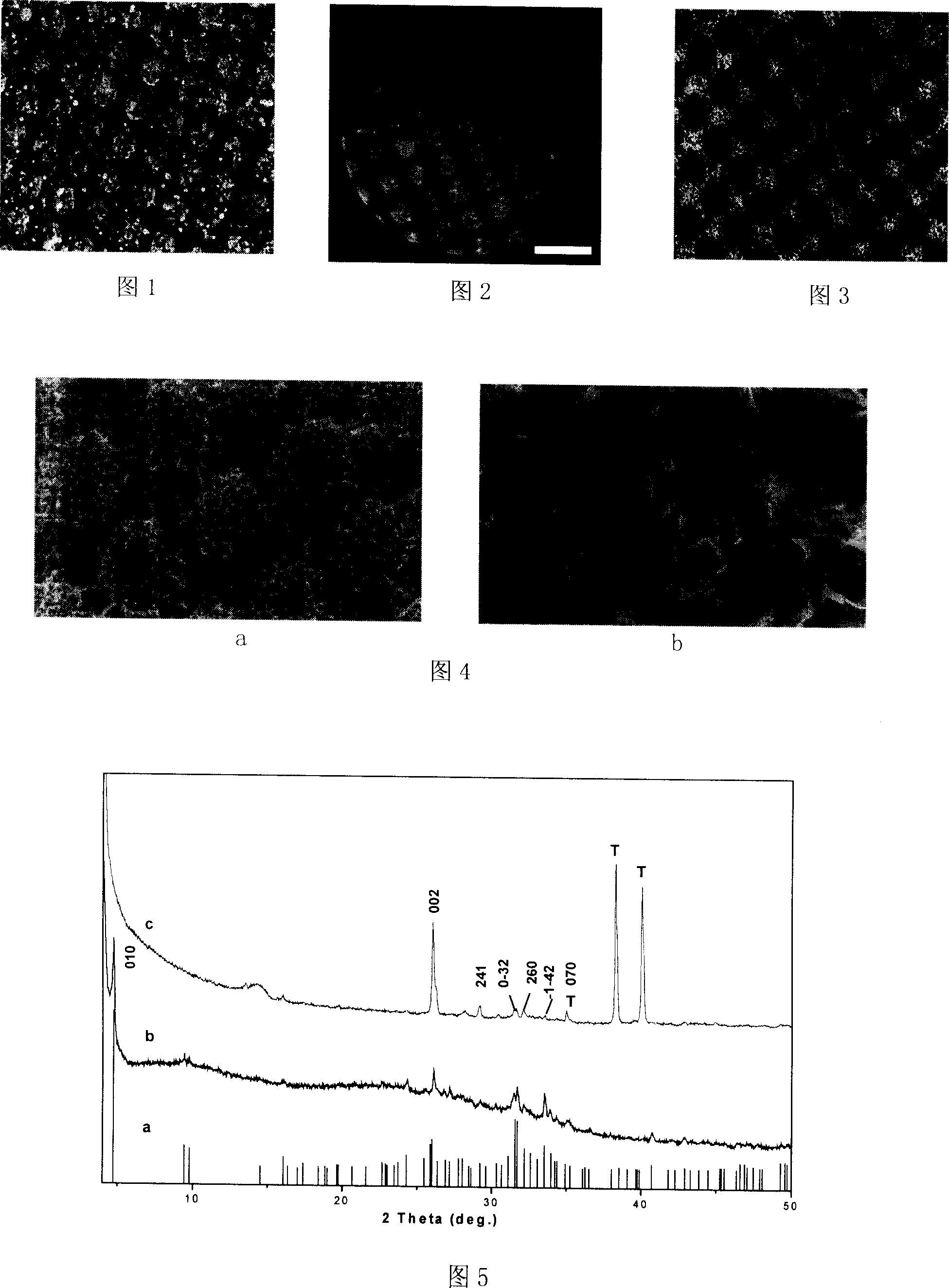

[0023] Embodiment 1: The base material is a pure titanium plate of 15mm×20mm×2mm. After the surface of the titanium plate is polished with sandpaper, it is ultrasonically cleaned in acetone, ethanol and three times of water for 10 minutes, and after taking it out, it is rinsed with three times of water and air-dried for later use. Under room temperature conditions, the electrochemical anodic oxidation of the substrate is carried out, the electrolyte is 0.5wt% HF, the preparation voltage is 20V, and the time is 20 minutes, that is, a layer of nano-ordered TiO is obtained on the surface of the substrate. 2 Nanotube array film layer. The anodized sample was soaked in 1wt% FSA-13 methanol solution for 1 hour, then dried at 140 °C for 1 hour to obtain superhydrophobic TiO 2 Nanotube array film layer. On superhydrophobic TiO 2 The nanotube array film is covered with a photomask, and after being irradiated with ultraviolet light for 60 minutes, a super-hydrophobic-superhydrophilic...

Embodiment 2

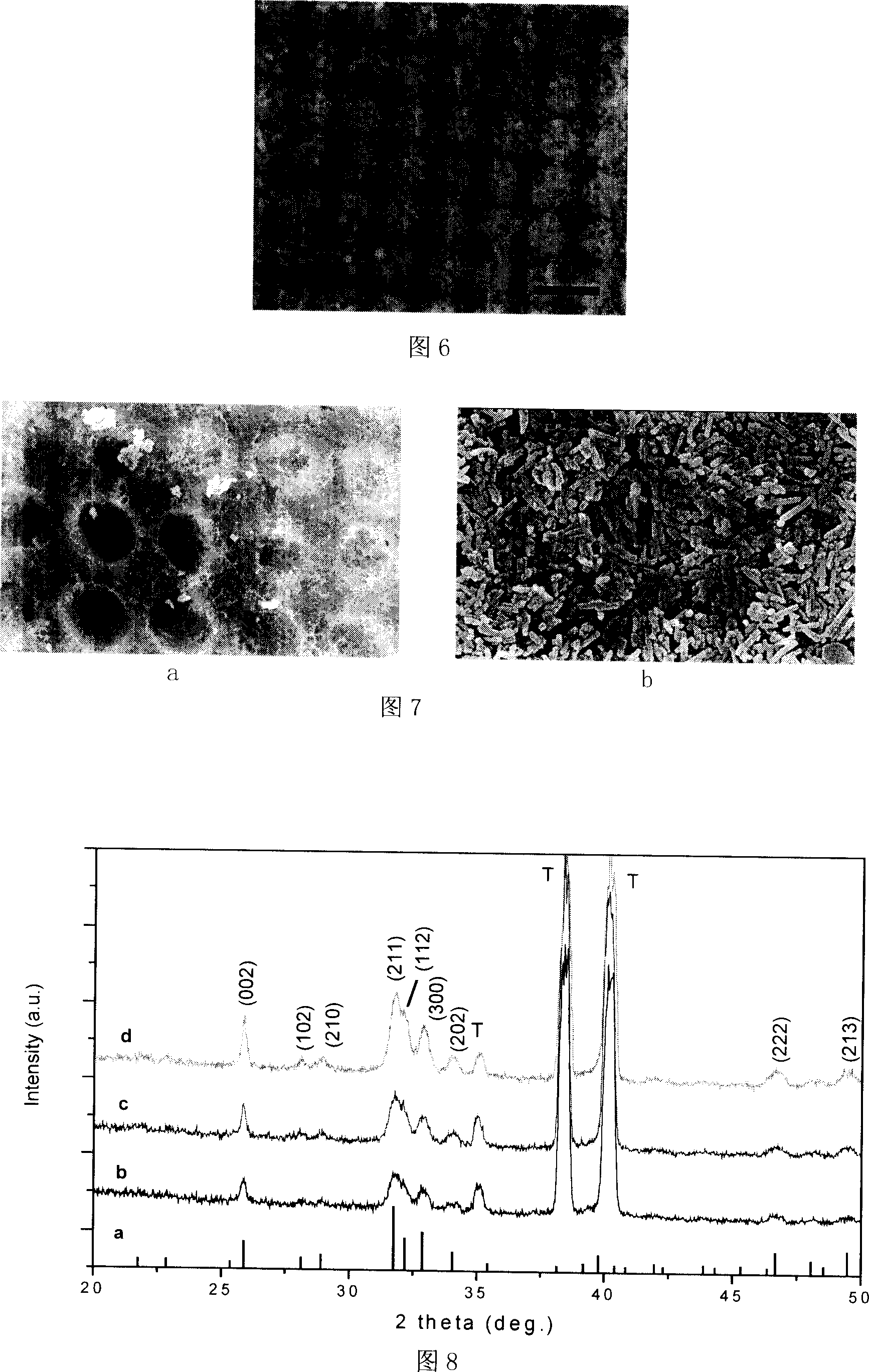

[0025]Embodiment 2: the preparation of the nanotube array film layer with super-repellent-super-hydrophilic pattern is the same as in Example 1, and then in the dehydrated ethanol electrolyte containing 3 g / L concentration of hydroxyapatite nanoparticles, the control voltage is At 30V, at room temperature, cathodic electrophoretic deposition was performed on samples with superphobic-superhydrophilic pattern templates. The deposition time is 15 seconds, and a micropattern of hydroxyapatite nanoparticles can be obtained on the surface of the titanium substrate. See Figures 6, 7 and Table 1 for the results. From Figure 6, it can be clearly seen that the brighter circular superhydrophilic region is covered with a layer of hydroxyapatite nanoparticle film, while in the other superhydrophobic regions, there is little or no hydroxyapatite nanoparticle film layer There, a microarray pattern completely consistent with the superphobic-superhydrophilic template (Figure 1) was formed. F...

Embodiment 3

[0029] Similar to Example 1, the difference is that the base material is titanium alloy (Ti6A14V). Use 0.05 mol / L NaOH to adjust the pH of the electrolyte to 6, and the controlled current density is 0.1 mA / cm 2 , for cathodic electrochemical deposition. The deposition time is 5 minutes, and a nano-ordered calcium phosphate (CaP) film layer micropattern is obtained on the surface of the titanium substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com