Preparation method of photo-anode of ZnS/Au/TiO2 nano composite film

A nano-composite and photo-anode technology, applied in the field of photo-anode, can solve the problems of poor photocathode protection effect and low photoelectric conversion efficiency of nano-materials, and achieve the effects of improving the protection effect, reducing the recombination probability and increasing the photocurrent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

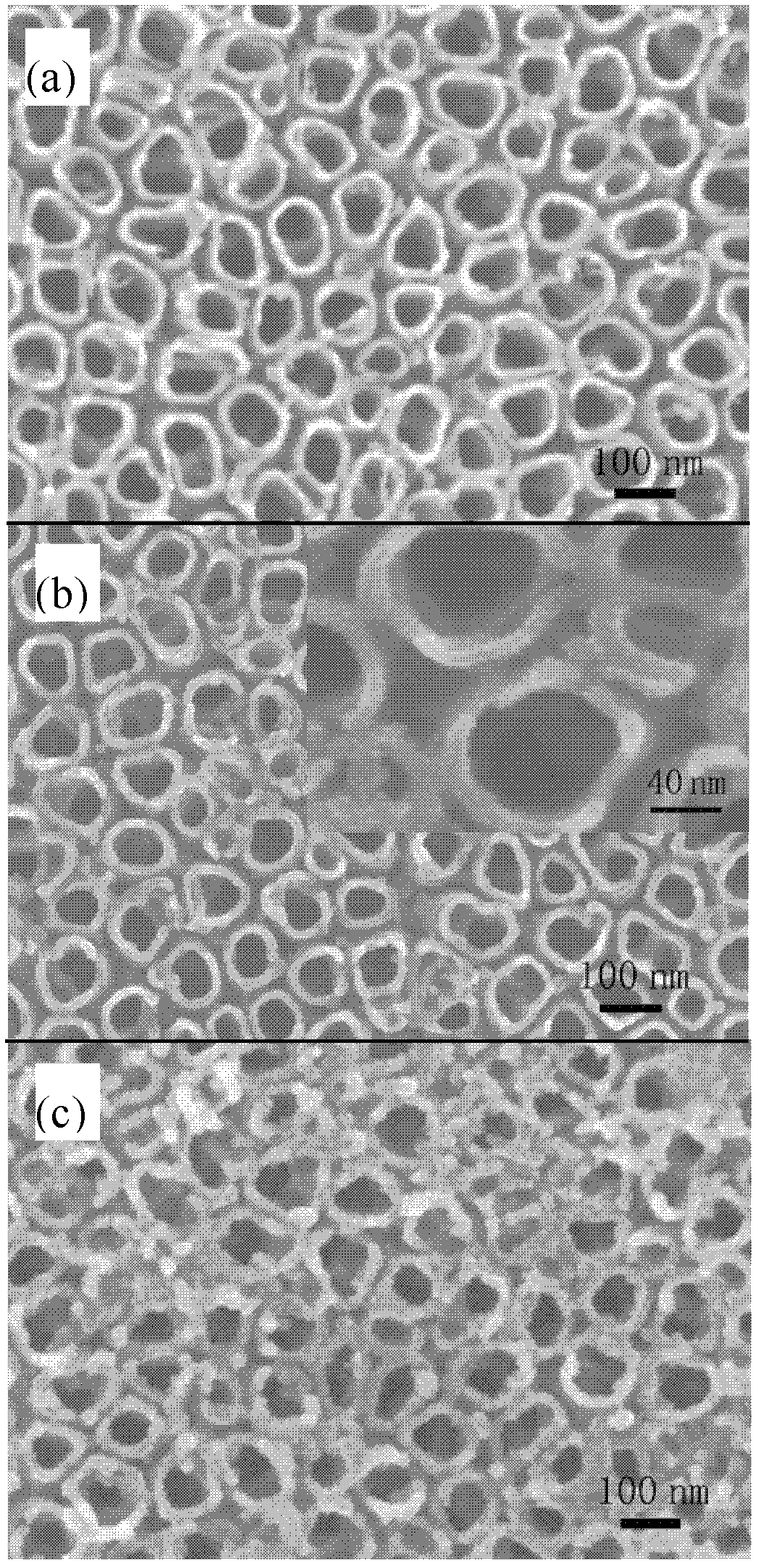

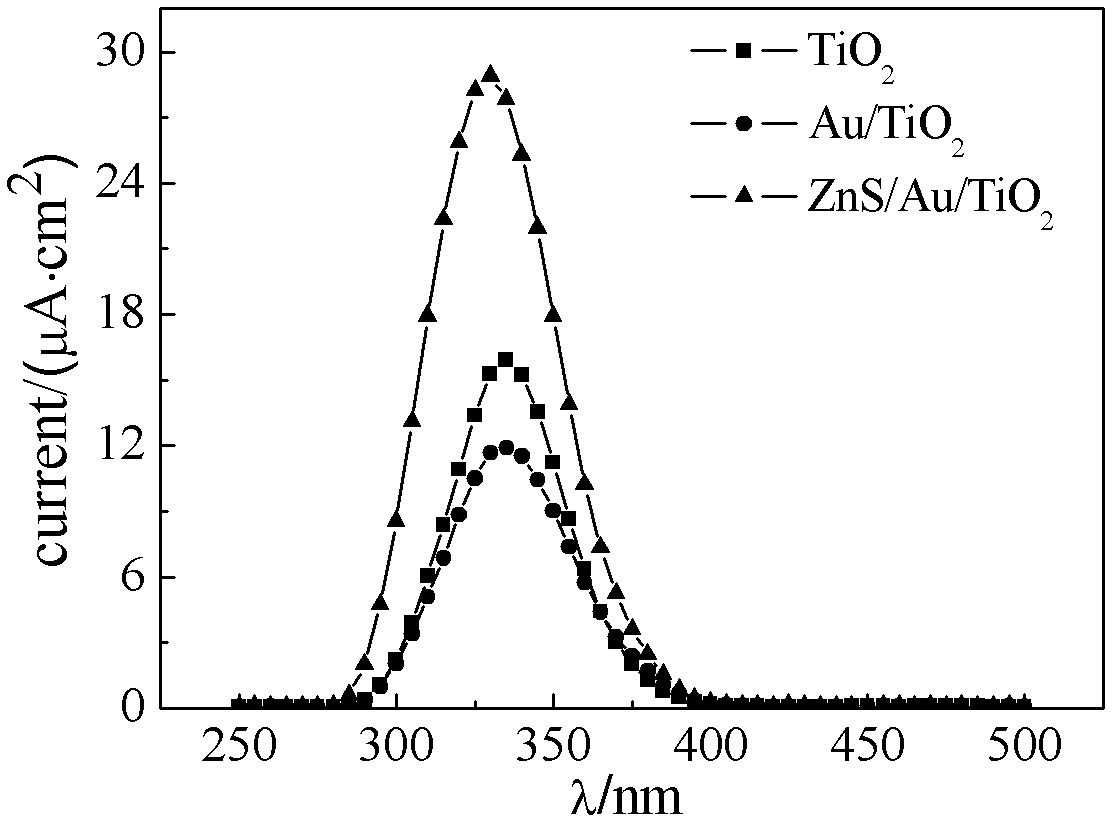

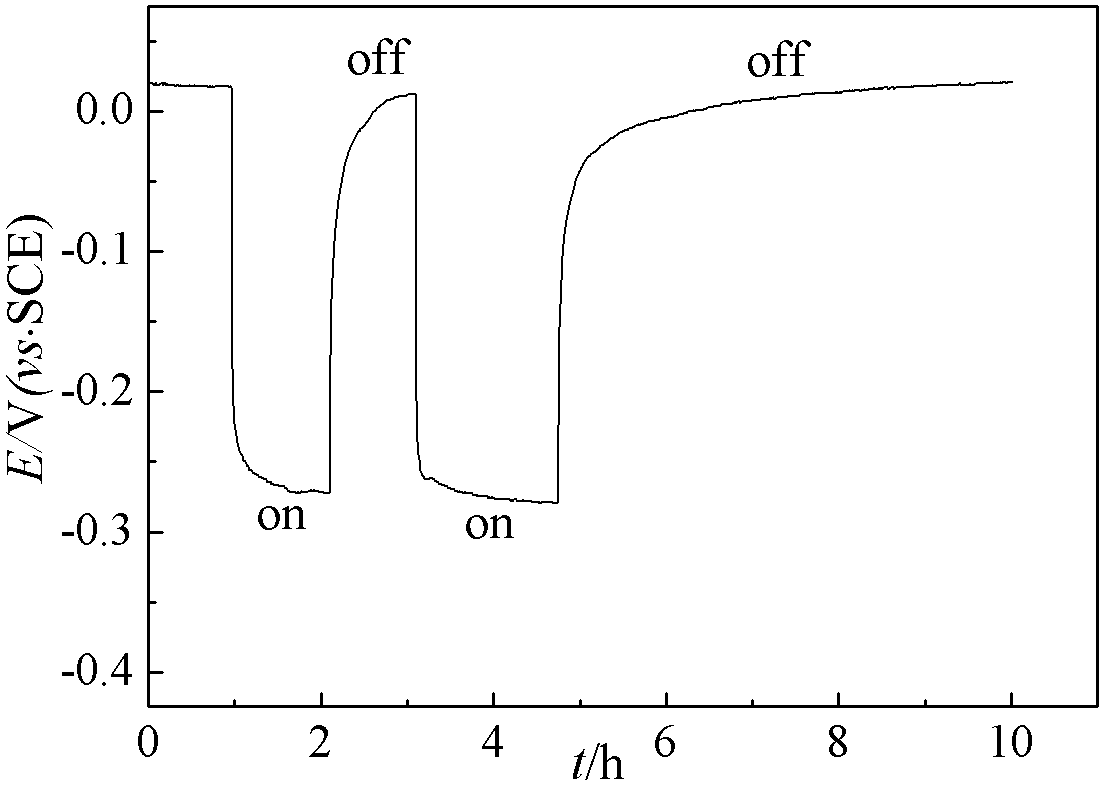

[0028] According to the above-mentioned technical scheme (concrete steps), prepare ZnS / Au / TiO 2 Nanocomposite film photoanode, and test the cathodic protection effect of this film on 403 stainless steel.

[0029] First, take a pure titanium foil sample with a thickness of 0.1 mm, a length of 2.0 cm, and a width of 1.0 cm, and pass through 10% (w) HNO at room temperature 3 +1% (w) HF solution etching treatment for 1 min, followed by ultrasonic cleaning in acetone, absolute ethanol and deionized water for 30 min to complete the pretreatment of the titanium matrix sample.

[0030] TiO 2 Preparation of the nanotube array film: at room temperature, with the treated titanium foil as the anode and the platinum sheet as the cathode, apply a voltage of 20V in 0.5% (w) HF solution, and anodize the sample for 30 minutes. After the reaction, the samples were washed with deionized water, dried and placed in a muffle furnace for heat treatment at 450 °C for 2 h.

[0031] Au-modified TiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com