Preparing method for electro-deposition molybdenum disulfide quantum dot modified titanium dioxide nanotube array

A technology of nanotube array and molybdenum disulfide, which is applied in the field of photocatalytic degradation of pollutant materials, can solve the problems of cumbersome process, complex conditions, and long time consumption, and achieve the effect of simple and easy operation, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

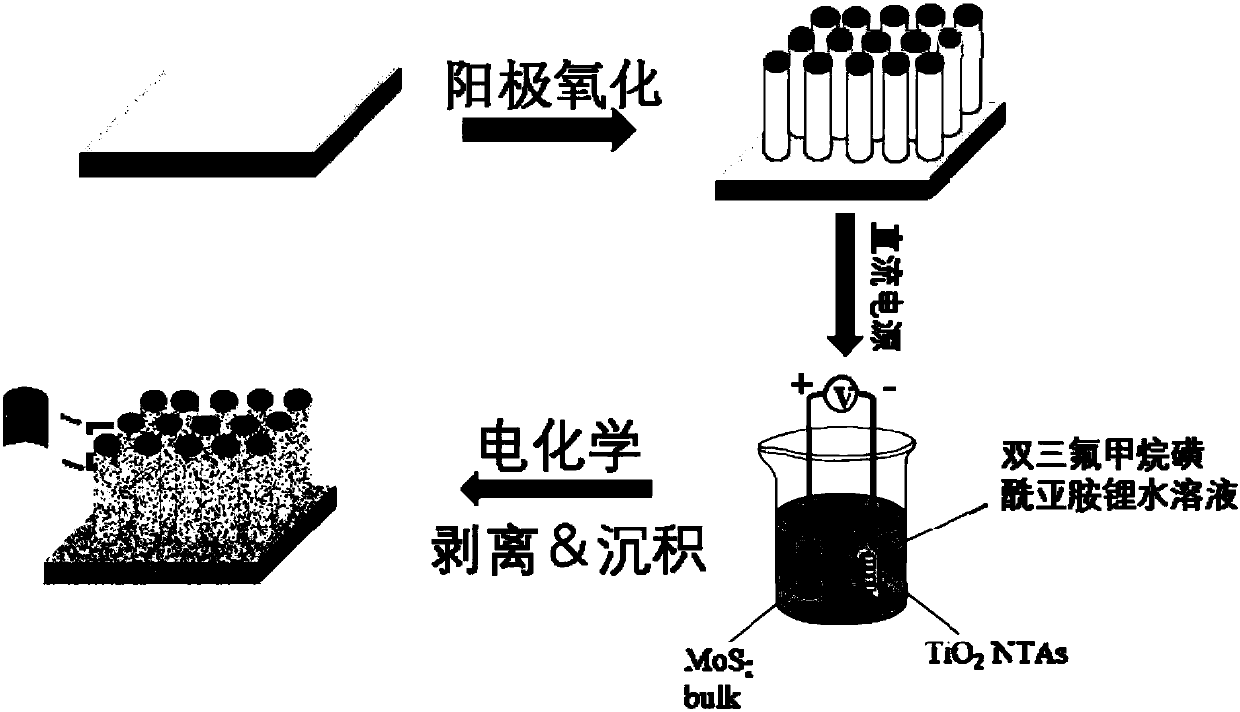

[0035] see figure 1 , figure 1 It is a schematic flow chart of the preparation method of the electrodeposited molybdenum disulfide quantum dot modified titanium dioxide nanotube array of the present invention. like figure 1 As shown, the present invention provides a method for preparing electrodeposited molybdenum disulfide quantum dots modified titanium dioxide nanotube arrays, comprising the following steps:

[0036] Pretreatment of titanium sheet;

[0037] Preparation of TiO by Anodic Oxidation 2 nanotube arrays;

[0038] Molybdenum disulfide powder is made into solid flake molybdenum disulfide nanosheets with an infrared tablet press;

[0039] Using the molybdenum disulfide nanosheet as an anode, the TiO 2 The nanotube array is used as the cathode, and the bistrifluoromethanesulfonimide lithium aqueous solution is used as the electrolyte, and an electrodeposited molybdenum disulfide quantum dot modified titanium dioxide nanotube array is prepared.

[0040] In order ...

Embodiment 1

[0060] This implementation case shows a preparation method of electrodepositing molybdenum disulfide quantum dots modified titanium dioxide nanotube arrays according to the following steps:

[0061] (1) Pretreatment of the titanium sheet: ultrasonically clean the base of the pure titanium sheet with acetone and absolute ethanol for 20 min. Using a platinum sheet electrode as a cathode, insert it into an electrolyte solution containing 98v% ethylene glycol (0.5wt% ammonium fluoride) + 2v% water at the same time, and apply a voltage of 50V for 2h to obtain TiO 2 The nanotube array was then calcined at 450°C for 2h to transform from amorphous state to anatase.

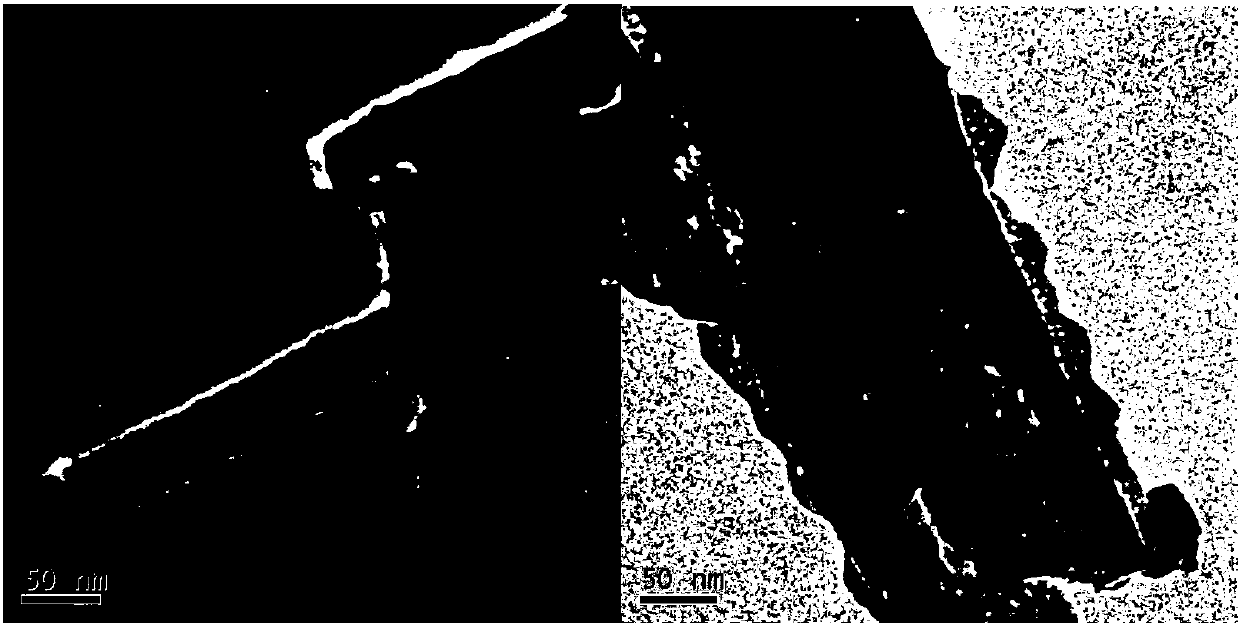

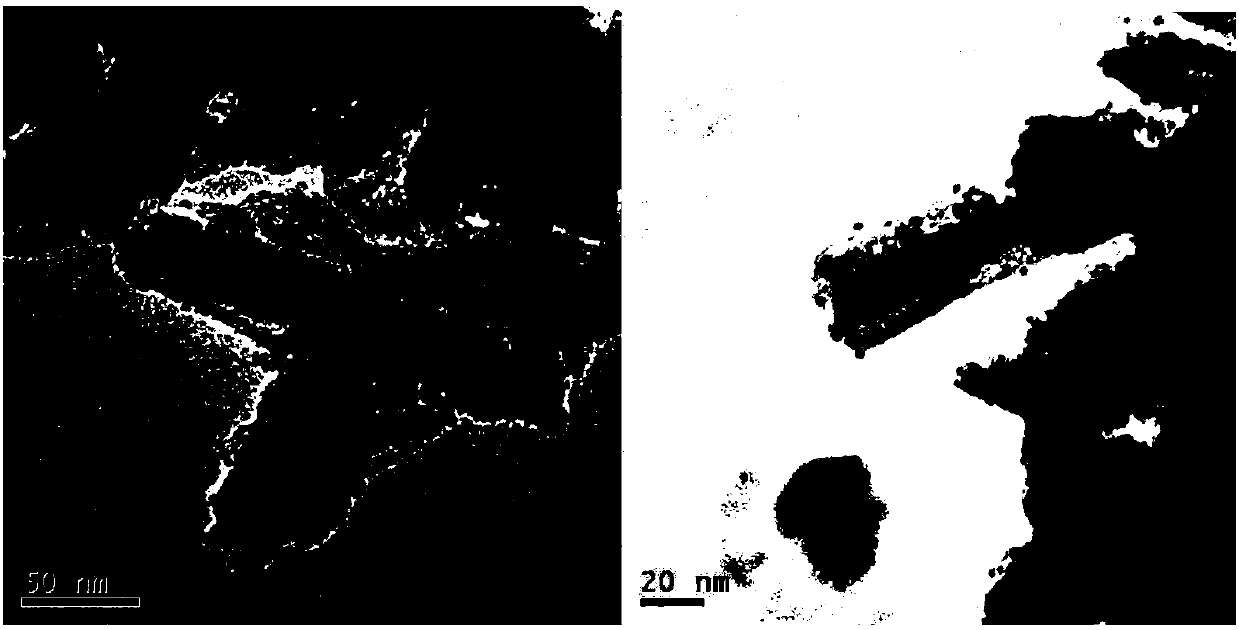

[0062] (2) The electrodeposition method is used to prepare the titanium dioxide nanotube array compounded with molybdenum disulfide nanoparticles. Prepare a 0.1wt% aqueous solution of lithium bistrifluoromethanesulfonimide, and use the solution as an electrolyte after the solution is uniformly dispersed. Use an infrared ...

Embodiment 2

[0071] This implementation case shows a preparation method of electrodepositing molybdenum disulfide quantum dots modified titanium dioxide nanotube arrays according to the following steps:

[0072] (1) Pretreatment of the titanium sheet: ultrasonically clean the base of the pure titanium sheet with acetone and absolute ethanol for 20 min. Using a platinum sheet electrode as a cathode, insert it into an electrolyte solution containing 98v% ethylene glycol (0.5% ammonium fluoride) + 2% water at the same time, apply a voltage of 50V for anodic oxidation for 2h, and obtain TiO 2 The nanotube array was then calcined at 450°C for 2h to transform from amorphous state to anatase.

[0073] (2) The electrodeposition method is used to prepare the titanium dioxide nanotube array compounded with molybdenum disulfide nanoparticles. Prepare a 0.1wt% aqueous solution of lithium bistrifluoromethanesulfonimide, and use the solution as an electrolyte after the solution is uniformly dispersed. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com