Titanium dioxide film synthesizing method and the product thereof

a titanium dioxide and film technology, applied in the field of thin film synthesis, can solve the problems of time-consuming titanium dioxide synthesizing method, limited application, and bulk titanium as a substra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

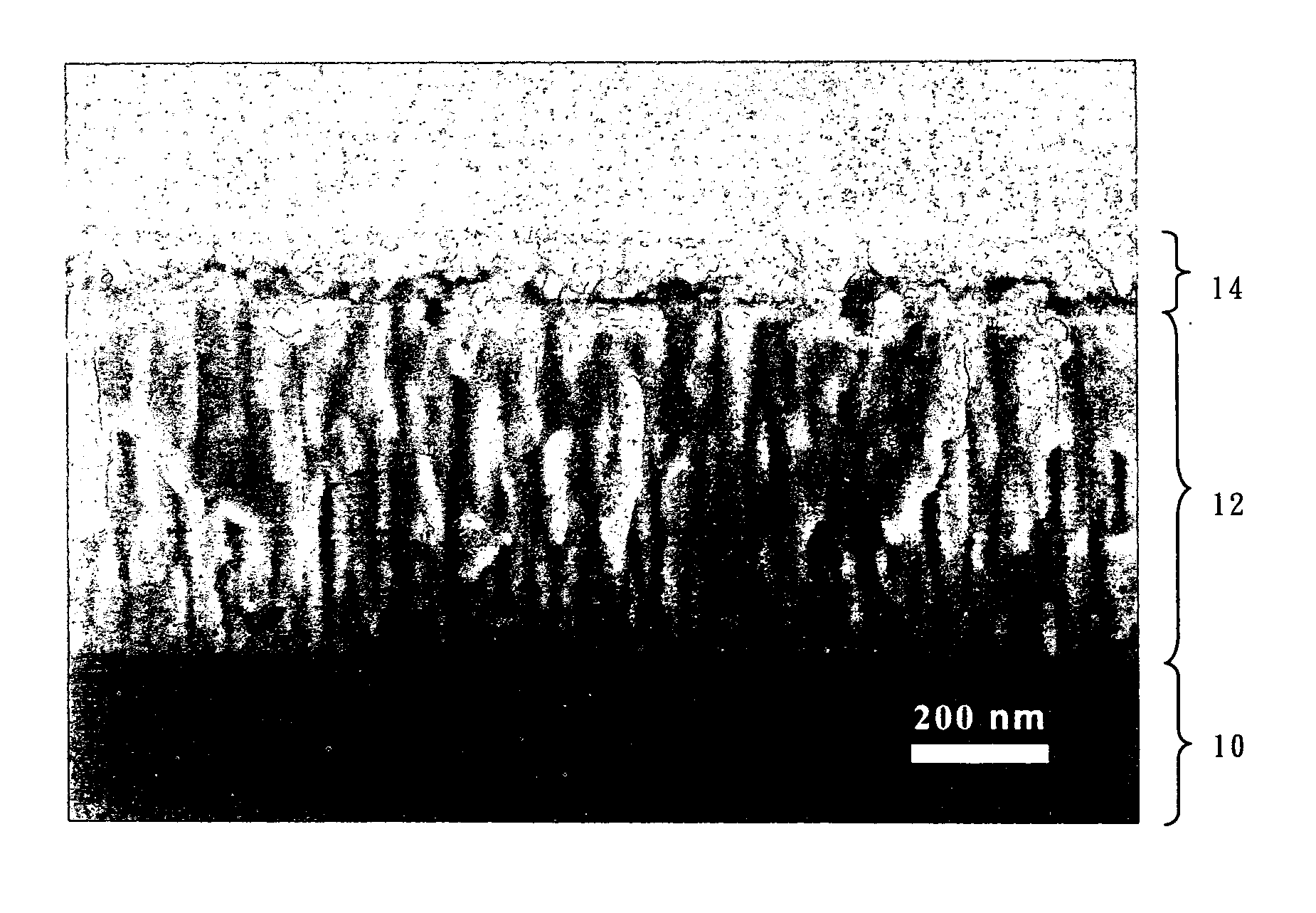

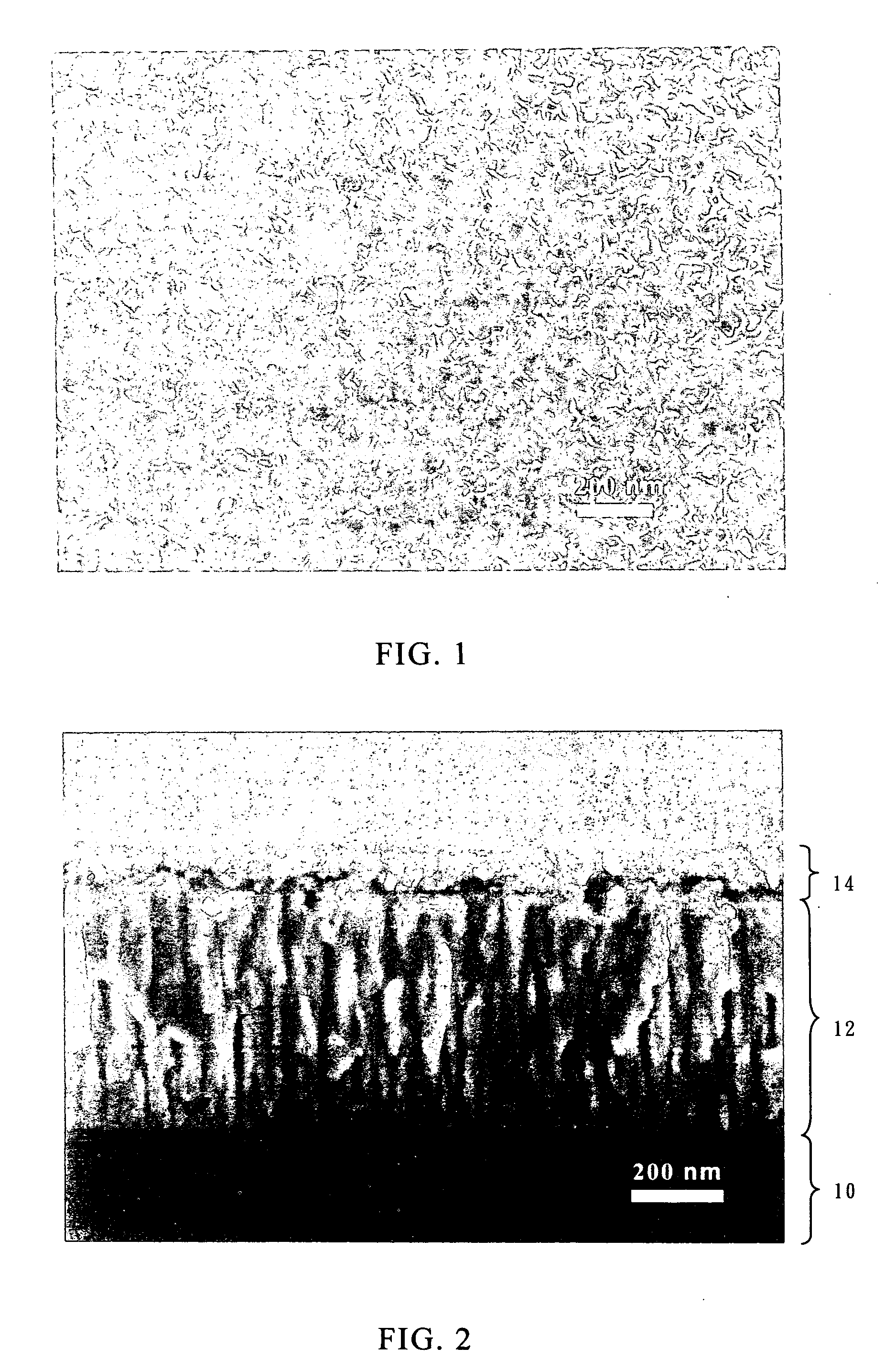

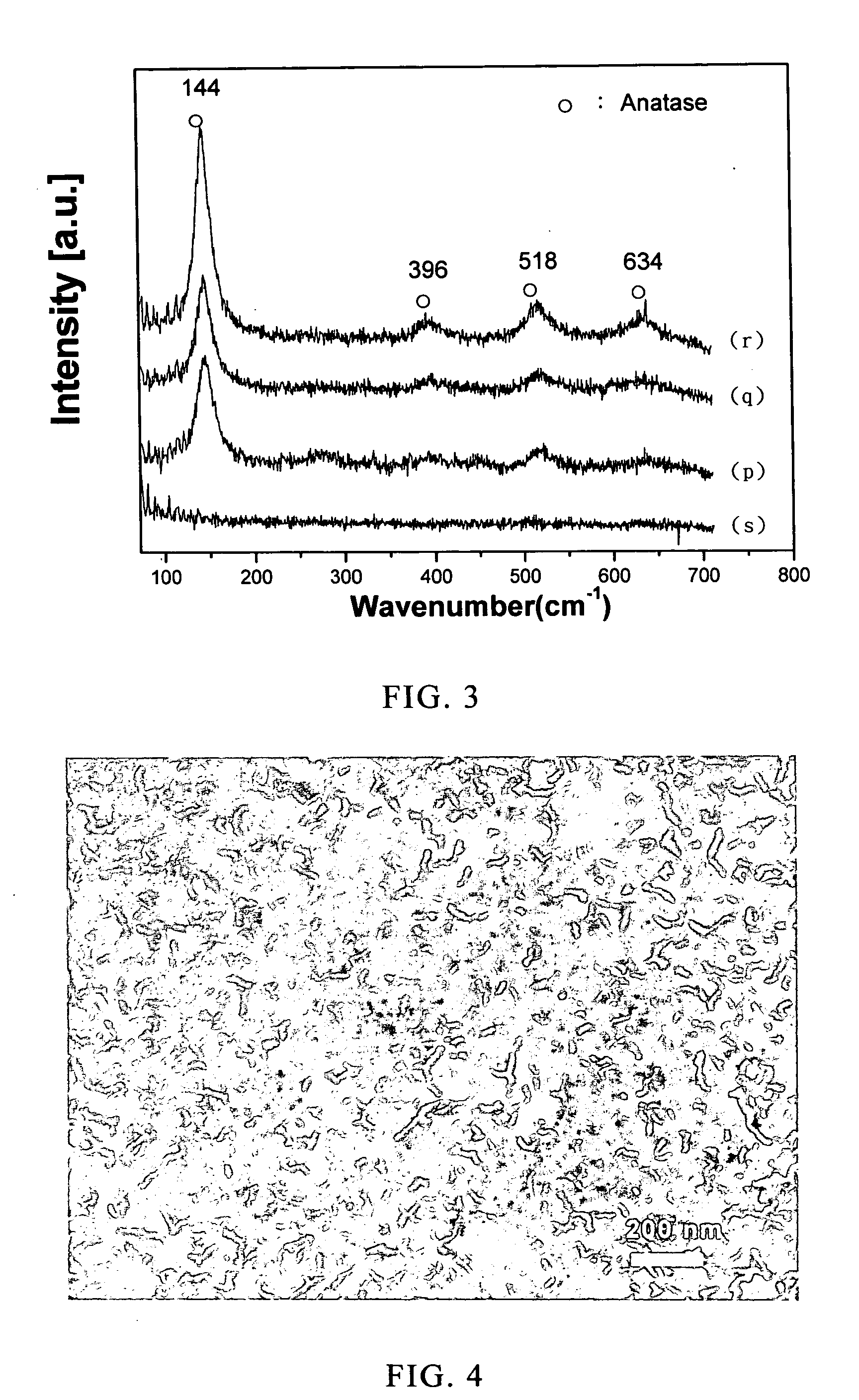

[0016] The first embodiment of the present invention is to synthesize titanium dioxide films on a homogenous substrate (titanium) or heterogeneous substrate (silicon or any of a variety of semiconductors, metal, glass, ceramics, or polymers). For illustration only, the first embodiment is described to synthesize titanium dioxide films on a silicon substrate.

[0017] The method of the first embodiment of the present invention includes two stages, namely, the first stage of pre-deposition and the second stage of electrochemical anodic oxidation. The first stage of pre-deposition is to deposit a titanium film on a silicon wafer by sputtering. Titanium film can also be deposited on a bulk titanium or substrate of any of a variety of other materials. The second stage of electrochemical anodic oxidation is to synthesize a nano-network structured titanium dioxide film on the titanium-coated silicon wafer in highly alkaline electrolytes, such as KOH (potassium hydroxide). In other words, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com