A kind of pu white primer and preparation method thereof

A white primer and alkyd resin technology, applied in the field of coatings, can solve problems such as loss of merchants, poor adhesion, paint peeling, etc., and achieve the effect of solving paint peeling and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

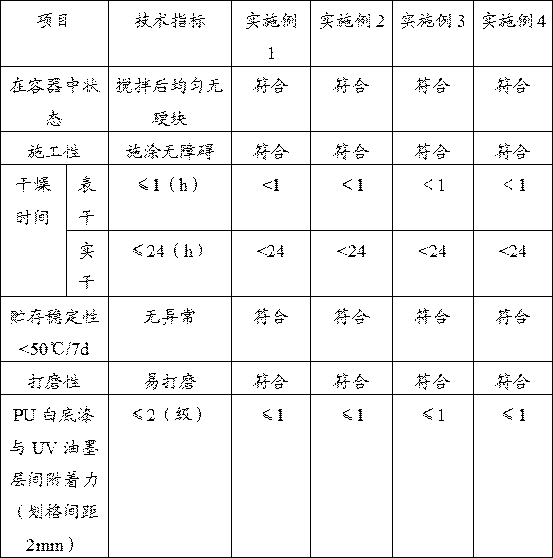

Examples

Embodiment 1

[0018] The PU white primer of this embodiment comprises the following raw materials: 36 parts of alkyd resin, 0.7 part of photosensitizer, 2.5 parts of hydroxyethyl methacrylate, 8 parts of solvent, 17 parts of titanium dioxide, 30 parts of filler and 2 parts of auxiliary agent.

[0019] Wherein, the alkyd resin is soybean oil modified alkyd resin. Wherein, the photosensitizer is photosensitizer 1173. Wherein, the solvent is mixed with 3.9 parts of xylene and 4.1 parts of butyl ester. Wherein, the filler is composed of 20 parts of heavy calcium and 10 parts of talcum powder. Among them, the auxiliary agent contains 0.6 parts of dispersant, 0.6 part of defoamer, 0.4 part of catalyst and 0.4 part of anti-sedimentation agent. Among them, the dispersant is polyurethane dispersant produced by Efka; the defoamer is produced by Guangdong Zuotong ; The anti-sedimentation agent is an organic expansive soil; the catalyst is an organotin.

[0020] Its preparation method comprises the ...

Embodiment 2

[0026] The PU white primer of this embodiment includes the following raw materials: 40 parts of alkyd resin, 0.5 part of photosensitizer, 2.5 parts of hydroxyethyl methacrylate, 8 parts of solvent, 15 parts of titanium dioxide, 25 parts of filler and 1 part of auxiliary agent.

[0027] Wherein, the alkyd resin is a mixture of 8 parts of acrylic modified alkyd resin, 20 parts of nanometer modified alkyd resin and 12 parts of soybean oil modified alkyd resin.

[0028] Wherein, the photosensitizer is a mixture of 0.15 part of azobisisobutylcyanine, 0.1 part of benzophenone, 0.125 part of tetraethylthiuram and 0.125 part of silver halide.

[0029] Wherein, the solvent is matched with 4 parts of xylene and 4 parts of butyl ester.

[0030] Among them, the filler is formed by mixing 7.5 parts of heavy calcium with a particle size of 0.05um, 7.5 parts of talcum powder and 10 parts of barium sulfate.

[0031] Wherein, auxiliary agent comprises 0.3 part of dispersant, 0.3 part of defoa...

Embodiment 3

[0038] The PU white primer of this embodiment includes the following raw materials: 40 parts of alkyd resin, 0.8 parts of photosensitizer, 3.0 parts of hydroxyethyl methacrylate, 10 parts of solvent, 17 parts of titanium dioxide, 35 parts of filler and 2 parts of auxiliary agent.

[0039] Wherein, the alkyd resin is a mixture of 10 parts of acrylic modified alkyd resin, 20 parts of nanometer modified alkyd resin and 10 parts of soybean oil modified alkyd resin.

[0040] Wherein, the photosensitizer is a mixture of 0.32 parts of azobisisobutylcyanine, 0.24 parts of benzophenone, 0.16 parts of tetraethylthiuram and 0.08 parts of silver halide.

[0041] Wherein, the solvent is matched with 4 parts of xylene and 6 parts of butyl ester.

[0042] Among them, the filler is mixed with 12.25 parts of heavy calcium, 10.5 parts of talcum powder and 12.25 parts of barium sulfate with a particle size of 0.05um.

[0043] The filler is made by mixing 12.25 parts of heavy calcium with a part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com