Cu-doping modified TiO2 photocatalyst and preparation method thereof

A photocatalyst, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of expensive equipment, difficult to reuse, complex recovery, etc., to increase adsorption capacity and adsorption capacity , Improve the degradation rate, the effect of high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

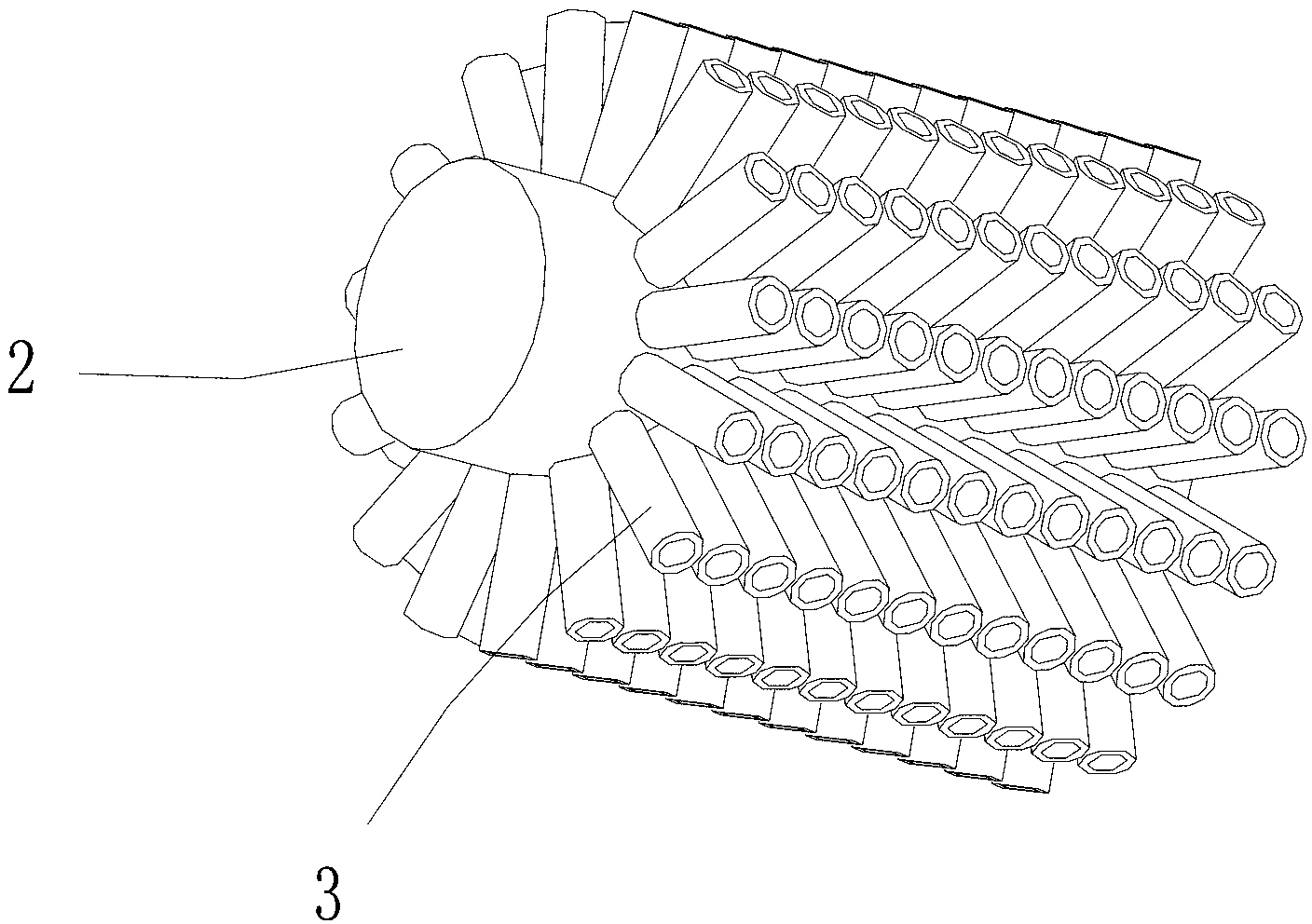

[0030] The invention provides a Cu-doped modified TiO 2 Photocatalyst and its preparation method, using electrochemical anodic oxidation method to directly prepare Cu-doped modified TiO with two-dimensional structure, highly ordered arrangement and strong visible light response performance on CuTi alloy wire or alloy rod substrate 2 Photocatalyst, which can increase the adsorption of catalytic degradation products and enhance TiO 2 Utilization efficiency of the solar spectrum by photocatalysts to promote TiO 2 Applications in the field of photocatalysis.

[0031] In this application, the term "crystallization" means that when TiO is annealed at a certain temperature 2 Structural transformation of nanotubes from amorphous to crystalline phase. The term "precursor" refers to TiO 2 Samples of nanotube array films without annealing and crystallization.

[0032] Using the two-dimensional structure of the present invention and Cu-doped TiO 2photocatalyst, added TiO 2 The spec...

Embodiment 1

[0034] In this example 1, Cu-doped TiO with a two-dimensional structure 2 A method for preparing a nanotube array, comprising the following steps:

[0035] (1) See figure 1 , a Cu5-Ti95 alloy wire substrate 1 with a diameter of 3 mm and a length of 20 mm is ground and polished with metallographic sandpaper, and the substrate 1 is prepared by an arc melting method;

[0036] (2) Clean the alloy wire obtained in step (1) ultrasonically in acetone for 15 minutes, then ultrasonically clean it in absolute ethanol for 5 to 15 minutes, and finally rinse it with distilled water for 3 to 5 times. Clean the Cu5-Ti95 alloy wire Purge and dry with inert gas (such as nitrogen or argon, etc.) for later use. In this embodiment 1, the inert gas adopts nitrogen;

[0037] (3) Weigh 5.55gNH 4 Dissolve F in 15ml deionized water and stir with a magnetic stirrer to make NH 4 F is completely dissolved, and then mixed with 485ml formamide to obtain an electrolyte;

[0038] (4) At room temperatur...

Embodiment 2

[0044] In this Example 2, Cu-doped TiO with a two-dimensional structure 2 A method for preparing a nanotube array, comprising the following steps:

[0045] Except for the voltage of step (4) and the annealing temperature of step (7), other implementation steps are the same as in Example 1. The voltage of step (4) is: a DC constant voltage of 30V; the annealing temperature of step (7) is 550°C.

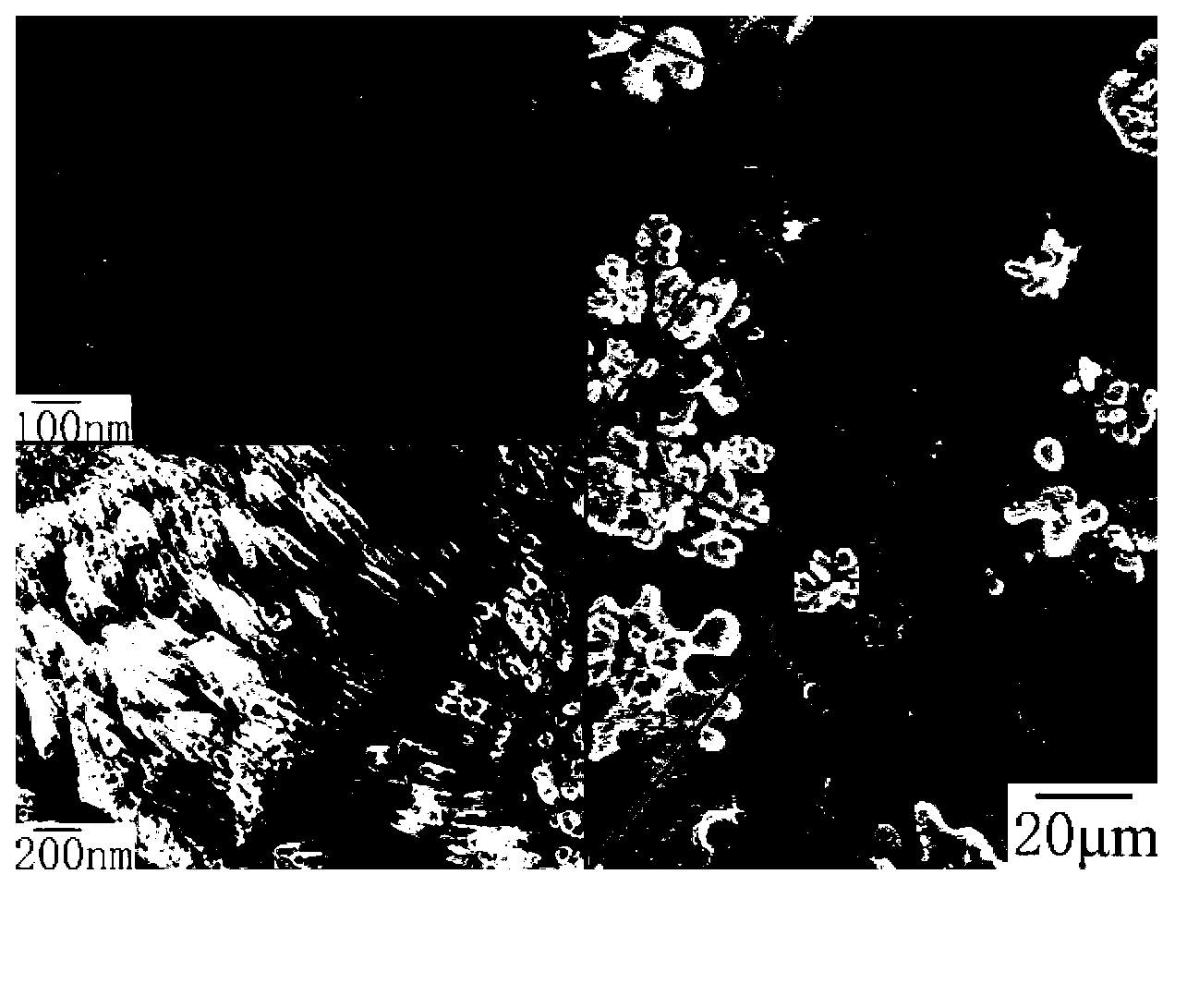

[0046] The two-dimensional structure Cu-doped modified TiO prepared in Example 2 2 Nanotube arrays whose structural units are Cu-doped TiO 2 Nanotubes, and there is a layered structure, in the large black area, Cu-doped TiO 2 The length, diameter and wall thickness of nanotubes are about 200~300nm, 40~50nm, 5~10nm, respectively. While in the petal-shaped region, Cu-doped TiO 2 The length, diameter and wall thickness of nanotubes are about 500-800nm, 40-50nm and 5-10nm, respectively. Cu-doped modified TiO prepared in Example 2 2 The absorption band edge of the nanotube array in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com